Professional Documents

Culture Documents

Spreying and Seeding Robo".: Design and Operation of Agriculture Based Pesticide Spraying and Seeding Robot

Spreying and Seeding Robo".: Design and Operation of Agriculture Based Pesticide Spraying and Seeding Robot

Uploaded by

mrunali bhopaleCopyright:

Available Formats

You might also like

- A Technical Seminar Report 443Document31 pagesA Technical Seminar Report 443Gayathri YaddalaNo ratings yet

- Android Phone Controlled Bluetooth Robot: April 2016Document12 pagesAndroid Phone Controlled Bluetooth Robot: April 2016Fakhr Al-TimimiNo ratings yet

- Android Phone Controlled Bluetooth RobotDocument12 pagesAndroid Phone Controlled Bluetooth RobotNazmul Shikder RiyadhNo ratings yet

- Solar Powered Mobile Operated Smart Multifunction Agriculture RobotDocument4 pagesSolar Powered Mobile Operated Smart Multifunction Agriculture RobotVIVA-TECH IJRINo ratings yet

- FireDocument14 pagesFireffire0502No ratings yet

- Irjet V7i61194Document4 pagesIrjet V7i61194Aryan ShrivaNo ratings yet

- Design and Development of Automatic Floor Cleaning Robot Using Mega 328PDocument7 pagesDesign and Development of Automatic Floor Cleaning Robot Using Mega 328Pwww.sangug06No ratings yet

- A On "Capsten Project Planning (CPP) - 22058" Topic - Voice Control Robot CarDocument18 pagesA On "Capsten Project Planning (CPP) - 22058" Topic - Voice Control Robot CarViresh bhoirNo ratings yet

- Segway: School of Electronics EngineeringDocument17 pagesSegway: School of Electronics EngineeringSMNo ratings yet

- Solar Powered Grass Cutter and Pesticide Spreading RobotDocument4 pagesSolar Powered Grass Cutter and Pesticide Spreading RobotNeha SurwaseNo ratings yet

- IRJET V7I5770 With Cover Page v2Document6 pagesIRJET V7I5770 With Cover Page v2pal sarveshNo ratings yet

- PLC Based Waste Management RobotDocument3 pagesPLC Based Waste Management RobotkirubelNo ratings yet

- Bharath Fire Fighting RobotDocument43 pagesBharath Fire Fighting RobotDebojit DasNo ratings yet

- Bluetooth Control RobotDocument20 pagesBluetooth Control RobotSyed arefinNo ratings yet

- FIRE FIGHTING ROBOT (Mini Project)Document21 pagesFIRE FIGHTING ROBOT (Mini Project)Hisham Kunjumuhammed100% (2)

- Chapter 222 LabviewDocument65 pagesChapter 222 LabviewRahul Virmani100% (1)

- Venu PKDocument9 pagesVenu PKVenu Venupk1431No ratings yet

- Wireless 4 Dof Robotic Arm Using Mega 2560-1Document11 pagesWireless 4 Dof Robotic Arm Using Mega 2560-1Kamal HasanNo ratings yet

- Automatic Paint Spraying Machine Using IR Sensor: Abstract: The Primary Aim of The Project Is To Design, DevelopDocument3 pagesAutomatic Paint Spraying Machine Using IR Sensor: Abstract: The Primary Aim of The Project Is To Design, DevelopSANAPA TEJASWININo ratings yet

- Bluetooth Car Using ArduinoDocument9 pagesBluetooth Car Using ArduinoVenu Venupk1431No ratings yet

- Garbage Collection Robot Using Wireless CommunicationsDocument20 pagesGarbage Collection Robot Using Wireless Communicationsvishalpawar050No ratings yet

- Android Mobile Phone Controlled Bluetooth Robot Using 8051 MicrocontrollerDocument4 pagesAndroid Mobile Phone Controlled Bluetooth Robot Using 8051 MicrocontrollerSanzu PebrurisNo ratings yet

- Smart Floor Cleaner Robot Using AndroidDocument5 pagesSmart Floor Cleaner Robot Using AndroidTejas chogale100% (1)

- Solar Based Agriculture TractorDocument23 pagesSolar Based Agriculture TractoryashNo ratings yet

- Agriculture Robotic Vehicles Based PestisideDocument4 pagesAgriculture Robotic Vehicles Based PestisideBiruNo ratings yet

- RF Controlled Solar Panel Based Robotic VehicleDocument6 pagesRF Controlled Solar Panel Based Robotic VehicleMohan Babu ANo ratings yet

- Ijeee-V6i4p102 Seminar 2Document4 pagesIjeee-V6i4p102 Seminar 2tesla231004No ratings yet

- Speed Control of AC Motor: International Journal of Innovative Technology and Exploring Engineering February 2021Document4 pagesSpeed Control of AC Motor: International Journal of Innovative Technology and Exploring Engineering February 2021SABARISH MechanicalNo ratings yet

- Irjet V4i4783 PDFDocument3 pagesIrjet V4i4783 PDFBipin S CNo ratings yet

- Team - CuriosityDocument5 pagesTeam - CuriositySakib RatulNo ratings yet

- Agribot: An Agriculture Robot: Vol. 4, Issue 1, January 2015Document3 pagesAgribot: An Agriculture Robot: Vol. 4, Issue 1, January 2015Mohammad Tahir Khan NiaziNo ratings yet

