Professional Documents

Culture Documents

Guide For Steam Trap Selection

Guide For Steam Trap Selection

Uploaded by

Tsouki Tsouki0 ratings0% found this document useful (0 votes)

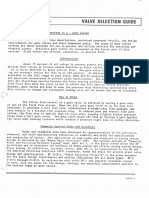

43 views1 pageTable with steam trap types per application

Original Title

Guide for Steam Trap Selection

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTable with steam trap types per application

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

43 views1 pageGuide For Steam Trap Selection

Guide For Steam Trap Selection

Uploaded by

Tsouki TsoukiTable with steam trap types per application

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 1

EXES 3-2:7-3A

Page tot STEAM TRAP APPLICATION, DESIGN EXON

Rev. 3 | April1987

DESIGN (Cont)

TABLE 2

GUIDE FOR SELECTION TYPE OF STEAM TRAP

INVERTED FLOAT

BUCKET | BIMETALLIC | BELLOWS | THERMOSTATIC | THERMODYNAMIC

SERVICE (a)(e)__ | THERMOSTATIC | THERMOSTATIC |" (a) (0) ©

‘Superheated Steam

Any Service

'00 Pounds Steam (e)

4150 Pounds ené Lower 1 1 2

Saturated Steam

Live Steam Mains

Low Pressure (20:35 Pounds) 1 1 2

High Pressure (90-180 Pounds) 1 1 2 2

600 Pounds 1 1 2 2

Supply Lines to Turbines 1 1 2 2

Supply Lines to Process |

Equipment

Low Pressure with Po > 50% Pi 1 1 2

High Pressure or Low Pressure

with Po < 50% Pi 4 1 2 2

Tracer Lines

Low Pressure with Po > 50% pi 1 1 2

High Pressure orLow Pressure |

with Po < 60% Pi 1 1 2 2

Process Rebollers and Closely 2 1 2

Controle Excrangers |

Process Heaters, Preneaters,

Kettes, Overs

Low Pressure 2 1

High Pressure 1 2

Turbine Casings Drains (4) 1 2

Storage Tank Heating Cols

o> 60% Pi 1 1 2

Po <50% Pi 1 1 2

Exhaust Steam Lines (Low Pressure)

P< 50% 1 1 2

uP > 50% Pi 1 1 2

\P — Difference between pressure at trap inlet (Pi) and trap outlet (Po).

41 First choice

2 Second choice

Notes:

(@) Inverted Bucket Traps and Flost-Thermostatc— Where intermitent operation mightesultin condensate eezing, ther

type traps shall be considered or freeze protection provides.

(©) Bellows - and float-hermastatic traps shall not be used where water hammer is expected such as tank steam heating

applications.

(©) _ Invented bucket traps should not be used where small loads would result in oss of prime.

(@) _Aliting.type trap is required for condensing turbines where exhaust steam pressure is below atmospheric.

. (@) Type of condensate removal device shail be approved by Owner's Engineer

(Steam losses inherent with thermodynamic traps shal be considered in thei application.

EXXON ENGINEERING STANDARDS

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- JHS-183 (E) 7ZPJD0559C (Ed1) SERVICE MANUALDocument120 pagesJHS-183 (E) 7ZPJD0559C (Ed1) SERVICE MANUALJose Vivar100% (3)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Module 2 Full Manual PDFDocument164 pagesModule 2 Full Manual PDFRam RajyaNo ratings yet

- Joint Communique: Flourishing Minority Nationality AreasDocument24 pagesJoint Communique: Flourishing Minority Nationality AreasTsouki TsoukiNo ratings yet

- Unite To Win Still Greater Victories: Statement of Ministry of Foreign Affairs of People's Republic of ChinaDocument23 pagesUnite To Win Still Greater Victories: Statement of Ministry of Foreign Affairs of People's Republic of ChinaTsouki TsoukiNo ratings yet

- Statement CF The Government ©F The People's Republic of OhinaDocument24 pagesStatement CF The Government ©F The People's Republic of OhinaTsouki TsoukiNo ratings yet

- Unbalanced Thrust Forces CalculationDocument4 pagesUnbalanced Thrust Forces CalculationTsouki TsoukiNo ratings yet

- Revie": - Multi-Purpose Use: T U R N I N G The HarmfulintothebeneficialDocument24 pagesRevie": - Multi-Purpose Use: T U R N I N G The HarmfulintothebeneficialTsouki TsoukiNo ratings yet

- Hdpe Pipe Wall Thickness CalculationsDocument1 pageHdpe Pipe Wall Thickness CalculationsTsouki Tsouki100% (1)

- Calculation of Closing Time of PumpsDocument1 pageCalculation of Closing Time of PumpsTsouki TsoukiNo ratings yet

- Gate Valves (From Exxon Valves Selection Guide-1982)Document1 pageGate Valves (From Exxon Valves Selection Guide-1982)Tsouki TsoukiNo ratings yet

- Control Valves & Esd Systems PDFDocument21 pagesControl Valves & Esd Systems PDFTsouki TsoukiNo ratings yet

- Orifice CalculationsDocument4 pagesOrifice CalculationsTsouki TsoukiNo ratings yet

- Killing in Gaza-EnlgishDocument15 pagesKilling in Gaza-EnlgishTsouki TsoukiNo ratings yet

- U A R H T M: EN 14015:2004 (Annex L - Par. L.4)Document2 pagesU A R H T M: EN 14015:2004 (Annex L - Par. L.4)Tsouki TsoukiNo ratings yet

