Professional Documents

Culture Documents

Data:: Work Sheet - 2 (Use Data Sheet)

Data:: Work Sheet - 2 (Use Data Sheet)

Uploaded by

api-3852712Copyright:

Available Formats

You might also like

- Drilling Questions and SolutionsDocument10 pagesDrilling Questions and SolutionsJohn Joseph100% (3)

- Sample Problems in Industrial Plant DesignDocument26 pagesSample Problems in Industrial Plant DesignSdhfdh Hdfhd100% (1)

- Problem Report Pump To EvaporatorDocument25 pagesProblem Report Pump To EvaporatorTakishima N VovoNo ratings yet

- MIP Thickener DesignDocument3 pagesMIP Thickener DesignHatem Salah100% (1)

- Rocket QuestionbankDocument2 pagesRocket QuestionbankSanjana RaoNo ratings yet

- PPE AssignmentDocument16 pagesPPE AssignmentlibbissujessyNo ratings yet

- TutorialDocument5 pagesTutorialAbdul Razak RahmatNo ratings yet

- Design Heat Exchanger Shell and Tube TheDocument8 pagesDesign Heat Exchanger Shell and Tube ThezatamaqeelNo ratings yet

- Lecture 9 Coagulation Design Criteria and ExamplesDocument12 pagesLecture 9 Coagulation Design Criteria and ExamplesAhmad Salih100% (1)

- Principle of Working of Grit ChamberDocument11 pagesPrinciple of Working of Grit ChamberAhmed Amedi100% (3)

- Ie5b02555 Si 001Document15 pagesIe5b02555 Si 001Akshay PatelNo ratings yet

- Abe Quiz Season XviiDocument7 pagesAbe Quiz Season XviiMeljun GementizaNo ratings yet

- Settling ChambersDocument2 pagesSettling ChambersAnonymous d3sWgsNo ratings yet

- Meng HMTDocument12 pagesMeng HMTMiskir AimNo ratings yet

- Ae708 Question Bank 2Document5 pagesAe708 Question Bank 2pRoBoTRoGe OPNo ratings yet

- Assignment 3Document3 pagesAssignment 3HARINo ratings yet

- Cycle Test 2 Rocket PropulsionDocument3 pagesCycle Test 2 Rocket Propulsionapi-271354682No ratings yet

- Isro Scientist Me 2020 Paper 80c39244Document20 pagesIsro Scientist Me 2020 Paper 80c39244Elsa PoirotNo ratings yet

- Reactor & Dryer DesignDocument19 pagesReactor & Dryer DesignSepribo BraideNo ratings yet

- BE ChemDocument53 pagesBE ChemMuddasar ShaikhNo ratings yet

- Hmtmta2 Main PDFDocument10 pagesHmtmta2 Main PDFONNDWELA RAMALAMULANo ratings yet

- Tutorial - Mass TransferDocument1 pageTutorial - Mass Transfer219016536No ratings yet

- 371hw06s (Rapid Mix Tank Design-Sample 1)Document5 pages371hw06s (Rapid Mix Tank Design-Sample 1)Yang Ching HianNo ratings yet

- A New Approach To Cooling and Prilling During Fertilizer ManufactureDocument11 pagesA New Approach To Cooling and Prilling During Fertilizer ManufactureHaider AliNo ratings yet

- Melt Index TestDocument4 pagesMelt Index TestFarooq Muhammad100% (1)

- Unit Operations Tutorial 2015-2016Document13 pagesUnit Operations Tutorial 2015-2016hazimraad0% (1)

- Drying Hopper Calculation-1Document3 pagesDrying Hopper Calculation-1Gilang Adi SetyawanNo ratings yet

- JJJJJJJJJJDocument4 pagesJJJJJJJJJJJoshua UmaliNo ratings yet

- Learning Assessment Activity 1. QUESTIONS.: Name: Franzes Mar Eria Heat and Mass Transfer Bsche 3Document7 pagesLearning Assessment Activity 1. QUESTIONS.: Name: Franzes Mar Eria Heat and Mass Transfer Bsche 3Franzes Mar EriaNo ratings yet

- TitleDocument2 pagesTitleJoel VazNo ratings yet

- Heat Transfer May2004 NR 310803Document8 pagesHeat Transfer May2004 NR 310803Nizam Institute of Engineering and Technology LibraryNo ratings yet

- Set CDocument11 pagesSet CRayver MambNo ratings yet

- Tripoli University Chemical Engineering Department: Homework #4Document2 pagesTripoli University Chemical Engineering Department: Homework #4Good BadNo ratings yet

