Professional Documents

Culture Documents

Reinforcement Steel

Reinforcement Steel

Uploaded by

Navneet Soni0 ratings0% found this document useful (0 votes)

252 views7 pagesReinforcement steel, also called rebar, is steel bars or mesh added to concrete to increase its tensile strength. Concrete is strong under compression but weak in tension, and rebar significantly improves the tensile strength of the overall structure. Reinforcement steel is tested for rolling margin and tensile strength to ensure it meets Indian standards for diameter, yield strength, and other material properties necessary to properly reinforce concrete structures.

Original Description:

hrh

Copyright

© © All Rights Reserved

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentReinforcement steel, also called rebar, is steel bars or mesh added to concrete to increase its tensile strength. Concrete is strong under compression but weak in tension, and rebar significantly improves the tensile strength of the overall structure. Reinforcement steel is tested for rolling margin and tensile strength to ensure it meets Indian standards for diameter, yield strength, and other material properties necessary to properly reinforce concrete structures.

Copyright:

© All Rights Reserved

0 ratings0% found this document useful (0 votes)

252 views7 pagesReinforcement Steel

Reinforcement Steel

Uploaded by

Navneet SoniReinforcement steel, also called rebar, is steel bars or mesh added to concrete to increase its tensile strength. Concrete is strong under compression but weak in tension, and rebar significantly improves the tensile strength of the overall structure. Reinforcement steel is tested for rolling margin and tensile strength to ensure it meets Indian standards for diameter, yield strength, and other material properties necessary to properly reinforce concrete structures.

Copyright:

© All Rights Reserved

You are on page 1of 7

REINFORCEMENT STEEL

Reinforcement Steel is a steel bar or mesh of steel wires used as a tension

device in reinforced concrete and reinforced masonry structures to

strengthen and aid the concrete under tension.

Concrete is strong under compression, but has weak tensile strength.

Rebar significantly increases the tensile strength of the structure.

ADVANTAGES OF USING REINFORCEMENT STEEL WITH CONCRETE

Steel is ductile material as compared to brittle nature of concrete, thus

stopping any sudden failure.

Modulus of Rigidity remains same for tension and compression, in case

of steel.

Coefficient of Thermal Expansion of both steel and concrete is same.

(12*10^-6 /degree Celsius)

Steel as a material has a very good bonding strength with concrete.

Steel and Concrete can stay together for more than 100 years.

Steel is recyclable.

Sizes and Grades Of Reinforcement Steel

Rebars are available in the following grades as per IS:1786-2008

FE 415

FE 415D

FE 415S

FE 500

FE 500D

FE 500S

FE 550

FE 550D

FE 600.

Indian Standard Rebar sizes

10MM

12MM

16MM

20MM

25MM

28MM

32MM

36MM

40MM

50MM

Indian Standard Codes on Reinforcement Details

Below enlisted are the IS codes that is recommended for reinforcement

detailing and guidance:

– IS:432- 1982: Mild steel & medium tensile steel bars and hard

drawn steel wires for concrete reinforcement : Part-II -Hard drawn

steel wire.

– IS:1786-2008:Specification for High strength deformed steel bars

and wires for concrete reinforcement.

– IS:2502-1963: Code of practice for bending & fixing of bars for

concrete reinforcement.

– IS:2751 -1998: Recommended practice for welding of mild steel

plain & deformed bars for reinforced construction.

– IS:5525 -1969: Recommendation for detailing of reinforcement in

reinforced concrete works.

– IS:9077 -1979: Code of practice for corrosion protection of steel

reinforcement in RB & RCC construction.

– SP:34 -1987: Handbook on concrete reinforcement detailing

TESTS OF REINFORCEMENT STEEL

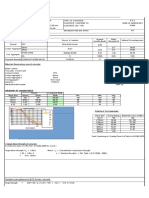

1. Rolling margin test

It is deviation of a actual unit weight to that of standard unit weight of

Steel as per IS standard.

Rolling Margin is calculated as under:-

Total Weight of Bars (Dia wise) / Total Running Metre of Bars =

Actual Sectional Weight of bars.

Compare sectional weight with Standard IS Weight.

Weight as per IS Standard = Dia x Dia / 162.

Rolling margin is the difference between the theoretical and actual

weight of steel. This is because of the die which is used for casting

of rebars.

Frequency of test is :

One sample for each lot received on site

One sample consist of 3 number of bars of atleast 0.5m length.

Relevant IS code: 1786-2008.

