Professional Documents

Culture Documents

Technical Data Sheet: System Volume Studies

Technical Data Sheet: System Volume Studies

Uploaded by

ubaid mehmood0 ratings0% found this document useful (0 votes)

15 views2 pagesThis document provides guidance on determining the volume of closed loop water systems using chemical tracers. Sodium molybdate is recommended as a tracer because it can be accurately measured at low concentrations using on-site tests. The volume is calculated based on adding a known amount of sodium molybdate and measuring its concentration before and after. Sample calculations and test procedures are provided to accurately determine system volume through chemical addition and analysis.

Original Description:

water analysis corrosion procedure and test include to determine iron in water

Original Title

Corrosion

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides guidance on determining the volume of closed loop water systems using chemical tracers. Sodium molybdate is recommended as a tracer because it can be accurately measured at low concentrations using on-site tests. The volume is calculated based on adding a known amount of sodium molybdate and measuring its concentration before and after. Sample calculations and test procedures are provided to accurately determine system volume through chemical addition and analysis.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

15 views2 pagesTechnical Data Sheet: System Volume Studies

Technical Data Sheet: System Volume Studies

Uploaded by

ubaid mehmoodThis document provides guidance on determining the volume of closed loop water systems using chemical tracers. Sodium molybdate is recommended as a tracer because it can be accurately measured at low concentrations using on-site tests. The volume is calculated based on adding a known amount of sodium molybdate and measuring its concentration before and after. Sample calculations and test procedures are provided to accurately determine system volume through chemical addition and analysis.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

TECHNICAL DATA SHEET

SYSTEM VOLUME STUDIES

INTRODUCTION However, the addition of NaCl concentration

necessary, based on analytical accuracy, can be

Successful implementation of a water treatment corrosive to the system metals (especially copper

program requires that the system’s water holding and aluminum metals).

capacity/volume is known. This information aids the

following: Lithium chloride brine is also used for this purpose

and can be fed at very low concentrations. However,

Selecting the quantity of chemical needed to lithium requires sophisticated analytical capabilities

preclean a system. (atomic absorption or equivalent) and consequently

Calculating the initial treatment chemical can not be measured onsite.

dosages.

Sodium molybdate is a salt that can be measured

Estimating and evaluating the antimicrobial agent down to low detection levels (consequently high

feedrates; i.e., shot dosages. concentrations are not required) and the

measurement can be done accurately onsite using a

Normally, the boiler manufacturer’s literature or

colorimeter (consequently the analytical cost is low

manual indicates the boiler’s water holding capacity

and testing can be done onsite). Normally, the water

in a flooded condition and at its normal operating

will not contain molybdate unless sodium molybdate

level. This same information is often unavailable for

has been added as a chemical treatment. However,

closed loop systems (heating and/or cooling), open

unless it is certain the system is void of sodium

recirculating cooling towers and air washer systems.

molybdate treatment, it is best to sample and analyze

The system’s sump capacity can be calculated if

the water before and after the tracer molybdate

dimensions are known or if they can be measured.

addition.

The holding capacity of the system’s piping can be

difficult to measure as well as time-consuming.

VOLUME MEASUREMENT CALCULATION

Consequently, it is typical that the system volume can

only be estimated at best. Considering the Concentration1 x Quantity1 = Concentration2 x Quantity2, or

importance and value of knowing a system volume, it Water Vol., Lbs. = (Concentration of tracer in product x

is well worth while to pursue an accurate Lbs. tracer added) (Concentration of tracer measured)

measurement.

Note 1: untreated water will typically be free of molybdate.

DETERMINING SYSTEM VOLUME

However, it is always best to sample for background

molybdate to ensure study accuracy. Obviously, a system

The system’s holding capacity can be readily known to have molybdate should be tested before & after.

obtained by chemical addition and analysis if three of Subtract the background molybdate from the “test”

the following four items are known. molybdate to determine true tracer measured.

Concentration1 x Quantity1 = Concentration2 x Quantity2

Example Criteria:

Where, The concentration of sodium molybdate as Mo+6 in

Quanty1 = system water volume, LBs. FORMULA 1250 is 80,000 ppm. Thus, the above

+6

Concentration1 = tracer measured in system, ppm as Mo equation can be reduced to:

Quantity2 = Lbs. of tracer-containing product added

Concentration2 = tracer concentration in product, ppm as Lbs. water = (80,000 ppm) x (Lbs. Product Added)

+6

Mo (“Test” molybdate – “Background” molybdate

Known quantities of sodium chloride and other measured in ppm as Mo+6)

chemicals have been employed for system volume

measurement.

