Professional Documents

Culture Documents

MS Isoiec 17025-2017

MS Isoiec 17025-2017

Uploaded by

DrAdel A. ElbasetCopyright:

Available Formats

You might also like

- FLEXUserManual PDFDocument356 pagesFLEXUserManual PDFalamahmad768100% (1)

- ISO-CASCO - ISO-IEC 17043-2023., Conformity Assessment - General Requirements For Proficiency TestingDocument28 pagesISO-CASCO - ISO-IEC 17043-2023., Conformity Assessment - General Requirements For Proficiency Testingabdelhafid0% (1)

- Decision Rule SopDocument3 pagesDecision Rule SopNageswara rao100% (1)

- FMT 09 - Management Review (IS 17025-2017) VITDocument2 pagesFMT 09 - Management Review (IS 17025-2017) VITSrirevathi Balapattabi100% (2)

- ISO 17025.2017 Management System TemplateDocument14 pagesISO 17025.2017 Management System TemplateDrAdel A. Elbaset50% (2)

- LQMS Exercise - 1Document2 pagesLQMS Exercise - 1Saravanan P100% (2)

- Lesson 12 15finalsDocument25 pagesLesson 12 15finalsREIMOND VINCE MENDOZANo ratings yet

- G133 - A2LA Guide For Establishing Proficiency Testing Plans-23603-1Document9 pagesG133 - A2LA Guide For Establishing Proficiency Testing Plans-23603-1Alberto Garcia100% (1)

- TOTL-SP02 Factilities and Environmental Conditions ProcedureDocument9 pagesTOTL-SP02 Factilities and Environmental Conditions ProcedureahmedNo ratings yet

- 04 Internal Audit ProceduresDocument4 pages04 Internal Audit ProceduresReama QumsanNo ratings yet

- Technical Requirement For ISO 17025-2005-SanasDocument11 pagesTechnical Requirement For ISO 17025-2005-Sanasyouni_2005No ratings yet

- ImpartialityDocument2 pagesImpartialitysujud100% (2)

- ISO 170252017 RequirementDocument6 pagesISO 170252017 RequirementAkkiNo ratings yet

- 4.4 Review of Requests, Tenders and ContractsDocument1 page4.4 Review of Requests, Tenders and ContractsGajaNand MallickNo ratings yet

- Selection, Verification and Validation of MethodsDocument47 pagesSelection, Verification and Validation of MethodsaloediyahNo ratings yet

- Omnex Internal Auditor Training For ISO 17025 - 2017Document1 pageOmnex Internal Auditor Training For ISO 17025 - 2017allaboutfreeNo ratings yet

- ISO 17025 SimplifiedDocument1 pageISO 17025 Simplifiedvasudeva yasas100% (1)

- Eurolab Handbook Iso Iec 17025 2017Document32 pagesEurolab Handbook Iso Iec 17025 2017Ali ZafarNo ratings yet

- Externally Provided Products and Services ChecklistDocument3 pagesExternally Provided Products and Services Checklistcosmicbunny100% (1)

- RiskAssessment Nov2013Document7 pagesRiskAssessment Nov2013Rama KrishnaNo ratings yet

- LINK1041 Operators ManualDocument155 pagesLINK1041 Operators ManualOli VierNo ratings yet

- Roche Elecsys 2010 User GuideDocument504 pagesRoche Elecsys 2010 User Guidesazunax63% (16)

- Self Assessment ChecklistDocument22 pagesSelf Assessment ChecklistjoshuaNo ratings yet

- Facilities and Environmental ConditionsDocument3 pagesFacilities and Environmental ConditionsneramopNo ratings yet

- CookBook 19 Impartiality and Confidentiality - 10-2018 PDFDocument2 pagesCookBook 19 Impartiality and Confidentiality - 10-2018 PDFJacek SobczykNo ratings yet

- Kejriwal Castings Limited (Testing Lab, DGP) : Qualty Management System Procedure For ImpartialityDocument3 pagesKejriwal Castings Limited (Testing Lab, DGP) : Qualty Management System Procedure For ImpartialityAniruddha ChatterjeeNo ratings yet

- EUROLAB Cook Book - Doc No 0 Tool For Transition From ISO 17025 2005 To 2017Document23 pagesEUROLAB Cook Book - Doc No 0 Tool For Transition From ISO 17025 2005 To 2017Eby Joy0% (2)

- ISO 17025 Risk Management Example: December 2019Document6 pagesISO 17025 Risk Management Example: December 2019paeg6512100% (1)

- ISO 17025-2017 Quality Manual TestingDocument69 pagesISO 17025-2017 Quality Manual Testinglabn6446100% (1)

- Sadcas TR 14 - Sadcas Policy - Iso Iec 17025-2017 TransitionDocument10 pagesSadcas TR 14 - Sadcas Policy - Iso Iec 17025-2017 TransitionSuresh KumarNo ratings yet

- ISO 17025 ChecklistDocument29 pagesISO 17025 ChecklistJuan Camilo PachiNo ratings yet

- QSP-001633 - Rev 04 - Luminus Testing Laboratory Quality Manual207Document34 pagesQSP-001633 - Rev 04 - Luminus Testing Laboratory Quality Manual207SureshNo ratings yet

- FINAL EXAMINATION (Internal Auditor Course - ISO 17025)Document5 pagesFINAL EXAMINATION (Internal Auditor Course - ISO 17025)Ranjit ThakurNo ratings yet

- ORA-LAB.5.3 Facilities and Environmental Conditions (v02)Document9 pagesORA-LAB.5.3 Facilities and Environmental Conditions (v02)allysa almagroNo ratings yet

- ISO/IEC 17025:2017: - General Requirements For The Competence of Testing and Calibration LaboratoriesDocument31 pagesISO/IEC 17025:2017: - General Requirements For The Competence of Testing and Calibration LaboratoriesObak Prithibi100% (1)

- Review of Requests, Tenders and ContractsDocument2 pagesReview of Requests, Tenders and ContractsMohamed GaballahNo ratings yet

- 07 - Risk Based Approach 17025Document10 pages07 - Risk Based Approach 17025सागर फुकटNo ratings yet

- Final Draft of Nabl 103Document51 pagesFinal Draft of Nabl 103prasadnn2001No ratings yet

- ISO 17025 ManualDocument7 pagesISO 17025 Manualvinodkvatsa50% (2)

- Iso-17025-2017-Lab Quality Manual of Nutracential & Functional FoodDocument9 pagesIso-17025-2017-Lab Quality Manual of Nutracential & Functional FoodrohitNo ratings yet

- Iso 17025Document6 pagesIso 17025Khurram Shehzad100% (1)

- Facilities and Environmental Conditions (Linked To Vol. III, Sec. 2) PDFDocument8 pagesFacilities and Environmental Conditions (Linked To Vol. III, Sec. 2) PDFimran shaukat100% (1)

- QSP 06 Control of Non Conforming ProductDocument3 pagesQSP 06 Control of Non Conforming Productkmvimal36No ratings yet

- Quality ManualDocument7 pagesQuality ManualFA KhanNo ratings yet

- ORA-LAB.5.5.1 Equipment Records v02Document6 pagesORA-LAB.5.5.1 Equipment Records v02Ayman Ali100% (2)

- Section 8.5 of ISO/IEC 17025:2017 Risks and OpportunitiesDocument3 pagesSection 8.5 of ISO/IEC 17025:2017 Risks and OpportunitiesVasaNo ratings yet

