Professional Documents

Culture Documents

Drillbench Dynamic Hydraulics Ps PDF

Drillbench Dynamic Hydraulics Ps PDF

Uploaded by

NestorMenesesPintoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drillbench Dynamic Hydraulics Ps PDF

Drillbench Dynamic Hydraulics Ps PDF

Uploaded by

NestorMenesesPintoCopyright:

Available Formats

Drillbench Dynamic Hydraulics

Evaluate and understand the hydraulic barrier

APPLICATIONS A module of Drillbench* dynamic drilling simulation software, Drillbench Dynamic Hydraulics

■■ Optimize mud weight and maintain is specifically designed for planning and forecasting drilling operations to manage the hydraulic

proper overbalance barrier. An accurate dynamic hydraulic model, including temperature transients, is used for

■■ Identify and avoid drilling conditions that calculating wellbore pressure for all operations.

can exceed pressure integrity boundaries

The Drillbench software is built around the well control workflow, covering pressure control, well

■■ Evaluate the impact on mud window control, and blowout control. This allows you to couple your well planning to operations workflows

of new drilling methods, such as dual and provide essential input to deliver safe and efficient well construction.

gradient, managed pressure, and

pressurized mud cap The user-friendly and intuitive interface enables efficient well planning, including specification of

batch jobs for simulation of an entire well section. Extensive graphics options and unique features

■■ Evaluate thermal effects and flow or

for sensitivity studies make it easy to enhance the drilling operation.

pressure buildup caused by temperature-

induced changes in mud volume Optimize primary well control practices

■■ Monitor local pressure and temperature The objective of primary well control is to make sure that the hydraulic barrier is in place for the entire

conditions to avoid exceeding tool drilling operation. The drilling process is highly dynamic and includes periods of drilling, circulation,

operating limitations static periods, and breaking of circulation after long static periods. Temperature conditions vary

■■ Use for all types of wells and all fluids significantly during the different operations and have a significant impact on the hydraulic barrier.

Understanding the impact of various operations is key to reaching challenging drilling targets.

BENEFITS

■■ Optimize procedures to drill efficiently When the operational window between pore and fracture pressure is decreasing, the importance

while maintaining pressure control of a transient model increases. Therefore, proper planning that includes transient effects clarifies

for all operations the drilling challenges and helps to mitigate unnecessary loss of productive time. Narrow mud-weight

windows are quite common in challenging wells, such as deepwater, extended-reach and HPHT wells,

■■ Drill virtually to identify hazards

but are also typical when drilling through depleted zones.

and prepare for efficient operations

■■ Obtain operational decision support

through “what if” analysis

■■ Train drilling crew

FEATURES

■■ Transient flow and temperature models

■■ Multiple fluid options

■■ Accurate PVT modeling, including

thermal expansion

■■ Pressure- and temperature-

dependent rheology

■■ Evaluation of thermal effects and changes

in mud weight in static wells

■■ Surge and swab modeling

■■ Modeling for calculation of gel-breaking

pressure

■■ Efficient simulation workflow, including batch

mode to model long operational sequences Use Drillbench Dynamic Hydraulics to model the equivalent circulating density relative to the mud-weight window

■■ Flexible user interface with unique features when forecasting the operational pressures to ensure that the well integrity boundaries are not exceeded.

for sensitivity studies and visualization

* Mark of Schlumberger

Copyright © 2016 Schlumberger. All rights reserved. 16-IS-129315 slb.com/Drillbench

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Well Control MethodsDocument90 pagesWell Control MethodsMike Ross100% (2)

- Factory Studio User GuideDocument218 pagesFactory Studio User GuideTulio Silva100% (1)

- Supervisor HandbookDocument11 pagesSupervisor HandbookMike RossNo ratings yet

- IWCF Monthly Update - April 2017Document3 pagesIWCF Monthly Update - April 2017Mike RossNo ratings yet

- IWCF Forum Candidate User RoleDocument7 pagesIWCF Forum Candidate User RoleMike RossNo ratings yet

- User Guide - Wellbarrier Illustration Tool 20 - Oct - 2016 PDFDocument81 pagesUser Guide - Wellbarrier Illustration Tool 20 - Oct - 2016 PDFMike RossNo ratings yet

- VB Macro - Outlook Task v1.00Document2 pagesVB Macro - Outlook Task v1.00Mike RossNo ratings yet

- Social Post GradDocument113 pagesSocial Post GradMike RossNo ratings yet

- Books by Swami Sivanandaji Maharaj PDFDocument4 pagesBooks by Swami Sivanandaji Maharaj PDFMike RossNo ratings yet

- Spe 112869 MSDocument24 pagesSpe 112869 MSMike RossNo ratings yet

- Baroid Mud RecapDocument61 pagesBaroid Mud RecapMike Ross100% (3)

- Halliburton VCH Front PageDocument2 pagesHalliburton VCH Front PageMike RossNo ratings yet

