Professional Documents

Culture Documents

Petra University (Architecture Ebook) Metal Building Systems - Design and Specifications-20610-Part79

Petra University (Architecture Ebook) Metal Building Systems - Design and Specifications-20610-Part79

Uploaded by

Mohamed SalikOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Petra University (Architecture Ebook) Metal Building Systems - Design and Specifications-20610-Part79

Petra University (Architecture Ebook) Metal Building Systems - Design and Specifications-20610-Part79

Uploaded by

Mohamed SalikCopyright:

Available Formats

METAL ROOFING

156 CHAPTER SIX

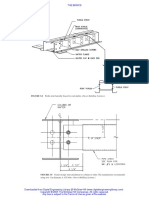

FIGURE 6.6 Exposed-fastener panels: Butlerib II by Butler Manufacturing. (a) Prepunched panels and purlins

ensure correct alignment. (b) Seam details with lock rivet. (c) Panel cross section. (Butler Manufacturing Co.)

For self-drilling screws, there are three main modes of failure: pullover, pullout, and shear (Fig.

6.8). In a pullout failure the screw loses its grip, while in the pullover failure the material around the

screw fractures. For heavier-gage materials (from 22 ga. to 1Ⲑ4-in thick), the pullout capacity typi-

cally controls; for thinner gages, pullover may govern. The pullout capacity of the fastener depends

mostly on the drill point size, diameter of the shank, and the number of threads per inch. The pullover

capacity depends chiefly on the head style, and to a lesser degree, on the drill point size.14

6.4.4 Protection against Leaks and Corrosion

To minimize vulnerability of through-fastened roofing to leaks at the points of attachment, rubber or

Neoprene washers are provided under the fasteners’ heads. Unfortunately, this protective measure is

only as good as the workmanship of the installer. In order for the gasketed washers to function prop-

erly, the screws must be driven to a proper depth. This is accomplished by using electric screwdrivers

or similar tools with accurate depth control.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

METAL ROOFING

METAL ROOFING 157

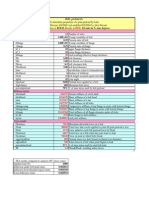

FIGURE 6.7 Fasteners used by one manufacturer to attach through-fastened

roofing to purlins and to one another. (The scrubolt is used only for attachment to

purlins.) (Butler Manufacturing Co.)

FIGURE 6.8 Various failure mechanisms for screw-type fasteners. (MBMA.)

A properly installed screw has its Neoprene washer slightly visible from under the edge of the

metal washer (Fig. 6.9a). When the Neoprene material cannot be seen from under the metal (Fig.

6.9b), the screw probably is not tightened enough, but when the Neoprene appears “squished” (Fig.

6.9c), the screw may be overtightened.15 An overdriven fastener can dimple the metal panel and

invite water to collect in the depression, further worsening the situation. The screws must be driven

perpendicular to the panel, otherwise the Neoprene will be squished on one side and not compressed

enough on the opposite side.

Exposed fasteners without a durable corrosion-resisting coating invite trouble. The better ones are

made of stainless steel or aluminum; galvanized or cadmium-plated screws are best left for interior

applications. To reduce complaints about fastener visibility, exposed fasteners may have a color-

coordinated head finish (or be fitted with colored plastic caps, a previously popular but now largely

obsolete solution).

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Almita Screw Pile Design Handbook 2008 PDFDocument59 pagesAlmita Screw Pile Design Handbook 2008 PDFMatthew Karabela100% (2)

- Preformed Expansion Joint Filler For Concrete (Bituminous Type)Document2 pagesPreformed Expansion Joint Filler For Concrete (Bituminous Type)Katerin HernandezNo ratings yet

- Ajax Rivets HandbookDocument15 pagesAjax Rivets HandbooknextreaderNo ratings yet

- Accesorios Roscados para PlásticosDocument32 pagesAccesorios Roscados para PlásticosjbertralNo ratings yet

- Bolts and TighteningDocument4 pagesBolts and TighteningArassen RunNo ratings yet

- Zap Screwlok Gen Proposal - Rev0107Document22 pagesZap Screwlok Gen Proposal - Rev0107ludwingNo ratings yet

- OchureDocument13 pagesOchureFabian CampañaNo ratings yet

- SPL Tapping InformationDocument9 pagesSPL Tapping InformationaldiNo ratings yet

