Professional Documents

Culture Documents

Miniature Flowmeters For Analytical Process DK 700: Installation and Operating Instructions

Miniature Flowmeters For Analytical Process DK 700: Installation and Operating Instructions

Uploaded by

Mateusz SynowieckiCopyright:

Available Formats

You might also like

- Apache 2,3,4.pdf4ba7b60f9c164Document1 pageApache 2,3,4.pdf4ba7b60f9c164Jordan PooleNo ratings yet

- ZM r6200 Rework Station Instruction Manual BgarebaDocument29 pagesZM r6200 Rework Station Instruction Manual Bgarebasergio0% (1)

- !!!! 2014-NGSTech-Proceedings PDFDocument119 pages!!!! 2014-NGSTech-Proceedings PDFMateusz SynowieckiNo ratings yet

- MID128 Engine ECU PID45 Inlet Air Heater Status (128 PID45) : Volvo Guided DiagnosticsDocument2 pagesMID128 Engine ECU PID45 Inlet Air Heater Status (128 PID45) : Volvo Guided DiagnosticsPreett Rajin Menabung100% (2)

- FlowMon Catalogue 2 PDFDocument12 pagesFlowMon Catalogue 2 PDFsimbamikeNo ratings yet

- Tech Sheet Series CDocument2 pagesTech Sheet Series CLalu Adam Akmal IsnenNo ratings yet

- Ficha Tecnica FlujometroDocument2 pagesFicha Tecnica FlujometroTatiana Mejías SeguraNo ratings yet

- Pipe Valves and Fittings - 15000Document11 pagesPipe Valves and Fittings - 15000willianNo ratings yet

- Main Valves Data SheetDocument18 pagesMain Valves Data SheetMahmoud GaberNo ratings yet

- D070Q Agr CatDocument4 pagesD070Q Agr CatRuben ManuelNo ratings yet

- Two Three Way Ball ValvesDocument6 pagesTwo Three Way Ball ValvesUzair AnsariNo ratings yet

- Vetec 62.7 Sanson Plug Tipo CanflexDocument12 pagesVetec 62.7 Sanson Plug Tipo CanflexAnderson SiqueiraNo ratings yet

- Ds 818Document3 pagesDs 818mmiranda.inmareproNo ratings yet

- CH 10 Additional ProductsDocument47 pagesCH 10 Additional Productssaddam khanNo ratings yet

- Cryogenic Valves For Industrial Gas Applications-43-44Document2 pagesCryogenic Valves For Industrial Gas Applications-43-44Abdul Hadi RashidNo ratings yet

- Specification - 2023 02 01 09 02 41Document10 pagesSpecification - 2023 02 01 09 02 41Chinnaraj SNo ratings yet

- Manual 80 81 Isolation RingsDocument10 pagesManual 80 81 Isolation RingsFelix UscangaNo ratings yet

- Spira X Sarco Fig 14Document2 pagesSpira X Sarco Fig 14Jacobus CalvelageNo ratings yet

- Check Valves Series Cv09Document6 pagesCheck Valves Series Cv09Uzair AnsariNo ratings yet

- Strainer Type 305Document5 pagesStrainer Type 305alexiel1806No ratings yet

- Switch Flujo DHDDocument6 pagesSwitch Flujo DHDAF VMNo ratings yet

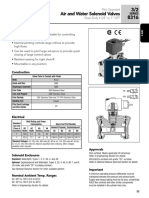

- Air and Water Solenoid Valves: FeaturesDocument4 pagesAir and Water Solenoid Valves: FeaturesZuñiga AntonioNo ratings yet

- King 7470 Series DatasheetDocument2 pagesKing 7470 Series DatasheetMacro MediciónNo ratings yet

- Flow Meter PDFDocument20 pagesFlow Meter PDFJoe Mari CapaNo ratings yet

- FS4-3 - Installation Instructions (MM-601J)Document8 pagesFS4-3 - Installation Instructions (MM-601J)mendozaNo ratings yet

- VT-BAYARD-Automatic Control Valves-FloatDocument8 pagesVT-BAYARD-Automatic Control Valves-Floatsiva ramakrishnanNo ratings yet

- Data Sheet 7.04 Issue C: Test & Drain Valve Fig. 801Document2 pagesData Sheet 7.04 Issue C: Test & Drain Valve Fig. 801Le DucNo ratings yet

- P Series Pipe - Needle Valve CatalogDocument4 pagesP Series Pipe - Needle Valve CatalogHenry PorcoNo ratings yet

- K-CV-KT20 Coperion K-Tron Product Specification Volumetric Twin Screw Compact FeederDocument2 pagesK-CV-KT20 Coperion K-Tron Product Specification Volumetric Twin Screw Compact FeederARK MurpheyNo ratings yet

- C16601 Proinert®2 Selector ValveDocument2 pagesC16601 Proinert®2 Selector Valvevld20082No ratings yet

- Data Sheet Daniel Series 700 Model v788 en 6385002Document10 pagesData Sheet Daniel Series 700 Model v788 en 6385002Marcelo PinheiroNo ratings yet

- Variable Reach 1101 Serie Top Loading Arm: Technical SpecificationsDocument2 pagesVariable Reach 1101 Serie Top Loading Arm: Technical SpecificationsRenalyn TorioNo ratings yet