Example Data: 4. After adding a known quantity to the system,

allow some time for mixing of the molybdate in

- 2.5 LB product added to system. the system (say ½ - 1 hour) if system is relatively

- 0 ppm molybdate tested before product addition void of “stagnant” areas.

- 24 ppm molybdate tested after product addition

5. Collect a representative water sample for

Lbs. water = (80,000 ppm) x (2.5 Lbs. Product

analysis. Note: use a clean bottle and do not

Added) (24 ppm – 0 ppm molybdate as Mo+6) =

reuse the bottle. Be careful to collect sample

8333 LBs. or 1000 gallons of system volume (i.e.,

away from where the chemical is added to avoid

8333 LBs/8.33 LBs/gallon).

sampling a concentration pocket of tracer.

It is important to accurately measure the quantity of

6. As always, clearly label sample; request a

tracer added and to add enough so that the “Test”

molybdate analysis, note name & quantity of

molybdate can be easily detected. To ensure

molybdate product added.

reasonable test accuracy 2.5 Lbs. to 5.0 Lbs. of

FORMULA 1250 should be added for each 1,000

7. Testing onsite with a molybdate colorimeter

gallons of water anticipated in the system (less if

should yield accurate results.

powder molybdate/FORMULA 1920 is used).

MISCELLANEOUS

As noted, the presence of background molybdate

should be accounted for and may require a

Sodium molybdate salt can be reported in different

somewhat higher dose of molybdate to improve test

ways. For example, many field tests will report

accuracy.

sodium molybdate salt as Mo+6 (molybdenum) or as

Na2MoO4 (sodium molybdate). The raw material

A second, perhaps simpler, calculation can be used

often used is sodium molybdate dihydrate and so the

to calculate volume and is based on the concept that

product sodium molybdate concentration may be

1 LB of product added to 1000 gallons will give 120

reported as Na2MoO4 2H2O (sodium molybdate

ppm product concentration:

dihydrate). Below are the molecular weights for

these various forms of sodium molybdate reporting

[120 ppm/LBadded to 1000 gal x LBs (active molybdate

and some guide on converting from one to another.

added, as Mo+6) measured molybdate, as ppm

Mo+6] x 1000 gallons = gallons of system volume

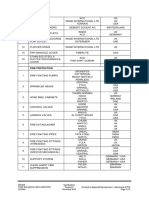

Mo+6 = MW of 96

Na2MoO4 = MW of 206

TEST IMPLEMENTATION & PRECAUTIONS

Na2MoO4 2H2O = MW of 242

1. Collect sample of water from system before

Mo+6 to Na2MoO4 , multiply by 2.15 (206/96)

molybdate addition (even if it is thought to be

untreated) to ensure study accuracy.

Mo+6 to Na2MoO4 2H2O, multiply by 2.50 (242/96)

2. Make an initial estimate of system volume, and

add 2.5 LB to 5.0 LB of FORMULA 1250 per Na2MoO4 to Na2MoO4 2H2O, multiply by 1.17 (242/206)

1,000 gallons of water in system. You can use

less (0.5 LB to 1.0 LB if adding FORMULA 1920 Na2MoO4 to Mo+6, multiply by 0.47 (96/206)

(powder molybdate concentrate). More of both

molybdate products may be required if Na2MoO4 2H2O to Mo+6, multiply by 0.40 (96/242)

background molybdate is present.

Na2MoO4 2H2O to Na2MoO4, multiply by 0.85 (206/242)

3. Discontinue system bleedoff while molybdate

tracer is being mixed into the circulating water

(this especially applies to open recirculating

systems). Add the entire amount of tracer as a

slug over a very short period of time.