- Maersk DelivererDocument10 pagesMaersk DelivererMike RossNo ratings yet

- Tubulars - Connections (W250) Mar 08 - Part 3Document15 pagesTubulars - Connections (W250) Mar 08 - Part 3Mike Ross100% (1)

- Cat - Dcs.sis - Controller (12H - 8MN)Document2 pagesCat - Dcs.sis - Controller (12H - 8MN)Warley Moraes Oliveira100% (1)

- MIR - LML - Golovina L. I. and Yaglom I. M. - Induction in GeometryDocument134 pagesMIR - LML - Golovina L. I. and Yaglom I. M. - Induction in Geometryavast2008100% (2)

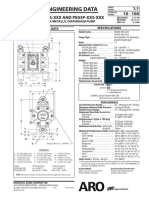

- Sales and Engineering Data: Pd03P-Xxs-Xxx and Pe03P-Xxs-Xxx 10 - 100 1:1Document4 pagesSales and Engineering Data: Pd03P-Xxs-Xxx and Pe03P-Xxs-Xxx 10 - 100 1:1jarosNo ratings yet

- Assignent 4Document2 pagesAssignent 4Beshir Heyru Mohammed100% (1)

- An Intelligent Black Widow Optimization On Image Enhancement With Deep Learning Based Ovarian Tumor Diagnosis ModelDocument16 pagesAn Intelligent Black Widow Optimization On Image Enhancement With Deep Learning Based Ovarian Tumor Diagnosis ModelAgnesNo ratings yet

- Catalog GIPPS (March 2023) - EnglishDocument16 pagesCatalog GIPPS (March 2023) - EnglishgbcomsrlNo ratings yet

- Hygienic Process ConnectionsDocument22 pagesHygienic Process Connectionsabcdario666No ratings yet

- WH Mind Map 3Document1 pageWH Mind Map 3Print KullathatNo ratings yet

- Zoning Complaint Form 2010Document1 pageZoning Complaint Form 2010Web BinghamNo ratings yet

- Assignment 3 11-5-23Document3 pagesAssignment 3 11-5-23Haider khan100% (2)

- Development of A Signal-Free Intersection Control System For CAVs and Corridor Level Impact AssessmentDocument16 pagesDevelopment of A Signal-Free Intersection Control System For CAVs and Corridor Level Impact AssessmentChristian Kyle BeltranNo ratings yet

- 48TMSS07R0 Active - Passive Shelters For Telecommunication FacilitiesDocument15 pages48TMSS07R0 Active - Passive Shelters For Telecommunication FacilitiesMohamed NasrNo ratings yet

- PAKEDMON Pendahuluan Telematika 2019 PDFDocument13 pagesPAKEDMON Pendahuluan Telematika 2019 PDFkhashina afiffNo ratings yet

- Lecture 7Document28 pagesLecture 7Nkugwa Mark WilliamNo ratings yet

- Problem 2.32 PDFDocument1 pageProblem 2.32 PDFKauê BrittoNo ratings yet

- Design Practices in Design Thinking Kimbell 2009Document24 pagesDesign Practices in Design Thinking Kimbell 2009subirNo ratings yet

- DSM TutorialDocument17 pagesDSM TutorialGuilherme Ribeiro da SilvaNo ratings yet

- РАЗЛИКИ 200002Document31 pagesРАЗЛИКИ 200002MamattiNo ratings yet

- Quantstudio 5 Real-Time PCR System For Human IdentificationDocument2 pagesQuantstudio 5 Real-Time PCR System For Human IdentificationNiraj SilwalNo ratings yet

- Header Specification: Mplab Icd 2Document12 pagesHeader Specification: Mplab Icd 2knoppix2008No ratings yet

- 4 Conical Orifice PlateDocument41 pages4 Conical Orifice PlateAVULADODDI GIRI BABUNo ratings yet

- NC101 Module 1Document6 pagesNC101 Module 1Sarah May Nacion MorescoNo ratings yet

- DT - NU-EEE342-Lecture 4-Smith Charts 2017 PDFDocument62 pagesDT - NU-EEE342-Lecture 4-Smith Charts 2017 PDFSabit ShaihollaNo ratings yet

- Ugay, Nicole G. BS Psychology 3-ADocument4 pagesUgay, Nicole G. BS Psychology 3-ANicoleNo ratings yet

- 2019 Recitation Chap 2 PDFDocument21 pages2019 Recitation Chap 2 PDFGull100% (1)

- CatapultDocument4 pagesCatapultapi-305320178No ratings yet

- 1.4d Emergency Shower Eye Wash Inspection ChecklistDocument1 page1.4d Emergency Shower Eye Wash Inspection ChecklistShafie ZubierNo ratings yet

- IMG Xios XG Supreme USB Operating InstructionsDocument80 pagesIMG Xios XG Supreme USB Operating InstructionsClarity DentalNo ratings yet

- Turbo HD D3T Series Bullet & Turret & Dome Camera: User ManualDocument10 pagesTurbo HD D3T Series Bullet & Turret & Dome Camera: User Manualluis silvaNo ratings yet