- Fv101x - Specsht2Document1 pageFv101x - Specsht2Claudio Rivadeneira CarrascoNo ratings yet

- TRDP - SSSVDocument23 pagesTRDP - SSSVsambhajiNo ratings yet

- Valv Diluvio Claval Diafragma TubularDocument29 pagesValv Diluvio Claval Diafragma TubularDaniel ReyNo ratings yet

- Bermad - C80Document3 pagesBermad - C80Santiago RodaNo ratings yet

- Density ColumnDocument2 pagesDensity Columnjrlr65No ratings yet

- Załacznik NR 2 Spec - techn.MASONEILANDocument7 pagesZałacznik NR 2 Spec - techn.MASONEILANEric CastilloNo ratings yet

- Data Sheet For Plug ValveDocument2 pagesData Sheet For Plug ValveTauqueerAhmadNo ratings yet

- Liquid Flow Switch: DimensionDocument1 pageLiquid Flow Switch: DimensionChhomNo ratings yet

- Victaulic Flexible Hose Connecting To Dry Barrel SprinklerDocument27 pagesVictaulic Flexible Hose Connecting To Dry Barrel SprinklerOwais AhmedNo ratings yet

- De Sanding 2021Document1 pageDe Sanding 2021Phasin ChitutsahaNo ratings yet

- 45BYMP Check Valve PDDocument4 pages45BYMP Check Valve PDYen NguyenNo ratings yet

- Aqua MagDocument4 pagesAqua MagMahua ChakrabarttyNo ratings yet

- Cooling Tower SpecificationDocument14 pagesCooling Tower SpecificationAmzad DPNo ratings yet

- CVH Series PDFDocument9 pagesCVH Series PDFhendrabudimanNo ratings yet

- Tubular Level GaugesDocument3 pagesTubular Level GaugesKarthikeyanNo ratings yet

- Type 119 Control Valve: Bulletin 51.1:119Document4 pagesType 119 Control Valve: Bulletin 51.1:119Fernando GiadansNo ratings yet

- A700 EnglishDocument16 pagesA700 EnglishPablo MNo ratings yet

- WT 14 - Indirect HeaterDocument2 pagesWT 14 - Indirect Heatershakouri1370_8902064No ratings yet

- MN-89242-22-7 SpecDocument6 pagesMN-89242-22-7 Specrenhat parulian sitorusNo ratings yet

- 5658 Electric Actuated 3-Way Ball Valves: FeaturesDocument6 pages5658 Electric Actuated 3-Way Ball Valves: FeaturesRADHAKRISHNANNo ratings yet

- Asco Flow Control Valves CatalogDocument4 pagesAsco Flow Control Valves CatalogCristian GutiérrezNo ratings yet

- Rotametro ABBDocument10 pagesRotametro ABBjoticamario123No ratings yet

- FlowMon Catalogue 2Document12 pagesFlowMon Catalogue 2dhanu_aquaNo ratings yet

- Asco Series 316 Air Water CatalogDocument4 pagesAsco Series 316 Air Water CatalogekoNo ratings yet

- Datasheet Vetec TY005.030Document16 pagesDatasheet Vetec TY005.030Ali Abdul MannanNo ratings yet

- Installation Instructions: Durametallic MW-200 SeriesDocument8 pagesInstallation Instructions: Durametallic MW-200 SeriesEli Emmanuel Cárcamo Rodríguez100% (1)

- Tech Spec Spiral Pipe For Faide Project.r1Document5 pagesTech Spec Spiral Pipe For Faide Project.r1Delshad DuhokiNo ratings yet

- Yokogawa-WIKA C13WT+series Ed0Document20 pagesYokogawa-WIKA C13WT+series Ed0haisamsarwarNo ratings yet

- leaf-ABO Series 3e-Eng - 2014 - 11 - 07Document6 pagesleaf-ABO Series 3e-Eng - 2014 - 11 - 07BHARGAVNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Flyer +Rosemount+370XA+Gas+ChromatographDocument4 pagesFlyer +Rosemount+370XA+Gas+ChromatographMateusz SynowieckiNo ratings yet

- Process Instrumentation and Analytics: Reliable Processes Thanks To Perfect Integration of All ComponentsDocument32 pagesProcess Instrumentation and Analytics: Reliable Processes Thanks To Perfect Integration of All ComponentsMateusz SynowieckiNo ratings yet

- Ammonia Monitoring For: Denox ProcessDocument2 pagesAmmonia Monitoring For: Denox ProcessMateusz SynowieckiNo ratings yet

- Advances in OpticalDocument19 pagesAdvances in OpticalMateusz SynowieckiNo ratings yet

- GRP 1800series Datasheet UK V1Document1 pageGRP 1800series Datasheet UK V1Mateusz SynowieckiNo ratings yet

- GE Sample Systems WhitepaperDocument4 pagesGE Sample Systems WhitepaperMateusz SynowieckiNo ratings yet

- Bi-Prop Present 68IACDocument5 pagesBi-Prop Present 68IACMateusz SynowieckiNo ratings yet

- Rarata G., Surmacz P.Document9 pagesRarata G., Surmacz P.Mateusz SynowieckiNo ratings yet

- An 112 Magnos28 Oxygen Purity Measurement enDocument3 pagesAn 112 Magnos28 Oxygen Purity Measurement enMateusz SynowieckiNo ratings yet