- Course Summary ISO 17025Document7 pagesCourse Summary ISO 17025Umer AhsanNo ratings yet

- QSP 02 - 6.2 - Competance and Training - IEC 17025-17, Cl. No. 6.2.5, Pg. 4 OBSDocument3 pagesQSP 02 - 6.2 - Competance and Training - IEC 17025-17, Cl. No. 6.2.5, Pg. 4 OBSV Vijay100% (1)

- ORA-LAB - QM ORA Laboratory Manual of Quality Policies (v03)Document47 pagesORA-LAB - QM ORA Laboratory Manual of Quality Policies (v03)Ahmad shayebNo ratings yet

- Laboratory Housekeeping: 1.0 PurposeDocument3 pagesLaboratory Housekeeping: 1.0 PurposeAbu MuazNo ratings yet

- Water Quality. Sampling. Guidance On Quality Assurance and Quality Control of Environmental Water Sampling and Handling - Libgen - LiDocument46 pagesWater Quality. Sampling. Guidance On Quality Assurance and Quality Control of Environmental Water Sampling and Handling - Libgen - Lilouis bothe100% (1)

- General Accreditation Criteria: Metrological Traceability PolicyDocument24 pagesGeneral Accreditation Criteria: Metrological Traceability Policyarli krisnandika100% (1)

- Iso15189 2022checklistDocument42 pagesIso15189 2022checklistReema Md100% (1)

- PROCEDURE For Non Conforming WorkDocument1 pagePROCEDURE For Non Conforming WorkGopal Mallick100% (2)

- ALACC Method VerificationDocument10 pagesALACC Method VerificationVasu Raja100% (1)

- PR-GM 09 Identification and Control Ofnon Conformance ProcedureDocument5 pagesPR-GM 09 Identification and Control Ofnon Conformance ProcedureFULGENCE RUHARARANo ratings yet

- Quality Manual CalibrationDocument30 pagesQuality Manual CalibrationsaidvaretNo ratings yet

- Corrective And Preventative Action A Complete Guide - 2020 EditionFrom EverandCorrective And Preventative Action A Complete Guide - 2020 EditionNo ratings yet

- Nominal Cross-References 17025 To 9001 PDFDocument3 pagesNominal Cross-References 17025 To 9001 PDFwhitemithrilNo ratings yet

- IMS ManualDocument62 pagesIMS ManualKimpoh ChaiNo ratings yet

- Iso17025 ChecklistDocument28 pagesIso17025 ChecklistBhavna ShahNo ratings yet

- Laboratory Assessment ChecklistDocument28 pagesLaboratory Assessment ChecklistPanneer Selvam100% (2)

- Turtle SampleDocument7 pagesTurtle Samplerodolfo1649No ratings yet

- An Audit Questionnaire That Examines Specifically The Management of Technical Activities Clauses in Iso 15189Document7 pagesAn Audit Questionnaire That Examines Specifically The Management of Technical Activities Clauses in Iso 15189Rekha NirwanNo ratings yet

- F ISO 17025Document51 pagesF ISO 17025Shishir MaharjanNo ratings yet

- Paper #37CDocument6 pagesPaper #37CDrAdel A. ElbasetNo ratings yet

- A Modified Perturb and Observe Algorithm For Maximum Power Point Tracking of Photovoltaic System Using Buck-Boost ConverterDocument19 pagesA Modified Perturb and Observe Algorithm For Maximum Power Point Tracking of Photovoltaic System Using Buck-Boost ConverterDrAdel A. ElbasetNo ratings yet

- 276 FinalDocument6 pages276 FinalDrAdel A. ElbasetNo ratings yet

- Abd El Sattar8Document15 pagesAbd El Sattar8DrAdel A. ElbasetNo ratings yet

- Paper Ijetae Paper Template 14-05-2014Document10 pagesPaper Ijetae Paper Template 14-05-2014DrAdel A. ElbasetNo ratings yet

- AmalDocument25 pagesAmalDrAdel A. ElbasetNo ratings yet

- 1 PB - 3Document13 pages1 PB - 3DrAdel A. ElbasetNo ratings yet

- 1 s2.0 S1876610217365165 MainDocument6 pages1 s2.0 S1876610217365165 MainDrAdel A. ElbasetNo ratings yet

- بيان التدرج الوظيفي PDFDocument1 pageبيان التدرج الوظيفي PDFDrAdel A. ElbasetNo ratings yet

- Smoothing of Grid-Connected Wind-Diesel Power Output Using Energy Capacitor SystemDocument6 pagesSmoothing of Grid-Connected Wind-Diesel Power Output Using Energy Capacitor SystemDrAdel A. ElbasetNo ratings yet

- Biorad CFX Maestro User GuideDocument256 pagesBiorad CFX Maestro User GuideDenis FreedmanNo ratings yet

- Optidist: Benchmark in Atmospheric Distillation TestingDocument4 pagesOptidist: Benchmark in Atmospheric Distillation TestingAnonh AdikoNo ratings yet

- Computer - System - Validation - An - Integral - Part - For - Effective - Laboratory - Automation - Service 2Document12 pagesComputer - System - Validation - An - Integral - Part - For - Effective - Laboratory - Automation - Service 2Nitin KashyapNo ratings yet

- Academic Research Record-KeepingDocument6 pagesAcademic Research Record-KeepingYongSing YouNo ratings yet

- Thermo Scientific LIMS: A Solution For Water and Environmental Testing LaboratoriesDocument4 pagesThermo Scientific LIMS: A Solution For Water and Environmental Testing Laboratoriesbudi_alamsyahNo ratings yet

- V UnitDocument50 pagesV UnitB.MAHAALAKSHMINo ratings yet

- Clarity Lims PDFDocument18 pagesClarity Lims PDFCesar Arturo Marino SaavedraNo ratings yet

- 22MSC-LIMS Product SummaryDocument2 pages22MSC-LIMS Product SummaryEmad AliNo ratings yet

- Project Final Report FinalDocument35 pagesProject Final Report FinalRITESH JANGIDNo ratings yet

- Automation in Diagnostic MicrobiologyDocument3 pagesAutomation in Diagnostic Microbiologymicrobehunter007No ratings yet

- DocumentationDocument52 pagesDocumentationthanh_cdt01No ratings yet

- Simple and Accurate Measurements: For Results at Your FingertipsDocument16 pagesSimple and Accurate Measurements: For Results at Your FingertipsGenlajt DOOELNo ratings yet

- Job Description Officer QC Srirangs ReplacementDocument2 pagesJob Description Officer QC Srirangs ReplacementSiddhesh ShirodkarNo ratings yet

- Reference List 2009Document51 pagesReference List 2009Đặng Trung AnhNo ratings yet

- RT PCR Solutions - Bulletin - 6629Document8 pagesRT PCR Solutions - Bulletin - 6629dwin05No ratings yet

- Guide For Using LOINC Microbiology Terms: Logical Observation Identifiers Names and Codes (LOINC )Document124 pagesGuide For Using LOINC Microbiology Terms: Logical Observation Identifiers Names and Codes (LOINC )Ashwini KalantriNo ratings yet

- Lims Sap Integration PDF FreeDocument24 pagesLims Sap Integration PDF FreePavan ReddyNo ratings yet

