Professional Documents

Culture Documents

Figure (1) Condenser Overall Heat Transfer Coefficient

Figure (1) Condenser Overall Heat Transfer Coefficient

Uploaded by

Viola Zakaria0 ratings0% found this document useful (0 votes)

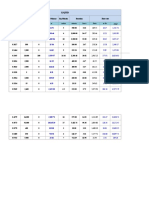

18 views10 pagesThe document contains 7 figures and 2 tables regarding heat transfer coefficients and hydraulic losses in condenser tubes. Table 1 provides correction factors for the overall heat transfer coefficient based on tube material and wall thickness. Table 2 gives correction factors for pressure drop based on tube outer diameter and wall thickness. The figures present data on overall heat transfer coefficients, hydraulic losses in single- and two-pass condensers, and correction factors related to cooling water inlet temperature and friction losses.

Original Description:

used to get overall heat transfer

Original Title

Charts

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document contains 7 figures and 2 tables regarding heat transfer coefficients and hydraulic losses in condenser tubes. Table 1 provides correction factors for the overall heat transfer coefficient based on tube material and wall thickness. Table 2 gives correction factors for pressure drop based on tube outer diameter and wall thickness. The figures present data on overall heat transfer coefficients, hydraulic losses in single- and two-pass condensers, and correction factors related to cooling water inlet temperature and friction losses.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

18 views10 pagesFigure (1) Condenser Overall Heat Transfer Coefficient

Figure (1) Condenser Overall Heat Transfer Coefficient

Uploaded by

Viola ZakariaThe document contains 7 figures and 2 tables regarding heat transfer coefficients and hydraulic losses in condenser tubes. Table 1 provides correction factors for the overall heat transfer coefficient based on tube material and wall thickness. Table 2 gives correction factors for pressure drop based on tube outer diameter and wall thickness. The figures present data on overall heat transfer coefficients, hydraulic losses in single- and two-pass condensers, and correction factors related to cooling water inlet temperature and friction losses.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 10

Figure (1) Condenser overall heat transfer coefficient

Figure (2). Correction factors for overall heat transfer coefficient.

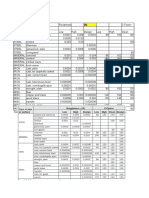

Table (1) Correction Factor for Overall Heat Transfer Coefficient

Tube Materials Tube Wall Gauge (BWG)

24 22 20 18 16 14 12

Adniiralty metal 1.06 1.04 1.02 1.00 0.96 0.92 0.87

Arscnica] copper 1.06 1.04 102 1.00 0.96 0.92 0.87

AJununum 1.06 1.04 1. 0 1.00 0.96 0.92 0.87

Aluminum brass 1.03 1.02 1 00 0.97 0.94 0.90 0.84

Aluminum bronze 1.03 1.02 1.00 0.97 0.94 0.90 0.84

Muntz metal 1.03 1.02 1.00 0.97 0.94 0.90 0.84

90-10 Cu-Ni 0.99 0.97 0.94 0.90 0.85 0.80 0.74

70-30Cu-Ni 0.93 0.90 0.87 0.82 0.77 0.71 0.64

Cold-rolled low

carbon steel 1.00 0.98 0.95 0.91 0.86 0.80 0.74

Stainless Sleds

Type 410/430 0.88 0.85 0.82 0.76 0.70 0.65 0.59

Type 304/316 0.83 0.79 0.75 0.69 0.63 0.56 0.49

Type 329 0.78 0.76 0.74 0.69 0.65 0.60 0.54

Titanium (tentative) 0.85 0.81 0.77 0.71 --- — —

Figure (3) Hydraulic loss of condenser tubes.

Figure(4) Hydraulic loss of condenser tubes for higher losses than figure(3).

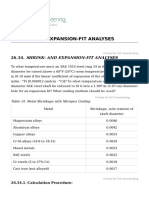

Gauge Correction Factor for Pressure Drop

Tube O.D. In. 12BWG 14BWG 16BWG 18BWC 20BWG 22BWG 24BWG

0.625 1.38 1.21 1.10 1.00 0.94 0.91 0.89

0.750 1.28 1.16 1.06 1.00 0.95 0.93 0.90

0.875 1.25 1.13 1.06 1.00 0.96 0.94 0.92

1.000 1.19 1.11 1.05 1.00 0.96 0.94 0.93

1.125 1.16 1.09 1.04 1.00 0.97 0.95" 0.94

1.250 1.14 1.08 1.04 1.00 0.97 | 0.96 0.94

Figure (5) Correction factor for friction loss in condenser due to cooling water

inlet temperature

Figure (6) Hydraulic losses for single pass condenser

Figure (7) Hydraulic losses for two passes condenser

You might also like

- Physics Laboratory Manual 4th Edition David Loyd Solutions ManualDocument7 pagesPhysics Laboratory Manual 4th Edition David Loyd Solutions ManualMarkMannjbcaw100% (15)