Neccesity of the Test:

During the process of manufacturing of steel bars:

Dye used for taking out steel bars of certain diameter have equal

diameter to that of steel bar. But this dye gets eroded due to

continuously usage of it and acquires more than the exact diameter

size.

Hence, when builder or contractor orders required quantity of steel

bars for slab or beams for construction. Then they get less numbers

of bars in bundles than the required quantity (let's take 13 bars of

10mm diameter)

Even though bundle of 10mm diameter having 13 nos of bars

having same weight to that of 12 nos. Of bars of 10.32mm [used

dye got eroded] diameter in each bundle.

Which is serious problem for builders or contractors as they

requires 13 bars in a girder beam supposed. For every 13th bar they

have to take out from the next bundle (as they received only 12

bars in a bundle of 10mm diameter). So due to this condition there

will be shortage of bars of 10mm diameter for next girder beam.

BIS (Bureau of Indian Standard) rolling margin of limits in steel:

• 8mm diA. Rolling Margin limit is +-7%

• 10mm diA. Rolling Margin limit is +-7%

• 12mm diA. Rolling Margin limit is +-5%

• 16mm diA. Rolling Margin limit is +-5%

• 20mm diA. Rolling Margin limit is +-3%

• 25mm diA. Rolling Margin limit is +-3%

• 32mm diA. Rolling Margin limit is +-3%

2. TENSILE TEST:

• Tensile test : No.s of rebar sample =4, length of rebar sample =about 600

mm.

• Inputs available :

Length of sample = L

Weight of sample = w

A = w/0.00785L mm2

[As per Cl. 6.3.1 of IS 1786-2008 given at right]

• Gauge length for a rebar of diameter D mm = 5D mm

• The rebar sample is marked at (5D/2) mm locations.

• Method:

Load vs Deflection Curve:

• After plotting the above Load Deflection Curve, we consider yield point

YP = lower YP, in Newton (N).

• Hence, yield stress YS = YP / A , in Mpa

• The value thus obtained must comply with 0.2 percent proof stress/yield

stress as given in Table 3, sl. No. i and ii of IS 1786-2008 amend 1 given

below:

• From curve, ultimate tensile point UTP = Max load, in Newton (N).

• Hence, ultimate tensile stress TS = UTP / A, in Mpa

The value thus obtained must comply with TS/YS ratio and minimum

value of tensile strength as given in Table 3, sl. No. iii of IS 1786-2008

amend 1 as given below:

You might also like

- Ipl Quiz QuestionsDocument9 pagesIpl Quiz QuestionsNavneet SoniNo ratings yet

- Repair Standard - SP131 May 2014Document29 pagesRepair Standard - SP131 May 2014fran_b_s100% (1)

- Approval Chit (Work)Document1 pageApproval Chit (Work)Julia IgingNo ratings yet

- New Holland t7030 t7040 t7050 t7060 Tractor PDF Service ManualDocument3,061 pagesNew Holland t7030 t7040 t7050 t7060 Tractor PDF Service ManualJose Vinicio50% (4)

- GEOGREEN BlanketsDocument13 pagesGEOGREEN Blanketsshravan38100% (2)

- Name of System - LGSF With Fiber Cement Board On Both Sides Using Glass Wool InsulationDocument7 pagesName of System - LGSF With Fiber Cement Board On Both Sides Using Glass Wool InsulationNishan GajurelNo ratings yet

- Project Management: Interview Questions With AnswersDocument6 pagesProject Management: Interview Questions With AnswersNavneet Soni100% (2)

- Sample WBS EPC ProjectDocument7 pagesSample WBS EPC ProjectNavneet Soni100% (1)

- Foundation Design For ChimneyDocument5 pagesFoundation Design For ChimneyAmit100% (2)

- Ansi Asabe Ep545 Mar1995 (r2010)Document10 pagesAnsi Asabe Ep545 Mar1995 (r2010)StephanNo ratings yet

- Bitumen Extraction TestsDocument17 pagesBitumen Extraction Testsmzaim100% (1)

- Bartec Datasheet PDS001rev24 - BF PDFDocument26 pagesBartec Datasheet PDS001rev24 - BF PDFSaidi NadjimNo ratings yet

- Rolltec Coupler BrochureDocument4 pagesRolltec Coupler BrochureMohammad Aasimuddin100% (1)

- RealEstate-STP Real EstateDocument143 pagesRealEstate-STP Real Estaterakesh patiNo ratings yet

- MBT CouplersDocument10 pagesMBT Couplersboris1516No ratings yet

- Pour Card: Correction For Moisture Content For DLCDocument1 pagePour Card: Correction For Moisture Content For DLCQuality JamNo ratings yet

