Professional Documents

Culture Documents

Thermal Profile (SSSP) Analysis of The Entire Estate An Example of The Analysis (Of A Certain Area)

Thermal Profile (SSSP) Analysis of The Entire Estate An Example of The Analysis (Of A Certain Area)

Uploaded by

dika.ti2008Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thermal Profile (SSSP) Analysis of The Entire Estate An Example of The Analysis (Of A Certain Area)

Thermal Profile (SSSP) Analysis of The Entire Estate An Example of The Analysis (Of A Certain Area)

Uploaded by

dika.ti2008Copyright:

Available Formats

Source:JASE-W Japanese Smart Energy Products & Technologies

http://www.jase-w.eccj.or.jp/technologies/index.html

F-01 L Technical Services

Pinch technology has been advancing since it emerged in the 1970s.

The first generation of pinch technology applied analysis to “process manufacturing equipment”.

In the second generation, the technology has been applied to factory infrastructure parts, called

“steam systems” or “energy systems” comprising elements such as boilers, turbines and steam

headers. Both have been applied to single factories.

Chiyoda Corporation has investigated how heat is used in oil refineries and in petrochemical factories,

considering the ideas that the two could share heat and energy, and that energy systems are a universal

requirement of factories. Until now, second-generation pinch technology has been applied to individual

factories, but Chiyoda’s research studied the potential for broadening the scope to analysis of energy

sharing between multiple factories in petrochemical complexes. It led to the development of the second-

generation factory complex edition of the technology, called “Area-wide Pinch Technology”.

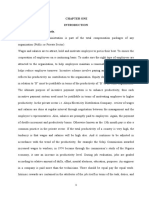

One tool in the area-wide pinch technology analyzes the transfer of heat among the energy systems of an

industrial area (among multiple plants). This can show that there is excess heat recovered from the

exhaust heat (left side of the figure) that can be given to the heat demand side (right side of the figure),

which will lead to energy saving.

Thermal profile (SSSP) analysis of the entire estate

An example of the analysis Solid line: Target

(of a certain area) Broken line: Current state

Optimization of the steam

generation level

Recovery and utilization of

low pressure steam

Optimization of the steam

usage level

Heat transfer

between plants

Recovery and utilization

of hot water

F-01

The results demonstrated that in the local area

there was scope for theoretical energy saving

equivalent to approximately 640,000kL of oil/year

in the Chiba refinery complex as a whole, through

measures such as energy system optimization.

That is a major energy saving, equivalent to one

day’s crude oil consumption for Japan as a whole.

also

Aerial view of the entire Chiba Industrial Area

Overseas Being installed in the largest industrial estate in Thailand, the Map Ta Phut Industrial Estate

Chiyoda Corporation is conducting an analysis on

energy sharing among the 15 plants selected from

a group of petroleum and petrochemical plants in

the Map Ta Phut Industrial Estate using the

Area-wide Pinch Technology with support from

NEDO and the Ministry of Industry of Thailand.

The energy saving potential of the entire estate

and a draft energy conservation project for the

estate will be determined as the results of the

analysis by the end of March 2014.

Sustinable Business Development Section, Strategic Business & Investment Management Unit

Minatomirai Grand Central Tower, 4-6-2 Minatomirai, Nishi-ku, Yokohama City, Kanagawa

Prefecture 220-8765, Japan

Tel: +81-45-225-4865 Fax: +81-45-225-4990

URL: http://www.chiyoda-corp.com/

You might also like

- Crisis in The Red Zone The Story of The Deadliest Ebola Outbreak in History and of The Outbreaks To Come Richard PrestonDocument43 pagesCrisis in The Red Zone The Story of The Deadliest Ebola Outbreak in History and of The Outbreaks To Come Richard Prestonryan.salvo790100% (6)

- "2040" Documentary Name: - : Viewing QuestionsDocument3 pages"2040" Documentary Name: - : Viewing Questionsapi-562285277No ratings yet

- Ravengro Expanded CompleteDocument10 pagesRavengro Expanded Completeitsme5616No ratings yet

- Carnot Battery Technology: A State-Of-The-Art ReviewDocument17 pagesCarnot Battery Technology: A State-Of-The-Art ReviewPaul MatteschkNo ratings yet

- Giz2014 en Market Potential Study Organic Rankine Cycle Technology India PDFDocument68 pagesGiz2014 en Market Potential Study Organic Rankine Cycle Technology India PDFdolphinNo ratings yet

- Daniel Humphrey EtalDocument9 pagesDaniel Humphrey Etalابراهيم عماد نجم محمدNo ratings yet