- Basic ScienceDocument7 pagesBasic ScienceGibbs AmbionNo ratings yet

- Filament Yarn Quench AirDocument2 pagesFilament Yarn Quench AirClarence AG YueNo ratings yet

- Mass Transfer Operations Model QuestionsDocument8 pagesMass Transfer Operations Model QuestionsIastraNo ratings yet

- Heat Exchanger DesignDocument15 pagesHeat Exchanger DesignCharito Sollera AlbaricoNo ratings yet

- AIr NummericalDocument2 pagesAIr NummericalArnav TiwariNo ratings yet

- Final SelectionDocument8 pagesFinal SelectionFahad KhokharNo ratings yet

- Rules of Thumb Ludwigs Applied Process PDFDocument9 pagesRules of Thumb Ludwigs Applied Process PDFAngelena Rani FrancisNo ratings yet

- Week 10Document11 pagesWeek 10Abhishek KumarNo ratings yet

- CRYOGENIC LAB Practical FileDocument10 pagesCRYOGENIC LAB Practical FileSantosh BaraiyaNo ratings yet

- HT AssignmentDocument12 pagesHT AssignmentCollano M. Noel RogieNo ratings yet

- Ped QuestionsDocument11 pagesPed QuestionsYashPatel100% (1)

- Hydrogenator DesignDocument9 pagesHydrogenator DesignA MNo ratings yet

- Rr310803 Heat TransferDocument8 pagesRr310803 Heat TransferSrinivasa Rao GNo ratings yet

- Lecture 6 1Document24 pagesLecture 6 1Dany LoboNo ratings yet

- Rules Thumb: Summary: P Z 90 TorrDocument9 pagesRules Thumb: Summary: P Z 90 TorrNdzalama RekotsoNo ratings yet

- rr310303 Thermal Engineering IIDocument9 pagesrr310303 Thermal Engineering IISRINIVASA RAO GANTANo ratings yet

- Tutorial - Transient ConductionDocument2 pagesTutorial - Transient Conduction219016536No ratings yet

- Ems TutorialDocument43 pagesEms TutorialJohn Eric Balarao Ferranco33% (3)

- Heat Transfer Jan2003 or 220852Document2 pagesHeat Transfer Jan2003 or 220852Nizam Institute of Engineering and Technology LibraryNo ratings yet

- Civil Engineer NotesDocument91 pagesCivil Engineer Notesishfaq hassanNo ratings yet

- Applied Thermodynamics QBDocument12 pagesApplied Thermodynamics QBapi-25999517100% (1)

- Heat Transfer in Polymer Composite Materials: Forming ProcessesFrom EverandHeat Transfer in Polymer Composite Materials: Forming ProcessesNicolas BoyardNo ratings yet

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"From EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"No ratings yet

- 3 Exiguobacterium Sp. LMNARJR 16S Ribosomal RNA Gene, Partial Sequence - Nucleotide - NCBI (9 Files Merged)Document9 pages3 Exiguobacterium Sp. LMNARJR 16S Ribosomal RNA Gene, Partial Sequence - Nucleotide - NCBI (9 Files Merged)api-3852712No ratings yet

- Modeling and Experimental Study For Winter Performance of An Earth To Air Heat Exchanger: An Alternative Energy Source For GreenhouseDocument14 pagesModeling and Experimental Study For Winter Performance of An Earth To Air Heat Exchanger: An Alternative Energy Source For Greenhouseapi-3852712No ratings yet

- Redundant Phrases Are Bad Habits Just Waiting To Take Control of Your Writing. Beware of The FollowingDocument3 pagesRedundant Phrases Are Bad Habits Just Waiting To Take Control of Your Writing. Beware of The Followingapi-3852712No ratings yet

- Life and Times in Engineering and Chemical EngineeringDocument15 pagesLife and Times in Engineering and Chemical Engineeringapi-3852712No ratings yet

- RSC Advances: PaperDocument10 pagesRSC Advances: Paperapi-3852712No ratings yet

- Lecture 34: Examples On Fixed and Fluidized BedsDocument5 pagesLecture 34: Examples On Fixed and Fluidized Bedsapi-3852712No ratings yet

- Chemical Engineering Journal: Chunhu Zhao, Xiaoping Zhang, Jiangling Ding, Yaru ZhuDocument10 pagesChemical Engineering Journal: Chunhu Zhao, Xiaoping Zhang, Jiangling Ding, Yaru Zhuapi-3852712No ratings yet

- Mass Transfer NotesDocument37 pagesMass Transfer Notesapi-3852712No ratings yet