- 2 1 6 072016 enDocument29 pages2 1 6 072016 enbaglamaNo ratings yet

- Laboratory Information Management Systems (Lims) Deployment: Project Charter ExampleDocument5 pagesLaboratory Information Management Systems (Lims) Deployment: Project Charter ExampleJoão CarvalhoNo ratings yet

- 24.7 Brochure PDFDocument4 pages24.7 Brochure PDFLilian Carolina Loreto MachadoNo ratings yet

- Vitro S 3600Document138 pagesVitro S 3600Sidney33% (3)

- Lesson 10 and 11: Laboratory Information Management System and Other Hospital Information SystemsDocument4 pagesLesson 10 and 11: Laboratory Information Management System and Other Hospital Information SystemsAngel Kaye FabianNo ratings yet

- Laboratory Information System PDFDocument96 pagesLaboratory Information System PDFTangled LimNo ratings yet

- Impulse HmisDocument6 pagesImpulse HmisjohnNo ratings yet

- Raul Sarmiento - ITDocument2 pagesRaul Sarmiento - ITChirantar KumarNo ratings yet

MS Isoiec 17025-2017

MS Isoiec 17025-2017

Uploaded by

DrAdel A. ElbasetOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MS Isoiec 17025-2017

MS Isoiec 17025-2017

Uploaded by

DrAdel A. ElbasetCopyright:

Available Formats

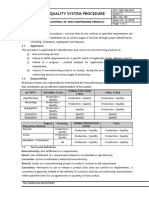

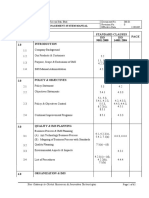

GAP ANALYSIS

MS ISO/IEC 17025:2017

Disclaimer: This gap analysis is only meant as a reference. It may not include all

the requirements of MS ISO/IEC 17025:2017

MS ISO/IEC 17025:2017 MS ISO/IEC 17025:2005 Remark

4 General requirement (NEW) 4.1.5 b) have arrangements to ensure Impartiality

that its management and personnel are -Policy (8.2.2)

4.1 Impartiality (NEW) free from any undue internal and -Undertaking,

external commercial, financial and other -Structure

4.1.1 undertaken impartially, pressures and influences that may -Activities-

structured, managed- safeguard adversely affect the quality of their independent

impartiality work; auditors

4.1.2 committed to impartiality 4.1.5 c) policy and procedure protection Need to address

confidentiality 4.1.4 – to identify

4.1.3 responsible for impartiality activities,

4.1.5 d) have policies and procedures relationship

4.1.4 identify risk to impartiality and to avoid involvement in any activities

other risks. (on-going basis) (NEW) that would diminish confidence in its

competence, impartiality, judgement or

4.1.5 demonstrate to eliminates risk operational integrity;

4.7.1 The laboratory shall be willing to

4.2 Confidentiality (NEW) cooperate with customers or their

representatives in clarifying the

4.2.1 responsible, legally customer's request and in monitoring

enforceable commitment on the laboratory’s performance in relation

confidentiality (NEW) to the work performed, provided that

the laboratory ensures confidentiality to

4.2.2 inform customer on information other customers.

release required by law

5.4.7.2 b) procedures are established

4.2.3 confidential about information and implemented for protecting the

obtained and sources of information data; such procedures shall include, but

not be limited to, integrity and

4.2.4 all personnel keep confidential confidentiality of data entry or

all information (similar 4.1.5 c) collection, data storage, data

transmission and data processing;

5. Structure requirement 4.1 Organisation 5.3* e.g. testing

only. sampling not

5.1 Legal entity (similar 4.1.1) 4.1.1 legal entity included

4.1.2 responsibility

5.2 identify management (similar 4.1.3 system cover permanent or site *5.3 - accredited

4.1.5 a), 4.1.5 h), 4.2.6) 4.1.5 lab to have: scope to exclude

a) managerial and technical personnel ongoing

5.3* define and document range of b) arrangement subcontracted tests

activity which conforms to MS c) policy and procedure protection which the laboratory

ISO/IEC 17025, excludes externally d) policy and procedure avoid is not or unable to

provided laboratory activities on an involvement perform

ongoing basis (Similar 1.2 scope) e) define org chart, parent organisation,

quality, tech operation and support

Issue date: 7 May 2018 Page 1 of 13

GAP ANALYSIS

MS ISO/IEC 17025:2017

Disclaimer: This gap analysis is only meant as a reference. It may not include all

the requirements of MS ISO/IEC 17025:2017

MS ISO/IEC 17025:2017 MS ISO/IEC 17025:2005 Remark

5.4 meeting regulatory requirement f) specify responsibility 5.5 c) consistently

(similar 4.1.2), permanent or site g) supervision of staff uses term

(similar 4.1.3) h) have tech management “procedure” when

i) appoint quality manager, direct the intent is for

5.5 lab shall: access (REMOVED) laboratory to

a) define lab structure, parent maintain

organisation, management, tech *5.3 (Similar 1.2 scope) The word documentation.

operation, support services (similar "scope" was REMOVED from the

4.1.5 e) Introduction, clauses 1.2, 4.2.1, 5.4.1,

5.4.4 b), 5.4.5.2, 5.4.6.2)

b) Specify responsibility ...

personnel(similar 4.1.5 f, 4.2.6,

5.2.4)

c) document procedures to the

extent necessary to ensure the

consistent application of its

laboratory activities and the validity

of the results. (similar 4.2.1)

5.6 personnel who, have the 4.1.5 (a) have managerial personnel, Focus on

authority and resources needed to have authority and resources responsibilities and

carry out their duties,…..[(similar 4.1.5 (h) have technical authorities rather

4.1.5 (a)] management….responsible for than the

a) implement .... system technical operation title/position.

b) identification deviation... 4.1.5 (i) appoint as quality manager

c) initiate to minimize deviation 4.1.5 (j) appoint deputy for key

d) report lab performance managerial personnel (REMOVED)

e) ensuring effectiveness lab

activities

5.7 lab management shall ensure 4.1.6 appropriate communication

a) communication take place (similar 4.2.7 planned changes maintained

4.1.6) integrity

b) planned changes maintain

integrity (similar 4.2.7)

6.2 Personnel 5.2 Personnel 6.2.2 Need criteria &

records

6.2.1 personnel act impartially 5.2.1 i) ensure the competence, ii)

(similar 4.1.5 d), competent (similar qualified personnel perform specific 6.2.4 Job description

5.2.1) task still relevant

6.2.2 document competence 5.2.2 i) formulate goal..,ii) policy and

requirement of personnel (NEW, old procedure for identify training,

not clear) (REPHRASED - Refer 6.2.5)

Issue date: 7 May 2018 Page 2 of 13

GAP ANALYSIS

MS ISO/IEC 17025:2017

Disclaimer: This gap analysis is only meant as a reference. It may not include all

the requirements of MS ISO/IEC 17025:2017

MS ISO/IEC 17025:2017 MS ISO/IEC 17025:2005 Remark

6.2.3 ensure personnel have 5.2.2 iii) evaluate effectiveness of

competency training (REMOVED)

6.2.4 communicate to personnel of 5.2.4 – job description (moved to 5.5b)

their duties etc. (NEW)

5.2.5 – authorisation of specific

6.2.5 – procedure and record for personnel

a) determining the competence

requirements (NEW); 5.4.3 – assigned to qualified personnel

b) selection of personnel;

c) training of personnel;

d) supervision of personnel;

e) authorization of personnel;

f) monitoring of competence of

personnel (NEW)