- Agriculture Robotic Vehicles Based Pesticides SprayerDocument4 pagesAgriculture Robotic Vehicles Based Pesticides Sprayerlikhith dogiparthiNo ratings yet

- XXXXXXXXX (Title) : Submitted by Chaitanya Ranade 64Document12 pagesXXXXXXXXX (Title) : Submitted by Chaitanya Ranade 64HRITHIK POOJARYNo ratings yet

- Spy Robot Wireless Video Surveillance Using ArduinoDocument5 pagesSpy Robot Wireless Video Surveillance Using ArduinoEyob SintNo ratings yet

- Arduino Based Solar Operated Grass Cutter: Shivani A. Raut, R. J. BhiwaniDocument12 pagesArduino Based Solar Operated Grass Cutter: Shivani A. Raut, R. J. BhiwaniVj Vicky's100% (1)

- Vehicle Monitoring Controlling and Tracking System by Using Android ApplicationDocument7 pagesVehicle Monitoring Controlling and Tracking System by Using Android Applicationنائب إبليسNo ratings yet

- Development of An Obstacle Avoiding Robot: December 2015Document10 pagesDevelopment of An Obstacle Avoiding Robot: December 2015NIDHIN COCHINNo ratings yet

- Android Application Based Speed Control of A MotorDocument2 pagesAndroid Application Based Speed Control of A MotorVarun VadluriNo ratings yet

- سفاريDocument3 pagesسفاريhawrasdqNo ratings yet

- Gripper Robot: Solution Architecture Document ProjectDocument9 pagesGripper Robot: Solution Architecture Document Projectmonika nagarNo ratings yet

- Title: Bluetooth Based Robot: Submition Date Sat, 17 July Submited To Dr.R.GoppyDocument19 pagesTitle: Bluetooth Based Robot: Submition Date Sat, 17 July Submited To Dr.R.Goppymesfin mathewosNo ratings yet

- Project XDocument46 pagesProject Xhamza malikNo ratings yet

- Speed Control of DC Motor Using Mobile PhoneDocument4 pagesSpeed Control of DC Motor Using Mobile PhonegowrishankarplNo ratings yet

- Project Outline GP No 14 Sparsh RishabhJain NagaPranavDocument3 pagesProject Outline GP No 14 Sparsh RishabhJain NagaPranavRishabh JainNo ratings yet

- Wi - Fi Control Robot Using Node MCU: January 2018Document5 pagesWi - Fi Control Robot Using Node MCU: January 2018NayaaNo ratings yet

- Agribot: An Agriculture Robot: Vol. 4, Issue 1, January 2015Document3 pagesAgribot: An Agriculture Robot: Vol. 4, Issue 1, January 2015Dreamer JayaNo ratings yet

- Design of Smart Mechanical Grass CutterDocument4 pagesDesign of Smart Mechanical Grass CutterQhai AnimatorNo ratings yet

- Design of Smart Mechanical Grass CutterDocument4 pagesDesign of Smart Mechanical Grass CutterLarweh DanielNo ratings yet

- Design and Development of A Control Unit of An Automated Guided VehicleDocument9 pagesDesign and Development of A Control Unit of An Automated Guided VehicleDanil KhardniNo ratings yet

- Design and Development of Digital PID Controller For DC Motor Drive System Using Embedded Platform For Mobile RobotDocument5 pagesDesign and Development of Digital PID Controller For DC Motor Drive System Using Embedded Platform For Mobile Robotenghasan1969No ratings yet

- V15I5090Document3 pagesV15I5090tariq qureshiNo ratings yet

- Webcam Based Wireless Welding MachineDocument18 pagesWebcam Based Wireless Welding MachineAnuj TripathiNo ratings yet

- JETIR1804103Document6 pagesJETIR1804103Himanshu KumarNo ratings yet

- JournalDocument8 pagesJournalVarun SharmaNo ratings yet

- 412-Report-Induction Motor Protection SysteamDocument97 pages412-Report-Induction Motor Protection Systeamarishmomin44No ratings yet

- Speech Recognition System For A Voice Controlled Robot With Real Time Obstacle Detection and AvoidanceDocument5 pagesSpeech Recognition System For A Voice Controlled Robot With Real Time Obstacle Detection and AvoidanceMansi YadavNo ratings yet

- VC 3Document28 pagesVC 3Reethika SNo ratings yet

- Engineering the Future at the Intersection: Groundbreaking Advances in Mechanical EngineeringFrom EverandEngineering the Future at the Intersection: Groundbreaking Advances in Mechanical EngineeringNo ratings yet

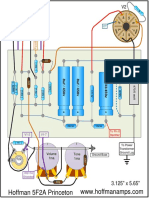

- Hoffman 5F2ADocument4 pagesHoffman 5F2ADakovic AleksandarNo ratings yet

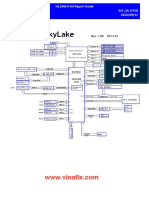

- Asus H110M-K-D3 RGDocument12 pagesAsus H110M-K-D3 RGNguyễn Quang SangNo ratings yet