- Hybrid Experimental Rocket Stuttgart: A Low-Cost Technology DemonstratorDocument17 pagesHybrid Experimental Rocket Stuttgart: A Low-Cost Technology DemonstratorMateusz SynowieckiNo ratings yet

- Stu-Ch09 MeasurementDocument35 pagesStu-Ch09 MeasurementMateusz SynowieckiNo ratings yet

- Sampling Systems Maintaining Quality and Safety FCDocument2 pagesSampling Systems Maintaining Quality and Safety FCMateusz SynowieckiNo ratings yet

- A Study of The Prediction of Ammonium Bisulfate Formation TemperaDocument74 pagesA Study of The Prediction of Ammonium Bisulfate Formation TemperaMateusz SynowieckiNo ratings yet

- 1127740Document188 pages1127740Mateusz SynowieckiNo ratings yet

- Practical Considerations of Gas Sampling and Gas Sampling SystemsDocument8 pagesPractical Considerations of Gas Sampling and Gas Sampling SystemsMateusz SynowieckiNo ratings yet

- Ultrasonic Chamber: DescriptionDocument3 pagesUltrasonic Chamber: DescriptionMateusz SynowieckiNo ratings yet

- Design On Line Chrom Sys Liq Fract FacilDocument16 pagesDesign On Line Chrom Sys Liq Fract FacilMateusz SynowieckiNo ratings yet

- Technical Publication: Verify Fluid Flow To Your Analyzer and Keep Your Plant RunningDocument5 pagesTechnical Publication: Verify Fluid Flow To Your Analyzer and Keep Your Plant RunningMateusz SynowieckiNo ratings yet

- Py-Gas Sample Conditioner Py-Gas Sample Conditioner: Principle of OperationDocument4 pagesPy-Gas Sample Conditioner Py-Gas Sample Conditioner: Principle of OperationMateusz SynowieckiNo ratings yet

- FS10A Analyzer Flow Assurance 8 30 12 PDFDocument5 pagesFS10A Analyzer Flow Assurance 8 30 12 PDFMateusz SynowieckiNo ratings yet

- P25double Coil CoolerDocument2 pagesP25double Coil CoolerMateusz SynowieckiNo ratings yet

- Cyclone Filter: Model A Specification B Specification Accessories Element Material & Range Body MaterialDocument2 pagesCyclone Filter: Model A Specification B Specification Accessories Element Material & Range Body MaterialMateusz SynowieckiNo ratings yet

- 401 Cem Engineering Design PDFDocument64 pages401 Cem Engineering Design PDFMateusz SynowieckiNo ratings yet

- P45drain PumpDocument2 pagesP45drain PumpMateusz SynowieckiNo ratings yet

- P35moisture Remover UnitDocument2 pagesP35moisture Remover UnitMateusz SynowieckiNo ratings yet

- 1083ch8 2 PDFDocument19 pages1083ch8 2 PDFMateusz SynowieckiNo ratings yet

- 402 B 04 001b 12 Final PDFDocument44 pages402 B 04 001b 12 Final PDFAbdul GhafoorNo ratings yet

- Coating PropertiesDocument1 pageCoating PropertiesArvin BabuNo ratings yet

- LMS Analisa SZ Qbig Semester 1 2021Document55 pagesLMS Analisa SZ Qbig Semester 1 2021Muhammad Nur HanifanNo ratings yet

- World'S Largest Selling: CPVC Pipes & FittingsDocument2 pagesWorld'S Largest Selling: CPVC Pipes & FittingsAPRWSEA WGNo ratings yet

- ShaftDocument15 pagesShaftj sNo ratings yet

- 2) Haseeb PresentationDocument27 pages2) Haseeb PresentationBilalAshrafNo ratings yet

- Cotter Pin, Stainless Steel: Page 1 of 1 REV-03 Date: August 4, 2015 Pin - Cot.SsDocument1 pageCotter Pin, Stainless Steel: Page 1 of 1 REV-03 Date: August 4, 2015 Pin - Cot.SsD_D_76No ratings yet

- Renolit H 443-HD 88Document2 pagesRenolit H 443-HD 88miguelfpintoNo ratings yet

- Impressa s95 PDFDocument22 pagesImpressa s95 PDFSergiu BejanNo ratings yet

- MAN-LA Ecomat Parts List Overview ServicelineDocument2 pagesMAN-LA Ecomat Parts List Overview ServicelineAnonymous PaN8o983No ratings yet

- HP EliteDisplay E221 DatasheetDocument2 pagesHP EliteDisplay E221 DatasheetMihaela CaciumarciucNo ratings yet

- Cast Iron Pipe Fittings Eng PDFDocument124 pagesCast Iron Pipe Fittings Eng PDFAnonymous PCsoNCt0mFNo ratings yet

- Network Topology Comparison: Topology Information Transfer Setup Expansion Troubleshooting Cost Cabling ConcernsDocument8 pagesNetwork Topology Comparison: Topology Information Transfer Setup Expansion Troubleshooting Cost Cabling ConcernsAshfaq RahmanNo ratings yet

- Kosovo Informal Settlement Upgrade ProposalsDocument24 pagesKosovo Informal Settlement Upgrade ProposalsSustainable Neighbourhoods NetworkNo ratings yet