6.2.6 authorised personnel for

specific activities (similar 5.2.5),

(related to 5.4.3)

6.3 Facilities and environmental 5.3 Accommodation

condition

5.3.2 – monitor environmental condition

6.3.2 Documented requirement for

F&E condition (NEW) 5.3.3 – effective separation,

incompatible

6.3.3 Monitor environmental

condition (similar 5.3.2) 5.3.4 – controlled access

6.3.4 Implement, monitor & 5.3.5 – good housekeeping

periodically review (NEW) :

a) accesses (similar 5.3.4)

b) prevent contamination (similar

5.3.3)

c) incompatible activities (similar

5.3.3)

6.3.5 perform activities outside,

meet requirement F&E (NEW) (Note

old 5.5.9 for equipment only)

6.4 Equipment 5.5 Equipment

6.4.1 access to equipment (similar 5.5.1 – furnished with equipment 6.4.1 Equipment

5.5.1, more flexibility) (NEW) 5.5.2 – equipment shall be capable includes;

achieve accuracy required, calibrated, measuring

calibration programme. instruments

Issue date: 7 May 2018 Page 3 of 13

GAP ANALYSIS

MS ISO/IEC 17025:2017

Disclaimer: This gap analysis is only meant as a reference. It may not include all

the requirements of MS ISO/IEC 17025:2017

MS ISO/IEC 17025:2017 MS ISO/IEC 17025:2005 Remark

6.4.2 use equipment outside, ensure 5.5.3 – operate by authorised personnel software

met requirement (related 5.5.9) 5.5.4 – uniquely identified measurement

5.5.5 – equipment record (8 item) standards

6.4.3 procedure for handling (similar e) manufacture instruction (deleted) reference

5.5.6) 5.5.6 – procedure for handling materials

5.5.7 – mark out of services reference data

6.4.4 verify equipment before 5.5.8 – labelled calibration status reagents

returned to services (reference 5.5.9 – checks after goes outside consumables

5.5.2) 5.5.10 - intermediate checks auxiliary

5.5.11 - Procedure for correction factor apparatus

6.4.5 capable to achieve accuracy 5.5.12- safeguard from adjustment

(similar 5.5.2) or MU required (NEW) 6.4.13 f) – more

details

6.4.6 equipment shall be calibrated

(similar 5.5.2)

6.4.7 calibration programme (similar

to 5.5.2), review and adjust (NEW)

6.4.8 labelled, readily identified

(similar 5.5.4 & 5.5.8)

6.4.13 equipment records (similar

5.5.5)

a) ..+ firmware (NEW)

b) unique ID

c) evidence of verification

d) similar

e) calibration date, or calibration

interval (NEW)

f) documentation of RM, result,

acceptance criteria (NEW)

g) ..+ maintenance carried out

h) details +....

6.5 Metrological traceability 5.6 Measurement traceability Wordings simplified

(RENAMED) and rephrased for

5.6.1 – program/procedure for further clarity.

Annex A (NEW) calibration of equipment

5.6.2.1 Calibration - traceable to SI Additional info in

Annex A.

5.6.2.2 Testing – CRM, RM

6.6 Externally provided products 4.5 Subcontracting of tests and 4.5 The term

and services calibrations subcontracting is no

6.6.1 ensure suitable provider used longer in use. The

for 4.5.1 advise customer and get approval lab is responsible for

a) incorporate to lab activities subcontractor’s

Issue date: 7 May 2018 Page 4 of 13

GAP ANALYSIS

MS ISO/IEC 17025:2017

Disclaimer: This gap analysis is only meant as a reference. It may not include all

the requirements of MS ISO/IEC 17025:2017

MS ISO/IEC 17025:2017 MS ISO/IEC 17025:2005 Remark

b) directly to lab customer 4.5.3 lab responsible for subcontractor results as per

c) support lab operation 7.8.2.2, 7.8.2.1(p)

4.5.4 list of subcontractor (REMOVED)

6.6.2 procedure for 4.6 Purchasing services and 6.6.2 b) and d) …re-

a) defined lab’s requirement for supplies evaluation

external providers (similar 4.6.2)

b) define criteria for evaluation, 4.6.1 procedure

selection, monitoring, re-evaluation 4.6.2 purchased item not used until

(related to 4.6.4) verified (MOVED to new 6.4.4)

c) ensure provider confirm to lab 4.6.2 supplies comply with specified

established requirement (NEW) requirement

d) taking action from evaluation, 4.6.4 evaluate supplier, list supplier

monitoring and re-evaluation (NEW) approved (REMOVED list)

6.6.3 communicate requirement to

providers (NEW)

a) services to be provided (NEW)

b) acceptance criteria

c) competence

d) activities to perform at providers

premises (NEW)

7.1 Review of request 4.4 Review of request 7.1.1 c) when

external providers is

7.1.1 have procedure 4.4.1 policy and procedure (REMOVED used, lab to advises

POLICY) the customer and

a) defined requirement gain customer’s

b) has capability & resource a) define requirement approval

c) advises the customer and gain b) has capability

customer’s approval (NEW) c) method selected meet customer’s New 7.1.7 from 4.7.1

d) appropriate method requirements (services to

customer)

7.1.2 inform customer if method contract acceptable by lab & customer

inappropriate 7.1.3 – Decision rule

4.4.2 maintained record of review for statement of

7.1.3 statement of conformity (NEW) conformity

4.4.3 review cover subcontracted

7.1.4 contract acceptable by lab and

customer (similar 4.4.1). Deviation 4.4.4 inform customer if deviation 7.1.7 no mention of

not impact integrity (NEW) confidentiality to

4.4.5 repeat contract if amended other customers

7.1.5 inform customer if deviation when a customer

(similar 4.4.4) witness specific lab

activities

7.1.6 repeat contract if amended

(4.4.5) Confidentiality is

covered in;

Issue date: 7 May 2018 Page 5 of 13

GAP ANALYSIS

MS ISO/IEC 17025:2017

Disclaimer: This gap analysis is only meant as a reference. It may not include all

the requirements of MS ISO/IEC 17025:2017

MS ISO/IEC 17025:2017 MS ISO/IEC 17025:2005 Remark

7.1.7 customer monitor testing i) 4.2.1 …all other

(similar 4.7.1) information…shall

be regarded as

7.1.8 retain record (similar 4.4.2) confidential.

ii) 7.4.1 – to protect

the integrity…

interest of lab and

the customer

7.2 Selection, verification and 5.4 Method and validation 7.2.1.4 The lab can

validation of methods select methods;

5.4.1 – method available to personnel i. in international,

7.2.1.1 used appropriate method regional or

and procedure 5.4.2 - confirm that it can properly national

operate standard methods (verification standards

7.2.1.2 method up to date, readily of method) ii. by reputable

available technical

5.4.3 lab method, to have planned and organizations

7.2.1.3 use latest, valid method qualified personnel iii. in relevant

scientific texts or

7.2.1.4 customer not specify journals

method, can use any method iv. by the

manufacturer of

7.2.1.5 verify method before use the equipment

(similar 5.4.2) v. Laboratory-

developed

7.2.1.6 method development vi. Modified

7.2.1.7 method deviation, technically

justified

7.2.2 validation of method 5.4.4 validation of non-standard method

7.3 Sampling 5.7 Sampling

7.3.1 sampling plan and method 5.7.1 sampling plan and procedures

(REMOVED ‘procedure’)