- Railway Applications - Fixed Installations - Electric Traction Overhead Contact LinesDocument12 pagesRailway Applications - Fixed Installations - Electric Traction Overhead Contact LinesandreadelsoleNo ratings yet

- 100 Relay DevicesDocument26 pages100 Relay DevicesAngel Fel Burlat100% (1)

- BA6286N Reversibel Motor DriverDocument8 pagesBA6286N Reversibel Motor Drivereldel81No ratings yet

- Roland TDA-700 Owner's ManualDocument20 pagesRoland TDA-700 Owner's ManualAnonymous cdQSIU03AQNo ratings yet

- Chapter 2. Basic Sensors and Principles: 2.1 Displacement MeasurementsDocument26 pagesChapter 2. Basic Sensors and Principles: 2.1 Displacement MeasurementsIlavarasan TamizhNo ratings yet

- Pages From FDM (Ducted Split R22) - 6 PDFDocument1 pagePages From FDM (Ducted Split R22) - 6 PDFZiyadawaliNo ratings yet

- 5908999Document86 pages5908999Duc Nguyen HuuNo ratings yet

- Brochure-QES-LCR - GeneratorsDocument16 pagesBrochure-QES-LCR - GeneratorsDaniel IdubeNo ratings yet

- HMC204MS8G 204MS8GE: Gaas Mmic SMT Passive Frequency Doubler, 4 - 8 GHZ InputDocument4 pagesHMC204MS8G 204MS8GE: Gaas Mmic SMT Passive Frequency Doubler, 4 - 8 GHZ InputMike BrdnNo ratings yet

- User'S Manual User'S Manual: 1. ApplicationDocument4 pagesUser'S Manual User'S Manual: 1. ApplicationAhmed TalaatNo ratings yet

- Ka 34063a (Cuk)Document6 pagesKa 34063a (Cuk)sujitNo ratings yet

- Assignment Plug Load Calculation: Submitted By: Amisha 16001006008Document4 pagesAssignment Plug Load Calculation: Submitted By: Amisha 16001006008amisha bansalNo ratings yet

- Plasmadyeing 200320162358Document24 pagesPlasmadyeing 200320162358Ayman SebaeiNo ratings yet

- Measure PWM Motor EfficiencyDocument5 pagesMeasure PWM Motor Efficiencydot11No ratings yet

- RobertsonWilliamJ1959 KBCDocument46 pagesRobertsonWilliamJ1959 KBCVikas RautNo ratings yet

- Sample Chapter ch17 PDFDocument37 pagesSample Chapter ch17 PDFMaitraNo ratings yet

- Electrical and Temperature Correlation To Monitor Fault Condition of Zno Surge ArresterDocument5 pagesElectrical and Temperature Correlation To Monitor Fault Condition of Zno Surge ArresterLucho RufoNo ratings yet

- Super Plasma: C A T N O F 2 2 0 4 0 3Document4 pagesSuper Plasma: C A T N O F 2 2 0 4 0 3David SMNo ratings yet

- Owner's Manual: Bridgeable Power AmplifierDocument64 pagesOwner's Manual: Bridgeable Power AmplifiervanderleySCLNo ratings yet

- VFO StabiliDocument21 pagesVFO StabiliAlexandru Popescu100% (1)

- Tornatech Controller Data Sheet For EFP-WDO PDFDocument13 pagesTornatech Controller Data Sheet For EFP-WDO PDFViệt Đặng XuânNo ratings yet

- Semiconductor Science and Light Emitting DiodesDocument26 pagesSemiconductor Science and Light Emitting Diodeszoex924No ratings yet

- Welding Procedure Specification (WPS) Yes Prequalified X Qualified by Testing or Procedure Qualification Records (PQR) YesDocument2 pagesWelding Procedure Specification (WPS) Yes Prequalified X Qualified by Testing or Procedure Qualification Records (PQR) YessdgshhNo ratings yet

- NRJCAT20023ENDocument64 pagesNRJCAT20023ENdanang nuralamsyahNo ratings yet

- ECE556 Notes CompleteDocument653 pagesECE556 Notes CompleteTaufiku RahmanNo ratings yet

- Chapter 2 Wireless Network PrinciplesDocument79 pagesChapter 2 Wireless Network PrinciplesramuarulmuruganNo ratings yet

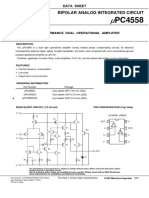

- Upc 4558Document11 pagesUpc 4558alex chapuzNo ratings yet

- UP-IV Pocket CardDocument2 pagesUP-IV Pocket Cardfelix3189100% (1)

Spreying and Seeding Robo".: Design and Operation of Agriculture Based Pesticide Spraying and Seeding Robot

Spreying and Seeding Robo".: Design and Operation of Agriculture Based Pesticide Spraying and Seeding Robot

Uploaded by

mrunali bhopaleOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spreying and Seeding Robo".: Design and Operation of Agriculture Based Pesticide Spraying and Seeding Robot

Spreying and Seeding Robo".: Design and Operation of Agriculture Based Pesticide Spraying and Seeding Robot

Uploaded by

mrunali bhopaleCopyright:

Available Formats

Design and operation of agriculture based pesticide spraying and seeding robot 2018

INTRODUCTION

The project aims on the design, development and fabrication of demonstration unit of the

project ”DESIGN AND OPRATION OF AGRICLUTURE BASED PESTICIDE

SPREYING AND SEEDING ROBO”.

