Professional Documents

Culture Documents

BDM Example 6 - 20170106 PDF

BDM Example 6 - 20170106 PDF

Uploaded by

amraja2001Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BDM Example 6 - 20170106 PDF

BDM Example 6 - 20170106 PDF

Uploaded by

amraja2001Copyright:

Available Formats

EXAMPLE 6 - DECK DESIGN, INCLUDING COLLISION ON A TYPE 7 & TYPE 10M BARRIER 1

EXAMPLE 6.1 - DECK DESIGN

GENERAL INFORMATION

Based on AASHTO LRFD Bridge Design Specifications 9.6.1, there are three permitted methods of

deck analysis:

1. Approximate Elastic Method, or "Equivalent Strip" Method (AASHTO 4.6.2.1)

2. Refined Methods (AASHTO 4.6.3.2)

3. Empirical Design Method (AASHTO 9.7.2)

This design example uses the Approximate Elastic Method (Equivalent Strip Method), in which the

deck is divided into transverse strips, assumed to be supported on rigid supports at the center of the

girders.

MATERIAL AND SECTION PROPERTIES

Structure type CIP Concrete Deck

Girder spacing, maximum SGdr = 8.00 ft.

Number of girders NGdr = 3 ea.

Overall deck width W Deck = 24.00 ft.

Deck slab thickness tDeck = 8.00 in.

Concrete top cover cTop = 2.00 in. AASHTO T.5.12.3-1

Concrete bottom cover cBot = 1.00 in. AASHTO T.5.12.3-1

Wearing surface tWS = 3.00 in.

Concrete strength f'c = 4.50 ksi (Concrete Class D compressive strength)

Reinforcement strength fy = 60.00 ksi (Minimum yield strength of grade 60 steel)

Concrete density WC = 0.150 kcf

Deck overlay density WWS = 0.145 kcf Section 3.4.2

Allowance for future utilities WUtl = 0.005 ksf Section 3.4.3

Resistance factors φSTR = 0.90 (strength limit state) AASHTO 5.5.4.2

φEE = 1.00 (extreme event limit state) AASHTO 1.3.2.1

Correction factor for source aggregate K1 = 1.00 AASHTO 5.4.2.4

Modulus of elasticity of reinforcement Es = 29000 ksi AASHTO 5.4.3.2

Modulus of elasticity of concrete Ec = 4435 ksi AASHTO 5.4.2.4

𝐸𝐸𝐸𝐸𝑐𝑐𝑐𝑐 = 120,000𝐾𝐾𝐾𝐾1 𝑊𝑊𝑊𝑊𝑐𝑐𝑐𝑐2 𝑓𝑓𝑓𝑓𝑐𝑐𝑐𝑐′0.33

Modular ratio n = ES / EC = 6.54

Girder type Bulb Tee - BT54

Girder web thickness web = 7.00 in.

Girder top flange width flange = 43.00 in.

Barrier type Type 7

Area of barrier section AB = 3.24 ft.2

Barrier weight WBarrier = 0.486 kip/ft.

(Refer to Example 6.3 and CDOT Bridge Worksheet B-606-7A for more details)

CDOT Bridge Design Manual January 2017

EXAMPLE 6 - DECK DESIGN, INCLUDING COLLISION ON A TYPE 7 & TYPE 10M BARRIER 2

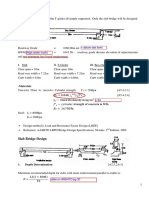

Typical Section

UNFACTORED DEAD LOADS

Dead Loads moments are calculated for a 1.00 ft. wide section of the bridge deck using approved

structural analysis methods. This includes continuous beam equation, moment distribution, simple

beam equation, or finite element analysis. Below bending moments produced by Dead Load are

calculated based on the Continuous Beam Coefficients Table (AISC Table 3-22c).

1. Dead Load of structural components (DC):

DCDeck = WC tDeck * 1 ft. = 0.150 kcf * 8.0 in. / 12 in./ft. * 1.0 ft. = 0.100 klf

DCBarrier = (2) WBarrier 1 ft. / W Deck = (2) 0.486 kip/ft. * 1 ft. / 24.0 ft. = 0.041 klf

Total DC = DCDeck + DCBarrier = 0.100 klf + 0.041 klf = 0.141 klf

2

Positive moment from DC +MDC = 0.07 DC SGdr2 = 0.07 * 0.141 klf * (8.0 ft.) = 0.632 kip-ft.

2

Negative moment from DC -MDC = -0.125 DC SGdr2 = -0.125 * 0.141 klf * (8.0 ft.) = -1.128 kip-ft.

2. Dead Load of wearing surfaces and utilities (DW):

DW WS = WWS tWS * 1 ft. = 0.145 kcf * 3.0 in. / 12 in./ft. * 1.0 ft. = 0.036 klf

DW Utl = WUtl 1 ft. = 0.005 ksf * 1 ft. = 0.005 klf

Total DW = DW WS + DW Utl = 0.036 klt + 0.005 klf = 0.041 klf

2

Positive moment from DW +MDW = 0.07 DW SGdr2 = 0.07 * 0.041 klf * (8.0 ft.) = 0.184 kip-ft.

2

Negative moment from DW -MDW = -0.125 DW SGdr2 = -0.125 * 0.041 klf * (8.0 ft.) = -0.328 kip-ft.

CDOT Bridge Design Manual January 2017

EXAMPLE 6 - DECK DESIGN, INCLUDING COLLISION ON A TYPE 7 & TYPE 10M BARRIER 3

UNFACTORED LIVE LOADS

In general, Live Load effects can be calculated by modeling the deck as a beam supported on girders,

with one or more axles placed side by side. These loads are moved transversely to maximize the

moments. To determine Live Load moment per unit width of the bridge, calculated total Live Load

moment is divided by an equivalent strip width, calculated per equations from AASHTO LRFD Bridge

Design Specifications T.4.6.2.1.3-1.

In lieu of determining an equivalent strip width, for bridges with decks supported on three or more

girders, Live Load moment can be determined using AASHTO LRFD Bridge Design Specifications

Appendix A4 T.A4-1. This table lists positive and negative Live Load moments calculated using the

Equivalent Strip Method. Table values include multiple presence factors and the dynamic load

allowance. Interpolation between given values is allowed. To use this table, distance from centerline of

girder to design section for negative moment has to be calculated first.

Deck superstructure type - k AASHTO T.4.6.2.2.1-1

Design section = min of 1/3 flange width or 15.00 in. = 14.33 in. AASHTO 4.6.2.1.6

Maximum Live Loads per unit width:

Positive Moment from LL +MLL = 5.21 kip-ft. AASHTO T. A4-1

Negative Moment from LL -MLL = -2.37 kip-ft. (interpolated) AASHTO T. A4-1

FACTORED DESIGN LOADS

Concrete decks must be investigated for strength, service and extreme limit states. Fatigue and

fracture limit states do not need to be investigated (AASHTO 9.5).

Mu = η [γDCMDC + γDWMDW + m γLL(MLL+ IM)]

η = 1.0 load modifier

γ - load factors specified in AASHTO T.3.4.1-1, T.3.4.1-2

m - multiple presence factor, included in values from AASHTO T. A4-1

IM - dynamic load allowance, included in values from AASHTO T. A4-1

Maximum Load Factor Design Moments

Load Combination

γDC γDW γLL +Mu (kip-ft.) -Mu (kip-ft.)

Strength I 1.25 1.50 1.75 10.18 -6.05

Service I 1.00 1.00 1.00 6.03 -3.83

Controlling positive factored moment +Mu = 10.18 kip-ft.

Controlling negative factored moment -Mu = -6.05 kip-ft.

Dead Load Deck Moment Diagram

CDOT Bridge Design Manual January 2017

EXAMPLE 6 - DECK DESIGN, INCLUDING COLLISION ON A TYPE 7 & TYPE 10M BARRIER 4

DECK SLAB STRENGTH DESIGN

Design of deck reinforcement, including flexural resistance, limits of reinforcement and control of

cracking is based on AASHTO LRFD Bridge Design Specifications 5.7.3 (typical rectangular beam

design). The following design method can be used for normal weight concrete with specified

compressive strengths up to 15.0 ksi. Refer to Section 9, Deck and Deck Systems, of this BDM for

information about acceptable deck reinforcement sizes and spacing.

Width of the design section b= 12.00 in.

Resistance factor for t

ension-controlled section φSTR = 0.90 AASHTO 5.5.4.2

Positive Moment Capacity (bottom reinforcement)

Try Bar size # 5

Bar spacing s= 9.00 in.

Bar Diameter db = 0.625 in.

Bar Area Ab = 0.31 in.2

Area of steel per design strip

2

AS = b (Ab / s) = 12.0 in. * 0.310 in. / 9.0 in. = 0.41 in.2/ft.

Effective depth of section

dS = tDeck - cBot - 1/2 db = 8.0 in. - 1.0 in. - 0.625 in. / 2 = 6.69 in.

Depth of equivalent stress block

𝐴𝐴𝐴𝐴𝑆𝑆𝑆𝑆 𝑓𝑓𝑓𝑓𝑦𝑦𝑦𝑦

𝑎𝑎𝑎𝑎 = = 0.41 in.2 * 60.0 ksi / (0.85 * 4.5 ksi * 12 in.) = 0.54 in.

0.85𝑓𝑓𝑓𝑓𝑐𝑐𝑐𝑐′ 𝑏𝑏𝑏𝑏

𝑎𝑎𝑎𝑎

Factored flexural resistance +𝜑𝜑𝜑𝜑𝑀𝑀𝑀𝑀𝑛𝑛𝑛𝑛 = 𝜑𝜑𝜑𝜑𝐴𝐴𝐴𝐴𝑆𝑆𝑆𝑆 𝑓𝑓𝑓𝑓𝑦𝑦𝑦𝑦 𝑑𝑑𝑑𝑑𝑆𝑆𝑆𝑆 − =

2

2

= 0.90 * 0.41 in. * 60.0 ksi * (6.69 in. - 0.54 in. / 2) / 12 in./ft. = 11.84 kip-ft.

𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶 + 𝜑𝜑𝜑𝜑𝑀𝑀𝑀𝑀𝑛𝑛𝑛𝑛 > +𝑀𝑀𝑀𝑀𝑢𝑢𝑢𝑢 : 11.84 kip-ft. > 10.18 kip-ft. OK

Negative Moment Capacity (top reinforcement)

Try Bar size # 5

Bar spacing s= 9.00 in.

Bar Diameter db = 0.625 in.