- Expansion Vessel CalculationDocument4 pagesExpansion Vessel CalculationTsouki TsoukiNo ratings yet

- Api676 Pumps Nozzles LoadingDocument1 pageApi676 Pumps Nozzles LoadingTsouki TsoukiNo ratings yet

- Hydrostop Check ValvesDocument8 pagesHydrostop Check ValvesTsouki TsoukiNo ratings yet

- Restriction OrificesDocument9 pagesRestriction OrificesTsouki TsoukiNo ratings yet

- Heat Transfer CalculationsDocument3 pagesHeat Transfer CalculationsTsouki TsoukiNo ratings yet

- Ansi b31.3 Allowable StressDocument2 pagesAnsi b31.3 Allowable StressTsouki Tsouki100% (2)

- Flammable Liquid Storage Tank Protection - National FoamDocument34 pagesFlammable Liquid Storage Tank Protection - National FoamTsouki TsoukiNo ratings yet

- Mitered BendsDocument1 pageMitered BendsTsouki TsoukiNo ratings yet

- Angus Engineering Manual Section 4 - Foam Base InjectionDocument26 pagesAngus Engineering Manual Section 4 - Foam Base InjectionTsouki TsoukiNo ratings yet

- Fe 360 Fe 430 Fe 510Document2 pagesFe 360 Fe 430 Fe 510Tsouki TsoukiNo ratings yet

- Steam Tracing For HfoDocument18 pagesSteam Tracing For HfoTsouki Tsouki0% (1)

- Case Study On Sab Miller IndiaDocument163 pagesCase Study On Sab Miller Indiaசக்தி தாசன்No ratings yet

- Fco Letter Betel NutDocument2 pagesFco Letter Betel NutCalon JenazahNo ratings yet

- Malaysia (Father of Malaysia)Document4 pagesMalaysia (Father of Malaysia)justin_styles_7100% (1)

- (Scaled Agile Framework) : Devops Team, Amid BorhaniDocument28 pages(Scaled Agile Framework) : Devops Team, Amid BorhaniAmid BorhaniNo ratings yet

- Government e Marketplace (GeM) - 10.01.2024Document9 pagesGovernment e Marketplace (GeM) - 10.01.2024SSPOS DHULENo ratings yet

- Ee2404 Set1 PDFDocument22 pagesEe2404 Set1 PDFsivagamiNo ratings yet

- NT140WHM N46Document34 pagesNT140WHM N46arif.fahmiNo ratings yet

- XLSCDocument8 pagesXLSCpanjumuttaaiNo ratings yet

- Unit 7 The Contemporary WorldDocument16 pagesUnit 7 The Contemporary WorldLyka Mae FajardoNo ratings yet

- Maritime Health Declarations 121333Document77 pagesMaritime Health Declarations 121333polaris25100% (2)

- Grp3 SM2Document8 pagesGrp3 SM2Kapil boratNo ratings yet

- NCERT Ruling The CountrysideDocument13 pagesNCERT Ruling The CountrysideDipankar KumarNo ratings yet

- BT Bogies FLEXX PowerDocument4 pagesBT Bogies FLEXX PowerMarius-Ovidiu Ene100% (1)

- Aeon7200 Service Manual-V00.01-A4Document37 pagesAeon7200 Service Manual-V00.01-A4annaya kitaNo ratings yet

- Saint Mary FINALDocument63 pagesSaint Mary FINALLeoul ZeweldeNo ratings yet

- Central Laitière:: By: Haddouch Imane Haddouch Amine Idrissi Chirif Malak Ennakhli ZakariaDocument8 pagesCentral Laitière:: By: Haddouch Imane Haddouch Amine Idrissi Chirif Malak Ennakhli ZakariaidrissiNo ratings yet

- MelanieresumeDocument1 pageMelanieresumeapi-253574700No ratings yet

- 2012 Catalogue With Prices Lo ResDocument359 pages2012 Catalogue With Prices Lo ResIoana Corbu Costache100% (1)

- Space Frame StructureDocument40 pagesSpace Frame StructureB-05 ISHA PATELNo ratings yet

- UntitledDocument56 pagesUntitledsolomon kpayehNo ratings yet

- WK 5 Audit Risk and MaterialityDocument43 pagesWK 5 Audit Risk and MaterialityYalliniNo ratings yet

- NLP 2 AdvDocument91 pagesNLP 2 AdvShamsul BasharNo ratings yet

- Aegis Emergency Data Sheet1Document2 pagesAegis Emergency Data Sheet1Armando RamirezNo ratings yet

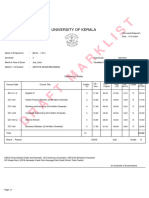

- Draft Marklist: University of KeralaDocument1 pageDraft Marklist: University of Keralamuraliadithya4No ratings yet

- Action Plan With Outcome (Community Action Plan)Document2 pagesAction Plan With Outcome (Community Action Plan)Nora Varshavski100% (1)

- SGOD PERSONNEL COORDINATORSHIP - SPECIAL ASSIGNMENTS - DESIGNATIONS (Responses)Document1 pageSGOD PERSONNEL COORDINATORSHIP - SPECIAL ASSIGNMENTS - DESIGNATIONS (Responses)Jofit DayocNo ratings yet

- Bus Reservation System WebBased ApllicationDocument73 pagesBus Reservation System WebBased ApllicationVaibhav0% (1)

- BI012789-00-EN Manual de Parte MD5050T - SERIE DR911175 PDFDocument430 pagesBI012789-00-EN Manual de Parte MD5050T - SERIE DR911175 PDFEliecer godoy67% (3)