More than 42% of the total population in the world has chosen agriculture as their

primary occupation. In recent years the development of autonomous vehicles in agriculture has

experienced increased interest. This development has led many researches start developing more

rational and adaptable vehicles. In the field of agriculture autonomous vehicles, a concept in

being developed to investigate if multiple small vehicles, machines would be more efficient than

traditional large tractors and human force.

These vehicles should be capable of working 24 hours a day all year round, in most

weather conditions. More over such a system may have less environmental impact if it can

reduce over application of chemicals and high usage of energy such as diesel and fertilizer, by

controls that are better match to stochastic requirements.

In agriculture farm, green house, farmers have to suffer many problems while farming

like hazards human health insects eat their crops, breathing problem, insects are cause of many

agriculture problems as they eat and damage the leaves and crops of farm.

There are ways to kill the insects without chemicals. The robot could submerge then in

container with water or into one closed up to produce extreme heat in the sun .Microbial fuel

cells could be used to reduce the insects to electrical power with bacteria pesticide kills

everything .Robot could be programmed particular pests and not harmed anything else.

Department of electrical engineering. Page 1

Design and operation of agriculture based pesticide spraying and seeding robot 2018

OBJECTIVE

The objective is to build a base framework for agriculture that can be centrally controller

using Arduino and smart phone.

The Robot can basically complete the work of automatic control and meet spraying and

seeding requirements in the farm.

The system has the advantage of high speed, high quality and processing precision.

Department of electrical engineering. Page 2

Design and operation of agriculture based pesticide spraying and seeding robot 2018

LITERATURE SURVEY

Design and operation of Agriculture based Pesticide Spraying Robot

o In order to protect laborer and reduce labor intensity, we develop a prototype of

pesticide spraying robot specially used in the greenhouse. Robot is controlled with

a 89C52 microcontroller. Designing of the latest inverted ROBOT which can be

controlling using an APP for android mobile. We are developing the remote

buttons in the android app by which we can control the robot motion with them

and in which we use Bluetooth communication to interface controller and android.

Controller can be interfaced to the Bluetooth model through UART protocol.

According to commands received from android the robot motion can be

controlled. The consistent output of a robotic system along with quality and

repeatability are unmatched Although the productivity of thee prototype is not

quite efficient, the robot still meets the requirements of pesticide spraying in the

greenhouse without human operators.

Autonomous Pesticide Spraying Robot for use in a Greenhouse:-

o This paper presents an engineering solution to the current human health hazards

involved in spraying potentially toxic chemicals in the confined space of hot and

steamy greenhouse. This is achieved by the design and construction of an

autonomous mobile Robot for using paste control and disease prevention

applications in commercial greenhouse. The effectiveness of this platform is

shown by the platforms ability to successfully navigate itself down rows of a

greenhouse.

Department of electrical engineering. Page 3

Design and operation of agriculture based pesticide spraying and seeding robot 2018

METHODOLOGY

Selection of topic:

In this primary stage we have gone through many topics on that we can work.

Finally we have selected this topic because it is a sponsored project, so by doing this we

can solve industry problem. At the same time we can increasing the efficiency and

accuracy of their system.

Selection of Components:

After selection of topic we select the required components for hardware.

Building Block diagram:

After finalising of our project component we started working on block diagram.

After working on this we have made the selection of block diagram.

Software design:

We write the program on embedded C for controller.

Design and interfacing :

In this we make the PCB design and done with interfacing of motor with motor

driver circuit.

Mechanical Design:

Here we drive the motor in clockwise and anticlockwise direction.

Preparation of Spray and Seeding system:

we will prepare mixture tank and chemical tank and seed vessel.

System implementation:

After completion of programming and simulation we will start system

implementation. We will divide the work of implementation in stages. The system

implementation follows the block diagram.

Testing of system:

After the successful implementation of system we will have test on it and then

after we will give the demo

Department of electrical engineering. Page 4

Design and operation of agriculture based pesticide spraying and seeding robot 2018

Block Diagram

Wireless Android

camera App

Bluetooth

Module

Battery

supply

M1

Arduino Motor

M2

Reset Driver 1

Circuit M3

M4

Crystal

Oscillator Motor Driver

Relay Circuit

Motor

for

seeding

Spray DC Pump

Department of electrical engineering. Page 5

Design and operation of agriculture based pesticide spraying and seeding robot 2018

COMPONENT

Bluetooth module

Power Supply

Arduino

L293D

DC Motor

Relay Driver Circuit

DC Pump

1. BLUETOOTH MODULE

HC-05 is a Bluetooth module which is designed for wireless communication. This

module can be used in a master or slave configuration.

Department of electrical engineering. Page 6

Design and operation of agriculture based pesticide spraying and seeding robot 2018

BLUETOOTHHC-05 has red LED which indicates connection status, whether the Bluetooth

is connected or not. Before connecting to HC-05 module this red LED blinks continuously in

a periodic manner. When it gets connected to any other Bluetooth device, its blinking slows

down to two seconds.