Bar Area Ab = 0.31 in.2

CDOT Bridge Design Manual January 2017

EXAMPLE 6 - DECK DESIGN, INCLUDING COLLISION ON A TYPE 7 & TYPE 10M BARRIER 5

Area of steel per 1.00 ft. design strip

2

AS = B (Ab / s) = 12 in. * 0.310 in. / 9.00 in. = 0.41 in.2/ft.

Effective depth of section

dS = tDeck - cTop - 1/2 db = 8.0 in. - 2.0 in. - 0.625 in. / 2 = 5.69 in.

Depth of equivalent stress block

𝐴𝐴𝐴𝐴𝑠𝑠𝑠𝑠 𝑓𝑓𝑓𝑓𝑦𝑦𝑦𝑦 2

𝑎𝑎𝑎𝑎 = = 0.41 in./ft. * 60.0 ksi / (0.85 * 4.5 ksi * 12 in.) = 0.54 in.

0.85𝑓𝑓𝑓𝑓𝑐𝑐𝑐𝑐′ 𝑏𝑏𝑏𝑏

𝑎𝑎𝑎𝑎

Factored flexural resistance −𝜑𝜑𝜑𝜑𝑀𝑀𝑀𝑀𝑛𝑛𝑛𝑛 = 𝜑𝜑𝜑𝜑𝐴𝐴𝐴𝐴𝑠𝑠𝑠𝑠 𝑓𝑓𝑓𝑓𝑦𝑦𝑦𝑦 𝑑𝑑𝑑𝑑𝑠𝑠𝑠𝑠 − =

2

2

= 0.90 * 0.41in. * 60.0 ksi * (5.69 in. - 0.54 in. / 2) / 12 in./ft. = 10.00 kip-ft.

𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶 − 𝜑𝜑𝜑𝜑𝑀𝑀𝑀𝑀𝑛𝑛𝑛𝑛 > −𝑀𝑀𝑀𝑀𝑢𝑢𝑢𝑢 : 10.00 kip-ft. > 6.05 kip-ft. OK

Minimum Reinforcement AASHTO 5.7.3.3.2

Unless otherwise specified, the amount of prestressed and non-prestressed tensile reinforcement shall

be adequate to develop a factored flexural resistance, Mr = φMn, at least equal to the lesser of:

• 1.33 times the positive factored ultimate moment

• Cracking moment

𝑆𝑆𝑆𝑆𝑐𝑐𝑐𝑐

Cracking moment 𝑀𝑀𝑀𝑀𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 = 𝛾𝛾𝛾𝛾3 𝛾𝛾𝛾𝛾1 𝑓𝑓𝑓𝑓𝑐𝑐𝑐𝑐 + 𝛾𝛾𝛾𝛾2 𝑓𝑓𝑓𝑓𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 𝑆𝑆𝑆𝑆𝑐𝑐𝑐𝑐 − 𝑀𝑀𝑀𝑀𝑑𝑑𝑑𝑑𝑛𝑛𝑛𝑛𝑛𝑛𝑛𝑛 −1 AASHTO 5.7.3.3.2-1

𝑆𝑆𝑆𝑆𝑛𝑛𝑛𝑛𝑐𝑐𝑐𝑐

When simplified by removing all values applicable to prestressed and noncomposite sections, this

equation becomes the following: 𝑀𝑀𝑀𝑀𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 = 𝛾𝛾𝛾𝛾3 𝛾𝛾𝛾𝛾1 𝑓𝑓𝑓𝑓𝑐𝑐𝑐𝑐 𝑆𝑆𝑆𝑆𝑐𝑐𝑐𝑐

Where:

Flexural cracking variability factor γ1 = 1.60 (non-segmental brg.)

Ratio of specified min. yield strength to ultimate tensile strength γ3 = 0.67 (A615 steel)

Concrete density modification factor λ= 1.00 AASHTO 5.4.2.8

Modulus of rupture 𝑓𝑓𝑓𝑓𝑐𝑐𝑐𝑐 = 0.24𝜆𝜆𝜆𝜆 𝑓𝑓𝑓𝑓𝑐𝑐𝑐𝑐′ = 0.51 ksi AASHTO 5.4.2.6

2

𝑏𝑏𝑏𝑏𝐶𝐶2 𝑏𝑏𝑏𝑏𝑡𝑡𝑡𝑡𝐷𝐷𝐷𝐷𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝐷𝐷𝐷𝐷 2

Section modulus of design section 𝑆𝑆𝑆𝑆𝑐𝑐𝑐𝑐 = = = 12.0in. * (8.0 in.) / 6 = 128.00 in.3

6 6

- Check Positive Moment reinforcement

1.33 (+Mu) = 1.33 * 10.18 kip-ft. = 13.54 kip-ft.

𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶 + 𝜑𝜑𝜑𝜑𝑀𝑀𝑀𝑀𝑛𝑛𝑛𝑛 ≥ 𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 3

Mcr = 0.67 * 1.60 * 0.51 ksi * 128.0 in. / 12 in./ft. = 5.83 kip-ft.

11.84 kip-ft. > 5.83 kip-ft. OK

- Check Negative Moment reinforcement

1.33 (-Mu) = 1.33 * 6.05 kip-ft. = 8.05 kip-ft.

𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶 − 𝜑𝜑𝜑𝜑𝑀𝑀𝑀𝑀𝑛𝑛𝑛𝑛 ≥ 𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 3

Mcr = 0.67 * 1.60 * 0.51 ksi * 128.0 in. / 12 in./ft. = 5.83 kip-ft.

10.00 kip-ft. > 5.83 kip-ft. OK

CDOT Bridge Design Manual January 2017

EXAMPLE 6 - DECK DESIGN, INCLUDING COLLISION ON A TYPE 7 & TYPE 10M BARRIER 6

CONTROL OF CRACKING AT SERVICE LIMIT STATE

Cracking is controlled by the spacing of mild steel reinforcement in the layer closest to the tension face,

which shall satisfy the following (need not be less than 5.00 in.):

700𝛾𝛾𝛾𝛾𝑐𝑐𝑐𝑐 AASHTO 5.7.3.4-1

𝑠𝑠𝑠𝑠 ≤ − 2𝑑𝑑𝑑𝑑𝑐𝑐𝑐𝑐

𝛽𝛽𝛽𝛽𝑠𝑠𝑠𝑠 𝑓𝑓𝑓𝑓𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠

In which: γe = 0.75 - exposure factor (1.0 for Class 1 and 0.75 for Class 2)

βs - ratio of flexural strain at the extreme tension face to the strain at the centroid of the

reinforcement layer nearest the tension face

fss - calculated tensile stress in mild steel reinforcement at the service limit state

(≤ 0.60 fy ksi)

dc - thickness of concrete cover measured from extreme tension fiber to center of the

flexural reinforcement located closest thereto. For calculation purposes, dc need not

be taken greater than 2 in. plus the bar radius

- Check Cracking at the Bottom of Deck (spacing of Positive Moment reinforcement):

dc = cBot + 1/2 db = 1.00 in. + 0.625 in. / 2 = 1.31 in.

𝑑𝑑𝑑𝑑𝐶𝐶𝐶𝐶

𝛽𝛽𝛽𝛽𝑆𝑆𝑆𝑆 = 1 + = 1 + 1.31 in. / [0.7 (8.0 in. - 1.31 in.)] = 1.28

0.7(𝑡𝑡𝑡𝑡𝐷𝐷𝐷𝐷𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝐷𝐷𝐷𝐷 − 𝑑𝑑𝑑𝑑𝐶𝐶𝐶𝐶 )

𝐴𝐴𝐴𝐴𝑆𝑆𝑆𝑆 2

Tension reinforcement ratio 𝜌𝜌𝜌𝜌 = = 0.41 in. / (12 in. * 6.69 in.) = 0.0051

𝑏𝑏𝑏𝑏𝑑𝑑𝑑𝑑𝑆𝑆𝑆𝑆

𝐶𝐶𝐶𝐶 = 2𝑚𝑚𝑚𝑚𝜌𝜌𝜌𝜌 + 𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 2 − 𝑚𝑚𝑚𝑚𝜌𝜌𝜌𝜌 = 0.23

𝑗𝑗𝑗𝑗 = 1 − 𝐶𝐶𝐶𝐶/3 = 0.92

+𝑀𝑀𝑀𝑀𝑢𝑢𝑢𝑢_𝑠𝑠𝑠𝑠𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 2

𝑓𝑓𝑓𝑓𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠 = = 6.03 kip-ft. * 12in./ft. / (0.41 in. * 0.92 * 6.69 in.) = 28.67 ksi

𝐴𝐴𝐴𝐴𝑆𝑆𝑆𝑆 𝑗𝑗𝑗𝑗𝑑𝑑𝑑𝑑𝑆𝑆𝑆𝑆

700𝛾𝛾𝛾𝛾𝑐𝑐𝑐𝑐

𝑠𝑠𝑠𝑠𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 = − 2𝑑𝑑𝑑𝑑𝐶𝐶𝐶𝐶 = 700 * 0.75 / (1.28 * 28.67 ksi) - 2 * 1.31in. = 11.69 in.

𝛽𝛽𝛽𝛽𝑆𝑆𝑆𝑆 𝑓𝑓𝑓𝑓𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆

Spacing of positive moment reinforcement used in the design = 9.00 in.

𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶 𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑠𝑠𝑠𝑠 𝑢𝑢𝑢𝑢𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠 ≤ 𝑠𝑠𝑠𝑠𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 : 9.00 in. < 11.69 in. OK

- Check Cracking at Top of Deck (spacing of Negative Moment reinforcement):

dc = cTop + 1/2 db = 2.0 in. + 0.625 in. / 2 = 2.31 in.