- Gripsholm Shipping S.A.: Bi - Monthly Supervision and Maintenance ReportDocument8 pagesGripsholm Shipping S.A.: Bi - Monthly Supervision and Maintenance Reportjgonzalez1980No ratings yet

- Cleaning Glassware Sigma Aldrich PDFDocument4 pagesCleaning Glassware Sigma Aldrich PDFC.No ratings yet

- Microcontroller Based Temperature Measurement and ControllingDocument94 pagesMicrocontroller Based Temperature Measurement and ControllingNitesh Chauhan67% (3)

- Review Paper On Study On Properties of Black Cotton Soil Using Stone Dust and Sisal FiberDocument3 pagesReview Paper On Study On Properties of Black Cotton Soil Using Stone Dust and Sisal FiberEditor IJTSRDNo ratings yet

- The Effect of Fiber Orientation On The Post-Cracking Behavior of Steel Fiber Reinforced Concrete Under Bending and Uniaxial Tensile TestsDocument43 pagesThe Effect of Fiber Orientation On The Post-Cracking Behavior of Steel Fiber Reinforced Concrete Under Bending and Uniaxial Tensile TestsPCPCNo ratings yet

- Makalah Reversible Dan Irreversible EngineDocument5 pagesMakalah Reversible Dan Irreversible EngineAqeila Muz DalifahNo ratings yet

- Composites in Manufacturing of VehiclesDocument4 pagesComposites in Manufacturing of VehiclesRushabh PatelNo ratings yet

- Lecture 1 Theory of StructuresDocument14 pagesLecture 1 Theory of StructuresShay Patrick CormacNo ratings yet

- ASTM A672 Grade CC 60 EFW Pipe SuppliersDocument4 pagesASTM A672 Grade CC 60 EFW Pipe SuppliersRELIABLE PIPES & TUBESNo ratings yet

- Isotech Hyperion DragoDocument4 pagesIsotech Hyperion DragoJose Luis CorreaNo ratings yet

- Ramos, Christian Paul C. A1-4BSCE-05 CIE055-Construction Materials and Project ManagementDocument1 pageRamos, Christian Paul C. A1-4BSCE-05 CIE055-Construction Materials and Project ManagementChristian Paul RamosNo ratings yet

- Geometrixs Architects and Engineers Company ProfileDocument9 pagesGeometrixs Architects and Engineers Company ProfileRaman NagarajaNo ratings yet

- MMV 1300 1500 - EnglDocument2 pagesMMV 1300 1500 - EnglEmilian PopaNo ratings yet

- University of Engineering & Technology Peshawar, Pakistan: TranscriptDocument1 pageUniversity of Engineering & Technology Peshawar, Pakistan: TranscriptEngr Zeeshan UllahNo ratings yet

Miniature Flowmeters For Analytical Process DK 700: Installation and Operating Instructions

Miniature Flowmeters For Analytical Process DK 700: Installation and Operating Instructions

Uploaded by

Mateusz SynowieckiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Miniature Flowmeters For Analytical Process DK 700: Installation and Operating Instructions

Miniature Flowmeters For Analytical Process DK 700: Installation and Operating Instructions

Uploaded by

Mateusz SynowieckiCopyright:

Available Formats

4000666201

KROHNE 08/2009

Installation and

Miniature flowmeters Operating Instructions

for analytical process DK 700

Installation Initial startup

Ensure materials compatibility Close needle valve at the flowmeter.

The temperature of the product and the allowable operating Open shutoff valves upstream and downstream of flowmeter.

pressure must not exceed the specified maximum values Slowly open needle valve and set the desired flowrate.

(see Technical Data). Where liquids are involved, carefully vent the pipeline to

The measuring section is also permitted to be filled with avoid water hammer that may cause breakage of the glass

flammable liquids, provided a potentially explosive cone.

atmosphere is not permanently or for prolonged periods On gas service, increase pressure slowly up to the operating

present in the measuring tube. pressure. Make sure the float does not accelerate to the

The calculation of the pressurized parts is effected with upper stop (e.g. in conjunction with solenoid valves) as this

allowance for corrosion, erosion through abrasion or may damage the flowmeter.

cavitation. The flowrate value is read off from the top edge of the float

(ball).

Installation in the pipeline

The variable area flowmeter has to be installed vertically Reading line

(float measuring principle - flow direction from bottom to top).

Before installing the flowmeter, blow or flush out the pipeline

leading to the flowmeter.

Use connectors suitable for the flowmeter version. Align the

pipes axially with the bolt holes un the flowmeter without Technical Data

incurring stresses.

If necessary, support the pipeline on both sides of the Measuring ranges see Flow table

flowmeter to prevent vibration from being transferred to the

Accuracy to VDI/VDE Code 3513, Sh. 2 (qG = 50%)

flowmeter. DK 701 6%

DK 702 4%

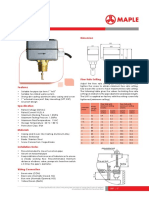

Panel mounting

Measuring cone

Type NG 50

(see Dimensions and Weights)

Length 60mm (2.36")

Prepare the panel recess as shown in the drawing. Scale division flow units

Before installing, remove the clamp clip 1 and Float shape ball

Allen screw 2, 4mm Allen key, from the flowmeter.

Operating data

Insert flowmeter into recess and align vertically.