- Energy: Asif Iqbal, Khalid A. Al-GhamdiDocument10 pagesEnergy: Asif Iqbal, Khalid A. Al-GhamdiengrfaisalNo ratings yet

- 2-Page Annex 48Document2 pages2-Page Annex 48durjoythermaxNo ratings yet

- Optimum Superheat Utilization of Extraction Steam in Double ReheatDocument10 pagesOptimum Superheat Utilization of Extraction Steam in Double ReheatAhmed AsaadNo ratings yet

- Editor in Chief,+1109-FinalDocument8 pagesEditor in Chief,+1109-FinalUnaixah KhanNo ratings yet

- Exergy Analysis of Biomass Organic Rankine Cycle For Power GenerationDocument8 pagesExergy Analysis of Biomass Organic Rankine Cycle For Power Generationsergio matomaNo ratings yet

- An Innovative Approach To Design Cogeneration Systems B - 2020 - Energy ConversiDocument20 pagesAn Innovative Approach To Design Cogeneration Systems B - 2020 - Energy Conversidragos costelNo ratings yet

- Chemical Plant Energy Auditing-3Document59 pagesChemical Plant Energy Auditing-3Anurag SrivastavaNo ratings yet

- Economic and Technical Evaluation of Solar-Assisted Water Pump Stations For Mining Applications: A Case of StudyDocument6 pagesEconomic and Technical Evaluation of Solar-Assisted Water Pump Stations For Mining Applications: A Case of StudyJulioNo ratings yet

- Energy Saving in Atmospheric Distillation Unit by Retrofit Design of Heat Exchanger Networks of Al Basra Refinery IJERTV6IS040316Document6 pagesEnergy Saving in Atmospheric Distillation Unit by Retrofit Design of Heat Exchanger Networks of Al Basra Refinery IJERTV6IS040316Stive BrackNo ratings yet

- Diseño PDFDocument7 pagesDiseño PDFLina M GutierrezNo ratings yet

- Retrofit of The Heat Recovery System of A Petroleum Refinery Using Pinch AnalysisDocument6 pagesRetrofit of The Heat Recovery System of A Petroleum Refinery Using Pinch AnalysisEkaStaVTVNo ratings yet

- Bottom-Up Analysis of Industrial Waste Heat Potential in Taiwan - Energy - 20200314Document8 pagesBottom-Up Analysis of Industrial Waste Heat Potential in Taiwan - Energy - 20200314劉家豪No ratings yet

- Economical Analysis of Thermal Energy Storage by Partially OperationDocument5 pagesEconomical Analysis of Thermal Energy Storage by Partially Operationyousufali56No ratings yet

- Deep Learning Algorithms To Predict Output Electrical Power of An Industrial Steam TurbineDocument13 pagesDeep Learning Algorithms To Predict Output Electrical Power of An Industrial Steam TurbineaminardakaniNo ratings yet

- Formative Assessment 1 FloresDocument6 pagesFormative Assessment 1 FloresEmilio Joaquin FloresNo ratings yet

- Neepco AvikDocument18 pagesNeepco Avikavik0381No ratings yet

- Implementation of Lean Maintenance For Optimizing Duration of Overhaul Turbine Inspection (TI) at PT IPDocument9 pagesImplementation of Lean Maintenance For Optimizing Duration of Overhaul Turbine Inspection (TI) at PT IPInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Small Cogeneration in Industry: Requirements and Solutions With An Efficient Gas TurbineDocument7 pagesSmall Cogeneration in Industry: Requirements and Solutions With An Efficient Gas TurbineLeonidas VeraNo ratings yet

- EnergyEudit28thPublication PDFDocument15 pagesEnergyEudit28thPublication PDFMădălina ȘtefanNo ratings yet

- ICAE PaperDocument5 pagesICAE Paperzhor El hallaouiNo ratings yet

- ETKE 6 OPtimization of Pumped HydroDocument20 pagesETKE 6 OPtimization of Pumped HydroSyarifah AdrianaNo ratings yet

- 6904 25817 1 RVDocument7 pages6904 25817 1 RVM. Hadi KusumaNo ratings yet

- Energy Conversion and Management: Wei Cai, Fei Liu, Jun Xie, Xiaona ZhouDocument11 pagesEnergy Conversion and Management: Wei Cai, Fei Liu, Jun Xie, Xiaona ZhouSaifullah ZadranNo ratings yet

- # EC Guidelines Industries (Category - A) - Apr 2018Document71 pages# EC Guidelines Industries (Category - A) - Apr 2018shubhi agarwalNo ratings yet