𝑑𝑑𝑑𝑑𝐶𝐶𝐶𝐶

𝛽𝛽𝛽𝛽𝑠𝑠𝑠𝑠 = 1 + = 1+ 2.31 in. / [0.7 * (8.0 in. - 2.31 in.)] = 1.58

0.7(𝑡𝑡𝑡𝑡𝐷𝐷𝐷𝐷𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝐷𝐷𝐷𝐷 − 𝑑𝑑𝑑𝑑𝐶𝐶𝐶𝐶 )

𝐴𝐴𝐴𝐴𝑆𝑆𝑆𝑆 2

Tension reinforcement ratio 𝜌𝜌𝜌𝜌 = = 0.41 in. / (12 in. * 5.69 in.) = 0.0060

𝑏𝑏𝑏𝑏𝑑𝑑𝑑𝑑𝑆𝑆𝑆𝑆

Modular ratio n = ES / EC = 29000 ksi / 4435 ksi = 6.54

CDOT Bridge Design Manual January 2017

EXAMPLE 6 - DECK DESIGN, INCLUDING COLLISION ON A TYPE 7 & TYPE 10M BARRIER 7

𝐶𝐶𝐶𝐶 = 2𝑚𝑚𝑚𝑚𝜌𝜌𝜌𝜌 + 𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 2 − 𝑚𝑚𝑚𝑚𝜌𝜌𝜌𝜌 = 0.24

𝑗𝑗𝑗𝑗 = 1 − 𝐶𝐶𝐶𝐶/3 = 0.92

−𝑀𝑀𝑀𝑀𝑢𝑢𝑢𝑢_𝑠𝑠𝑠𝑠𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 2

𝑓𝑓𝑓𝑓𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠 = = 3.83 kip-ft. * 12in./ft. / (0.41 in. * 0.92 * 5.69 in.) = 21.41 ksi

𝐴𝐴𝐴𝐴𝑆𝑆𝑆𝑆 𝑗𝑗𝑗𝑗𝑑𝑑𝑑𝑑𝑆𝑆𝑆𝑆

700𝛾𝛾𝛾𝛾𝑐𝑐𝑐𝑐

𝑠𝑠𝑠𝑠𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 = − 2𝑑𝑑𝑑𝑑𝐶𝐶𝐶𝐶 = 700 * 0.75 / (1.58 * 21.41 ksi) - 2 * 2.31 in. = 10.90 in.

𝛽𝛽𝛽𝛽𝑆𝑆𝑆𝑆 𝑓𝑓𝑓𝑓𝑆𝑆𝑆𝑆𝑆𝑆𝑆𝑆

Spacing of negative moment reinforcement used in the design = 9.00 in.

𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶 𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑎𝑠𝑠𝑠𝑠 𝑢𝑢𝑢𝑢𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠 ≤ 𝑠𝑠𝑠𝑠𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚 : 9.00 in. < 10.90 in. OK

LONGITUDINAL REINFORCEMENT

Minimum reinforcement is required in all directions to accommodate shrinkage and temperature

changes near the surface of the slab. Longitudinal reinforcement on each face shall meet the following:

1.3𝑏𝑏𝑏𝑏 𝑡𝑡𝑡𝑡𝐷𝐷𝐷𝐷𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝐷𝐷𝐷𝐷

𝐴𝐴𝐴𝐴𝑆𝑆𝑆𝑆 ≥ AASHTO 5.10.8-1

2(𝑏𝑏𝑏𝑏 + 𝑡𝑡𝑡𝑡𝐷𝐷𝐷𝐷𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝐷𝐷𝐷𝐷 )𝑓𝑓𝑓𝑓𝑦𝑦𝑦𝑦

0.11 ≤ 𝐴𝐴𝐴𝐴𝑆𝑆𝑆𝑆 ≤ 0.60 AASHTO 5.10.8-2

As,min = 1.3 * 12.0 in.* 8.0 in. / [2 (12.0 in. + 8.0 in.) 60.0 ksi] = 0.052 in. /ft. 2

As,min = 0.11 in. /ft. 2

- controls

Also, per Section 9.6 of this BDM, the minimum longitudinal reinforcing steel in the top of the concrete

bridge deck shall be #4 @ 6.00 in. Longitudinal reinforcement in the bottom of the deck slab can be

distributed as a percentage of the primary reinforcement for positive moment.

Top reinforcement try #4 @ 6.00" on center: AS = 0.40 in.2/ft.

𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶 𝐴𝐴𝐴𝐴𝑆𝑆𝑆𝑆 ≥ 𝐴𝐴𝐴𝐴𝑆𝑆𝑆𝑆 𝑚𝑚𝑚𝑚𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠 OK

Effective span length 𝑆𝑆𝑆𝑆 = 𝑆𝑆𝑆𝑆𝐺𝐺𝐺𝐺𝑑𝑑𝑑𝑑𝑑𝑑𝑑𝑑 − 𝑤𝑤𝑤𝑤𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶 = 8.0 ft. - 7.0in. / 12in./ft. = 7.42 ft. AASHTO 9.7.2.3

Amount of reinforcement required in secondary direction in the bottom of the slab

220 220

≤ 67% = 81% Use - 67% AASHTO 9.7.3.2

𝑆𝑆𝑆𝑆 𝑆𝑆𝑆𝑆

Area of primary reinforcement for positive moment = 0.41 in.2/ft.

2

Required area of bottom longitudinal steel: AS_Req = 67% * 0.41 in./ft.= 0.27 in.2/ft.

Bottom reinforcement try #5 @ 12.00" on center: AS = 0.31 in.2/ft.

𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶 𝐴𝐴𝐴𝐴𝑆𝑆𝑆𝑆 ≥ 𝐴𝐴𝐴𝐴𝑆𝑆𝑆𝑆 𝑚𝑚𝑚𝑚𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠 OK

𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶 𝐴𝐴𝐴𝐴𝑆𝑆𝑆𝑆 ≥ 𝐴𝐴𝐴𝐴𝑆𝑆𝑆𝑆_𝑅𝑅𝑅𝑅𝑐𝑐𝑐𝑐𝑅𝑅𝑅𝑅 OK

CDOT Bridge Design Manual January 2017

EXAMPLE 6 - DECK DESIGN, INCLUDING COLLISION ON A TYPE 7 & TYPE 10M BARRIER 8

Deck Section Summary

DECK SECTION SUMMARY

Deck Depth 8.00 in.

Top Transverse Reinforcement #5 @ 9.00"

Bottom Transverse Reinforcement #5 @ 9.00"

Top Longitudinal Reinforcement #4 @ 6.00"

Bottom Longitudinal Reinforcement #5 @ 12.00"

CDOT Bridge Design Manual January 2017

EXAMPLE 6 - DECK DESIGN, INCLUDING COLLISION ON A TYPE 7 & TYPE 10M BARRIER 9

EXAMPLE 6.2 - OVERHANG DESIGN

GENERAL INFORMATION

Bridge deck overhang shall be designed for three separate design cases: AASHTO A13.4.1

• Case 1 - Horizontal and longitudinal forces from vehicle collision load (Extreme Event II limit state)

• Case 2 - Vertical force from vehicle collision load (Extreme Event II limit state)

• Case 3 - Vertical Dead and Live Load at the overhang section (Strength I limit state)

The deck overhang region shall be designed to have resistance larger than the resistance of the

concrete barrier. Therefore, resistance of approved barriers must be established first. Refer to Example

6.3 for detailed strength calculations for Barrier Type 7 and to Example 6.4 for Barrier Type 10M.

Barrier type Type 7 (Overhang design with Barrier Type 10M is

similar)

Width of barrier base WB = 18.00 in.

Barrier weight WBarrier = 0.486 kip/ft. (see Example 6.1, Deck Design)

Deck overlay density WWS = 0.145 kcf Section 3.4.2

Concrete density WC = 0.150 kcf

Barrier center of gravity XC.G. = 6.84 in.

Axial load per unit length TAxial = 7.18 kip/ft. (refer to Example 6.3)

Moment capacity of the barrier MC = 16.16 kip-ft./ft. (refer to Example 6.3)

Critical length of yield line LC = 10.74 ft. (refer to Example 6.3)

Overhang width SOH = 4.00 ft.

Edge of deck to edge of flange SGdr_Edge = 2.21 ft.

Overhang minimum depth tOH(min) = 8.00 in.

Overhang maximum depth tOH(max) = 10.00 in. (at exterior edge of flange)

Concrete top cover cTop = 2.00 in. AASHTO T.5.12.3-1

Concrete strength f'c = 4.50 ksi

Reinforcement strength fy = 60.00 ksi

DESIGN CASE 1: HORIZONTAL VEHICULAR COLLISION LOAD

The deck overhang is designed to resist an axial tension force from vehicular collision acting

simultaneously with the Dead Load moment. The design moment critical section shall be taken at one-

third of the flange width from the centerline of exterior girder. (AASHTO 4.6.2.1.6). Loads can be

assumed to be distributed a 45° angle starting from the face of the barrier.

CDOT Bridge Design Manual January 2017

EXAMPLE 6 - DECK DESIGN, INCLUDING COLLISION ON A TYPE 7 & TYPE 10M BARRIER 10

Overhang Region - Design Case 1

1. Design Loads - Dead Load and Collision

Distance from edge of deck to design section K= 2.81 ft. AASHTO 4.6.2.1.6

Distance from barrier face to design section X= 1.31 ft.

Depth of the section under consideration hDesign = 8.00 in. (may add min haunch depth if needed,

conservative to use constant deck depth)

Bending moments from dead load of structural components and nonstructural attachments:

Barrier MDC-Barrier = W Barrier * (K - XC.G.) = 0.486 kip * (2.81 ft. - 6.84 in. / 12 in./ft.) = 1.09 kip-ft.

2

Deck MDC-Deck = W C * tOH(min) * K2 / 2 = 0.150 kcf * 8 in. / 12 in./ft. * (2.81 ft.) / 2 = 0.39 kip-ft.

Additional overhang concrete MDC-Add = 0.5 W C * SGdr_Edge (TOH(max) - TOH(min)) * (K - 2/3 SGdr_Edge) =

= 0.5 * 0.150 kcf * 2.21 ft. * (10.0 in. - 8.0 in.) / 12 in./ft. * (2.81 ft. - 2/3 * 2.21 ft.) = 0.037 kip-ft.

Total DC = MDC-Barrier + MDC-Deck + MDC-Add = 1.09 kip-ft.+0.39 kip-ft.+0.037 kip-ft. = 1.517 kip-ft.

Bending moments from wearing surfaces and utilities:

Deck overlay

2

MDW-WS = W C * 3 in. * X2 / 2 = 0.145 kcf * 3in. / 12 in./ft. * (1.31 ft.) / 2 = 0.031 kip-ft.

Both design bending moment and design axial tension are calculated based on the properties of the

barrier on the deck. See Example 6.3 for information about Barrier Type 7 and Example 6.4 for

information about Barrier Type10M. Per AASHTO A.13.4.2, live load collision moment is taken to equal

the flexural capacity of the barrier.

Bending moment from vehicular collision MCT = MC = 16.16 kip-ft.

CDOT Bridge Design Manual January 2017

EXAMPLE 6 - DECK DESIGN, INCLUDING COLLISION ON A TYPE 7 & TYPE 10M BARRIER 11

Design factored moment (Extreme Event II) AASHTO 3.4.1, A13.4.1

Mu1 = 1.0MDC + 1.0MDW + 1.0MCT = 1.517 kip-ft. + 0.031 kip-ft. + 16.16 kip-ft. = 17.71 kip-ft.