Max. allowable op. pressure 4 bar

Fasten the flowmeter with the clamp clip and Allen screw (4 Max. product temperature 100°C

mm Allen key).

Connection

Standard G 1/8

Option tube connection 6 mm

Fitting dimension 75 mm

Diameter of needle valve

Flow ranges

< 5 l/h water, ≤ 100 l/h air 1,0 mm

> 5 l/h water, > 100 l/h air 2,5 mm

Materials

Measuring cone Borosilicate glass

Float Stainless steel 1.4401, glass

Gaskets

Standard FKM / PTFE

Option FFKM / PTFE

Valve spindle Stainless steel 1.4571 (316 Ti)

Mount

Rail Aluminium anodized

Front plate Polycarbonat

Top and bottom blocks PVDF

Dimensions and weights

Dimensions approx. Weight

a b c d e f

mm inches mm inches mm inches mm inches mm inches mm inches kg lbs

97 3.82 25 0.99 75 2.95 max. 65 max.2.56 94 3.70 23 0.91 0.1 0.22

Panel recess

Flow table

Float material stainless steel 1.4571 (316 Ti), glass

Calibration data: Water at 20°C (68°F)

Air at 20°C, (68°F), 1.2 bar abs. (17.4 psig) (in normal state)

100% flow values

Rangeability 10 : 1

Ball Ø Air Water

DK 701 (Scale on frontplate) DK 702 Scale on glass cone) DK 702 (Scale on glass cone)

mm inches l/h SCFH l/h SCFH l/h US GPM

4 0.16 - - 5 0.2 - -

4 0.16 - - 8 0.3 - -

4 0.16 - - 16 0.6 - -

4 0.16 - - 25 1 - -

4 0.16 - - 40 1.5 - -

4 0.16 40 1.5 60 2.5 2.5 0.01

6 0.24 100 4 100 4 5 0.02

6 0.24 150 6 250 10 12 0.05

6 0.24 250 10 500 20 25 0.1

6 0.24 - 800 30 40 0.16

Product liability and warranty

Responsibility for the suitability and usage to the intended purpose of these flowmeters rests solely with the operator. Improper installation or

improper operation of the flowmeters may lead to the loss of warranty. In addition, the "General conditions of sale" which forms the basis of the

purchase contract are applicable.

If you need to return the unit for checkout or repair, please pay strict attention to the following points:

Due to statutory regulations concerning protection of the environment and the health and safety of our personnel, KROHNE may only handle, test

and repair returned flowmeters that have been in contact with liquids if it is possible to do so without risk to personnel and environment.

This means that KROHNE can only service your unit if it is accompanied by a certificate confirming that the flowmeter is safe to handle.

If the unit has been operated with toxic, caustic, flammable or water-endangering liquids, you are kindly requested:

● To check and ensure, if necessary by rinsing or neutralizing, that all the cavities are free from such dangerous substances.

● To enclose a certificate with the flowmeter confirming that is safe to handle and stating the liquid used.

KROHNE regret that we cannot service your device unless it is accompanied by such a certificate and thank you for your understanding.

You might also like

- Apache 2,3,4.pdf4ba7b60f9c164Document1 pageApache 2,3,4.pdf4ba7b60f9c164Jordan PooleNo ratings yet

- ZM r6200 Rework Station Instruction Manual BgarebaDocument29 pagesZM r6200 Rework Station Instruction Manual Bgarebasergio0% (1)

- !!!! 2014-NGSTech-Proceedings PDFDocument119 pages!!!! 2014-NGSTech-Proceedings PDFMateusz SynowieckiNo ratings yet

- MID128 Engine ECU PID45 Inlet Air Heater Status (128 PID45) : Volvo Guided DiagnosticsDocument2 pagesMID128 Engine ECU PID45 Inlet Air Heater Status (128 PID45) : Volvo Guided DiagnosticsPreett Rajin Menabung100% (2)

- FlowMon Catalogue 2 PDFDocument12 pagesFlowMon Catalogue 2 PDFsimbamikeNo ratings yet

- Tech Sheet Series CDocument2 pagesTech Sheet Series CLalu Adam Akmal IsnenNo ratings yet

- Ficha Tecnica FlujometroDocument2 pagesFicha Tecnica FlujometroTatiana Mejías SeguraNo ratings yet

- Pipe Valves and Fittings - 15000Document11 pagesPipe Valves and Fittings - 15000willianNo ratings yet

- Main Valves Data SheetDocument18 pagesMain Valves Data SheetMahmoud GaberNo ratings yet

- D070Q Agr CatDocument4 pagesD070Q Agr CatRuben ManuelNo ratings yet

- Two Three Way Ball ValvesDocument6 pagesTwo Three Way Ball ValvesUzair AnsariNo ratings yet

- Vetec 62.7 Sanson Plug Tipo CanflexDocument12 pagesVetec 62.7 Sanson Plug Tipo CanflexAnderson SiqueiraNo ratings yet

- Ds 818Document3 pagesDs 818mmiranda.inmareproNo ratings yet

- CH 10 Additional ProductsDocument47 pagesCH 10 Additional Productssaddam khanNo ratings yet

- Cryogenic Valves For Industrial Gas Applications-43-44Document2 pagesCryogenic Valves For Industrial Gas Applications-43-44Abdul Hadi RashidNo ratings yet