1998 Eastern Technologies Incorporated, P.O. Box 269, Morgantown, PA 19543-0269. All rights reserved.

TDS-005-G 2 4/02

You might also like

- Hach Nitrate Method 10206 Final 01102013Document10 pagesHach Nitrate Method 10206 Final 01102013dunavko1No ratings yet

- Discussion Cod UpdatedDocument3 pagesDiscussion Cod UpdatedFaeez Zain100% (2)

- Epa Method - 245 - Determination of Mercury in WaterDocument18 pagesEpa Method - 245 - Determination of Mercury in Waterகுமார் எஸ்No ratings yet

- Cod Procedure For HACH DR 2800Document8 pagesCod Procedure For HACH DR 2800Berliana Cahya NingtiasNo ratings yet

- Advanced Pharmaceutical analysisFrom EverandAdvanced Pharmaceutical analysisRating: 4.5 out of 5 stars4.5/5 (2)

- AC 43.13-1B - Section10 - Safety Methods For TurnbucklesDocument5 pagesAC 43.13-1B - Section10 - Safety Methods For TurnbucklesJoel CordovaNo ratings yet

- Markowitz WhitepaperDocument10 pagesMarkowitz WhitepaperWen BinNo ratings yet

- TEST QUESTIONS IN SCIENCE 9 MELC-BASED (Analysis, Application and Evaluation)Document26 pagesTEST QUESTIONS IN SCIENCE 9 MELC-BASED (Analysis, Application and Evaluation)mayette100% (1)

- Alkali Metal Cations Na, K, Li 7405: NIOSH Manual of Analytical Methods (NMAM), Fifth EditionDocument5 pagesAlkali Metal Cations Na, K, Li 7405: NIOSH Manual of Analytical Methods (NMAM), Fifth EditionLINDA IVON PARRADO SÁNCHEZNo ratings yet

- Mercurio Por FIMSDocument23 pagesMercurio Por FIMSKarina Castillo CórdovaNo ratings yet

- Fosfatos en Agua de MarDocument26 pagesFosfatos en Agua de Marcris200391No ratings yet

- Method 900-0 1980Document10 pagesMethod 900-0 1980Omar SuarezNo ratings yet

- Carbon DioxideDocument2 pagesCarbon DioxideSarah Marie ArquizaNo ratings yet

- Determination of Mercury in Soil Samples: Utilizing Direct Mercury Analysis in As Little As 6 Minutes Per SampleDocument3 pagesDetermination of Mercury in Soil Samples: Utilizing Direct Mercury Analysis in As Little As 6 Minutes Per SampleJorge Sierra PaezNo ratings yet

- COD (Chemical Oxygen Demand)Document6 pagesCOD (Chemical Oxygen Demand)api-546041117No ratings yet

- AAS - K - USGS-Method-I-3631Document2 pagesAAS - K - USGS-Method-I-3631Ahmed GwealyNo ratings yet

- Determination of Total Mercury in Environmental SamplesDocument4 pagesDetermination of Total Mercury in Environmental SampleswillwNo ratings yet

- 3051aSOPver12 W SPKDocument8 pages3051aSOPver12 W SPKAfroditiNo ratings yet

- PI e BICARB 15Document2 pagesPI e BICARB 15Khuon BunthaNo ratings yet

- Doc316 53 01061Document6 pagesDoc316 53 01061Naranyu JantarawongsaNo ratings yet

- HG en Residuos Sólidos y SemisólidosDocument7 pagesHG en Residuos Sólidos y SemisólidosNieves CardenasNo ratings yet

- Metode Oseanografi Kimia Dan SedimenDocument53 pagesMetode Oseanografi Kimia Dan SedimenFirdhauzi Dhian PriafitaNo ratings yet

- App Determination GBDocument3 pagesApp Determination GBAkhmad ArdiNo ratings yet

- 3500 Na SODIODocument3 pages3500 Na SODIOCecilia AvilaNo ratings yet

- RBM2560 BURST MODE - Practical 3 - Enzyme Kinetics (NEW)Document15 pagesRBM2560 BURST MODE - Practical 3 - Enzyme Kinetics (NEW)aliza.oyarceNo ratings yet

- Organic MatterDocument11 pagesOrganic MatterElly Paul Andres TomasNo ratings yet

- MEASURE TP (Fixed)Document2 pagesMEASURE TP (Fixed)Trần Văn BìnhNo ratings yet

- PI e BICARB 16Document2 pagesPI e BICARB 16Jaydev DegloorkarNo ratings yet

- Epa 7473 (Mercury in Solids and Solutions by Thermal Decomposition, Amalgamation,)Document15 pagesEpa 7473 (Mercury in Solids and Solutions by Thermal Decomposition, Amalgamation,)Osmel García MorfiNo ratings yet

- FAQDocument30 pagesFAQPhong LeNo ratings yet

- CHLORINE DIOXIDE Training ModulusDocument18 pagesCHLORINE DIOXIDE Training ModulusAbdülhamit KAYYALİNo ratings yet