Design axial tensile load TAxial = 7.18 kip/ft.

2. Resistance of the Section

Top transverse reinforcement: Bar size # 5 (see Example 6.1)

Bar spacing s= 9.00 in.

2

Area of steel per design strip AS = b (Ab / s) = 12 in. * 0.31 in. / 9.0 in. = 0.41 in.2/ft.

Effective depth of section dS = hDesign - cTop - 1/2 db = 8 in. - 2 in. - 0.625 in./ 2 = 5.69 in.

2

Maximum allowable tension in reinforcement TReinf = ASFy = 0.41 in.* 60.0 ksi = 24.60 kip

Depth of equivalent stress block

𝑇𝑇𝑇𝑇𝑅𝑅𝑅𝑅𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑅𝑅𝑅𝑅

𝑎𝑎𝑎𝑎 = = 24.60 kip / (0.85 * 4.50 ksi * 12 in.) = 0.54 in.

0.85𝑓𝑓𝑓𝑓𝑐𝑐𝑐𝑐′ 𝑏𝑏𝑏𝑏

𝑎𝑎𝑎𝑎 𝐶𝐶𝐷𝐷𝐷𝐷𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝐷𝐷𝐷𝐷𝑛𝑛𝑛𝑛 𝑎𝑎𝑎𝑎

Factored flexural resistance 𝜑𝜑𝜑𝜑𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 𝑀𝑀𝑀𝑀𝑛𝑛𝑛𝑛 = 𝜑𝜑𝜑𝜑𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 𝑇𝑇𝑇𝑇𝑅𝑅𝑅𝑅𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑅𝑅𝑅𝑅 𝑑𝑑𝑑𝑑𝑆𝑆𝑆𝑆 − − 𝑇𝑇𝑇𝑇𝐴𝐴𝐴𝐴𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝐴𝐴𝐴𝐴 − =

2 2 2

= 1.0 [24.60 kip (5.69 in. - 0.54 in./ 2) - 7.18 kip (8.00 in./ 2 - 0.54 in./ 2)] /12 in./ft. = 8.88 kip-ft./ft.

𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶 𝜑𝜑𝜑𝜑𝑀𝑀𝑀𝑀𝑛𝑛𝑛𝑛 > 𝑀𝑀𝑀𝑀𝑢𝑢𝑢𝑢 : 8.88 kip-ft. < 17.71 kip-ft. FAILS *

* Top deck reinforcement is not sufficient to resist collision moment and tension. Increase size

of the top deck reinforcement or place additional bars in overhang region.

With additional overhang bars #5 @ 4.50" (one additional bar between top deck reinf.)

2

Area of steel per design strip AS = 12 in. (Ab / db) = 12 in. * 0.310 in. / 4.5 in. = 0.83 in.2/ft.

Effective depth of section dS = hDesign - cTop - 1/2 db = 8 in. - 2 in. - 0.625 in./ 2 = 5.69 in.

2

Maximum allowable tension in reinforcement TReinf = ASFy = 0.83 in.* 60.0 ksi = 49.80 kip

Depth of equivalent stress block

𝑇𝑇𝑇𝑇𝑅𝑅𝑅𝑅𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑅𝑅𝑅𝑅

𝑎𝑎𝑎𝑎 = = 49.80 kip / (0.85 * 4.50 ksi * 12 in.) = 1.08 in.

0.85𝑓𝑓𝑓𝑓𝑐𝑐𝑐𝑐′ 𝑏𝑏𝑏𝑏

𝑎𝑎𝑎𝑎 𝐶𝐶𝐷𝐷𝐷𝐷𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝐷𝐷𝐷𝐷𝑛𝑛𝑛𝑛 𝑎𝑎𝑎𝑎

Factored flexural resistance 𝜑𝜑𝜑𝜑𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 𝑀𝑀𝑀𝑀𝑛𝑛𝑛𝑛 = 𝜑𝜑𝜑𝜑𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 𝑇𝑇𝑇𝑇𝑅𝑅𝑅𝑅𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑅𝑅𝑅𝑅 𝑑𝑑𝑑𝑑𝑆𝑆𝑆𝑆 − − 𝑇𝑇𝑇𝑇𝐴𝐴𝐴𝐴𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝐴𝐴𝐴𝐴 − =

2 2 2

= 1.0 [49.80 kip (5.69 in. - 1.08 in./ 2) - 7.18 kip (8.00 in./ 2 - 1.08 in./ 2)] /12 in./ft. = 19.30 kip-ft./ft.

𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶 𝜑𝜑𝜑𝜑𝑀𝑀𝑀𝑀𝑛𝑛𝑛𝑛 > 𝑀𝑀𝑀𝑀𝑢𝑢𝑢𝑢 : 19.30 kip-ft. > 17.71 kip-ft. OK

CDOT Bridge Design Manual January 2017

EXAMPLE 6 - DECK DESIGN, INCLUDING COLLISION ON A TYPE 7 & TYPE 10M BARRIER 12

DESIGN CASE 2: VERTICAL COLLISION FORCE

Based on common practice, the case of vertical collision never controls the design of concrete

overhangs; therefore, it does not have to be checked.

DESIGN CASE 3: DEAD AND LIVE LOADS AT STRENGTH LIMIT STATE

The overhang is designed to resist gravity forces from the Dead Load of structural components and

attachments to the cantilever, as well as a concentrated Live Load positioned 12.00 in. from the face of

the barrier. This case rarely controls the design, except for decks with widely spaced girders that allow

the use of wider overhangs.

For decks with overhangs not exceeding 6.00 ft. measured from the centerline of the exterior girder to

the face of a structurally continuous concrete railing, the outside row of wheel loads may be replaced

with a uniformly distributed line load of 1.0 klf intensity per AASHTO LRFD Bridge Design Specifications

3.6.1.3.4.

Overhang Region - Design Case 3

Distance from edge of deck to design section K= 2.81 ft.

Distance from barrier face to design section X= 1.31 ft.

Depth of the section under consideration hDesign = 8.00 in.

Distance from LL application to design section z = 0.31 ft.

Live Load multiple presence factor m= 1.20 AASHTO T.3.6.1.1.2-1

Dynamic load allowance IM = 33% AASHTO 3.6.2

CDOT Bridge Design Manual January 2017

EXAMPLE 6 - DECK DESIGN, INCLUDING COLLISION ON A TYPE 7 & TYPE 10M BARRIER 13

Bending moment from Dead Loads (equal to the loads calculated for Design Case 1)

Barrier MDC-Barrier = 1.09 kip-ft.

Deck MDC-Deck = 0.39 kip-ft.

Add. overhang concrete MDC-Add = 0.037 kip-ft.

Deck overlay MDW-WS = 0.031 kip-ft.

Bending moment from live load MLL = 1.0 klf * 0.31 ft. = 0.31 kip-ft.

Design factored moment (Strength I) Mu3 = 1.25MDC+1.50MDW+1.75m(MLL+IM) =

= 1.25 * 1.52 kip-ft. + 1.50 * 0.031 kip-ft. + 1.75 * 1.20 * 1.33 * 0.31 kip-ft. = 2.81 kip-ft.

Design moment for this case is smaller than the design moment in Case 1; therefore, Design Case 3

will not control the design.

DETAILS OF REINFORCEMENT

The additional bars placed in the top of the deck overhang must extend beyond the centerline of the

exterior beam into the first interior bay. The cutoff length will occur when the sum of collision and Dead

Load moments equals the negative moment strength of the typical deck reinforcement.

1. Location at Which Additional Overhang Reinforcement is no Longer Required

Assume that 50% of the bending moment experienced at the design section of the exterior girder

carries over to the next girder (conservative estimate, true for restrained rotation at first interior girder).

The design moment over the exterior girder is calculated assuming a 45° load distribution angle.

𝑀𝑀𝑀𝑀𝑢𝑢𝑢𝑢 𝐿𝐿𝐿𝐿𝐶𝐶𝐶𝐶

𝑀𝑀𝑀𝑀𝑢𝑢𝑢𝑢(𝐺𝐺𝐺𝐺𝑑𝑑𝑑𝑑𝑑𝑑𝑑𝑑𝑑) =

𝐿𝐿𝐿𝐿𝐶𝐶𝐶𝐶 + 2𝑋𝑋𝑋𝑋

𝑋𝑋𝑋𝑋 = 𝑆𝑆𝑆𝑆𝑂𝑂𝑂𝑂𝑂𝑂𝑂𝑂 − 𝑊𝑊𝑊𝑊𝐵𝐵𝐵𝐵 = 2.50 ft.

Bending Moment Along the First Interior Bay

Girder 1 10% 20% 30% 50% 70% 80% 90% Girder 2

Mu1 -12.08 -10.27 -8.46 -6.64 -3.02 0.60 2.42 4.23 6.04

Mu3 -1.92 -1.63 -1.34 -1.06 -0.48 0.10 0.38 0.67 0.96

Mu1 - Bending moment from Collision Load, Design Case 1 (Extreme event condition)

Mu3 - Bending moment from Live and Dead Load, Design Case 3 (Strength I condition)

Negative moment capacity of the section φMn = -10.00 kip-ft. (see Deck Design section)

This moment shall be reduced due to the axial tension force:

CDOT Bridge Design Manual January 2017

EXAMPLE 6 - DECK DESIGN, INCLUDING COLLISION ON A TYPE 7 & TYPE 10M BARRIER 14

𝑇𝑇𝑇𝑇𝐴𝐴𝐴𝐴𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝐴𝐴𝐴𝐴 𝑀𝑀𝑀𝑀𝑢𝑢𝑢𝑢

+ ≤ 1.0

𝜑𝜑𝜑𝜑𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 𝑇𝑇𝑇𝑇𝑅𝑅𝑅𝑅𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑅𝑅𝑅𝑅 𝜑𝜑𝜑𝜑𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 𝑀𝑀𝑀𝑀𝑛𝑛𝑛𝑛

𝑇𝑇𝑇𝑇𝐴𝐴𝐴𝐴𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝐴𝐴𝐴𝐴

𝑀𝑀𝑀𝑀𝑢𝑢𝑢𝑢 = 𝜑𝜑𝜑𝜑𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 𝑀𝑀𝑀𝑀𝑛𝑛𝑛𝑛 1 − = 1.0 (-10.0 kip-ft.)(1 - 7.18 kip / (1.0 * 49.80 kip)) = -7.08 kip-ft.

𝜑𝜑𝜑𝜑𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 𝑇𝑇𝑇𝑇𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐

Length of the first interior bay SGdr = 8.00 ft.