This module works on 3.3 V. We can connect 5V supply voltage as well since the module

has on board 5 to 3.3 V regulator.

As HC-05 Bluetooth module has 3.3 V level for RX/TX and microcontroller can detect 3.3 V

level, so, no need to shift transmit level of HC-05 module. But we need to shift the transmit

voltage level from microcontroller to RX of HC-05 module.

2. POWER SUPPLY

In most of our electronic product or project we need a power supply for converting mains

AC voltages to a regulated DC voltage. For making a power supply designing of each and every

component is essential. Here I’m going to discuss the designing of regulated 5V Power Supply.

As we require a 5V we need LM7805 Voltage Regulator IC.

7805 IC Rating:

Input voltage range 7V-35V

Current rating I-1A

Output voltage range Vmax=5.2v Vmax=4.8v

Department of electrical engineering. Page 7

Design and operation of agriculture based pesticide spraying and seeding robot 2018

The 7805 is a three terminal positive voltage regulator IC which gives regulated 5V

D.C.output. The maximum input voltage that can be applied to input pin is the 35V. The

minimum difference between input and output voltage required is the 2V. The pin no. 1 is the

input pin where the unregulated input voltage is applied. Pin no. 2 is connected to the ground,

whereas pin no. 3 is the output pin at which the regulated 5V output can be obtained. For proper

operation a common ground is required between input and output voltages.

3. Arduino

Arduino is an Open-source-electronic-prototyping-base for simple used hardware and

softwarein the field of micro controlling. It is suitable to realize fascinating projects in a short

time.

Many of them can be found on YouTube under Arduino. It is mostly used by artists,

designer ortinkers to realize creative ideas. But Arduino is also increasingly used by universities

and schools to teach an interesting andsimple beginning to the world of micro controlling.

The term Arduino its mostly used for both components. The hardware (Arduino

Boards)and the corresponding software (Arduino).

Department of electrical engineering. Page 8

Design and operation of agriculture based pesticide spraying and seeding robot 2018

4. MOTOR DRIVER L293D:-

Specification of Motor Driver L293D:-

16 PIN IC

Two DC motor with single L293D IC

High-Noise-Immunity Inputs

Separate Input-Logic Supply

Output Current 1 A Per Channel (600 mA for L293D)

Department of electrical engineering. Page 9

Design and operation of agriculture based pesticide spraying and seeding robot 2018

L293D is a typical Motor driver or Motor Driver IC which allows DC motor to drive on

either direction. L293D is a 16-pin IC which can control a set of two DC motors simultaneously

in any direction. It means that you can control two DC motor with a single L293D IC.

L293D is a dual H-bridge motor driver integrated circuit (IC). Motor drivers act as current

amplifiers since they take a low-current control signal and provide a higher-current signal. This

higher current signal is used to drive the motors.

L293D contains two inbuilt H-bridge driver circuits. In its common mode of operation,

two DC motors can be driven simultaneously, both in forward and reverse direction. The motor

operations of two motors can be controlled by input logic at pins 2 & 7 and 10 & 15. Input logic

00 or 11 will stop the corresponding motor. Logic 01 and 10 will rotate it in clockwise and

anticlockwise directions, respectively.

Department of electrical engineering. Page 10

Design and operation of agriculture based pesticide spraying and seeding robot 2018

Enable pins 1 and 9 (corresponding to the two motors) must be high for motors to start

operating. When an enable input is high, the associated driver gets enabled. As a result, the

outputs become active and work in phase with their inputs. Similarly, when the enable input is

low, that driver is disabled, and their outputs are off and in the high-impedance state.

5. DC MOTOR

Brushless DC motors utilise the same electromagnetic phenomenon as brushed motors in

order to producemechanical rotation - the force which is exerted on a current carrying conductor

placed in a magnetic field. Abrushless motor is mechanically simpler than a brushed motor .

6. RELAY DRIVER CIRCUIT

Here to turn on the Relay with Arduino we just need to make that Arduino Pin High (A0

in our case) where Relay module is connected. Below given is Relay Driver Circuit to build your

own Relay module:

Department of electrical engineering. Page 11

Design and operation of agriculture based pesticide spraying and seeding robot 2018

7. DC Pump

The working principle of a water pump depends on the type of motor – Electric,

Centrifugal, Diesel Driven, etc. The main principal behind the working of every water pressure

Department of electrical engineering. Page 12

Design and operation of agriculture based pesticide spraying and seeding robot 2018

booster pump for home is the conversion of energy into mechanical energy and using it for

providing the required pressure for pumping the water.

Pumps basically use the forces of nature in order to move the liquid. With the beginning

of movement in the pump parts such as an impeller or piston diaphragm, air is pushed out of the

way. A partial low pressure is created, which can be filled up by water.

Department of electrical engineering. Page 13

Design and operation of agriculture based pesticide spraying and seeding robot 2018

Circuit Diagram

Department of electrical engineering. Page 14

Design and operation of agriculture based pesticide spraying and seeding robot 2018

FUTURE SCOPE

It provides safety to the farmers from harmful pesticides.

The future scope of this types of Robots are very bright because it is very useful in

agriculture and reduce the workload.

It reduce the time consumed in spraying the pesticides liquid and works very effectively.