- Niosh 6009 PDFDocument5 pagesNiosh 6009 PDFCaleb ConnerNo ratings yet

- Sjac 20200802 17Document8 pagesSjac 20200802 17GauravNo ratings yet

- Section 1 Gross Alpha and Gross Beta Radioactivity in Drinking Water METHOD 900.0 1.0 Scope and Application 1.1Document9 pagesSection 1 Gross Alpha and Gross Beta Radioactivity in Drinking Water METHOD 900.0 1.0 Scope and Application 1.1Pataki SandorNo ratings yet

- Enzyme Catalysis LabDocument4 pagesEnzyme Catalysis LabMeera KumarNo ratings yet

- 6.POTASSIUM EnzymaticDocument2 pages6.POTASSIUM EnzymaticHiếu Chí PhanNo ratings yet

- Sample Lab ReportljDocument10 pagesSample Lab ReportljDavid DavisNo ratings yet

- Feed and Boiler Water: Language UK Page 1/1Document15 pagesFeed and Boiler Water: Language UK Page 1/1Alexander BaziotisNo ratings yet

- Method 351.2, Revision 2.0: Determination of Total Kjeldahl Nitrogen by Semi-Automated ColorimetryDocument16 pagesMethod 351.2, Revision 2.0: Determination of Total Kjeldahl Nitrogen by Semi-Automated ColorimetryAhsan RohmanNo ratings yet

- METHOD 375.2 Determination of Sulfate by Automated ColorimetryDocument13 pagesMETHOD 375.2 Determination of Sulfate by Automated ColorimetrykiranNo ratings yet

- MBR STP 600 KLD Imp PointDocument2 pagesMBR STP 600 KLD Imp PointKAMLESHNo ratings yet

- Manual Experiment SMA TestDocument9 pagesManual Experiment SMA TestJair Ferreira JúniorNo ratings yet

- Cobalt, Atomic Absorption Spectrometric, Direct: 1. ApplicationDocument2 pagesCobalt, Atomic Absorption Spectrometric, Direct: 1. ApplicationCristian Javier Guzman DiazNo ratings yet

- TocDocument5 pagesTocReza Hafidz SukamtoNo ratings yet

- Measure TbaDocument2 pagesMeasure Tbatuan vănNo ratings yet

- Metodo FIAS Enva100Document20 pagesMetodo FIAS Enva100Lalo Ruiz100% (1)

- UOP-Mercury-Removal-From-Natural-Gas-and-Liquid-Streams-Tech-Paper 2 PDFDocument9 pagesUOP-Mercury-Removal-From-Natural-Gas-and-Liquid-Streams-Tech-Paper 2 PDFPedraza Velandia JhonNo ratings yet

- ابريتنغ منولDocument86 pagesابريتنغ منولGhassan Al HaririNo ratings yet

- On-Line TOC Measurement PresentationDocument33 pagesOn-Line TOC Measurement PresentationAndy Rojas50% (2)

- A06 Articulo Julian 2013Document7 pagesA06 Articulo Julian 2013Carol HernándezNo ratings yet

- Epa - 7471b MERCURY IN SOLID OR SEMISOLID WASTE (MANUAL COLD-VAPOR TECHNIQUEDocument8 pagesEpa - 7471b MERCURY IN SOLID OR SEMISOLID WASTE (MANUAL COLD-VAPOR TECHNIQUEahmad munawirNo ratings yet

- TOC Application - TOC-L - TOC - Determination According To USP 643Document2 pagesTOC Application - TOC-L - TOC - Determination According To USP 643Ramon Trinidad De la ONo ratings yet

- Laboratory Manual and GuidelineDocument27 pagesLaboratory Manual and GuidelineFatih Rushdi100% (1)

- CODLab ReportDocument14 pagesCODLab ReportVerlon VincentNo ratings yet

- Standard - Methods 5220D Metodología DQODocument2 pagesStandard - Methods 5220D Metodología DQOAndreaFigueroaNo ratings yet

- P-4 Determination of SodiumDocument4 pagesP-4 Determination of SodiumTahir SarwarNo ratings yet

- Urea 275Document12 pagesUrea 275ckpellegrino5809No ratings yet

- E38IA049EN A ApplReport QuickRoutineSVTDigestion of Fe andCU OreDocument4 pagesE38IA049EN A ApplReport QuickRoutineSVTDigestion of Fe andCU OreAl KayprofNo ratings yet