7.3.2 sampling method (NEW)

a) selection of samples or sites 5.7.2 deviations, additions or exclusions

b) sampling plan from procedure, shall recorded &

c) preparation & treatment of communicated

samples

5.7.3 procedures for recording relevant

7.3.3 records of sampling data data and operations

Issue date: 7 May 2018 Page 6 of 13

GAP ANALYSIS

MS ISO/IEC 17025:2017

Disclaimer: This gap analysis is only meant as a reference. It may not include all

the requirements of MS ISO/IEC 17025:2017

MS ISO/IEC 17025:2017 MS ISO/IEC 17025:2005 Remark

a) reference sampling method - sampling procedures (REMOVED

(NEW) procedure)

b) date & time (NEW)

c) data identify & describe sample

(NEW)

d) ID personnel performing sampling

(similar Clause 5.7.3)

e) ID equipment (NEW)

f) environmental (similar Clause

5.7.3) or transport conditions (NEW)

g) diagrams (similar Clause 5.7.3)

h) deviations (similar Clause 5.7.2)

7.4 Handling of test items 5.8 Handling of test/calibration item

7.4.2 – Sub division

7.4.1 procedure (similar 5.8.1), 5.8.1 procedure transportation of items

precautions 5.8.2 – identify cal/test item

5.8.4 – procedure for avoid

7.4.2 system for identification of test deterioration, loss

item. Retain ID. (similar 5.8.2)

7.4.3 record deviation of item,

consult customer. Inclusion of

disclaimer (NEW) (link to 7.1.4)

7.4.4 store under specified condition

(Similar to 5.8.4)

7.5 Technical records 4.13.2 Technical records

7.5.1 ensure original data (similar

4.13.2.1), date, identify personnel,

recorded at the time made (similar

4.13.2.2), identifiable

7.6 Evaluation of measurement 5.4.6 Estimation of uncertainty of

uncertainty (RENAMED) measurement

7.6.1 identify significance 5.4.6.1 procedure for MU (REMOVED

contribution to MU procedure)

5.4.6.3 uncertainty component

7.6.2 MU for calibration

7.6.3 NOTE 2 (NEW)

Issue date: 7 May 2018 Page 7 of 13

GAP ANALYSIS

MS ISO/IEC 17025:2017

Disclaimer: This gap analysis is only meant as a reference. It may not include all

the requirements of MS ISO/IEC 17025:2017

MS ISO/IEC 17025:2017 MS ISO/IEC 17025:2005 Remark

7.7 Ensuring the validity of result 5.9 Assuring quality of test result Lab to also comply

with SAMM Policy

7.7.1 have procedure (similar 5.9.1) 5.9.1 have quality control procedure (SP4) - Policy for

participation in

11 item to be used 5 items to be used/participate proficiency testing

j) intralaboratory activities (the SP4

5.9.2 analysis of data, action if outside requirements are

7.7.2 monitor performance by pre-defined criteria derived from ILAC

comparison with other lab: P9 - ILAC Policy for

a) PT participation in

b) interlaboratory comparison proficiency testing

activities).

7.7.3 analysis of data, action if

outside pre-defined criteria (similar

5.9.2)

7.8 Reporting of results 5.10 Reporting result

7.8.1 General (similar to 5.10.1) 5.10.1 general, simplified report 7.8.6.1 decision rule

5.10.2 cal/test report information a) – k)

7.8.1.1 reviewed and authorized 5.10.3.2 move to 7.8.5- reporting

prior to release (NEW) sampling

7.8.1.2 reports shall be retained as 5.10.6 testing and calibration results

technical records (similar to obtained from subcontractors

4.13.2.1) [REMOVED. Covered in 7.8.2.1 p)]

7.8.1.3 simplified report (similar 5.10.7 electronic transmission of results

5.10.1 last para) (REMOVED, covered in 7.11)

7.8.2 Common requirements for 5.10.8 Format of reports and

reports (test, calibration or sampling) certificates (REMOVED)

(similar to 5.10.2, 5.10.3)

7.8.2.1 h) the date of sampling 5.10.9 Amendment to certificates

(NEW)

7.8.2.1 j) date of issue (NEW) Supplement to test report.....(Changed

7.8.2.1 n) additions to, deviations, or to Amendment)

exclusions from the method (similar

to 5.10.3.1 a), 5.10.3.2 f)

7.8.2.1 n) identification of the

person(s) authorizing the report

(REMOVED signature)

7.8.2.1 p) clear identification when

results are from external provider

(NEW-5.10.6)

Issue date: 7 May 2018 Page 8 of 13

GAP ANALYSIS

MS ISO/IEC 17025:2017

Disclaimer: This gap analysis is only meant as a reference. It may not include all

the requirements of MS ISO/IEC 17025:2017

MS ISO/IEC 17025:2017 MS ISO/IEC 17025:2005 Remark

7.8.2.2 responsibility on the

information provided in the reports

(NEW)

7.8.3 Specific requirements for test

reports (similar to 5.10.3.1)

7.8.4 Specific requirements for

calibration certificate (similar 5.10.4)

7.8.5 Reporting sampling –specific

requirements (similar to 5.10.3.2)

7.8.5 f) information required to

evaluate MU (NEW under sampling)

7.8.6 Reporting statements of

conformity (similar to 5.10.4.2)

7.8.7 Reporting opinions and

interpretations (similar to 5.10.5)

7.8.7.1 Only personnel authorized

for expression release the

respective statement (NEW)

7.8.7.3 …. a record of the dialogue

shall be retained (NEW)

7.8.8 Amendments to reports

(similar to 5.10.9 (NEW-more clear))

7.8.8.1 change clearly identified,

reason for change (NEW)

7.8.8.3 (Similar last para 5.10.9)

7.9 Complaint 4.8 Complaints Complaint process

described.

7.9.1 documented processes Policy and procedure for resolution of Lab needs to include

complaint. Record maintained aspects stated.

7.9.2 confirm validity of complaint

Nothing prescribed

7.9.3 complaint processes in old version.

a) receive, validate, investigate,

decide action to be taken Small laboratories

may be required to

b) tracking/record (NEW) use outside

Issue date: 7 May 2018 Page 9 of 13

GAP ANALYSIS

MS ISO/IEC 17025:2017

Disclaimer: This gap analysis is only meant as a reference. It may not include all

the requirements of MS ISO/IEC 17025:2017

MS ISO/IEC 17025:2017 MS ISO/IEC 17025:2005 Remark

c) ensure appropriate action taken resources to meet

7.9.6.

7.9.4 gather and verify info (to

validate the complaint)

7.9.5 acknowledge receipt and

provide progress report (if possible)

(NEW)

7.9.6 communicate outcome, review

and approve complaint, by

individual(s) not involved in the

original laboratory activities in

question.