- Made by Anurag Rao Dakshal PatelDocument10 pagesMade by Anurag Rao Dakshal Patelapi-3852712No ratings yet

- Ads or PtionDocument14 pagesAds or Ptionapi-3852712No ratings yet

- 02 WholeDocument148 pages02 Wholeapi-3852712No ratings yet

- Simulation of Air-Steam GasiDocument10 pagesSimulation of Air-Steam Gasiapi-3852712No ratings yet

- Flow Regimes and Flow Transitions in Liquid Fluidized BedsDocument18 pagesFlow Regimes and Flow Transitions in Liquid Fluidized Bedsapi-3852712No ratings yet

- Physico Chemical Properties of Biodiesel Manufactured From Waste Frying Oil Using Domestic AdsorbentsDocument10 pagesPhysico Chemical Properties of Biodiesel Manufactured From Waste Frying Oil Using Domestic Adsorbentsapi-3852712No ratings yet

- United Molasses Draft SurveyDocument35 pagesUnited Molasses Draft Surveyapi-3852712No ratings yet

Data:: Work Sheet - 2 (Use Data Sheet)

Data:: Work Sheet - 2 (Use Data Sheet)

Uploaded by

api-3852712Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data:: Work Sheet - 2 (Use Data Sheet)

Data:: Work Sheet - 2 (Use Data Sheet)

Uploaded by

api-3852712Copyright:

Available Formats

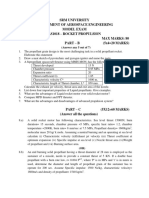

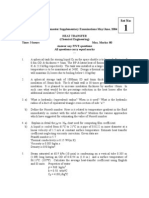

WORK SHEET – 2 [ USE DATA SHEET]

1. Design a perforated plate distributor for use in a commercial fluidized bed reactor.

Data:

Dt = 3 m; Lmf = 1.8m; mf = 0.5

s = 1450 kg/m3; s = 1; g=3.5 kg/m3;

g = 2 x 10-5 kg/(m.sec)

2. Design a perforated plate distributor for use in a commercial fluidized bed reactor.

Data:

Dt = 2.5 m; Lmf = 2.0m; mf = 0.45

s = 1650 kg/m3; s = 0.90; g=2.8 kg/m3;

-5

g = 2 x 10 kg/(m.sec)

3. Estimate the power consumption for a reactor 8m high by 3.5 m ID for the following

conditions:

The inlet gas from the reactor and the inlet gas to the blower are both at atmospheric

pressure (1033gm wt/cm2) s=8gm/cm2, mf=0.4

Desired height of fluidized bed=1.5 m

Air is compressed and passes through the bed, and leaves at 1 atm.

Average diameter of bed=15cm

4. Discuss

I. Discuss the mixing and segregation of particles in a fluidized bed.

II. Liquid Solid Circulating Fluidised bed.

III. Inverse fluidised bed.

5. Estimate the bed to immersed surface heat transfer coefficient for a bed of alumina

particles operating at atmospheric pressure and a temperature of 480oC,given the

following properties:

Particle mean size = 0.475 mm

Particle density = 3650 kg/m3

Fluidizing velocity = 0.40 m/s

Gas properties:

Density = 0.40 kg/m3

Viscosity = 3.5 x 10-5 kg/m s

Thermal conductivity = 5.0 x 10-5 kW/mK

You might also like

- Drilling Questions and SolutionsDocument10 pagesDrilling Questions and SolutionsJohn Joseph100% (3)

- Sample Problems in Industrial Plant DesignDocument26 pagesSample Problems in Industrial Plant DesignSdhfdh Hdfhd100% (1)

- Problem Report Pump To EvaporatorDocument25 pagesProblem Report Pump To EvaporatorTakishima N VovoNo ratings yet

- MIP Thickener DesignDocument3 pagesMIP Thickener DesignHatem Salah100% (1)

- Rocket QuestionbankDocument2 pagesRocket QuestionbankSanjana RaoNo ratings yet

- PPE AssignmentDocument16 pagesPPE AssignmentlibbissujessyNo ratings yet

- TutorialDocument5 pagesTutorialAbdul Razak RahmatNo ratings yet

- Design Heat Exchanger Shell and Tube TheDocument8 pagesDesign Heat Exchanger Shell and Tube ThezatamaqeelNo ratings yet

- Lecture 9 Coagulation Design Criteria and ExamplesDocument12 pagesLecture 9 Coagulation Design Criteria and ExamplesAhmad Salih100% (1)

- Principle of Working of Grit ChamberDocument11 pagesPrinciple of Working of Grit ChamberAhmed Amedi100% (3)