Distance from edge of deck to CL Ext. Girder SOH = 4.00 ft.

Distance from CL Ext. Girder to point of -M capacity = 2.21 ft. (28)%

Location where additional reinforcement is no longer required = 6.21 ft. (from edge of deck)

2. Embedment Length Beyond the Point Where no Longer Required

Extend additional overhang reinforcement beyond the point at which it is no longer required to resist

flexure for a distance of not less than the cut-off length or the development length, whichever is greater.

dS = 5.69 in. AASHTO 5.11.1.2.1

Cut-off length = max 15 db = 9.38 in.

1/20 LSpan = 4.80 in.

𝑙𝑙𝑙𝑙𝑐𝑐𝑐𝑐𝑢𝑢𝑢𝑢𝑐𝑐𝑐𝑐−𝑜𝑜𝑜𝑜𝑅𝑅𝑅𝑅𝑅𝑅𝑅𝑅 = 9.38 in.

𝜆𝜆𝜆𝜆𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 𝜆𝜆𝜆𝜆𝑐𝑐𝑐𝑐𝑅𝑅𝑅𝑅 𝜆𝜆𝜆𝜆𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 𝜆𝜆𝜆𝜆𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐

Development length, 𝑙𝑙𝑙𝑙𝑑𝑑𝑑𝑑 = 𝑙𝑙𝑙𝑙𝑑𝑑𝑑𝑑𝑑𝑑𝑑𝑑 AASHTO 5.11.2.1

𝜆𝜆𝜆𝜆

2.4 𝑑𝑑𝑑𝑑𝑑𝑑𝑑𝑑 𝑓𝑓𝑓𝑓𝑦𝑦𝑦𝑦

𝑙𝑙𝑙𝑙𝑑𝑑𝑑𝑑𝑑𝑑𝑑𝑑 = = 2.4 * 0.625 in.* 60.0 ksi /√4.5 ksi = 42.43 in.

𝑓𝑓𝑓𝑓𝑐𝑐𝑐𝑐′

λrl = 1.00 λer = 1.00 (conservative)

λcf = 1.20 λ= 1.00

λrc = 0.40

𝑙𝑙𝑙𝑙𝑑𝑑𝑑𝑑 = 42.43 in.* 1.00 * 1.20 * 0.40 * 1.00 / 1.00 = 20.37 in. (controls)

Theoretical length of additional overhang bar = 6.21 ft. + 20.37 in. - 2 in. clr = 7.74 ft.

Use - 8.00 ft.

CDOT Bridge Design Manual January 2017

EXAMPLE 6 - DECK DESIGN, INCLUDING COLLISION ON A TYPE 7 & TYPE 10M BARRIER 15

Overhang Section Summary

OVERHANG SECTION SUMMARY

Top Deck Reinforcement #5 @ 9.00"

Additional Overhang Bars 8.00 ft. #5 @ 4.50"

Bottom Longitudinal Bars in Overhang #5 @ 6.00"

CDOT Bridge Design Manual January 2017

EXAMPLE 6 - DECK DESIGN, INCLUDING COLLISION ON A TYPE 7 & TYPE 10M BARRIER 16

EXAMPLE 6.3 - BARRIER TYPE 7 STRENGTH DESIGN

GENERAL INFORMATION

The CDOT Bridge Rail Type 7 design follows AASHTO LRFD Bridge Design Specifications A13.3.1

design procedure for concrete railings, using strength design for reinforced concrete. The Bridge Rail

Type 7 shall be designed for Test Level 4 (TL 4) as required by CDOT. See CDOT Worksheet B-606-

7A for barrier details.

Following calculations show case of impact within barrier segment, assuming that barrier will be

extended past the limits of the bridge. For cases concerning impact at end of the barrier, refer to

AASHTO Appendix A13.

Overall barrier height HB = 35.00 in.

Concrete strength f'c = 4.50 ksi (Concrete Class D compressive strength)

Reinforcement strength fy = 60.00 ksi (Specified minimum yield strength of grade 60 steel)

Concrete cover c= 2.00 in.

Resistance factor φ= 1.00 (Extreme Event) AASHTO 1.3.2.1

Test level TL-4 AASHTO T A13.2-1

Transverse design force Ft = 54.00 kips

Impact force distribution Lt = 3.50 ft.

Barrier Dimensions

Section1 Section2 Section3

Section top width 10.50 13.00 18.00 in.

Section bottom width 13.00 18.00 18.00 in.

Section height 24.00 7.00 4.00 in.

Center of gravity from back face XC.G. = 6.84 in.

Barrier Type 7

CDOT Bridge Design Manual January 2017

EXAMPLE 6 - DECK DESIGN, INCLUDING COLLISION ON A TYPE 7 & TYPE 10M BARRIER 17

BARRIER FLEXURAL CAPACITY

1. Determine M C : flexural resistance of cantilevered parapet about an axis parallel to the longitudinal

axis of the bridge. Flexural moment resistance is based on the vertical reinforcement in the barrier.

Front face vertical

reinforcement: #4 @ 8.00" Bar Diameter = 0.500 in.

Bar Area = 0.20 in.2

AS h(avg) dS b a=ASfy/k φMn MC

k=.85f'Cb

(in.2) (in.) (in.) (in.) (in.) (kip-ft.) (kip-ft./ft.)

Section 1 0.30 11.75 9.50 12.00 45.90 0.39 13.96 9.57

Section 2 0.30 15.50 13.25 12.00 45.90 0.39 19.58 3.92

Section 3 0.30 18.00 15.75 12.00 45.90 0.39 23.33 2.67

Barrier MC = 16.16 kip-ft./ft.

AS - area of steel per design strip

h(avg) - average section width

dS - effective depth of design section

b- width of design strip

a- depth of equivalent stress block

𝑎𝑎𝑎𝑎

𝜑𝜑𝜑𝜑𝑀𝑀𝑀𝑀𝑛𝑛𝑛𝑛 = 𝜑𝜑𝜑𝜑𝐴𝐴𝐴𝐴𝑆𝑆𝑆𝑆 𝑓𝑓𝑓𝑓𝑦𝑦𝑦𝑦 𝑑𝑑𝑑𝑑𝑆𝑆𝑆𝑆 −

2

𝑛𝑛𝑛𝑛

𝑀𝑀𝑀𝑀𝐶𝐶𝐶𝐶 = � 𝜑𝜑𝜑𝜑𝑀𝑀𝑀𝑀𝑛𝑛𝑛𝑛 � 𝑆𝑆𝑆𝑆𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝑆𝑆𝑆𝑆𝑚𝑚𝑚𝑚𝑆𝑆𝑆𝑆𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶 /𝑆𝑆𝑆𝑆𝐵𝐵𝐵𝐵

1

2. Determine M W : flexural resistance of the parapet about its vertical axis.

Front and back face

horizontal reinforcement Size = #4 Bar Diameter = 0.500 in.

Bar Area = 0.20 in2

Stirrup Dia. = 0.50 in.

No. of AS h(avg) dS b a=ASfy/k φMW

k=.85f'Cb

Bars (in.2) (in.) (in.) (in.) (in.) (kip-ft.)

Section 1 3.00 0.60 11.75 9.00 24.00 91.80 0.39 26.42

Section 2 1.00 0.20 15.50 12.75 7.00 26.78 0.45 12.53

Section 3 1.00 0.20 18.00 15.25 4.00 15.30 0.78 14.86

Barrier MW = 53.81 kip-ft.

CDOT Bridge Design Manual January 2017

EXAMPLE 6 - DECK DESIGN, INCLUDING COLLISION ON A TYPE 7 & TYPE 10M BARRIER 18

3. Rail resistance within a wall segment.

2 𝑀𝑀𝑀𝑀𝐶𝐶𝐶𝐶 𝐿𝐿𝐿𝐿2𝐶𝐶𝐶𝐶

𝑅𝑅𝑅𝑅𝑊𝑊𝑊𝑊 = 8𝑀𝑀𝑀𝑀𝑑𝑑𝑑𝑑 + 8𝑀𝑀𝑀𝑀𝑊𝑊𝑊𝑊 + AASHTO A13.3.1-1

2𝐿𝐿𝐿𝐿𝐶𝐶𝐶𝐶 − 𝐿𝐿𝐿𝐿𝑐𝑐𝑐𝑐 𝑆𝑆𝑆𝑆

2

𝐿𝐿𝐿𝐿𝑐𝑐𝑐𝑐 𝐿𝐿𝐿𝐿𝑐𝑐𝑐𝑐 8𝑆𝑆𝑆𝑆 𝑀𝑀𝑀𝑀𝑑𝑑𝑑𝑑 + 𝑀𝑀𝑀𝑀𝑊𝑊𝑊𝑊

𝐿𝐿𝐿𝐿𝐶𝐶𝐶𝐶 = + + AASHTO A13.3.1-2

2 2 𝑀𝑀𝑀𝑀𝐶𝐶𝐶𝐶

Additional flexural resistance at top of wall Mb = 0.00 kip-ft.

Critical length of yield line LC = 10.74 ft.

Nominal transverse load resistance RW = 118.97 kips

Capacity Check Check R W > F t : 118.97 > 54.00 OK

BARRIER INTERFACE SHEAR CAPACITY AASHTO 5.8.4

Evaluate the shear capacity of the cold joint to transfer nominal resistance RW between the deck and

railing. Neglect effects of barrier Dead Load and assume that the surface of the deck is not roughened.

Interface width considered in shear transfer bV= 18.00 in.

Interface length considered in shear transfer LV = 12.00 in.

Shear contact area ACV = bV LV = 216.00 in.2

Shear reinforcement at front face #4 @ 8.00" Bar Area = 0.20 in.

Area of shear reinforcement AVF = 12.0 in. * 0.20 in. / 8.00 in. = 0.30 in.2/ft.