- Specification - 2023 02 01 09 02 41Document10 pagesSpecification - 2023 02 01 09 02 41Chinnaraj SNo ratings yet

- Manual 80 81 Isolation RingsDocument10 pagesManual 80 81 Isolation RingsFelix UscangaNo ratings yet

- Spira X Sarco Fig 14Document2 pagesSpira X Sarco Fig 14Jacobus CalvelageNo ratings yet

- Check Valves Series Cv09Document6 pagesCheck Valves Series Cv09Uzair AnsariNo ratings yet

- Strainer Type 305Document5 pagesStrainer Type 305alexiel1806No ratings yet

- Switch Flujo DHDDocument6 pagesSwitch Flujo DHDAF VMNo ratings yet

- Air and Water Solenoid Valves: FeaturesDocument4 pagesAir and Water Solenoid Valves: FeaturesZuñiga AntonioNo ratings yet

- King 7470 Series DatasheetDocument2 pagesKing 7470 Series DatasheetMacro MediciónNo ratings yet

- Flow Meter PDFDocument20 pagesFlow Meter PDFJoe Mari CapaNo ratings yet

- FS4-3 - Installation Instructions (MM-601J)Document8 pagesFS4-3 - Installation Instructions (MM-601J)mendozaNo ratings yet

- VT-BAYARD-Automatic Control Valves-FloatDocument8 pagesVT-BAYARD-Automatic Control Valves-Floatsiva ramakrishnanNo ratings yet

- Data Sheet 7.04 Issue C: Test & Drain Valve Fig. 801Document2 pagesData Sheet 7.04 Issue C: Test & Drain Valve Fig. 801Le DucNo ratings yet

- P Series Pipe - Needle Valve CatalogDocument4 pagesP Series Pipe - Needle Valve CatalogHenry PorcoNo ratings yet

- K-CV-KT20 Coperion K-Tron Product Specification Volumetric Twin Screw Compact FeederDocument2 pagesK-CV-KT20 Coperion K-Tron Product Specification Volumetric Twin Screw Compact FeederARK MurpheyNo ratings yet

- C16601 Proinert®2 Selector ValveDocument2 pagesC16601 Proinert®2 Selector Valvevld20082No ratings yet

- Data Sheet Daniel Series 700 Model v788 en 6385002Document10 pagesData Sheet Daniel Series 700 Model v788 en 6385002Marcelo PinheiroNo ratings yet

- Variable Reach 1101 Serie Top Loading Arm: Technical SpecificationsDocument2 pagesVariable Reach 1101 Serie Top Loading Arm: Technical SpecificationsRenalyn TorioNo ratings yet

- Fv101x - Specsht2Document1 pageFv101x - Specsht2Claudio Rivadeneira CarrascoNo ratings yet

- TRDP - SSSVDocument23 pagesTRDP - SSSVsambhajiNo ratings yet

- Valv Diluvio Claval Diafragma TubularDocument29 pagesValv Diluvio Claval Diafragma TubularDaniel ReyNo ratings yet

- Bermad - C80Document3 pagesBermad - C80Santiago RodaNo ratings yet

- Density ColumnDocument2 pagesDensity Columnjrlr65No ratings yet

- Załacznik NR 2 Spec - techn.MASONEILANDocument7 pagesZałacznik NR 2 Spec - techn.MASONEILANEric CastilloNo ratings yet

- Data Sheet For Plug ValveDocument2 pagesData Sheet For Plug ValveTauqueerAhmadNo ratings yet

- Liquid Flow Switch: DimensionDocument1 pageLiquid Flow Switch: DimensionChhomNo ratings yet

- Victaulic Flexible Hose Connecting To Dry Barrel SprinklerDocument27 pagesVictaulic Flexible Hose Connecting To Dry Barrel SprinklerOwais AhmedNo ratings yet

- De Sanding 2021Document1 pageDe Sanding 2021Phasin ChitutsahaNo ratings yet

- 45BYMP Check Valve PDDocument4 pages45BYMP Check Valve PDYen NguyenNo ratings yet

- Aqua MagDocument4 pagesAqua MagMahua ChakrabarttyNo ratings yet

- Cooling Tower SpecificationDocument14 pagesCooling Tower SpecificationAmzad DPNo ratings yet

- CVH Series PDFDocument9 pagesCVH Series PDFhendrabudimanNo ratings yet

- Tubular Level GaugesDocument3 pagesTubular Level GaugesKarthikeyanNo ratings yet

- Type 119 Control Valve: Bulletin 51.1:119Document4 pagesType 119 Control Valve: Bulletin 51.1:119Fernando GiadansNo ratings yet

- A700 EnglishDocument16 pagesA700 EnglishPablo MNo ratings yet

- WT 14 - Indirect HeaterDocument2 pagesWT 14 - Indirect Heatershakouri1370_8902064No ratings yet

- MN-89242-22-7 SpecDocument6 pagesMN-89242-22-7 Specrenhat parulian sitorusNo ratings yet

- 5658 Electric Actuated 3-Way Ball Valves: FeaturesDocument6 pages5658 Electric Actuated 3-Way Ball Valves: FeaturesRADHAKRISHNANNo ratings yet

- Asco Flow Control Valves CatalogDocument4 pagesAsco Flow Control Valves CatalogCristian GutiérrezNo ratings yet