- AMADA - Parameter HandbookDocument8 pagesAMADA - Parameter HandbookNirman Mujkic50% (2)

- AISI Type 302 Stainless Steel (UNS S30200) : Chemical CompositionDocument4 pagesAISI Type 302 Stainless Steel (UNS S30200) : Chemical CompositionnagboccaNo ratings yet

- ME3122-2 Lab Forced Convection Heat TransferDocument14 pagesME3122-2 Lab Forced Convection Heat TransferLinShaodun100% (2)

- Thermal Expansion CoeffDocument1 pageThermal Expansion CoeffJoel VinothNo ratings yet

- Sgps Id01 CalcDocument48 pagesSgps Id01 Calcsaroat moongwattanaNo ratings yet

- HeatTreatingDataEBook 2011Document115 pagesHeatTreatingDataEBook 2011mario fisgaNo ratings yet

- HT Xlpe PDFDocument3 pagesHT Xlpe PDFrengaramanujanNo ratings yet

- Pages From Ashrae 1997 Hvac Fundamentals HandbookDocument21 pagesPages From Ashrae 1997 Hvac Fundamentals HandbookAnkurNo ratings yet

- Copper Pipes To BS EN 1057Document12 pagesCopper Pipes To BS EN 1057wkcNo ratings yet

- Calculos EléctricosDocument7 pagesCalculos Eléctricosjohn rangelNo ratings yet

- Steel Bars, Carbon, Hot-Wrought, Special Quality: Standard Specification ForDocument6 pagesSteel Bars, Carbon, Hot-Wrought, Special Quality: Standard Specification ForIngrid Tatiana RojasNo ratings yet

- BASRID-922-March-2024-24Document1 pageBASRID-922-March-2024-24Atikela AkhilNo ratings yet

- Catálogo Mola PratoDocument24 pagesCatálogo Mola PratoJan MartinsNo ratings yet

- SDFSDFDocument2 pagesSDFSDFAdrian MerinoNo ratings yet

- Ceramics and Metals No AlDocument2 pagesCeramics and Metals No AlAdrian MerinoNo ratings yet

- ASHRAE Fundamentals 2005 - SI Units - Extract of Tables PDFDocument40 pagesASHRAE Fundamentals 2005 - SI Units - Extract of Tables PDFSufian SarwarNo ratings yet

- Reboiler 1Document12 pagesReboiler 1kishna009No ratings yet

- BASRID-922-March-2024-15Document1 pageBASRID-922-March-2024-15Atikela AkhilNo ratings yet

- Duplex Stainless SteelDocument17 pagesDuplex Stainless SteelthunderNo ratings yet

- Derating Factor Standard PDFDocument3 pagesDerating Factor Standard PDFiyan ahyaniNo ratings yet

- Arie TabelDocument10 pagesArie TabelDirga RiantoNo ratings yet

- Kembla Copper Tube New Zealand Standard NZS 3501Document4 pagesKembla Copper Tube New Zealand Standard NZS 3501cameronrogNo ratings yet

- Circular + RectangularDocument41 pagesCircular + RectangularMohammed IshaqueNo ratings yet

- Fitting Coeffitients DesignDocument4 pagesFitting Coeffitients Designs_aguilNo ratings yet

- Material CompositionsDocument8 pagesMaterial CompositionswanNo ratings yet

- 9Document25 pages9gazwang478No ratings yet

- BASRID-922-March-2024-8Document1 pageBASRID-922-March-2024-8Atikela AkhilNo ratings yet

- Shrink - and Expansion-Fit AnalysesDocument3 pagesShrink - and Expansion-Fit AnalysesScribdUser11235No ratings yet

- Table - 8 Conductor PropertiesDocument1 pageTable - 8 Conductor PropertiesMichael DarmstaedterNo ratings yet

- Victaulic Duplex Grooved Couplings Style 77DX Duplex Stainless Steel Flexible CouplingDocument9 pagesVictaulic Duplex Grooved Couplings Style 77DX Duplex Stainless Steel Flexible Couplingגרבר פליקסNo ratings yet

- BASRID-922-March-2024-18Document1 pageBASRID-922-March-2024-18Atikela AkhilNo ratings yet

- Mag General Business: Quality CertificateDocument1 pageMag General Business: Quality CertificateNilton Santillan OrtegaNo ratings yet