0.05𝐴𝐴𝐴𝐴𝑐𝑐𝑐𝑐𝑠𝑠𝑠𝑠

𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶 𝐴𝐴𝐴𝐴𝑠𝑠𝑠𝑠𝑠𝑠𝑠𝑠 ≥ = 0.18 OK AASHTO 5.8.4.4-1

𝑓𝑓𝑓𝑓𝑦𝑦𝑦𝑦

Permanent compression force from barrier weight (neglected) Pc = 0.00 kip

For concrete placed against clean concrete surface, free of laitance, but not intentionally roughened

Cohesion factor c= 0.075 ksi AASHTO 5.8.4.3

Friction factor μ= 0.6

Shear factor 1 K1 = 0.2 (Fraction of concrete strength available to resist interface shear)

Shear factor 2 K2 = 0.8 ksi (Limiting interface shear resistance)

2

𝐾𝐾𝐾𝐾1 𝑓𝑓𝑓𝑓𝑐𝑐𝑐𝑐′ 𝐴𝐴𝐴𝐴𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶 = 0.20 * 4.50 ksi * 216.0 in. = 194.40 kip AASHTO 5.8.4.1

2

Vn = min 𝐾𝐾𝐾𝐾2 𝐴𝐴𝐴𝐴𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶 = 0.80 * 216.0 in. = 172.80 kip

2 2

𝐶𝐶𝐶𝐶𝐴𝐴𝐴𝐴𝐶𝐶𝐶𝐶𝐶𝐶𝐶𝐶 + 𝜇𝜇𝜇𝜇 𝐴𝐴𝐴𝐴𝐶𝐶𝐶𝐶𝑉𝑉𝑉𝑉 𝑓𝑓𝑓𝑓𝑦𝑦𝑦𝑦 + 𝑃𝑃𝑃𝑃𝐶𝐶𝐶𝐶 = 0.075 ksi*216in.+0.60(0.30 in.* 60 ksi+0kip) = 27.00 kip

CDOT Bridge Design Manual January 2017

EXAMPLE 6 - DECK DESIGN, INCLUDING COLLISION ON A TYPE 7 & TYPE 10M BARRIER 19

Resistance factor φ= 1.00 (Extreme Event) AASHTO 1.3.2.1

Factored Shear Resistance φVn = 27.00 kip

𝑅𝑅𝑅𝑅𝑊𝑊𝑊𝑊

Shear force acting on the barrier per 1.00 ft. strip 𝑉𝑉𝑉𝑉𝑢𝑢𝑢𝑢 = = 11.08 kip/ft.

𝐿𝐿𝐿𝐿𝐶𝐶𝐶𝐶

Capacity Check Check φV n > V u : 27.00 > 11.08 OK

OVERHANG DESIGN DATA

Barrier Type 7 satisfies all checks outlined in AASHTO LRFD Bridge Design Specifications Apendix13.

Use the following data for Deck overhang design when Barrier Type 7 is used (Test Level 4):

TAxial = RW /(LC + 2HB) AASHTO A13.4.2

Axial Load Per Unit Length of the Deck TAxial = 7.18 kip/ft.

Moment Capacity of the Barrier Mc = 16.16 kip-ft./ft.

CDOT Bridge Design Manual January 2017

EXAMPLE 6 - DECK DESIGN, INCLUDING COLLISION ON A TYPE 7 & TYPE 10M BARRIER 20

EXAMPLE 6.4 - BARRIER TYPE 10M STRENGTH DESIGN

GENERAL INFORMATION

CDOT Bridge Rail Type 10M consists of a concrete parapet and a metal rail. The resistance to

transverse vehicular impact loads shall be determined as specified in AASHTO LRFD Bridge Design

Specifications A13.3.3. Two failure modes shall be evaluated: single span (impact at midspan of the

rail) and two span (impact directly at the center post). The Bridge Rail Type 10M shall be designed for

Test Level 4 (TL 4) as required by CDOT.

See CDOT Worksheet B-606-10 for barrier details.

Overall barrier height HB = 35.00 in.

Concrete cover c= 2.00 in.

Resistance factors φEE = 1.00 (Extreme Event) AASHTO 1.3.2.1

φS = 0.80 (A325 bolts in shear) AASHTO 6.5.4.2

φT = 0.80 (A325 bolts in tension) AASHTO 6.5.4.2

Test level TL-4 AASHTO T. A13.2-1

Transverse design force Ft = 54.00 kips

Impact force distribution Lt = 3.50 ft.

CONCRETE PARAPET

Height HW = 13.50 in.

Average width d= 17.75 in.

f'c = 4.50 ksi

fy = 60.00 ksi

RAIL POST

Type W8x18

Steel grade ASTM A-572, Grade 50

Post spacing L= 10.00 ft. (max)

Effective height HR = 27.25 in.

Area of post APost = 5.26 in.2

Web depth D= 7.48 in.

Web thickness tW = 0.23 in.

Flange thickness tF = 0.33 in.

Fy (post) = 50.00 ksi Barrier Type 10M

Zx-x (post) = 17.00 in. 3

CDOT Bridge Design Manual January 2017

EXAMPLE 6 - DECK DESIGN, INCLUDING COLLISION ON A TYPE 7 & TYPE 10M BARRIER 21

RAIL TUBES

Type TS 5x5x5/16

Steel grade ASTM A-500, Grade B

Area of one tube ATube = 5.26 in.2

Number of tubes nTubes = 2.00 ea.

Fy (tube) = 46.00 ksi

Z (tube) = 9.16 in.3

BASE PLATE

Width of base plate Wb = 8.00 in.

Distance to bolts db = 6.875 in.

Bolt diameter Ø= 1.00 in.

Bolt area Ab = 0.79 in.2

Min tensile strength Fub = 120.00 ksi

Number of bolts nb = 2.00

Base Plate

CONCRETE PARAPET CAPACITY

1. Determine M C : flexural resistance of cantilevered parapet about an axis parallel to the longitudinal

axis of the bridge. Flexural moment resistance is based on the vertical reinforcement in the barrier.

Front face vertical

reinforcement #4 @ 9.00" Bar Diameter = 0.500 in.

Bar Area = 0.20 in.2

Design strip, b = 12.00 in.

Area of steel per design strip AS = 12.00 in. (Bar Area / Bar Spacing) = 0.27 in.2/ft.

Effective depth of section dS = d - c - 1/2 Bar Diameter = 15.50 in.

Depth of equivalent stress block

𝐴𝐴𝐴𝐴𝑆𝑆𝑆𝑆 𝑓𝑓𝑓𝑓𝑦𝑦𝑦𝑦 2

𝑎𝑎𝑎𝑎 = = 0.27in. * 60.0 ksi / (0.85 * 4.50 ksi * 12.0 in.) = 0.35 in.

0.85𝑓𝑓𝑓𝑓𝑐𝑐𝑐𝑐′ 𝑏𝑏𝑏𝑏

𝑎𝑎𝑎𝑎

Flexural resistance =

𝑀𝑀𝑀𝑀𝐶𝐶𝐶𝐶 = 𝜑𝜑𝜑𝜑𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 𝐴𝐴𝐴𝐴𝑆𝑆𝑆𝑆 𝑓𝑓𝑓𝑓𝑦𝑦𝑦𝑦 𝑑𝑑𝑑𝑑𝑆𝑆𝑆𝑆 −

2

2

= 1.0 * 0.27 in. * 60.0 ksi * (15.50 in. - 0.35in. / 2) / 12 in./ft. = 20.69 kip-ft./ft.

CDOT Bridge Design Manual January 2017

EXAMPLE 6 - DECK DESIGN, INCLUDING COLLISION ON A TYPE 7 & TYPE 10M BARRIER 22

2. Determine M W : flexural resistance of the parapet about its vertical axis. Positive and negative

moment strength must be evaluated but will be equal based on barrier longitudinal reinforcement.

Back face horizontal

reinforcement Size = #4 Bar Diameter = 0.500 in.

Number of bars = 2.00 Bar Area = 0.20 in2

Stirrup Dia. = 0.50 in.

Design strip, b = 13.50 in.

Area of steel per design strip AS = Bar Area * NO. of bars = 0.40 in.2/ft.

Effective depth of section dS = d - c - 1/2 Bar Dia. - Stirrup Dia. = 15.00 in.

Depth of equivalent stress block

𝐴𝐴𝐴𝐴𝑆𝑆𝑆𝑆 𝑓𝑓𝑓𝑓𝑦𝑦𝑦𝑦 2

𝑎𝑎𝑎𝑎 = = 0.40 in. * 60.0 ksi / (0.85 * 4.50 ksi * 13.5 in.) = 0.46 in.

0.85𝑓𝑓𝑓𝑓𝑐𝑐𝑐𝑐′ 𝑏𝑏𝑏𝑏

𝑎𝑎𝑎𝑎

Flexural resistance 𝑀𝑀𝑀𝑀𝑊𝑊𝑊𝑊 = 𝜑𝜑𝜑𝜑𝐸𝐸𝐸𝐸𝐸𝐸𝐸𝐸 𝐴𝐴𝐴𝐴𝑆𝑆𝑆𝑆 𝑓𝑓𝑓𝑓𝑦𝑦𝑦𝑦 𝑑𝑑𝑑𝑑𝑆𝑆𝑆𝑆 − =

2

2

= 1.0 * 0.40 in. * 60.0 ksi * (15.00 in. - 0.46 in. / 2) / 12 in./ft. = 29.54 kip-ft.

3. Determine L C (critical length of yield line failure pattern) and R W (nominal railing resistance to

transverse load) within a wall segment.

2 𝑀𝑀𝑀𝑀𝐶𝐶𝐶𝐶 𝐿𝐿𝐿𝐿2𝐶𝐶𝐶𝐶

𝑅𝑅𝑅𝑅𝑊𝑊𝑊𝑊 = 8𝑀𝑀𝑀𝑀𝑑𝑑𝑑𝑑 + 8𝑀𝑀𝑀𝑀𝑊𝑊𝑊𝑊 + AASHTO A13.3.1-1

2𝐿𝐿𝐿𝐿𝐶𝐶𝐶𝐶 − 𝐿𝐿𝐿𝐿𝑐𝑐𝑐𝑐 𝑆𝑆𝑆𝑆𝑊𝑊𝑊𝑊

2

𝐿𝐿𝐿𝐿𝑐𝑐𝑐𝑐 𝐿𝐿𝐿𝐿𝑐𝑐𝑐𝑐 8𝑆𝑆𝑆𝑆𝑊𝑊𝑊𝑊 𝑀𝑀𝑀𝑀𝑑𝑑𝑑𝑑 + 𝑀𝑀𝑀𝑀𝑊𝑊𝑊𝑊

𝐿𝐿𝐿𝐿𝐶𝐶𝐶𝐶 = + + AASHTO A13.3.1-2

2 2 𝑀𝑀𝑀𝑀𝐶𝐶𝐶𝐶

There is no additional resistance at the top of the parapet in addition to MW , Mb = 0 kip-ft.

Values of Lt (longitudinal length of distribution of impact force) are found in AASHTO Table A.13.2-1.

Critical length of yield line LC = 5.74 ft.

Concrete parapet nominal transverse load resistance RW = 211.09 kip

STEEL RAIL CAPACITY

1. Impact between posts, single span failure mode (N=1).

Flexural resistance of rail tubes

MP_Tubes = Fy Z nTubes = 46.0 ksi * 9.16 in. * 2 / 12 in./ft. = 70.23 kip-ft.