- 10 04 13Document55 pages10 04 13Edu HernándezNo ratings yet

- OM 002 Belt Conveyor Idler Instruct 6E74091AB9993Document5 pagesOM 002 Belt Conveyor Idler Instruct 6E74091AB9993Imran DahalanNo ratings yet

- Aircraft Assembly Technology: Shenyang Aerospace UniversityDocument21 pagesAircraft Assembly Technology: Shenyang Aerospace Universityalokmotivation99No ratings yet

- WoodWard - Steering Column TechDocument6 pagesWoodWard - Steering Column TechLuiz EduardoNo ratings yet

- Click Bond Product Guide CD 720 120 2 EnglishDocument24 pagesClick Bond Product Guide CD 720 120 2 Englishjelliott48278No ratings yet

- Self Locking TapsDocument7 pagesSelf Locking Tapscamohunter71100% (1)

- 25 Series TrimLine POLE-OPERATED CAM HANDLE LOCKSDocument4 pages25 Series TrimLine POLE-OPERATED CAM HANDLE LOCKSWindow HardwareNo ratings yet

- STUD WELDING REQUIREMENTS From AWS D1.1-D 1.1M-2015Document10 pagesSTUD WELDING REQUIREMENTS From AWS D1.1-D 1.1M-2015Mark Darrel AranasNo ratings yet

- Design - Part 4 - Job Knowledge 93Document4 pagesDesign - Part 4 - Job Knowledge 93Billy TanNo ratings yet

- How Can You Trust Your Agitator To Keep Your Process Clean?Document4 pagesHow Can You Trust Your Agitator To Keep Your Process Clean?Miaoluan ChanNo ratings yet

- Overview of Cable Gland Construction TypesDocument1 pageOverview of Cable Gland Construction TypesGolfkung PairojNo ratings yet

- Machinery Vibration Related To Poor Bolting PracticesDocument24 pagesMachinery Vibration Related To Poor Bolting PracticesBitbitterNo ratings yet

- Tools GuideDocument2 pagesTools GuideMario RivasNo ratings yet

- Din-2353 Гайки и ЛещиDocument17 pagesDin-2353 Гайки и Лещиyulian.stanevNo ratings yet

- Guide For Installation of Overhead ConductorDocument22 pagesGuide For Installation of Overhead Conductorryan_jay55No ratings yet

- Material Submittal For Glass and MirrorDocument104 pagesMaterial Submittal For Glass and MirrorChris EnyinnayaNo ratings yet

- Tapping Screws: Ductility Testing ofDocument2 pagesTapping Screws: Ductility Testing ofRavindra ErabattiNo ratings yet

- KRW Product Range Current Insulated Bearings enDocument10 pagesKRW Product Range Current Insulated Bearings enAmazonas ManutençãoNo ratings yet

- Composite Materials and Technology: Chapter - 3 Fabrication of CompositesDocument25 pagesComposite Materials and Technology: Chapter - 3 Fabrication of CompositespincoNo ratings yet

- Specifying CamberDocument3 pagesSpecifying CamberarsiajanNo ratings yet

- Instructions For The Use of WirelockDocument6 pagesInstructions For The Use of WirelockLeo MottaNo ratings yet

- CH 7 Simple Beam End Connections-9-13Document60 pagesCH 7 Simple Beam End Connections-9-13JakesNo ratings yet

- T o o L I N GDocument38 pagesT o o L I N GNatural AlNo ratings yet

- Design - Part 4 - TWIDocument6 pagesDesign - Part 4 - TWISumantaNo ratings yet

- Machining Processes Used To Produce Round Shapes: Turning and Hole MakingDocument14 pagesMachining Processes Used To Produce Round Shapes: Turning and Hole MakingArvin BabuNo ratings yet

- Rebar Coupler EconomicsDocument6 pagesRebar Coupler Economicsakgupta733779No ratings yet

- D 260 BarlockweldablecouplerDocument2 pagesD 260 BarlockweldablecouplerGustavo Brea MalavéNo ratings yet

- Self Clinching Fastener HandbookDocument16 pagesSelf Clinching Fastener HandbookgunallNo ratings yet

- Shaft Strain Gaging Guide v4Document11 pagesShaft Strain Gaging Guide v4craigNo ratings yet

- Welding DesignDocument28 pagesWelding DesignSitaram JhaNo ratings yet

- Self-Tapping Screws How To ChooseDocument3 pagesSelf-Tapping Screws How To ChooseoarmstroNo ratings yet