- Lab 1 For Merge 1Document4 pagesLab 1 For Merge 1utsho dasNo ratings yet

- X Bar & R Bar SampleDocument2 pagesX Bar & R Bar SampleRaajha MunibathiranNo ratings yet

- Power Cables With Their Electricals Characteristics, Overall Length and WeightDocument6 pagesPower Cables With Their Electricals Characteristics, Overall Length and WeightRoumya Darshan RayNo ratings yet

- Friction Losses in Pipe Fittings Resistance Coefficient K (Use in Formula H KV /2g)Document12 pagesFriction Losses in Pipe Fittings Resistance Coefficient K (Use in Formula H KV /2g)Alvin KimNo ratings yet

- Adams Auto-Lubrication System DesignDocument4 pagesAdams Auto-Lubrication System DesignRobin Ace SamonteNo ratings yet

- Measurement of The Drag Coefficients of Spherical ParticlesDocument10 pagesMeasurement of The Drag Coefficients of Spherical Particlessr3shNo ratings yet

- Sound Speed & Pipe Size Data: (For Ultrasonic Flowmeters)Document50 pagesSound Speed & Pipe Size Data: (For Ultrasonic Flowmeters)sherio amrousyNo ratings yet

- The Formalization of Selection ProceduresDocument4 pagesThe Formalization of Selection ProceduresHamza KarimNo ratings yet

- DPS Calculation SheetDocument133 pagesDPS Calculation SheetKraiwan Aranyawat100% (1)

- BASRID-922-March-2024-11Document1 pageBASRID-922-March-2024-11Atikela AkhilNo ratings yet

- Pressure To Decrease Increase The Amount of Power That A Pump Must Deliver To The FluidDocument42 pagesPressure To Decrease Increase The Amount of Power That A Pump Must Deliver To The FluidNixon RamsaranNo ratings yet

- A 213 Â " A 213M Â " 03 - QTIXMY9BMJEZTS1SRUQDocument14 pagesA 213 Â " A 213M Â " 03 - QTIXMY9BMJEZTS1SRUQhNo ratings yet

- Technical Info About Die CastingDocument5 pagesTechnical Info About Die CastingSanoj KumarNo ratings yet

- Ju 001 06 0918 0000 04 Re 0002 - 1Document8 pagesJu 001 06 0918 0000 04 Re 0002 - 1aach17No ratings yet

- Mag General Business: Quality CertificateDocument1 pageMag General Business: Quality CertificateNilton Santillan OrtegaNo ratings yet

- Brochure Bohler BeneluxDocument8 pagesBrochure Bohler Beneluxmohsen_267No ratings yet

- ResourcesFrictionLossData PDFDocument4 pagesResourcesFrictionLossData PDFEduardo MirandaNo ratings yet

- ResourcesFrictionLossData PDFDocument4 pagesResourcesFrictionLossData PDFhmid007No ratings yet

- ChoiceAnalytical NCSDocument163 pagesChoiceAnalytical NCSQuality Officer GeosKendari (Pandu)No ratings yet

- Bahra MediumVoltage - LowRes - ForwebDocument112 pagesBahra MediumVoltage - LowRes - Forwebayman saberNo ratings yet

- Cs Pipe Fab Amp Erect CostsDocument6 pagesCs Pipe Fab Amp Erect CostsBudi SantonyNo ratings yet

- Valve MOC and ImportantDocument22 pagesValve MOC and ImportantUdhayakumar VenkataramanNo ratings yet

- Cyclic Plasticity of Engineering Materials: Experiments and ModelsFrom EverandCyclic Plasticity of Engineering Materials: Experiments and ModelsNo ratings yet

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- Analytical Troubleshooting of Process Machinery and Pressure Vessels: Including Real-World Case StudiesFrom EverandAnalytical Troubleshooting of Process Machinery and Pressure Vessels: Including Real-World Case StudiesRating: 3 out of 5 stars3/5 (1)

- Salad Tutorial 2 - Writing A Script: © Xtrados Pty LTD, 2007Document6 pagesSalad Tutorial 2 - Writing A Script: © Xtrados Pty LTD, 2007Viola ZakariaNo ratings yet

- 1) Thermoelectric Cooling System: HeatsinkDocument3 pages1) Thermoelectric Cooling System: HeatsinkViola ZakariaNo ratings yet

- Steam EffDocument4 pagesSteam EffViola ZakariaNo ratings yet

- What Is Boiler Corrosion?Document4 pagesWhat Is Boiler Corrosion?Viola ZakariaNo ratings yet

- P&ID Diagram of Teaching Unit in A3Document1 pageP&ID Diagram of Teaching Unit in A3Viola ZakariaNo ratings yet