- Hardened ConcreteDocument40 pagesHardened ConcreteHVRANANo ratings yet

- IS 16172 2014 Coupler Splice BarDocument16 pagesIS 16172 2014 Coupler Splice BarMayank KumarNo ratings yet

- Pile Load Test Procedure-3Document6 pagesPile Load Test Procedure-3S GoudaNo ratings yet

- Book 1Document16 pagesBook 1ernarendersainiNo ratings yet

- HKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH EkudDocument16 pagesHKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH EkudRajesh GangwalNo ratings yet

- Reinforcement Steel WorksDocument28 pagesReinforcement Steel WorksPooja PawarNo ratings yet

- Core Cutter TestDocument6 pagesCore Cutter TestMian M KhurramNo ratings yet

- Plaster Masonry TolerancesDocument8 pagesPlaster Masonry TolerancesGhayas JawedNo ratings yet

- Concrete Mix DesignDocument5 pagesConcrete Mix DesignshafeekNo ratings yet

- TDS Nitocote EM 300 India2 PDFDocument2 pagesTDS Nitocote EM 300 India2 PDFAarish Khan100% (1)

- 2019.03.27 QA-QC B&CI Piles Hand Out 1 PDF - Dr. FawziDocument137 pages2019.03.27 QA-QC B&CI Piles Hand Out 1 PDF - Dr. FawziNiroshani RajapakshaNo ratings yet

- Concrete Mix DesignDocument7 pagesConcrete Mix DesignNathan AsinasNo ratings yet

- Andhra Pradesh Class 1 Registration Certificate FormatDocument2 pagesAndhra Pradesh Class 1 Registration Certificate Formatgsatyasrikanth0% (3)

- Fibrous Materials Reinforced Composites PDFDocument25 pagesFibrous Materials Reinforced Composites PDFyigitilgazNo ratings yet

- 54M Height RCC Chimney General ArrangementDocument3 pages54M Height RCC Chimney General ArrangementMoorthy SSIDCNo ratings yet

- Concrete Mix Design - M60 Grade of Concrete (OPC 53 Grade)Document2 pagesConcrete Mix Design - M60 Grade of Concrete (OPC 53 Grade)greatpicNo ratings yet

- Is 16720 Product Manual Fuel AshDocument7 pagesIs 16720 Product Manual Fuel AshKolkata PIUNo ratings yet

- M25 (PPC)Document2 pagesM25 (PPC)Jagdev GuleriaNo ratings yet

- Rebound Hammer Test (Astm C 805-02) : Witnessed By: Conducted By: Noted byDocument1 pageRebound Hammer Test (Astm C 805-02) : Witnessed By: Conducted By: Noted byJohn Errol Saldevar MarcosNo ratings yet

- Proedure For PlasteringDocument4 pagesProedure For PlasteringAkhilesh KumarNo ratings yet

- SunanodeDocument2 pagesSunanodeKaleeswari GNo ratings yet

- Nitobond EP2Document4 pagesNitobond EP2Sanjeev KumarNo ratings yet

- Coupler PresentationDocument70 pagesCoupler PresentationSmart ShivaNo ratings yet

- Semiemperical Estimate of Pile Capacity Conforming Aashto Lrfd-2007Document1 pageSemiemperical Estimate of Pile Capacity Conforming Aashto Lrfd-2007civixxNo ratings yet

- Disclosure To Promote The Right To InformationDocument17 pagesDisclosure To Promote The Right To Informationchannakeshava pandurangaNo ratings yet

- Repair and Strengthening MaterialsDocument10 pagesRepair and Strengthening MaterialsabdulkaderNo ratings yet

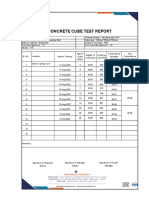

- Cube Test ReportDocument1 pageCube Test ReportShubham MareNo ratings yet

- Kelco-Crete DG-FDocument3 pagesKelco-Crete DG-FPelleNo ratings yet

- Mac GuideDocument16 pagesMac GuideColin SillmanNo ratings yet

- Mix Design (Aci - Method)Document14 pagesMix Design (Aci - Method)Bengkulu BetonNo ratings yet

- Couplers PaperDocument6 pagesCouplers PaperPiyush BhardwajNo ratings yet

- Company Profile: Japan'S LeadingDocument50 pagesCompany Profile: Japan'S LeadingnirmalNo ratings yet

- Nitobond AR Std.Document4 pagesNitobond AR Std.Dinesh Kumar PatelNo ratings yet