- Chapter Three: Purlin Strut Laterally Braced To Roof Purlin. (Nucor Building Systems.)Document6 pagesChapter Three: Purlin Strut Laterally Braced To Roof Purlin. (Nucor Building Systems.)Anonymous 5GdZOikrrANo ratings yet

- Chapter Three: Purlin Strut Laterally Braced To Roof Purlin. (Nucor Building Systems.)Document6 pagesChapter Three: Purlin Strut Laterally Braced To Roof Purlin. (Nucor Building Systems.)Anonymous 5GdZOikrrANo ratings yet

- Preloaded Bolting: (Image Courtesy of Mabey Bridge LTD.)Document9 pagesPreloaded Bolting: (Image Courtesy of Mabey Bridge LTD.)Benjamin IndrawanNo ratings yet

- Extrusion ToolingDocument31 pagesExtrusion ToolingsvedanthNo ratings yet

- TAPER GRIP-TWIST Brochure - RevB-red PDFDocument4 pagesTAPER GRIP-TWIST Brochure - RevB-red PDFGonzalo AbarcaNo ratings yet

- Cherry Maxibolt® Blind Bolt SystemDocument6 pagesCherry Maxibolt® Blind Bolt SystemCHO METNo ratings yet

- Literature Review of BearingDocument5 pagesLiterature Review of Bearingea4c954q100% (1)

- Crosby Catalog 2008 - Page 76 To 88Document13 pagesCrosby Catalog 2008 - Page 76 To 88Prejit RadhakrishnaNo ratings yet

- Stud Welding: 7.1 ScopeDocument8 pagesStud Welding: 7.1 ScopeAndrés OchoaNo ratings yet

- Anchor Watch 02Document7 pagesAnchor Watch 02Janaka KarunarathnaNo ratings yet

- Metal Face Seals v3Document30 pagesMetal Face Seals v3ntchobanov0% (1)

- NFRC Guidance Note GN01-Self Drilling Fasteners746.33 KB01 092019 EN UKDocument2 pagesNFRC Guidance Note GN01-Self Drilling Fasteners746.33 KB01 092019 EN UKfahim007No ratings yet

- SW Vs Kammprofile GsktsDocument4 pagesSW Vs Kammprofile GsktsFilipNo ratings yet

- Fusealloy Fabrication Guidelines 2016Document25 pagesFusealloy Fabrication Guidelines 2016Vitor Rigueira de GodoyNo ratings yet

- The Design of Welding Tooling For Split Console FrameDocument5 pagesThe Design of Welding Tooling For Split Console FrameVaibhav ShahNo ratings yet

- Installation Instructions Slide Lag - June - 2013Document10 pagesInstallation Instructions Slide Lag - June - 2013Viet Nam M-TechNo ratings yet

- Tooling by Design - Springback in High-Strength Steel Stampings - Compensation Is Not Commensurate With Experience - MetalForming MagazineDocument2 pagesTooling by Design - Springback in High-Strength Steel Stampings - Compensation Is Not Commensurate With Experience - MetalForming MagazineSIMONENo ratings yet

- Pyro-Bloc YDocument16 pagesPyro-Bloc YAjin SNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Advances in Ceramic Armor XFrom EverandAdvances in Ceramic Armor XJerry C. LaSalviaNo ratings yet

- Warping Torsion PDFDocument22 pagesWarping Torsion PDFMohamed SalikNo ratings yet

- Lecture 6 - DR Sabareesh G RDocument76 pagesLecture 6 - DR Sabareesh G RMohamed SalikNo ratings yet

- Floor Diaphragms 353Document1 pageFloor Diaphragms 353Mohamed SalikNo ratings yet

- Multiple Choice Practice Objective Questions and Answers On Environmental Science and Ecology PDFDocument31 pagesMultiple Choice Practice Objective Questions and Answers On Environmental Science and Ecology PDFMohamed Salik100% (1)

- Design Difference IS Vs AISC PDFDocument2 pagesDesign Difference IS Vs AISC PDFMohamed SalikNo ratings yet

- Prospectus2018 PDFDocument95 pagesProspectus2018 PDFMohamed SalikNo ratings yet

- Explanatory Handbook ONDocument1 pageExplanatory Handbook ONMohamed SalikNo ratings yet

- S.No. Description of Item Concrete Quantity QuantityDocument4 pagesS.No. Description of Item Concrete Quantity QuantityMohamed SalikNo ratings yet

- MBS Installation HelpDocument26 pagesMBS Installation HelpMohamed SalikNo ratings yet