It will help the farmers to do work in any season and conditions.

The system can further modified for picking fruits, and actual cutting process by the

system.

Department of electrical engineering. Page 15

Design and operation of agriculture based pesticide spraying and seeding robot 2018

References

[1]Sammons P J, Furukawa T, Bulgin A.”Autonomous Pesticide Spraying Robot for Use

in A Greenhouse [A]”,Australian Conference on Robotics and Australian Conference on

Robotics and Automation, Sydney

Mu Nan, Zhang Australian 2008.

[2]Zhang Ying, Xueqin.”The Development Status and Trends of Facility Agriculture

Overseas[J]”.

[3]” Bluetooth based android phone/tablet controlled robot”, Available:

http://www.robokits.co.inand http://www.robokitsworld.com.

[4]R. Eaten ,J. Katupitiya, K.W.Siew,B.Howarth ,Autonomous farming: Modeling and

control of agricultural machinery in a unified framework”,In Proc.15th Int. Conf.

Mechatronics and Machine Vision Practice ,Aukland, New Zealand, Dec.

[4] R. Eaton, J. Katupitiya, K. W. Siew, B. Howarth, Autonomous

farming: Modeling and control of agricultural machinery in

a unified framework", In Proc. 15th Int. Conf. Mechatronics

and Machine Vision Practice, Auckland, New Zealand, Dec.

Department of electrical engineering. Page 16

You might also like

- A Technical Seminar Report 443Document31 pagesA Technical Seminar Report 443Gayathri YaddalaNo ratings yet

- Android Phone Controlled Bluetooth Robot: April 2016Document12 pagesAndroid Phone Controlled Bluetooth Robot: April 2016Fakhr Al-TimimiNo ratings yet

- Android Phone Controlled Bluetooth RobotDocument12 pagesAndroid Phone Controlled Bluetooth RobotNazmul Shikder RiyadhNo ratings yet

- Solar Powered Mobile Operated Smart Multifunction Agriculture RobotDocument4 pagesSolar Powered Mobile Operated Smart Multifunction Agriculture RobotVIVA-TECH IJRINo ratings yet

- FireDocument14 pagesFireffire0502No ratings yet

- Irjet V7i61194Document4 pagesIrjet V7i61194Aryan ShrivaNo ratings yet

- Design and Development of Automatic Floor Cleaning Robot Using Mega 328PDocument7 pagesDesign and Development of Automatic Floor Cleaning Robot Using Mega 328Pwww.sangug06No ratings yet

- A On "Capsten Project Planning (CPP) - 22058" Topic - Voice Control Robot CarDocument18 pagesA On "Capsten Project Planning (CPP) - 22058" Topic - Voice Control Robot CarViresh bhoirNo ratings yet

- Segway: School of Electronics EngineeringDocument17 pagesSegway: School of Electronics EngineeringSMNo ratings yet

- Solar Powered Grass Cutter and Pesticide Spreading RobotDocument4 pagesSolar Powered Grass Cutter and Pesticide Spreading RobotNeha SurwaseNo ratings yet

- IRJET V7I5770 With Cover Page v2Document6 pagesIRJET V7I5770 With Cover Page v2pal sarveshNo ratings yet

- PLC Based Waste Management RobotDocument3 pagesPLC Based Waste Management RobotkirubelNo ratings yet

- Bharath Fire Fighting RobotDocument43 pagesBharath Fire Fighting RobotDebojit DasNo ratings yet

- Bluetooth Control RobotDocument20 pagesBluetooth Control RobotSyed arefinNo ratings yet

- FIRE FIGHTING ROBOT (Mini Project)Document21 pagesFIRE FIGHTING ROBOT (Mini Project)Hisham Kunjumuhammed100% (2)

- Chapter 222 LabviewDocument65 pagesChapter 222 LabviewRahul Virmani100% (1)

- Venu PKDocument9 pagesVenu PKVenu Venupk1431No ratings yet

- Wireless 4 Dof Robotic Arm Using Mega 2560-1Document11 pagesWireless 4 Dof Robotic Arm Using Mega 2560-1Kamal HasanNo ratings yet

- Automatic Paint Spraying Machine Using IR Sensor: Abstract: The Primary Aim of The Project Is To Design, DevelopDocument3 pagesAutomatic Paint Spraying Machine Using IR Sensor: Abstract: The Primary Aim of The Project Is To Design, DevelopSANAPA TEJASWININo ratings yet

- Bluetooth Car Using ArduinoDocument9 pagesBluetooth Car Using ArduinoVenu Venupk1431No ratings yet

- Garbage Collection Robot Using Wireless CommunicationsDocument20 pagesGarbage Collection Robot Using Wireless Communicationsvishalpawar050No ratings yet

- Android Mobile Phone Controlled Bluetooth Robot Using 8051 MicrocontrollerDocument4 pagesAndroid Mobile Phone Controlled Bluetooth Robot Using 8051 MicrocontrollerSanzu PebrurisNo ratings yet

- Smart Floor Cleaner Robot Using AndroidDocument5 pagesSmart Floor Cleaner Robot Using AndroidTejas chogale100% (1)

- Solar Based Agriculture TractorDocument23 pagesSolar Based Agriculture TractoryashNo ratings yet