- Energy Consumption Based On Actual Building Load Profile: June 2006Document6 pagesEnergy Consumption Based On Actual Building Load Profile: June 2006dcs.tesNo ratings yet

- 10 1016@j Enconman 2018 08 042 PDFDocument15 pages10 1016@j Enconman 2018 08 042 PDFteorikdeliNo ratings yet

- Review of Concentrating Solar Energies InMechanical Heat Process ApplicationsDocument4 pagesReview of Concentrating Solar Energies InMechanical Heat Process ApplicationsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Utilizing Gland SteamDocument7 pagesUtilizing Gland SteamZulhakim SharudinNo ratings yet

- Bmse PCMDocument18 pagesBmse PCMyogeshNo ratings yet

- Case Studies in Thermal Engineering: SciencedirectDocument5 pagesCase Studies in Thermal Engineering: SciencedirectQukuh Mukti AlhamdulillahNo ratings yet

- Jana 2010Document10 pagesJana 2010Nipun ChopraNo ratings yet

- DU WP Ind TES WebDocument38 pagesDU WP Ind TES WebalaqelshakerNo ratings yet

- Flexible Operation of Thermal Power Plants - NTPCDocument57 pagesFlexible Operation of Thermal Power Plants - NTPCmarishankar46115No ratings yet

- Electricity Storage - Technology BriefDocument28 pagesElectricity Storage - Technology BriefJose MNo ratings yet

- Electroplating BrochureDocument2 pagesElectroplating Brochurenadam54321No ratings yet

- Sciencedirect Sciencedirect SciencedirectDocument6 pagesSciencedirect Sciencedirect Sciencedirectzaenal abdulkholiqNo ratings yet

- Electric Power Consumption of Spinning Mill C5693028319Document8 pagesElectric Power Consumption of Spinning Mill C5693028319OUSMAN SEIDNo ratings yet

- Merch N 2017Document13 pagesMerch N 2017pbNo ratings yet

- Modeling of Internal Combustion Engine Based CogenerationDocument14 pagesModeling of Internal Combustion Engine Based CogenerationALEJANDRO CADENA DAZANo ratings yet

- SimplifieddesignprocedureDocument8 pagesSimplifieddesignprocedureHeri SetyantoNo ratings yet

- Industrial Training Seminar 2019Document31 pagesIndustrial Training Seminar 2019Siddhant GoswamiNo ratings yet

- Applied Energy: Sarah Brückner, Selina Liu, Laia Miró, Michael Radspieler, Luisa F. Cabeza, Eberhard LävemannDocument11 pagesApplied Energy: Sarah Brückner, Selina Liu, Laia Miró, Michael Radspieler, Luisa F. Cabeza, Eberhard LävemannerikaNo ratings yet

- JournalNX - Solar PV SystemDocument5 pagesJournalNX - Solar PV SystemJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Performance Evaluation of Alaoji Thermal Power PlantDocument8 pagesPerformance Evaluation of Alaoji Thermal Power PlantIjaems JournalNo ratings yet

- Chakraborty 2018Document5 pagesChakraborty 2018iiee alcNo ratings yet

- Integration of Absorption Heat Pumps inDocument7 pagesIntegration of Absorption Heat Pumps inPaulo GaiaNo ratings yet

- Opcion 1Document17 pagesOpcion 1María Lucía Pérez MoralesNo ratings yet

- Regional Performance of Thermal Power Generation in India: Satvir Singh, Sonu MadanDocument4 pagesRegional Performance of Thermal Power Generation in India: Satvir Singh, Sonu MadanIJAERS JOURNALNo ratings yet

- CSP in Non-Electrical Application: Ministério DaDocument28 pagesCSP in Non-Electrical Application: Ministério DaWanderson WadjôNo ratings yet

- Aerodynamic Analysis of RC PlaneDocument43 pagesAerodynamic Analysis of RC PlaneZahid AsifNo ratings yet

- Parhi 2019Document13 pagesParhi 2019Arifah Sukasri Jurusan Teknik KimiaNo ratings yet

- Presentation 1Document20 pagesPresentation 1Parveen Bairagi100% (1)

- Energy: Jonathan Reynolds, Yacine Rezgui, Alan Kwan, Sol Ene PiriouDocument11 pagesEnergy: Jonathan Reynolds, Yacine Rezgui, Alan Kwan, Sol Ene PiriouAlireza PiroozNo ratings yet

- Powerplant EngineeringDocument126 pagesPowerplant EngineeringSharmin Ahmed TinaNo ratings yet