7.9.7 give formal notice (if possible)

(NEW)

7.10 Nonconforming work 4.9 Control of nonconforming work

7.10.1 have procedure cover item a) 4.9.1 policy (REMOVED) and

till f) procedure cover a) – d) items

7.10.2 retain record 4.9.2 NCR recur, implement corrective

action

7.10.3 NCR recur, implement

corrective action (similar 4.9.2)

7.11 Control of data and 5.4.7 control of data

information management system LIMS includes

5.4.7.1 calculation/data transfer management of data

7.11.1 accesses to data and checked systematic manner and information

information needed (NEW) system in both;

5.4.7.2 when automated equipment i) Computerized

7.11.2 validate LIMS for functioning used, lab shall ensure: ii) Non-computerized

and interfaces. Re-validate if any a) software validated

changes b) procedure established

c) computed maintained

7.11.3 LIMS shall

a) be protected

b) safeguard

c) operated complies with lab spec

d) maintained

e) recording system failure

Issue date: 7 May 2018 Page 10 of 13

GAP ANALYSIS

MS ISO/IEC 17025:2017

Disclaimer: This gap analysis is only meant as a reference. It may not include all

the requirements of MS ISO/IEC 17025:2017

MS ISO/IEC 17025:2017 MS ISO/IEC 17025:2005 Remark

7.11.5 manual, reference data

available to personnel

7.11.6 calculation/data transfer

checked systematic manner (similar

5.4.7.1)

8.2 Management system 4.2 Management system Lab still has to

documentation establish, document

4.2.1 System communicate, and maintain

8.2.1 System acknowledged and understood, available, implemented policies and

implemented all levels (similar 4.2.1) objectives for the

4.2.2 i) to have quality manual fulfillment of

8.2.2 – policy and objectives (REMOVED), ii) objectives competence,

addresses competency, impartiality (CHANGES), iii) statement of quality impartiality and

and consistent operation (NEW) policy...(CHANGES) consistent operation

4.2.5 – i) quality manual to reference to of the lab as stated

8.2.3 evidence of commitment supporting procedure, ii) structure of in clause 8.2.1 and

(similar 4.2.3) documentation (REMOVED) 8.2.2.

4.2.6 – role and responsibility of QM

8.2.4 document linked (similar 4.2.5) and TM

4.2.7 – planned changes ensure

8.2.5 personnel accesses document integrity

(similar 4.2.2 d)

8.3 Control of management 4.3 Document controlled Refer note 8.3.1-

system documents documents means

4.3.1 – procedure to control all policy statements,

8.3.1 controlled all document document (REMOVED) procedures,

specifications,

8.3.2 ensure: 4.3.2.1 – all docs to be review and manufacturer’s

a) approved prior to issue approved (REMOVED “review”), instructions,

(similar 4.3.2.1) established master list (REMOVED), .... calibration tables,

b) periodic review (similar 4.3.2.2 b) charts, text books,

c) changes identified (similar 4.3.2.2 procedure ensure... posters, notices,

4.3.3.2) a) memoranda,

d) available for use and distribution b) drawings, plans, etc.

is controlled

e) uniquely identified (similar 4.3.2.3 – uniquely identified of all

4.3.2.3) document (REMOVED other part of

4.3.2.3)

4.3.3.1 – changes of document to be

review and approved

4.3.3.2 – identified new text

Issue date: 7 May 2018 Page 11 of 13

GAP ANALYSIS

MS ISO/IEC 17025:2017

Disclaimer: This gap analysis is only meant as a reference. It may not include all

the requirements of MS ISO/IEC 17025:2017

MS ISO/IEC 17025:2017 MS ISO/IEC 17025:2005 Remark

8.4 Control of records 4.13 control of records

Technical records

8.4.1 establish and retain legible 4.13.1.1 maintain procedure (removed) covered under 7.5.

records to demonstrate fulfilment of

the requirements in this document 4.13.1.4 procedure to protect and back-

(NEW) up (REMOVED)

8.4.2 implement control need

identification etc. Control accesses 4.13.2.3 mistake occur not

and readily available erased...(similar to technical records

7.5.2)

8.5 Action to address risk and

opportunity (NEW)

8.5.1 consider risk and opportunity

associated.

8.5.2

a) action plan to address risk and

opportunity

b) -implement action into

management system

-evaluate effectiveness

8.5.3 action taken proportional

8.6 Improvement 4.10 Improvement

8.6.1 identify improvement continually improve system Services to

customer 4.7 moved

8.6.2 customers feedback and to 7.1.7 and 8.6.2

analysis (similar to 4.7.2)

8.7 Corrective action 4.11 Corrective action Improve PDCA

approach

8.7.1 when NCR occurs, shall: 4.11.1 - policy and procedure

a) react the nonconformity (REMOVED),

-control and correct

-address consequences 4.11.2 – cause analysis

b) evaluate to eliminate the cause 4.11.3 – select corrective action,

-review and analysis eliminate problem, prevent recurrence

-determining the course

-determining if similar NCRs exist or 4.11.4 monitoring of corrective action-

potentially (NEW) ensure effective

Issue date: 7 May 2018 Page 12 of 13

GAP ANALYSIS

MS ISO/IEC 17025:2017

Disclaimer: This gap analysis is only meant as a reference. It may not include all

the requirements of MS ISO/IEC 17025:2017

MS ISO/IEC 17025:2017 MS ISO/IEC 17025:2005 Remark

c) implement action 4.11.5 Additional audit (REMOVED)

d) review effectiveness

e) update risk and opportunity (if

necessary) (NEW)

f) changes system (if necessary)

(NEW)

8.8 Internal audit 4.14 Internal audit Reminder:

All lab activities shall

8.8.1 planned interval (4.14.1) 4.14.1 be carried out by

i) predetermined schedule competent and

8.2.2 (CHANGED), impartial personnel

a) audit programme (NEW) ii) procedure (REMOVED), based on 6.2.1.

(frequency, method, responsibility... iii) qualified personnel (covered in

reporting (audit report)… including 6.2.1) Audit method:

result previous audit) iv) independent (covered 6.2.1) review document,

b) define audit criteria and scope. record, interview,

c) report to management (NEW) witnessing etc.

d) undue delay (timely corrective

action 4.14.2) Frequency at least

e) retain record (similar 4.14.3) once in 12 months

(SAMM Circular

4/2017)

8.9 Management review 4.15 Management review

-input & output of

8.9.1 planned interval (similar 4.15.1 ...predetermined schedule review

4.15.1) (CHANGED), procedure (REMOVED) -inputs related

information a) - o)

8.9.2 inputs have 15 items. Input item (8):

-report from managerial and Frequency at least

6 NEW items: supervisory (REMOVED) once in a year

a) changes (internal, external issue) (SAMM Circular

b) fulfillment of objectives 4.15.2 .....agreed time scale 4/2017)

d) status from previous meeting (REMOVED)

i) .... + personnel feedback

l) adequacy of resources

m) result of risk identification

Issue date: 7 May 2018 Page 13 of 13

You might also like

- FLEXUserManual PDFDocument356 pagesFLEXUserManual PDFalamahmad768100% (1)

- ISO-CASCO - ISO-IEC 17043-2023., Conformity Assessment - General Requirements For Proficiency TestingDocument28 pagesISO-CASCO - ISO-IEC 17043-2023., Conformity Assessment - General Requirements For Proficiency Testingabdelhafid0% (1)

- Decision Rule SopDocument3 pagesDecision Rule SopNageswara rao100% (1)

- FMT 09 - Management Review (IS 17025-2017) VITDocument2 pagesFMT 09 - Management Review (IS 17025-2017) VITSrirevathi Balapattabi100% (2)

- ISO 17025.2017 Management System TemplateDocument14 pagesISO 17025.2017 Management System TemplateDrAdel A. Elbaset50% (2)