- Rotametro ABBDocument10 pagesRotametro ABBjoticamario123No ratings yet

- FlowMon Catalogue 2Document12 pagesFlowMon Catalogue 2dhanu_aquaNo ratings yet

- Asco Series 316 Air Water CatalogDocument4 pagesAsco Series 316 Air Water CatalogekoNo ratings yet

- Datasheet Vetec TY005.030Document16 pagesDatasheet Vetec TY005.030Ali Abdul MannanNo ratings yet

- Installation Instructions: Durametallic MW-200 SeriesDocument8 pagesInstallation Instructions: Durametallic MW-200 SeriesEli Emmanuel Cárcamo Rodríguez100% (1)

- Tech Spec Spiral Pipe For Faide Project.r1Document5 pagesTech Spec Spiral Pipe For Faide Project.r1Delshad DuhokiNo ratings yet

- Yokogawa-WIKA C13WT+series Ed0Document20 pagesYokogawa-WIKA C13WT+series Ed0haisamsarwarNo ratings yet

- leaf-ABO Series 3e-Eng - 2014 - 11 - 07Document6 pagesleaf-ABO Series 3e-Eng - 2014 - 11 - 07BHARGAVNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Flyer +Rosemount+370XA+Gas+ChromatographDocument4 pagesFlyer +Rosemount+370XA+Gas+ChromatographMateusz SynowieckiNo ratings yet

- Process Instrumentation and Analytics: Reliable Processes Thanks To Perfect Integration of All ComponentsDocument32 pagesProcess Instrumentation and Analytics: Reliable Processes Thanks To Perfect Integration of All ComponentsMateusz SynowieckiNo ratings yet

- Ammonia Monitoring For: Denox ProcessDocument2 pagesAmmonia Monitoring For: Denox ProcessMateusz SynowieckiNo ratings yet

- Advances in OpticalDocument19 pagesAdvances in OpticalMateusz SynowieckiNo ratings yet

- GRP 1800series Datasheet UK V1Document1 pageGRP 1800series Datasheet UK V1Mateusz SynowieckiNo ratings yet

- GE Sample Systems WhitepaperDocument4 pagesGE Sample Systems WhitepaperMateusz SynowieckiNo ratings yet

- Bi-Prop Present 68IACDocument5 pagesBi-Prop Present 68IACMateusz SynowieckiNo ratings yet

- Rarata G., Surmacz P.Document9 pagesRarata G., Surmacz P.Mateusz SynowieckiNo ratings yet

- An 112 Magnos28 Oxygen Purity Measurement enDocument3 pagesAn 112 Magnos28 Oxygen Purity Measurement enMateusz SynowieckiNo ratings yet

- Hybrid Experimental Rocket Stuttgart: A Low-Cost Technology DemonstratorDocument17 pagesHybrid Experimental Rocket Stuttgart: A Low-Cost Technology DemonstratorMateusz SynowieckiNo ratings yet

- Stu-Ch09 MeasurementDocument35 pagesStu-Ch09 MeasurementMateusz SynowieckiNo ratings yet

- Sampling Systems Maintaining Quality and Safety FCDocument2 pagesSampling Systems Maintaining Quality and Safety FCMateusz SynowieckiNo ratings yet

- A Study of The Prediction of Ammonium Bisulfate Formation TemperaDocument74 pagesA Study of The Prediction of Ammonium Bisulfate Formation TemperaMateusz SynowieckiNo ratings yet

- 1127740Document188 pages1127740Mateusz SynowieckiNo ratings yet

- Practical Considerations of Gas Sampling and Gas Sampling SystemsDocument8 pagesPractical Considerations of Gas Sampling and Gas Sampling SystemsMateusz SynowieckiNo ratings yet

- Ultrasonic Chamber: DescriptionDocument3 pagesUltrasonic Chamber: DescriptionMateusz SynowieckiNo ratings yet

- Design On Line Chrom Sys Liq Fract FacilDocument16 pagesDesign On Line Chrom Sys Liq Fract FacilMateusz SynowieckiNo ratings yet

- Technical Publication: Verify Fluid Flow To Your Analyzer and Keep Your Plant RunningDocument5 pagesTechnical Publication: Verify Fluid Flow To Your Analyzer and Keep Your Plant RunningMateusz SynowieckiNo ratings yet

- Py-Gas Sample Conditioner Py-Gas Sample Conditioner: Principle of OperationDocument4 pagesPy-Gas Sample Conditioner Py-Gas Sample Conditioner: Principle of OperationMateusz SynowieckiNo ratings yet

- FS10A Analyzer Flow Assurance 8 30 12 PDFDocument5 pagesFS10A Analyzer Flow Assurance 8 30 12 PDFMateusz SynowieckiNo ratings yet

- P25double Coil CoolerDocument2 pagesP25double Coil CoolerMateusz SynowieckiNo ratings yet

- Cyclone Filter: Model A Specification B Specification Accessories Element Material & Range Body MaterialDocument2 pagesCyclone Filter: Model A Specification B Specification Accessories Element Material & Range Body MaterialMateusz SynowieckiNo ratings yet

- 401 Cem Engineering Design PDFDocument64 pages401 Cem Engineering Design PDFMateusz SynowieckiNo ratings yet