- Agriculture Robotic Vehicles Based PestisideDocument4 pagesAgriculture Robotic Vehicles Based PestisideBiruNo ratings yet

- RF Controlled Solar Panel Based Robotic VehicleDocument6 pagesRF Controlled Solar Panel Based Robotic VehicleMohan Babu ANo ratings yet

- Ijeee-V6i4p102 Seminar 2Document4 pagesIjeee-V6i4p102 Seminar 2tesla231004No ratings yet

- Speed Control of AC Motor: International Journal of Innovative Technology and Exploring Engineering February 2021Document4 pagesSpeed Control of AC Motor: International Journal of Innovative Technology and Exploring Engineering February 2021SABARISH MechanicalNo ratings yet

- Irjet V4i4783 PDFDocument3 pagesIrjet V4i4783 PDFBipin S CNo ratings yet

- Team - CuriosityDocument5 pagesTeam - CuriositySakib RatulNo ratings yet

- Agribot: An Agriculture Robot: Vol. 4, Issue 1, January 2015Document3 pagesAgribot: An Agriculture Robot: Vol. 4, Issue 1, January 2015Mohammad Tahir Khan NiaziNo ratings yet

- Agriculture Robotic Vehicles Based Pesticides SprayerDocument4 pagesAgriculture Robotic Vehicles Based Pesticides Sprayerlikhith dogiparthiNo ratings yet

- XXXXXXXXX (Title) : Submitted by Chaitanya Ranade 64Document12 pagesXXXXXXXXX (Title) : Submitted by Chaitanya Ranade 64HRITHIK POOJARYNo ratings yet

- Spy Robot Wireless Video Surveillance Using ArduinoDocument5 pagesSpy Robot Wireless Video Surveillance Using ArduinoEyob SintNo ratings yet

- Arduino Based Solar Operated Grass Cutter: Shivani A. Raut, R. J. BhiwaniDocument12 pagesArduino Based Solar Operated Grass Cutter: Shivani A. Raut, R. J. BhiwaniVj Vicky's100% (1)

- Vehicle Monitoring Controlling and Tracking System by Using Android ApplicationDocument7 pagesVehicle Monitoring Controlling and Tracking System by Using Android Applicationنائب إبليسNo ratings yet

- Development of An Obstacle Avoiding Robot: December 2015Document10 pagesDevelopment of An Obstacle Avoiding Robot: December 2015NIDHIN COCHINNo ratings yet

- Android Application Based Speed Control of A MotorDocument2 pagesAndroid Application Based Speed Control of A MotorVarun VadluriNo ratings yet

- سفاريDocument3 pagesسفاريhawrasdqNo ratings yet

- Gripper Robot: Solution Architecture Document ProjectDocument9 pagesGripper Robot: Solution Architecture Document Projectmonika nagarNo ratings yet

- Title: Bluetooth Based Robot: Submition Date Sat, 17 July Submited To Dr.R.GoppyDocument19 pagesTitle: Bluetooth Based Robot: Submition Date Sat, 17 July Submited To Dr.R.Goppymesfin mathewosNo ratings yet

- Project XDocument46 pagesProject Xhamza malikNo ratings yet

- Speed Control of DC Motor Using Mobile PhoneDocument4 pagesSpeed Control of DC Motor Using Mobile PhonegowrishankarplNo ratings yet

- Project Outline GP No 14 Sparsh RishabhJain NagaPranavDocument3 pagesProject Outline GP No 14 Sparsh RishabhJain NagaPranavRishabh JainNo ratings yet

- Wi - Fi Control Robot Using Node MCU: January 2018Document5 pagesWi - Fi Control Robot Using Node MCU: January 2018NayaaNo ratings yet

- Agribot: An Agriculture Robot: Vol. 4, Issue 1, January 2015Document3 pagesAgribot: An Agriculture Robot: Vol. 4, Issue 1, January 2015Dreamer JayaNo ratings yet

- Design of Smart Mechanical Grass CutterDocument4 pagesDesign of Smart Mechanical Grass CutterQhai AnimatorNo ratings yet

- Design of Smart Mechanical Grass CutterDocument4 pagesDesign of Smart Mechanical Grass CutterLarweh DanielNo ratings yet

- Design and Development of A Control Unit of An Automated Guided VehicleDocument9 pagesDesign and Development of A Control Unit of An Automated Guided VehicleDanil KhardniNo ratings yet

- Design and Development of Digital PID Controller For DC Motor Drive System Using Embedded Platform For Mobile RobotDocument5 pagesDesign and Development of Digital PID Controller For DC Motor Drive System Using Embedded Platform For Mobile Robotenghasan1969No ratings yet

- V15I5090Document3 pagesV15I5090tariq qureshiNo ratings yet

- Webcam Based Wireless Welding MachineDocument18 pagesWebcam Based Wireless Welding MachineAnuj TripathiNo ratings yet

- JETIR1804103Document6 pagesJETIR1804103Himanshu KumarNo ratings yet

- JournalDocument8 pagesJournalVarun SharmaNo ratings yet

- 412-Report-Induction Motor Protection SysteamDocument97 pages412-Report-Induction Motor Protection Systeamarishmomin44No ratings yet