16𝑀𝑀𝑀𝑀𝑃𝑃𝑃𝑃_𝑇𝑇𝑇𝑇𝑢𝑢𝑢𝑢𝑢𝑢𝑢𝑢𝑢𝑢𝑢𝑢𝑢𝑢𝑢𝑢 + 𝑁𝑁𝑁𝑁 − 1 𝑁𝑁𝑁𝑁 + 1 𝑃𝑃𝑃𝑃𝑐𝑐𝑐𝑐 𝐿𝐿𝐿𝐿

Strength capacity of steel rail (Mode 1) 𝑅𝑅𝑅𝑅𝑅𝑅𝑅𝑅 = = 68.10 kip

2𝑁𝑁𝑁𝑁𝐿𝐿𝐿𝐿 − 𝐿𝐿𝐿𝐿𝑐𝑐𝑐𝑐

AASHTO A13.3.2-1

CDOT Bridge Design Manual January 2017

EXAMPLE 6 - DECK DESIGN, INCLUDING COLLISION ON A TYPE 7 & TYPE 10M BARRIER 23

2. Impact at post, two span failure mode (N=2).

𝐹𝐹𝐹𝐹𝑦𝑦𝑦𝑦 𝑍𝑍𝑍𝑍𝑚𝑚𝑚𝑚−𝑚𝑚𝑚𝑚 𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐

𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐

Plastic moment resistance of a single post 𝑀𝑀𝑀𝑀𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐 = = 70.83 kip-ft

12𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚/𝑓𝑓𝑓𝑓𝑡𝑡𝑡𝑡

Assume shear force of a single post corresponding to Mpost is located at the center of the post,

distance Y from the top of the curb 𝑌𝑌𝑌𝑌 = (𝑆𝑆𝑆𝑆𝐵𝐵𝐵𝐵 − 𝑆𝑆𝑆𝑆𝑊𝑊𝑊𝑊 )/2 = 10.75 in.

Shear force on a single post which corresponds to Mpost 𝑃𝑃𝑃𝑃𝑃𝑃𝑃𝑃 = 12𝑀𝑀𝑀𝑀𝑃𝑃𝑃𝑃 /𝑌𝑌𝑌𝑌 = 79.07 kip

16𝑀𝑀𝑀𝑀𝑃𝑃𝑃𝑃_𝑇𝑇𝑇𝑇𝑢𝑢𝑢𝑢𝑢𝑢𝑢𝑢𝑢𝑢𝑢𝑢𝑢𝑢𝑢𝑢 + 𝑁𝑁𝑁𝑁 2 𝑃𝑃𝑃𝑃𝑃𝑃𝑃𝑃 𝐿𝐿𝐿𝐿

Strength capacity of steel rail (Mode 2) 𝑅𝑅𝑅𝑅𝑅𝑅𝑅𝑅𝑅𝑅 = = 117.44 kip

2𝑁𝑁𝑁𝑁𝐿𝐿𝐿𝐿 − 𝐿𝐿𝐿𝐿𝑐𝑐𝑐𝑐

AASHTO A13.3.2-2

COMBINATION BARRIER CAPACITY AASHTO 13.3.3

1. Impact between posts, single span failure mode.

RR

RW

Strength of combination rail at midspan of rail 𝑅𝑅𝑅𝑅1 = 𝑅𝑅𝑅𝑅𝑅𝑅𝑅𝑅 + 𝑅𝑅𝑅𝑅𝑊𝑊𝑊𝑊 = 279.19 kip

AASHTO A13.3.3-1

𝑅𝑅𝑅𝑅𝑅𝑅𝑅𝑅 𝑆𝑆𝑆𝑆𝑅𝑅𝑅𝑅 + 𝑅𝑅𝑅𝑅𝑊𝑊𝑊𝑊 𝑆𝑆𝑆𝑆𝑊𝑊𝑊𝑊

Effective height 𝑌𝑌𝑌𝑌1 = = 16.85 in. AASHTO A13.3.3-2

𝑅𝑅𝑅𝑅1

Shear force on a rail located at distance Y1 from deck 𝑃𝑃𝑃𝑃𝑃𝑃𝑃𝑃1 = 12𝑀𝑀𝑀𝑀𝑃𝑃𝑃𝑃 /𝑌𝑌𝑌𝑌1 = 50.44 kip

The moment produced by horizontal impact load will be transferred into the overhang through the rail

and post to the concrete parapet connection. Calculate loads at the face of the curb, assuming that

loads are distributed as a vector at 1:1 from the point of application. Equations given in AASHTO

A13.4.3.1 assume rail is connected directly to the deck and have to be modified to account for the curb:

Distance from back face of base plate to front face of curb X = db + 7 3/8 = 14.25 in.

12𝑃𝑃𝑃𝑃𝑃𝑃𝑃𝑃1

Axial load per unit length 𝑇𝑇𝑇𝑇𝐴𝐴𝐴𝐴𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝐴𝐴𝐴𝐴 = = 12.81 kip/ft.

2

𝑊𝑊𝑊𝑊𝑑𝑑𝑑𝑑 + 2 𝑋𝑋𝑋𝑋 2 + 𝑆𝑆𝑆𝑆𝑊𝑊𝑊𝑊

12𝑀𝑀𝑀𝑀𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐𝑐

Deck overhang moment 𝑀𝑀𝑀𝑀𝑑𝑑𝑑𝑑 = = 17.99 kip-ft./ft.

2

𝑊𝑊𝑊𝑊𝑑𝑑𝑑𝑑 + 2 𝑋𝑋𝑋𝑋 2 + 𝑆𝑆𝑆𝑆𝑊𝑊𝑊𝑊

CDOT Bridge Design Manual January 2017

EXAMPLE 6 - DECK DESIGN, INCLUDING COLLISION ON A TYPE 7 & TYPE 10M BARRIER 24

2. Impact at post, two span failure mode.

R'R Pp

R'W

Concrete parapet strength, reduced to resist post load

𝑅𝑅𝑅𝑅𝑊𝑊𝑊𝑊 𝑆𝑆𝑆𝑆𝑊𝑊𝑊𝑊 − 𝑃𝑃𝑃𝑃𝑃𝑃𝑃𝑃 𝑆𝑆𝑆𝑆𝑅𝑅𝑅𝑅

𝑅𝑅𝑅𝑅𝑅𝑅𝑊𝑊𝑊𝑊 = = 51.49 kip AASHTO 13.3.3-5

𝑆𝑆𝑆𝑆𝑊𝑊𝑊𝑊

′

Strength of combination rail over two spans 𝑅𝑅𝑅𝑅2 = 𝑃𝑃𝑃𝑃𝑃𝑃𝑃𝑃 + 𝑅𝑅𝑅𝑅𝑅𝑅𝑅𝑅𝑅𝑅 + 𝑅𝑅𝑅𝑅𝑊𝑊𝑊𝑊 = 248.00 kip

AASHTO A13.3.3-3

′

𝑃𝑃𝑃𝑃𝑃𝑃𝑃𝑃 𝑆𝑆𝑆𝑆𝑅𝑅𝑅𝑅 + 𝑅𝑅𝑅𝑅𝑅𝑅𝑅𝑅𝑅𝑅 𝑆𝑆𝑆𝑆𝑅𝑅𝑅𝑅 + 𝑅𝑅𝑅𝑅𝑊𝑊𝑊𝑊 𝑆𝑆𝑆𝑆𝑊𝑊𝑊𝑊

Effective height 𝑌𝑌𝑌𝑌2 = = 24.40 in. AASHTO A13.3.3-4

𝑅𝑅𝑅𝑅2

Shear force on a rail located at distance Y2 from deck 𝑃𝑃𝑃𝑃𝑃𝑃𝑃𝑃2 = 12𝑀𝑀𝑀𝑀𝑃𝑃𝑃𝑃 /𝑌𝑌𝑌𝑌2 = 34.83 kip

The moment produced by horizontal impact load will be transferred into the overhang through the rail

and post to the concrete parapet connection. Calculate loads at the face of the curb, assuming that

loads are distributed as a vector at 1:1 from the point of application. Equations given in AASHTO

A13.4.3.1 assume rail is connected directly to the deck and have to be modified to account for the curb:

12𝑃𝑃𝑃𝑃𝑃𝑃𝑃𝑃2

Axial load per unit length 𝑇𝑇𝑇𝑇𝐴𝐴𝐴𝐴𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝑚𝐴𝐴𝐴𝐴 = = 8.84 kip/ft.

2

𝑊𝑊𝑊𝑊𝑑𝑑𝑑𝑑 + 2 𝑋𝑋𝑋𝑋 2 + 𝑆𝑆𝑆𝑆𝑊𝑊𝑊𝑊

ANCHOR BOLT CAPACITY AND PUNCHING SHEAR CHECK

Barriers similar to Bridge Rail Type 10M were crash tested and determined to be satisfactory for the

Test Level 4 loads. Therefore, it is assumed that anchor bolt shear and concrete punching shear are

not critical failure modes. These checks will be omitted for the purpose of this design example.

SUMMARY

Single span failure mode with impact between posts controls the strength design of the rail. Because

impact load on the rail will be transferred to the overhang through the post connection, results from this

failure mode will also control design of the deck overhang. Use the following values for deck overhang

design when Barrier Type 10M is used (Test Level 4):

Controlling Axial Load Per Unit Length of the Deck TAxial = 12.81 kip/ft.

Deck Overhang Moment Md = 17.99 kip-ft./ft.