- Cod StandardDocument14 pagesCod Standardreza_karbordiNo ratings yet

- LW2 EAC Instructions 21-22Document8 pagesLW2 EAC Instructions 21-22josune ramirez romeroNo ratings yet

- Standard methods for the examination of water and sewageFrom EverandStandard methods for the examination of water and sewageNo ratings yet

- SummaryDocument35 pagesSummaryBiju SebastianNo ratings yet

- N2 RequirementDocument2 pagesN2 RequirementsandeshNo ratings yet

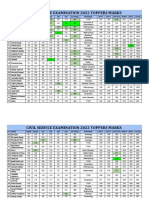

- Selected Candidates Marks CSE 2022Document6 pagesSelected Candidates Marks CSE 2022hara vardhan reddy naruNo ratings yet

- BASF Global Construction Brochure enDocument68 pagesBASF Global Construction Brochure enHector OliverNo ratings yet

- Credit and Saving Management SystemDocument96 pagesCredit and Saving Management SystemFitsum TesfayeNo ratings yet

- ER306 Fast DiodeDocument3 pagesER306 Fast DiodeDaniel SantosNo ratings yet

- Saudi Aramco Pre-Commissioning Form: Sapmt Inspection Operations Signature & DateDocument2 pagesSaudi Aramco Pre-Commissioning Form: Sapmt Inspection Operations Signature & Datemahdi_gNo ratings yet

- SW Techical DataDocument5 pagesSW Techical DataImer RedzovicNo ratings yet

- Ion PropulsionDocument16 pagesIon PropulsionMimsisiNo ratings yet

- Jurnal Belimbing WuluhDocument6 pagesJurnal Belimbing WuluhPuspitasari NurulNo ratings yet

- Vendor ListDocument1 pageVendor ListbhimaNo ratings yet

- EstimateDocument6 pagesEstimateTrending JuanNo ratings yet

- Inspection of Rail Wear - Procedure RAP 5139: Engineering Practices Manual Civil EngineeringDocument5 pagesInspection of Rail Wear - Procedure RAP 5139: Engineering Practices Manual Civil EngineeringAgus EriantoNo ratings yet

- HaraprasadShastri NepalDurbarV-2 1915 TextDocument348 pagesHaraprasadShastri NepalDurbarV-2 1915 TextSIva85kami100% (1)

- Water Installation CodeDocument34 pagesWater Installation CodeDăňĩêĺ RăĵăNo ratings yet

- Hardox® 600: General Product DescriptionDocument2 pagesHardox® 600: General Product DescriptionTimur SonkayaNo ratings yet

- Precast Prestressed Concrete Short Span BridgesDocument41 pagesPrecast Prestressed Concrete Short Span Bridgescdestudos100% (1)

- Sample Individual Speech OutlineDocument3 pagesSample Individual Speech Outlineafnan fathiNo ratings yet

- 2009 Cat® Shop Supplies and Hand ToolsDocument460 pages2009 Cat® Shop Supplies and Hand Toolstintoreto106100% (5)

- EarclipsensorDocument1 pageEarclipsensortapoiuNo ratings yet

- TOEFL Test 1Document10 pagesTOEFL Test 1Chantha Neav ChanthaNo ratings yet

- Objective 4Document8 pagesObjective 4api-662676619No ratings yet

- Kateofgaia Wordpress Com 2014-05-07 Babylon Is FallenDocument18 pagesKateofgaia Wordpress Com 2014-05-07 Babylon Is FallenJames WatsonNo ratings yet

- The Hot Air Balloon HistoryDocument3 pagesThe Hot Air Balloon HistoryRonnel ManrezaNo ratings yet

- Pregnancy and Lactation AnswersDocument8 pagesPregnancy and Lactation AnswersAoiNo ratings yet

- Remote Control ManualDocument16 pagesRemote Control ManualRajput PratiksinghNo ratings yet

- Linepipe Induction Bends (AMENDMENTS/SUPPLEMENTS TO DEP 31.40.20.30-Gen. AND DEP 31.40.20.31-Gen.)Document28 pagesLinepipe Induction Bends (AMENDMENTS/SUPPLEMENTS TO DEP 31.40.20.30-Gen. AND DEP 31.40.20.31-Gen.)resp-ectNo ratings yet