- P45drain PumpDocument2 pagesP45drain PumpMateusz SynowieckiNo ratings yet

- P35moisture Remover UnitDocument2 pagesP35moisture Remover UnitMateusz SynowieckiNo ratings yet

- 1083ch8 2 PDFDocument19 pages1083ch8 2 PDFMateusz SynowieckiNo ratings yet

- 402 B 04 001b 12 Final PDFDocument44 pages402 B 04 001b 12 Final PDFAbdul GhafoorNo ratings yet

- Coating PropertiesDocument1 pageCoating PropertiesArvin BabuNo ratings yet

- LMS Analisa SZ Qbig Semester 1 2021Document55 pagesLMS Analisa SZ Qbig Semester 1 2021Muhammad Nur HanifanNo ratings yet

- World'S Largest Selling: CPVC Pipes & FittingsDocument2 pagesWorld'S Largest Selling: CPVC Pipes & FittingsAPRWSEA WGNo ratings yet

- ShaftDocument15 pagesShaftj sNo ratings yet

- 2) Haseeb PresentationDocument27 pages2) Haseeb PresentationBilalAshrafNo ratings yet

- Cotter Pin, Stainless Steel: Page 1 of 1 REV-03 Date: August 4, 2015 Pin - Cot.SsDocument1 pageCotter Pin, Stainless Steel: Page 1 of 1 REV-03 Date: August 4, 2015 Pin - Cot.SsD_D_76No ratings yet

- Renolit H 443-HD 88Document2 pagesRenolit H 443-HD 88miguelfpintoNo ratings yet

- Impressa s95 PDFDocument22 pagesImpressa s95 PDFSergiu BejanNo ratings yet

- MAN-LA Ecomat Parts List Overview ServicelineDocument2 pagesMAN-LA Ecomat Parts List Overview ServicelineAnonymous PaN8o983No ratings yet

- HP EliteDisplay E221 DatasheetDocument2 pagesHP EliteDisplay E221 DatasheetMihaela CaciumarciucNo ratings yet

- Cast Iron Pipe Fittings Eng PDFDocument124 pagesCast Iron Pipe Fittings Eng PDFAnonymous PCsoNCt0mFNo ratings yet

- Network Topology Comparison: Topology Information Transfer Setup Expansion Troubleshooting Cost Cabling ConcernsDocument8 pagesNetwork Topology Comparison: Topology Information Transfer Setup Expansion Troubleshooting Cost Cabling ConcernsAshfaq RahmanNo ratings yet

- Kosovo Informal Settlement Upgrade ProposalsDocument24 pagesKosovo Informal Settlement Upgrade ProposalsSustainable Neighbourhoods NetworkNo ratings yet

- Gripsholm Shipping S.A.: Bi - Monthly Supervision and Maintenance ReportDocument8 pagesGripsholm Shipping S.A.: Bi - Monthly Supervision and Maintenance Reportjgonzalez1980No ratings yet

- Cleaning Glassware Sigma Aldrich PDFDocument4 pagesCleaning Glassware Sigma Aldrich PDFC.No ratings yet

- Microcontroller Based Temperature Measurement and ControllingDocument94 pagesMicrocontroller Based Temperature Measurement and ControllingNitesh Chauhan67% (3)

- Review Paper On Study On Properties of Black Cotton Soil Using Stone Dust and Sisal FiberDocument3 pagesReview Paper On Study On Properties of Black Cotton Soil Using Stone Dust and Sisal FiberEditor IJTSRDNo ratings yet

- The Effect of Fiber Orientation On The Post-Cracking Behavior of Steel Fiber Reinforced Concrete Under Bending and Uniaxial Tensile TestsDocument43 pagesThe Effect of Fiber Orientation On The Post-Cracking Behavior of Steel Fiber Reinforced Concrete Under Bending and Uniaxial Tensile TestsPCPCNo ratings yet

- Makalah Reversible Dan Irreversible EngineDocument5 pagesMakalah Reversible Dan Irreversible EngineAqeila Muz DalifahNo ratings yet

- Composites in Manufacturing of VehiclesDocument4 pagesComposites in Manufacturing of VehiclesRushabh PatelNo ratings yet

- Lecture 1 Theory of StructuresDocument14 pagesLecture 1 Theory of StructuresShay Patrick CormacNo ratings yet

- ASTM A672 Grade CC 60 EFW Pipe SuppliersDocument4 pagesASTM A672 Grade CC 60 EFW Pipe SuppliersRELIABLE PIPES & TUBESNo ratings yet

- Isotech Hyperion DragoDocument4 pagesIsotech Hyperion DragoJose Luis CorreaNo ratings yet

- Ramos, Christian Paul C. A1-4BSCE-05 CIE055-Construction Materials and Project ManagementDocument1 pageRamos, Christian Paul C. A1-4BSCE-05 CIE055-Construction Materials and Project ManagementChristian Paul RamosNo ratings yet

- Geometrixs Architects and Engineers Company ProfileDocument9 pagesGeometrixs Architects and Engineers Company ProfileRaman NagarajaNo ratings yet

- MMV 1300 1500 - EnglDocument2 pagesMMV 1300 1500 - EnglEmilian PopaNo ratings yet

- University of Engineering & Technology Peshawar, Pakistan: TranscriptDocument1 pageUniversity of Engineering & Technology Peshawar, Pakistan: TranscriptEngr Zeeshan UllahNo ratings yet