CDOT Bridge Design Manual January 2017

You might also like

- IGE-UP-10 Ed 3Document129 pagesIGE-UP-10 Ed 3Paulo100% (2)

- Waler Beam Design TemplateDocument1 pageWaler Beam Design TemplateArjun RajaNo ratings yet

- Gantry CraneDocument18 pagesGantry Craneamirthraj7494% (16)

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- Design Calculation of Louvers-1Document7 pagesDesign Calculation of Louvers-1vj8584No ratings yet

- BDM Example 6 - 20180101Document23 pagesBDM Example 6 - 20180101mustafurade1No ratings yet

- Semi-Integral-Abutment Design Example (USA Unit)Document20 pagesSemi-Integral-Abutment Design Example (USA Unit)Ya YangNo ratings yet

- Design of Grating For PlatformDocument5 pagesDesign of Grating For PlatformKho C AhlNo ratings yet

- API 650 Design TanksDocument34 pagesAPI 650 Design TanksSyedZainAli100% (13)

- Shell Structures in Civil and Mechanical Eng PDFDocument368 pagesShell Structures in Civil and Mechanical Eng PDFamraja2001100% (1)

- Detalii Tehnice Pergola Retractabila Aluminiu Bioclimatica Persa 3Document24 pagesDetalii Tehnice Pergola Retractabila Aluminiu Bioclimatica Persa 3Florin StanescuNo ratings yet

- Taj Mahal PalaceDocument16 pagesTaj Mahal PalaceAnand100% (1)

- Example 6 Deck Design 2022Document18 pagesExample 6 Deck Design 2022aizaz ahmadNo ratings yet

- BASEPLT9Document5 pagesBASEPLT9Bunkun15No ratings yet

- Owner:-North Eastern Owner: - North Eastern: Electric Power Corporation Ltd. Electric Power Corporation LTDDocument13 pagesOwner:-North Eastern Owner: - North Eastern: Electric Power Corporation Ltd. Electric Power Corporation LTDIrshad KhanNo ratings yet

- 200-Foot Simple Span Bridge Girder Design Using NU2000 V1Document50 pages200-Foot Simple Span Bridge Girder Design Using NU2000 V1Anthony GravagneNo ratings yet

- Base Plate Anchor Bolt DesignDocument8 pagesBase Plate Anchor Bolt DesignnoneofyourbusineesNo ratings yet

- Lecture 9 Design of Beams IIDocument27 pagesLecture 9 Design of Beams IIujjwalsingh8509No ratings yet

- Element 3 Position I: IX - Shear ConnertorsDocument17 pagesElement 3 Position I: IX - Shear ConnertorsLEONCIOCARRASCONo ratings yet

- B17 RC Detailing To EC2Document69 pagesB17 RC Detailing To EC2Mahmoud Moustafa Elnegihi100% (1)

- BASEPLT9Document27 pagesBASEPLT9Homero Silva100% (3)

- Design of A Slab Bridge On Abeya River A PDFDocument13 pagesDesign of A Slab Bridge On Abeya River A PDFAbera Mamo Jaleta100% (1)

- Prestressed Concrete I Beam - Design ExampleDocument67 pagesPrestressed Concrete I Beam - Design ExampleNOEL RODRIGUEZ100% (1)

- Continuous BeamDocument57 pagesContinuous BeamZulhilmi MohanapNo ratings yet

- BW - Calculation Sheet - Rev01Document15 pagesBW - Calculation Sheet - Rev01Ernest NavarroNo ratings yet

- AISC 360 VerificationBeamDesign PDFDocument7 pagesAISC 360 VerificationBeamDesign PDFCarl Patrick Erni RagasNo ratings yet

- Gorakhpur Bypass RobDocument9 pagesGorakhpur Bypass RobvivekNo ratings yet

- CVX7640 32Document14 pagesCVX7640 32malingauomNo ratings yet

- ACI 318M-11 RC Bracket and Corbel Design - v0.03 - 2017-04-10Document5 pagesACI 318M-11 RC Bracket and Corbel Design - v0.03 - 2017-04-10arken123No ratings yet

- ACI Pad Foundation ExampleDocument7 pagesACI Pad Foundation ExampleEm MarNo ratings yet

- Precast Prestressed Concrete Girder Bridge - Design ExampleDocument37 pagesPrecast Prestressed Concrete Girder Bridge - Design Examplerammiris100% (1)

- Shear Strength CalculationDocument4 pagesShear Strength CalculationAnil kumar RNo ratings yet

- Purlin Cleat 220908Document24 pagesPurlin Cleat 220908kalpanaadhi100% (2)

- Shaft Footing ExampleDocument10 pagesShaft Footing Exampleอภิรักษ์ มานะกิจศิริสุทธิNo ratings yet

- Proposed 3-Storey Residence With Lower GroundDocument92 pagesProposed 3-Storey Residence With Lower Groundfrancis sebastian lagamayoNo ratings yet

- Bracing ConnectionDocument10 pagesBracing ConnectionrajedmaglinteNo ratings yet

- MotorDocument51 pagesMotorp_ignatiusNo ratings yet

- 013 URGENT Rectangular Cap ExDocument54 pages013 URGENT Rectangular Cap ExJimmy Villca SainzNo ratings yet

- Presented By: Irfan KhanDocument63 pagesPresented By: Irfan KhanIrfan KhanNo ratings yet

- Ce 03024Document211 pagesCe 03024kimchhoungNo ratings yet

- 8 - Design For TorsionDocument34 pages8 - Design For TorsionACTION plusNo ratings yet

- Calculations XavierDocument35 pagesCalculations XavierAlexo NgendaNo ratings yet

- MRT 7 Sta.10 STP Struct. Design & Analysis Slab A2Document6 pagesMRT 7 Sta.10 STP Struct. Design & Analysis Slab A2johnrexNo ratings yet

- Connection No.: 66: Load Ver. Brace L120X120X10 AxialDocument5 pagesConnection No.: 66: Load Ver. Brace L120X120X10 Axialrts123No ratings yet

- Deck Design gkp2Document2 pagesDeck Design gkp2api-401204381No ratings yet

- Combined Gusset Plate DesignDocument3 pagesCombined Gusset Plate Designkalpanaadhi100% (3)

- Materials: Slab Bridge DesignDocument13 pagesMaterials: Slab Bridge DesignephremNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysNo ratings yet

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- Engineering Vibroacoustic Analysis: Methods and ApplicationsFrom EverandEngineering Vibroacoustic Analysis: Methods and ApplicationsStephen A. HambricNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Electricity in Fish Research and Management: Theory and PracticeFrom EverandElectricity in Fish Research and Management: Theory and PracticeNo ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- O level Physics Questions And Answer Practice Papers 2From EverandO level Physics Questions And Answer Practice Papers 2Rating: 5 out of 5 stars5/5 (1)

- Chapter 2 of FEMA 356 Prestandard PDFDocument30 pagesChapter 2 of FEMA 356 Prestandard PDFamraja2001No ratings yet

- Lecture 02 LoadsDocument61 pagesLecture 02 Loadsamraja2001No ratings yet

- Example Concrete Shear Wall BuildingDocument19 pagesExample Concrete Shear Wall Buildingamraja2001No ratings yet

- Professional Review Guidance Mar 2019Document26 pagesProfessional Review Guidance Mar 2019amraja2001No ratings yet

- Chapter 1 of FEMA 356 Prestandard PDFDocument36 pagesChapter 1 of FEMA 356 Prestandard PDFamraja2001No ratings yet

- Wisser Bridge 2000Document12 pagesWisser Bridge 2000amraja2001No ratings yet

- Shear Key - Dry & Epoxy Joint - 248-1-ctr PDFDocument111 pagesShear Key - Dry & Epoxy Joint - 248-1-ctr PDFamraja2001No ratings yet

- Practical Understanding of JyothisyaDocument28 pagesPractical Understanding of Jyothisyaamraja20010% (1)

- Bridge Launching-Brian PearsonDocument179 pagesBridge Launching-Brian Pearsonamraja2001No ratings yet

- Hand Book Structural Steel-Alok Baishya PDFDocument218 pagesHand Book Structural Steel-Alok Baishya PDFamraja2001100% (2)

- Aisc 360 - Staad Design ParamDocument4 pagesAisc 360 - Staad Design Paramamraja2001No ratings yet

- 1 - Method Statement For Trial Pit ExcavtionDocument1 page1 - Method Statement For Trial Pit Excavtionamraja2001No ratings yet

- Collapse of Hotel New World - SingaporeDocument71 pagesCollapse of Hotel New World - SingaporePriyam AndhariaNo ratings yet

- Resume Salma Mostafa 01 PDFDocument5 pagesResume Salma Mostafa 01 PDFSalma MoustafaNo ratings yet

- NavrongoDocument40 pagesNavrongoNabil ElHaddouchiNo ratings yet

- Internal Case Summary PDFDocument124 pagesInternal Case Summary PDFManav Gupta0% (1)

- Astm C79Document3 pagesAstm C79Jony Gutiérrez AbantoNo ratings yet

- Industry Applications For Industrial Refrigeration PDFDocument1 pageIndustry Applications For Industrial Refrigeration PDFsaifasad100% (1)

- H8 ManualDocument905 pagesH8 Manualapi-19479717No ratings yet

- Middle East Interiors Boca Do LoboDocument110 pagesMiddle East Interiors Boca Do LoboapNo ratings yet

- Ss Garbage ChutesDocument6 pagesSs Garbage ChutesSahil MalikNo ratings yet

- CoreXL Administration GuideDocument11 pagesCoreXL Administration GuideDinesh PalNo ratings yet

- Ashrae 90.1-2013 - IpDocument10 pagesAshrae 90.1-2013 - IpphlxuNo ratings yet

- Method Statement - Site Preparation & Back FillDocument8 pagesMethod Statement - Site Preparation & Back Fillmahesh naikNo ratings yet

- IPTV MediaroomDocument6 pagesIPTV Mediaroomapi-121646735No ratings yet

- Ccna 4 Practice Final QuestionsDocument18 pagesCcna 4 Practice Final Questionsnot_ckas28801No ratings yet

- Treasures of The Aga Khan MuseumDocument379 pagesTreasures of The Aga Khan Museumnordurljos100% (2)

- PW DebugDocument2 pagesPW DebugNanang WibisonoNo ratings yet

- A4-P 1.0 enDocument141 pagesA4-P 1.0 enmkpqNo ratings yet

- LON220004Document16 pagesLON220004Ptolemy Egan (Was Louisa Egan)No ratings yet

- CNv6 instructorPPT Chapter8Document26 pagesCNv6 instructorPPT Chapter8ISHETUNo ratings yet

- Scheudle of Rates For The Year 2018 - 19 For MIDC Civil WorksDocument285 pagesScheudle of Rates For The Year 2018 - 19 For MIDC Civil WorksJ. Kumar Infraprojects Ltd67% (6)

- Auth Manager SP4Document62 pagesAuth Manager SP4Mohammed Nehal AktherNo ratings yet

- D81242GC10 AgDocument104 pagesD81242GC10 AgHector Perez VilcapazaNo ratings yet

- Types of SheltersDocument10 pagesTypes of SheltersRobert D. BeasleyNo ratings yet

- Multibasements: Educational Resource.Document240 pagesMultibasements: Educational Resource.shrikant100% (4)

- CitectSCADA User GuideDocument1,100 pagesCitectSCADA User GuideFatum48No ratings yet

- Sector File Provider DescriptorDocument2 pagesSector File Provider DescriptorSantiagoLópezNo ratings yet