- LQMS Exercise - 1Document2 pagesLQMS Exercise - 1Saravanan P100% (2)

- Lesson 12 15finalsDocument25 pagesLesson 12 15finalsREIMOND VINCE MENDOZANo ratings yet

- G133 - A2LA Guide For Establishing Proficiency Testing Plans-23603-1Document9 pagesG133 - A2LA Guide For Establishing Proficiency Testing Plans-23603-1Alberto Garcia100% (1)

- TOTL-SP02 Factilities and Environmental Conditions ProcedureDocument9 pagesTOTL-SP02 Factilities and Environmental Conditions ProcedureahmedNo ratings yet

- 04 Internal Audit ProceduresDocument4 pages04 Internal Audit ProceduresReama QumsanNo ratings yet

- Technical Requirement For ISO 17025-2005-SanasDocument11 pagesTechnical Requirement For ISO 17025-2005-Sanasyouni_2005No ratings yet

- ImpartialityDocument2 pagesImpartialitysujud100% (2)

- ISO 170252017 RequirementDocument6 pagesISO 170252017 RequirementAkkiNo ratings yet

- 4.4 Review of Requests, Tenders and ContractsDocument1 page4.4 Review of Requests, Tenders and ContractsGajaNand MallickNo ratings yet

- Selection, Verification and Validation of MethodsDocument47 pagesSelection, Verification and Validation of MethodsaloediyahNo ratings yet

- Omnex Internal Auditor Training For ISO 17025 - 2017Document1 pageOmnex Internal Auditor Training For ISO 17025 - 2017allaboutfreeNo ratings yet

- ISO 17025 SimplifiedDocument1 pageISO 17025 Simplifiedvasudeva yasas100% (1)

- Eurolab Handbook Iso Iec 17025 2017Document32 pagesEurolab Handbook Iso Iec 17025 2017Ali ZafarNo ratings yet

- Externally Provided Products and Services ChecklistDocument3 pagesExternally Provided Products and Services Checklistcosmicbunny100% (1)

- RiskAssessment Nov2013Document7 pagesRiskAssessment Nov2013Rama KrishnaNo ratings yet

- LINK1041 Operators ManualDocument155 pagesLINK1041 Operators ManualOli VierNo ratings yet

- Roche Elecsys 2010 User GuideDocument504 pagesRoche Elecsys 2010 User Guidesazunax63% (16)

- Self Assessment ChecklistDocument22 pagesSelf Assessment ChecklistjoshuaNo ratings yet

- Facilities and Environmental ConditionsDocument3 pagesFacilities and Environmental ConditionsneramopNo ratings yet

- CookBook 19 Impartiality and Confidentiality - 10-2018 PDFDocument2 pagesCookBook 19 Impartiality and Confidentiality - 10-2018 PDFJacek SobczykNo ratings yet

- Kejriwal Castings Limited (Testing Lab, DGP) : Qualty Management System Procedure For ImpartialityDocument3 pagesKejriwal Castings Limited (Testing Lab, DGP) : Qualty Management System Procedure For ImpartialityAniruddha ChatterjeeNo ratings yet

- EUROLAB Cook Book - Doc No 0 Tool For Transition From ISO 17025 2005 To 2017Document23 pagesEUROLAB Cook Book - Doc No 0 Tool For Transition From ISO 17025 2005 To 2017Eby Joy0% (2)

- ISO 17025 Risk Management Example: December 2019Document6 pagesISO 17025 Risk Management Example: December 2019paeg6512100% (1)

- ISO 17025-2017 Quality Manual TestingDocument69 pagesISO 17025-2017 Quality Manual Testinglabn6446100% (1)

- Sadcas TR 14 - Sadcas Policy - Iso Iec 17025-2017 TransitionDocument10 pagesSadcas TR 14 - Sadcas Policy - Iso Iec 17025-2017 TransitionSuresh KumarNo ratings yet

- ISO 17025 ChecklistDocument29 pagesISO 17025 ChecklistJuan Camilo PachiNo ratings yet

- QSP-001633 - Rev 04 - Luminus Testing Laboratory Quality Manual207Document34 pagesQSP-001633 - Rev 04 - Luminus Testing Laboratory Quality Manual207SureshNo ratings yet

- FINAL EXAMINATION (Internal Auditor Course - ISO 17025)Document5 pagesFINAL EXAMINATION (Internal Auditor Course - ISO 17025)Ranjit ThakurNo ratings yet

- ORA-LAB.5.3 Facilities and Environmental Conditions (v02)Document9 pagesORA-LAB.5.3 Facilities and Environmental Conditions (v02)allysa almagroNo ratings yet

- ISO/IEC 17025:2017: - General Requirements For The Competence of Testing and Calibration LaboratoriesDocument31 pagesISO/IEC 17025:2017: - General Requirements For The Competence of Testing and Calibration LaboratoriesObak Prithibi100% (1)

- Review of Requests, Tenders and ContractsDocument2 pagesReview of Requests, Tenders and ContractsMohamed GaballahNo ratings yet

- 07 - Risk Based Approach 17025Document10 pages07 - Risk Based Approach 17025सागर फुकटNo ratings yet

- Final Draft of Nabl 103Document51 pagesFinal Draft of Nabl 103prasadnn2001No ratings yet

- ISO 17025 ManualDocument7 pagesISO 17025 Manualvinodkvatsa50% (2)

- Iso-17025-2017-Lab Quality Manual of Nutracential & Functional FoodDocument9 pagesIso-17025-2017-Lab Quality Manual of Nutracential & Functional FoodrohitNo ratings yet

- Iso 17025Document6 pagesIso 17025Khurram Shehzad100% (1)

- Facilities and Environmental Conditions (Linked To Vol. III, Sec. 2) PDFDocument8 pagesFacilities and Environmental Conditions (Linked To Vol. III, Sec. 2) PDFimran shaukat100% (1)

- QSP 06 Control of Non Conforming ProductDocument3 pagesQSP 06 Control of Non Conforming Productkmvimal36No ratings yet

- Quality ManualDocument7 pagesQuality ManualFA KhanNo ratings yet

- ORA-LAB.5.5.1 Equipment Records v02Document6 pagesORA-LAB.5.5.1 Equipment Records v02Ayman Ali100% (2)

- Section 8.5 of ISO/IEC 17025:2017 Risks and OpportunitiesDocument3 pagesSection 8.5 of ISO/IEC 17025:2017 Risks and OpportunitiesVasaNo ratings yet

- Course Summary ISO 17025Document7 pagesCourse Summary ISO 17025Umer AhsanNo ratings yet

- QSP 02 - 6.2 - Competance and Training - IEC 17025-17, Cl. No. 6.2.5, Pg. 4 OBSDocument3 pagesQSP 02 - 6.2 - Competance and Training - IEC 17025-17, Cl. No. 6.2.5, Pg. 4 OBSV Vijay100% (1)

- ORA-LAB - QM ORA Laboratory Manual of Quality Policies (v03)Document47 pagesORA-LAB - QM ORA Laboratory Manual of Quality Policies (v03)Ahmad shayebNo ratings yet

- Laboratory Housekeeping: 1.0 PurposeDocument3 pagesLaboratory Housekeeping: 1.0 PurposeAbu MuazNo ratings yet