- Prefabricated Structures - Exam, Viva, Interview Questions With Solution For Civil EngineeringDocument15 pagesPrefabricated Structures - Exam, Viva, Interview Questions With Solution For Civil Engineeringनोलराज पौडेल100% (1)

- Lenton Mech Coupler Lt0962-1Document15 pagesLenton Mech Coupler Lt0962-1lolo1001No ratings yet

- TDS - Polyalk CP 293+Document1 pageTDS - Polyalk CP 293+Anonymous ouZFaSBRNo ratings yet

- Paper On Concrete Mix DesignDocument5 pagesPaper On Concrete Mix DesignZac MwebNo ratings yet

- Larsen & Toubro Limited Construction Heavy Civil Infrastructure IcDocument4 pagesLarsen & Toubro Limited Construction Heavy Civil Infrastructure IcAyush GuptaNo ratings yet

- IS 2386 Part-1 1963 RA 2021Document23 pagesIS 2386 Part-1 1963 RA 2021Palani.MNo ratings yet

- Concrete Mix Proportioning Using Micro SilicaDocument6 pagesConcrete Mix Proportioning Using Micro SilicaGandhi HammoudNo ratings yet

- Chapter-I-Soil Investigation or Soil ExplorationDocument54 pagesChapter-I-Soil Investigation or Soil ExplorationVijaykumar NagnaikNo ratings yet

- Paver Block DesignDocument1 pagePaver Block DesignSonti KumarNo ratings yet

- DS - 645 - Pro Anticarb HB Elastomeric CoatingDocument2 pagesDS - 645 - Pro Anticarb HB Elastomeric CoatingRay EngineeringNo ratings yet

- Statement For Ordinary and Hard RockDocument4 pagesStatement For Ordinary and Hard RockPrasanta ParidaNo ratings yet

- Rockfall Protection Netting: Galvanized & Polymer Coated (10x12)Document2 pagesRockfall Protection Netting: Galvanized & Polymer Coated (10x12)Sudipto PaulNo ratings yet

- MoRTH Sec 400Document9 pagesMoRTH Sec 400mano3mmmNo ratings yet

- Solid BlocksDocument6 pagesSolid BlocksShesha ShayanNo ratings yet

- High Performance Concrete (HPC)Document14 pagesHigh Performance Concrete (HPC)badr amNo ratings yet

- Reinforcement: Industrial Training Report Tudawe Brothers LimitedDocument8 pagesReinforcement: Industrial Training Report Tudawe Brothers Limitedymanfas100% (1)

- Steel Reinforcements: Applications, Uses, and SpecsDocument11 pagesSteel Reinforcements: Applications, Uses, and SpecsMa. Christina BangngayNo ratings yet

- The Requirements Needed in Material and DesignDocument26 pagesThe Requirements Needed in Material and DesignJubillee MagsinoNo ratings yet

- Civil Engineering Reinforcement NewDocument29 pagesCivil Engineering Reinforcement Newsri balajee0% (1)

- Ma Slows Hierarchy of NeedDocument36 pagesMa Slows Hierarchy of NeedNavneet SoniNo ratings yet

- MathsKG II 1 - 1Document1 pageMathsKG II 1 - 1Navneet SoniNo ratings yet

- Interview Email TemplateDocument7 pagesInterview Email TemplateNavneet SoniNo ratings yet

- Sample Quality Control KPIs For Construction ProjectDocument2 pagesSample Quality Control KPIs For Construction ProjectNavneet Soni100% (4)

- Bidding StrategiesDocument17 pagesBidding StrategiesNavneet Soni100% (1)

- Project Evaluation & Review Techniques: CPM Du Pont Corporation and Remington-Rand)Document87 pagesProject Evaluation & Review Techniques: CPM Du Pont Corporation and Remington-Rand)Navneet SoniNo ratings yet

- Stunning Floral Inspired Religious Building-Lotus TempleDocument7 pagesStunning Floral Inspired Religious Building-Lotus TempleNavneet SoniNo ratings yet

- Parcomp PDFDocument94 pagesParcomp PDFNavneet SoniNo ratings yet

- Excel KolwanDocument2 pagesExcel KolwanNavneet SoniNo ratings yet

- Safety Plan: A) Personal Protective Equipment (Ppe)Document4 pagesSafety Plan: A) Personal Protective Equipment (Ppe)Navneet SoniNo ratings yet

- Environmental Initiatives in Nagpur Metro - IricenDocument10 pagesEnvironmental Initiatives in Nagpur Metro - IricenNavneet SoniNo ratings yet