- Speech Recognition System For A Voice Controlled Robot With Real Time Obstacle Detection and AvoidanceDocument5 pagesSpeech Recognition System For A Voice Controlled Robot With Real Time Obstacle Detection and AvoidanceMansi YadavNo ratings yet

- VC 3Document28 pagesVC 3Reethika SNo ratings yet

- Engineering the Future at the Intersection: Groundbreaking Advances in Mechanical EngineeringFrom EverandEngineering the Future at the Intersection: Groundbreaking Advances in Mechanical EngineeringNo ratings yet

- Hoffman 5F2ADocument4 pagesHoffman 5F2ADakovic AleksandarNo ratings yet

- Asus H110M-K-D3 RGDocument12 pagesAsus H110M-K-D3 RGNguyễn Quang SangNo ratings yet

- Railway Applications - Fixed Installations - Electric Traction Overhead Contact LinesDocument12 pagesRailway Applications - Fixed Installations - Electric Traction Overhead Contact LinesandreadelsoleNo ratings yet

- 100 Relay DevicesDocument26 pages100 Relay DevicesAngel Fel Burlat100% (1)

- BA6286N Reversibel Motor DriverDocument8 pagesBA6286N Reversibel Motor Drivereldel81No ratings yet

- Roland TDA-700 Owner's ManualDocument20 pagesRoland TDA-700 Owner's ManualAnonymous cdQSIU03AQNo ratings yet

- Chapter 2. Basic Sensors and Principles: 2.1 Displacement MeasurementsDocument26 pagesChapter 2. Basic Sensors and Principles: 2.1 Displacement MeasurementsIlavarasan TamizhNo ratings yet

- Pages From FDM (Ducted Split R22) - 6 PDFDocument1 pagePages From FDM (Ducted Split R22) - 6 PDFZiyadawaliNo ratings yet

- 5908999Document86 pages5908999Duc Nguyen HuuNo ratings yet

- Brochure-QES-LCR - GeneratorsDocument16 pagesBrochure-QES-LCR - GeneratorsDaniel IdubeNo ratings yet

- HMC204MS8G 204MS8GE: Gaas Mmic SMT Passive Frequency Doubler, 4 - 8 GHZ InputDocument4 pagesHMC204MS8G 204MS8GE: Gaas Mmic SMT Passive Frequency Doubler, 4 - 8 GHZ InputMike BrdnNo ratings yet

- User'S Manual User'S Manual: 1. ApplicationDocument4 pagesUser'S Manual User'S Manual: 1. ApplicationAhmed TalaatNo ratings yet

- Ka 34063a (Cuk)Document6 pagesKa 34063a (Cuk)sujitNo ratings yet

- Assignment Plug Load Calculation: Submitted By: Amisha 16001006008Document4 pagesAssignment Plug Load Calculation: Submitted By: Amisha 16001006008amisha bansalNo ratings yet

- Plasmadyeing 200320162358Document24 pagesPlasmadyeing 200320162358Ayman SebaeiNo ratings yet

- Measure PWM Motor EfficiencyDocument5 pagesMeasure PWM Motor Efficiencydot11No ratings yet

- RobertsonWilliamJ1959 KBCDocument46 pagesRobertsonWilliamJ1959 KBCVikas RautNo ratings yet

- Sample Chapter ch17 PDFDocument37 pagesSample Chapter ch17 PDFMaitraNo ratings yet

- Electrical and Temperature Correlation To Monitor Fault Condition of Zno Surge ArresterDocument5 pagesElectrical and Temperature Correlation To Monitor Fault Condition of Zno Surge ArresterLucho RufoNo ratings yet

- Super Plasma: C A T N O F 2 2 0 4 0 3Document4 pagesSuper Plasma: C A T N O F 2 2 0 4 0 3David SMNo ratings yet

- Owner's Manual: Bridgeable Power AmplifierDocument64 pagesOwner's Manual: Bridgeable Power AmplifiervanderleySCLNo ratings yet

- VFO StabiliDocument21 pagesVFO StabiliAlexandru Popescu100% (1)

- Tornatech Controller Data Sheet For EFP-WDO PDFDocument13 pagesTornatech Controller Data Sheet For EFP-WDO PDFViệt Đặng XuânNo ratings yet

- Semiconductor Science and Light Emitting DiodesDocument26 pagesSemiconductor Science and Light Emitting Diodeszoex924No ratings yet

- Welding Procedure Specification (WPS) Yes Prequalified X Qualified by Testing or Procedure Qualification Records (PQR) YesDocument2 pagesWelding Procedure Specification (WPS) Yes Prequalified X Qualified by Testing or Procedure Qualification Records (PQR) YessdgshhNo ratings yet

- NRJCAT20023ENDocument64 pagesNRJCAT20023ENdanang nuralamsyahNo ratings yet

- ECE556 Notes CompleteDocument653 pagesECE556 Notes CompleteTaufiku RahmanNo ratings yet

- Chapter 2 Wireless Network PrinciplesDocument79 pagesChapter 2 Wireless Network PrinciplesramuarulmuruganNo ratings yet

- Upc 4558Document11 pagesUpc 4558alex chapuzNo ratings yet

- UP-IV Pocket CardDocument2 pagesUP-IV Pocket Cardfelix3189100% (1)