- Sharma 2018Document8 pagesSharma 2018Fatia MbidaNo ratings yet

- Steam Tip Sheet #12Document2 pagesSteam Tip Sheet #12Muhammad NaeemNo ratings yet

- Energy and Thermal Management, Air-Conditioning, and Waste Heat Utilization: 2nd ETA Conference, November 22-23, 2018, Berlin, GermanyFrom EverandEnergy and Thermal Management, Air-Conditioning, and Waste Heat Utilization: 2nd ETA Conference, November 22-23, 2018, Berlin, GermanyChristine JuniorNo ratings yet

- Gligoric - I Play Against Pieces (2003) PDFDocument144 pagesGligoric - I Play Against Pieces (2003) PDFArdelean Lorela100% (3)

- Lesson 2Document15 pagesLesson 2Arriene Chris Ocho DiongsonNo ratings yet

- Organization Culture-Nikhil Peshawaria - Mohit WattsDocument32 pagesOrganization Culture-Nikhil Peshawaria - Mohit WattsAmit Anand KumarNo ratings yet

- The National Service Training Program (Ra 9163) : NSTP - Cwts 1 I. TitleDocument4 pagesThe National Service Training Program (Ra 9163) : NSTP - Cwts 1 I. TitleMekhaela Villaruel TinadorNo ratings yet

- Unit 5: Ind As 111: Joint ArrangementsDocument26 pagesUnit 5: Ind As 111: Joint ArrangementsDheeraj TurpunatiNo ratings yet

- Bey A1plus GrEx Wsh3&4 PDFDocument1 pageBey A1plus GrEx Wsh3&4 PDFCeciBravoNo ratings yet

- Scientific Method Test Study Guide2Document4 pagesScientific Method Test Study Guide2Gabriel TaylorNo ratings yet

- March Form 2Document1 pageMarch Form 2Jack PhanNo ratings yet

- Critical Book Report Written Language SkillDocument13 pagesCritical Book Report Written Language SkillMeysy Silvia SembiringNo ratings yet

- Maruti Suzuki India Limited (Msil)Document7 pagesMaruti Suzuki India Limited (Msil)KARUN RAJ K MBA IB 2018-20No ratings yet

- Bulletin February 2022 Over 18 Roles PDFDocument14 pagesBulletin February 2022 Over 18 Roles PDFaasim kNo ratings yet

- Free Guide Business Process ManagementDocument1 pageFree Guide Business Process ManagementpayoxNo ratings yet

- Mathematical Induction (John A Bather)Document8 pagesMathematical Induction (John A Bather)NuranaNo ratings yet

- RS125 Workshop ManualDocument290 pagesRS125 Workshop ManualJuan José Cázares RamírezNo ratings yet

- Le CorbusierDocument21 pagesLe CorbusierAbhishek GandhiNo ratings yet

- Out of The Jungle by Paul EllisDocument14 pagesOut of The Jungle by Paul Ellispurity_777No ratings yet

- Oracle® Territory Manager: User Guide Release 12.1Document80 pagesOracle® Territory Manager: User Guide Release 12.1Marcelo MestiNo ratings yet

- Ucl Thesis Citation StyleDocument6 pagesUcl Thesis Citation Stylemaryburgsiouxfalls100% (1)

- Health7 - Q2 - Mod5 Layout v1.0Document24 pagesHealth7 - Q2 - Mod5 Layout v1.0John Vincent D. Reyes100% (1)

- Zinc MTCDocument2 pagesZinc MTCMohd imranNo ratings yet

- People Vs SevillenoDocument6 pagesPeople Vs SevillenoChristineTanUmaliNo ratings yet

- 1-5 Wages and SalarieDocument40 pages1-5 Wages and SalarieKvng LearNo ratings yet

- Private Criminal Complaint v. Eric Calhoun & Alley Kat Bar With Lancaster City Police Response To Scene - September 22, 2007Document6 pagesPrivate Criminal Complaint v. Eric Calhoun & Alley Kat Bar With Lancaster City Police Response To Scene - September 22, 2007Stan J. CaterboneNo ratings yet

- Portage Manor PresentationDocument19 pagesPortage Manor PresentationWNDUNo ratings yet

- Examiner Application FormDocument5 pagesExaminer Application FormKcaj WongNo ratings yet

- Full Download Essentials of Management Information Systems 10th Edition Laudon Test BankDocument35 pagesFull Download Essentials of Management Information Systems 10th Edition Laudon Test Bankchetah.cciraz5cz100% (44)

- Dat AssDocument19 pagesDat AssMa k Kk60% (15)