- Water Quality. Sampling. Guidance On Quality Assurance and Quality Control of Environmental Water Sampling and Handling - Libgen - LiDocument46 pagesWater Quality. Sampling. Guidance On Quality Assurance and Quality Control of Environmental Water Sampling and Handling - Libgen - Lilouis bothe100% (1)

- General Accreditation Criteria: Metrological Traceability PolicyDocument24 pagesGeneral Accreditation Criteria: Metrological Traceability Policyarli krisnandika100% (1)

- Iso15189 2022checklistDocument42 pagesIso15189 2022checklistReema Md100% (1)

- PROCEDURE For Non Conforming WorkDocument1 pagePROCEDURE For Non Conforming WorkGopal Mallick100% (2)

- ALACC Method VerificationDocument10 pagesALACC Method VerificationVasu Raja100% (1)

- PR-GM 09 Identification and Control Ofnon Conformance ProcedureDocument5 pagesPR-GM 09 Identification and Control Ofnon Conformance ProcedureFULGENCE RUHARARANo ratings yet

- Quality Manual CalibrationDocument30 pagesQuality Manual CalibrationsaidvaretNo ratings yet

- Corrective And Preventative Action A Complete Guide - 2020 EditionFrom EverandCorrective And Preventative Action A Complete Guide - 2020 EditionNo ratings yet

- Nominal Cross-References 17025 To 9001 PDFDocument3 pagesNominal Cross-References 17025 To 9001 PDFwhitemithrilNo ratings yet

- IMS ManualDocument62 pagesIMS ManualKimpoh ChaiNo ratings yet

- Iso17025 ChecklistDocument28 pagesIso17025 ChecklistBhavna ShahNo ratings yet

- Laboratory Assessment ChecklistDocument28 pagesLaboratory Assessment ChecklistPanneer Selvam100% (2)

- Turtle SampleDocument7 pagesTurtle Samplerodolfo1649No ratings yet

- An Audit Questionnaire That Examines Specifically The Management of Technical Activities Clauses in Iso 15189Document7 pagesAn Audit Questionnaire That Examines Specifically The Management of Technical Activities Clauses in Iso 15189Rekha NirwanNo ratings yet

- F ISO 17025Document51 pagesF ISO 17025Shishir MaharjanNo ratings yet

- Paper #37CDocument6 pagesPaper #37CDrAdel A. ElbasetNo ratings yet

- A Modified Perturb and Observe Algorithm For Maximum Power Point Tracking of Photovoltaic System Using Buck-Boost ConverterDocument19 pagesA Modified Perturb and Observe Algorithm For Maximum Power Point Tracking of Photovoltaic System Using Buck-Boost ConverterDrAdel A. ElbasetNo ratings yet

- 276 FinalDocument6 pages276 FinalDrAdel A. ElbasetNo ratings yet

- Abd El Sattar8Document15 pagesAbd El Sattar8DrAdel A. ElbasetNo ratings yet

- Paper Ijetae Paper Template 14-05-2014Document10 pagesPaper Ijetae Paper Template 14-05-2014DrAdel A. ElbasetNo ratings yet

- AmalDocument25 pagesAmalDrAdel A. ElbasetNo ratings yet

- 1 PB - 3Document13 pages1 PB - 3DrAdel A. ElbasetNo ratings yet

- 1 s2.0 S1876610217365165 MainDocument6 pages1 s2.0 S1876610217365165 MainDrAdel A. ElbasetNo ratings yet

- بيان التدرج الوظيفي PDFDocument1 pageبيان التدرج الوظيفي PDFDrAdel A. ElbasetNo ratings yet

- Smoothing of Grid-Connected Wind-Diesel Power Output Using Energy Capacitor SystemDocument6 pagesSmoothing of Grid-Connected Wind-Diesel Power Output Using Energy Capacitor SystemDrAdel A. ElbasetNo ratings yet

- Biorad CFX Maestro User GuideDocument256 pagesBiorad CFX Maestro User GuideDenis FreedmanNo ratings yet

- Optidist: Benchmark in Atmospheric Distillation TestingDocument4 pagesOptidist: Benchmark in Atmospheric Distillation TestingAnonh AdikoNo ratings yet

- Computer - System - Validation - An - Integral - Part - For - Effective - Laboratory - Automation - Service 2Document12 pagesComputer - System - Validation - An - Integral - Part - For - Effective - Laboratory - Automation - Service 2Nitin KashyapNo ratings yet

- Academic Research Record-KeepingDocument6 pagesAcademic Research Record-KeepingYongSing YouNo ratings yet

- Thermo Scientific LIMS: A Solution For Water and Environmental Testing LaboratoriesDocument4 pagesThermo Scientific LIMS: A Solution For Water and Environmental Testing Laboratoriesbudi_alamsyahNo ratings yet

- V UnitDocument50 pagesV UnitB.MAHAALAKSHMINo ratings yet

- Clarity Lims PDFDocument18 pagesClarity Lims PDFCesar Arturo Marino SaavedraNo ratings yet

- 22MSC-LIMS Product SummaryDocument2 pages22MSC-LIMS Product SummaryEmad AliNo ratings yet

- Project Final Report FinalDocument35 pagesProject Final Report FinalRITESH JANGIDNo ratings yet

- Automation in Diagnostic MicrobiologyDocument3 pagesAutomation in Diagnostic Microbiologymicrobehunter007No ratings yet

- DocumentationDocument52 pagesDocumentationthanh_cdt01No ratings yet

- Simple and Accurate Measurements: For Results at Your FingertipsDocument16 pagesSimple and Accurate Measurements: For Results at Your FingertipsGenlajt DOOELNo ratings yet

- Job Description Officer QC Srirangs ReplacementDocument2 pagesJob Description Officer QC Srirangs ReplacementSiddhesh ShirodkarNo ratings yet

- Reference List 2009Document51 pagesReference List 2009Đặng Trung AnhNo ratings yet

- RT PCR Solutions - Bulletin - 6629Document8 pagesRT PCR Solutions - Bulletin - 6629dwin05No ratings yet

- Guide For Using LOINC Microbiology Terms: Logical Observation Identifiers Names and Codes (LOINC )Document124 pagesGuide For Using LOINC Microbiology Terms: Logical Observation Identifiers Names and Codes (LOINC )Ashwini KalantriNo ratings yet

- Lims Sap Integration PDF FreeDocument24 pagesLims Sap Integration PDF FreePavan ReddyNo ratings yet

- 2 1 6 072016 enDocument29 pages2 1 6 072016 enbaglamaNo ratings yet

- Laboratory Information Management Systems (Lims) Deployment: Project Charter ExampleDocument5 pagesLaboratory Information Management Systems (Lims) Deployment: Project Charter ExampleJoão CarvalhoNo ratings yet

- 24.7 Brochure PDFDocument4 pages24.7 Brochure PDFLilian Carolina Loreto MachadoNo ratings yet

- Vitro S 3600Document138 pagesVitro S 3600Sidney33% (3)

- Lesson 10 and 11: Laboratory Information Management System and Other Hospital Information SystemsDocument4 pagesLesson 10 and 11: Laboratory Information Management System and Other Hospital Information SystemsAngel Kaye FabianNo ratings yet

- Laboratory Information System PDFDocument96 pagesLaboratory Information System PDFTangled LimNo ratings yet

- Impulse HmisDocument6 pagesImpulse HmisjohnNo ratings yet

- Raul Sarmiento - ITDocument2 pagesRaul Sarmiento - ITChirantar KumarNo ratings yet