- Redox ReactionsDocument2 pagesRedox Reactionsf5hwtwt6cfNo ratings yet

- Bolts PreloadDocument5 pagesBolts Preloadmanoj983@gmail.comNo ratings yet

- Ultra-Low Profile Dome Key B3DDocument3 pagesUltra-Low Profile Dome Key B3DMuhamad PriyatnaNo ratings yet

- GENERAL CHEMISTRY 2Document20 pagesGENERAL CHEMISTRY 2Jin LianNo ratings yet

- Capillary TubeDocument8 pagesCapillary Tubeziko23100% (2)

- Chapter 2 Notes PDFDocument25 pagesChapter 2 Notes PDFHassaan SajidNo ratings yet

- Fatigue of Flexible RisersDocument145 pagesFatigue of Flexible Risersbobstar128No ratings yet

- HydridesDocument2 pagesHydridesLeyre GonzálezNo ratings yet

- The S.E (GSO) Circle, FESCO Faisalabad.: 132 KV Grid Station Kirana Hill 11KV O/G FeedersDocument5 pagesThe S.E (GSO) Circle, FESCO Faisalabad.: 132 KV Grid Station Kirana Hill 11KV O/G FeedersAzad UmerNo ratings yet

- UntitledDocument16 pagesUntitledСергей КартавицкийNo ratings yet

- Oxygen Scavenger in OilfieldDocument27 pagesOxygen Scavenger in Oilfieldguruhnurizal100% (1)

- Capacitance & Dielectrics: (Chapter 4)Document30 pagesCapacitance & Dielectrics: (Chapter 4)Allan Gabriel LariosaNo ratings yet

- g4 1stmonthlyexamDocument2 pagesg4 1stmonthlyexamtwinckel mae bienesNo ratings yet

- ACO StormBrixx BrochureDocument32 pagesACO StormBrixx BrochureJose MariaNo ratings yet

- MPI Report 009 Sub Structure B668Document1 pageMPI Report 009 Sub Structure B668John DolanNo ratings yet

- Electrochemistry: Electrochemistry Is Best Defined As The Study of TheDocument31 pagesElectrochemistry: Electrochemistry Is Best Defined As The Study of TheTetty ArsetyNo ratings yet

- Calorimetry HCDocument25 pagesCalorimetry HCSunnyNo ratings yet

- Save Time and Cost With Mod Code 429 Space Grade Micro-D's: A B C D E F G H J K L M N P QDocument4 pagesSave Time and Cost With Mod Code 429 Space Grade Micro-D's: A B C D E F G H J K L M N P QRoad BlasterNo ratings yet

- TMPL Pilot Plant ReportDocument67 pagesTMPL Pilot Plant Reportsufisafia100% (1)

- Uji Proksimat ThermogravimetryDocument5 pagesUji Proksimat ThermogravimetrylianyNo ratings yet

- Electrical & Electronics Applications: Epotec Epoxy SystemsDocument2 pagesElectrical & Electronics Applications: Epotec Epoxy SystemsAditya ShrivastavaNo ratings yet

- Flash Steam Recovery Calculation What Is Flash Steam?: Blow Down From BoilersDocument3 pagesFlash Steam Recovery Calculation What Is Flash Steam?: Blow Down From BoilersBeicha100% (1)

- Line Practice Concrete: Effect of Eccentric Loading of ColumnsDocument3 pagesLine Practice Concrete: Effect of Eccentric Loading of Columnsgnanasekar007No ratings yet

- A Review On The Potential Effect of Lime On Soil Properties and Crop Productivity ImprovementsDocument7 pagesA Review On The Potential Effect of Lime On Soil Properties and Crop Productivity Improvementsgetahun esubalewNo ratings yet

- Chemistry For Engineers Lesson No. 3: Energy Sources: Fuels and Combustion Prepared By: Lyka D. Lamoste, MSSEDocument16 pagesChemistry For Engineers Lesson No. 3: Energy Sources: Fuels and Combustion Prepared By: Lyka D. Lamoste, MSSEJohn Nelson LorenzoNo ratings yet

- Hanson Fibrecrete Brochure PDFDocument7 pagesHanson Fibrecrete Brochure PDFEmalaith BlackburnNo ratings yet

- Spun Piles PT. Komponindo BetonjayaDocument12 pagesSpun Piles PT. Komponindo Betonjayanapis jauhari100% (2)

- Pipa + Fitting PDFDocument4 pagesPipa + Fitting PDFSukiyatno YatnoNo ratings yet