- Modified Academic Calendar AY15-16Document3 pagesModified Academic Calendar AY15-16Navneet SoniNo ratings yet

- Construction Quality Management (GROUP - 6) : Project: Gravity Dam Material: Reinforcement Steel Kaizen TechnologyDocument43 pagesConstruction Quality Management (GROUP - 6) : Project: Gravity Dam Material: Reinforcement Steel Kaizen TechnologyNavneet SoniNo ratings yet

- Project Planning and Control by B.C.punmia and K.K.khandelwal CivilEnggForAllDocument263 pagesProject Planning and Control by B.C.punmia and K.K.khandelwal CivilEnggForAllVinay Kashyap100% (1)

- Details of Linear Aspects in Drainge Network Analysis of Study AreaDocument2 pagesDetails of Linear Aspects in Drainge Network Analysis of Study AreaNavneet SoniNo ratings yet

- IELTS Rainwater Diagram Reported 2015 PDFDocument20 pagesIELTS Rainwater Diagram Reported 2015 PDFNavneet SoniNo ratings yet

- Introduction To Composite Materials: Mr. S. G. KulkarniDocument66 pagesIntroduction To Composite Materials: Mr. S. G. KulkarniNavneet SoniNo ratings yet

- Twisting Towers To Couple Processes in A Non-Linear WayDocument8 pagesTwisting Towers To Couple Processes in A Non-Linear WayJJNo ratings yet

- Chemistry Worksheet 1 Year 11Document8 pagesChemistry Worksheet 1 Year 11fatma.darghouth2No ratings yet

- 1 Crystallography and Mineralogi Part 1Document20 pages1 Crystallography and Mineralogi Part 1Axel HeinsonNo ratings yet

- Power Piping: ASME B31.1-2016Document7 pagesPower Piping: ASME B31.1-2016mrjn0% (1)

- Deepchand Chemicals Pvt. LTD.: Ethylene Oxide CondensatesDocument3 pagesDeepchand Chemicals Pvt. LTD.: Ethylene Oxide CondensatesUtpalNo ratings yet

- Piping QuizDocument20 pagesPiping QuizMuhammad Tamanna ButhaNo ratings yet

- Mill GrindingDocument28 pagesMill GrindingMehmet C100% (2)

- Wacuman Company Profile v2 PDFDocument8 pagesWacuman Company Profile v2 PDFJohn Leo Rosas100% (1)

- Check List Review Progress ReportDocument14 pagesCheck List Review Progress ReportErick AriestioNo ratings yet

- Advanced Chemical Engineering Thermodynamics 31 July 2016Document185 pagesAdvanced Chemical Engineering Thermodynamics 31 July 2016RashidNo ratings yet

- Pchem11e Deeper Look 02Document2 pagesPchem11e Deeper Look 02Prateek Kumar MahapatraNo ratings yet

- Solid Waste ManagementDocument4 pagesSolid Waste ManagementRuzzel CarbajalNo ratings yet

- Mod 7Document47 pagesMod 7mkpq100% (1)

- Propylene From Methanol Via Lurgi MTP ProcessDocument2 pagesPropylene From Methanol Via Lurgi MTP ProcessbobNo ratings yet

- Progress in Additive Manufacturing On New MaterialsDocument50 pagesProgress in Additive Manufacturing On New Materialsdebisi14140No ratings yet

- KAR Products - Gloss White Aerosol PaintDocument7 pagesKAR Products - Gloss White Aerosol Paintjaredf@jfelectric.comNo ratings yet

- Gas Laws: Sagana National High SchoolDocument17 pagesGas Laws: Sagana National High SchoolHelma Jabello AriolaNo ratings yet

- Boiler Materials For USC Plants IJPGC 2000Document22 pagesBoiler Materials For USC Plants IJPGC 2000pawanumarji1100% (1)

- Akulon S223-EH: Property DataDocument2 pagesAkulon S223-EH: Property DataLuciana SouzaNo ratings yet

- Detail Section of Corridor Railing Spot DetailDocument9 pagesDetail Section of Corridor Railing Spot DetaildawitgggNo ratings yet

- Ahmed, Tarek - Reservoir Engineering HandbookDocument2 pagesAhmed, Tarek - Reservoir Engineering HandbookJenzelNo ratings yet

- AHSS Joining - An Investigation of Resistance Welding Performance of AHSSDocument115 pagesAHSS Joining - An Investigation of Resistance Welding Performance of AHSSAlief PambudhiNo ratings yet

- ASTM StandardsDocument4 pagesASTM StandardsBalaji Lubricants & ChemicalsNo ratings yet