- Ie5b02555 Si 001Document15 pagesIe5b02555 Si 001Akshay PatelNo ratings yet

- Abe Quiz Season XviiDocument7 pagesAbe Quiz Season XviiMeljun GementizaNo ratings yet

- Settling ChambersDocument2 pagesSettling ChambersAnonymous d3sWgsNo ratings yet

- Meng HMTDocument12 pagesMeng HMTMiskir AimNo ratings yet

- Ae708 Question Bank 2Document5 pagesAe708 Question Bank 2pRoBoTRoGe OPNo ratings yet

- Assignment 3Document3 pagesAssignment 3HARINo ratings yet

- Cycle Test 2 Rocket PropulsionDocument3 pagesCycle Test 2 Rocket Propulsionapi-271354682No ratings yet

- Isro Scientist Me 2020 Paper 80c39244Document20 pagesIsro Scientist Me 2020 Paper 80c39244Elsa PoirotNo ratings yet

- Reactor & Dryer DesignDocument19 pagesReactor & Dryer DesignSepribo BraideNo ratings yet

- BE ChemDocument53 pagesBE ChemMuddasar ShaikhNo ratings yet

- Hmtmta2 Main PDFDocument10 pagesHmtmta2 Main PDFONNDWELA RAMALAMULANo ratings yet

- Tutorial - Mass TransferDocument1 pageTutorial - Mass Transfer219016536No ratings yet

- 371hw06s (Rapid Mix Tank Design-Sample 1)Document5 pages371hw06s (Rapid Mix Tank Design-Sample 1)Yang Ching HianNo ratings yet

- A New Approach To Cooling and Prilling During Fertilizer ManufactureDocument11 pagesA New Approach To Cooling and Prilling During Fertilizer ManufactureHaider AliNo ratings yet

- Melt Index TestDocument4 pagesMelt Index TestFarooq Muhammad100% (1)

- Unit Operations Tutorial 2015-2016Document13 pagesUnit Operations Tutorial 2015-2016hazimraad0% (1)

- Drying Hopper Calculation-1Document3 pagesDrying Hopper Calculation-1Gilang Adi SetyawanNo ratings yet

- JJJJJJJJJJDocument4 pagesJJJJJJJJJJJoshua UmaliNo ratings yet

- Learning Assessment Activity 1. QUESTIONS.: Name: Franzes Mar Eria Heat and Mass Transfer Bsche 3Document7 pagesLearning Assessment Activity 1. QUESTIONS.: Name: Franzes Mar Eria Heat and Mass Transfer Bsche 3Franzes Mar EriaNo ratings yet

- TitleDocument2 pagesTitleJoel VazNo ratings yet

- Heat Transfer May2004 NR 310803Document8 pagesHeat Transfer May2004 NR 310803Nizam Institute of Engineering and Technology LibraryNo ratings yet

- Set CDocument11 pagesSet CRayver MambNo ratings yet

- Tripoli University Chemical Engineering Department: Homework #4Document2 pagesTripoli University Chemical Engineering Department: Homework #4Good BadNo ratings yet

- Basic ScienceDocument7 pagesBasic ScienceGibbs AmbionNo ratings yet

- Filament Yarn Quench AirDocument2 pagesFilament Yarn Quench AirClarence AG YueNo ratings yet

- Mass Transfer Operations Model QuestionsDocument8 pagesMass Transfer Operations Model QuestionsIastraNo ratings yet

- Heat Exchanger DesignDocument15 pagesHeat Exchanger DesignCharito Sollera AlbaricoNo ratings yet

- AIr NummericalDocument2 pagesAIr NummericalArnav TiwariNo ratings yet

- Final SelectionDocument8 pagesFinal SelectionFahad KhokharNo ratings yet

- Rules of Thumb Ludwigs Applied Process PDFDocument9 pagesRules of Thumb Ludwigs Applied Process PDFAngelena Rani FrancisNo ratings yet

- Week 10Document11 pagesWeek 10Abhishek KumarNo ratings yet

- CRYOGENIC LAB Practical FileDocument10 pagesCRYOGENIC LAB Practical FileSantosh BaraiyaNo ratings yet

- HT AssignmentDocument12 pagesHT AssignmentCollano M. Noel RogieNo ratings yet

- Ped QuestionsDocument11 pagesPed QuestionsYashPatel100% (1)

- Hydrogenator DesignDocument9 pagesHydrogenator DesignA MNo ratings yet

- Rr310803 Heat TransferDocument8 pagesRr310803 Heat TransferSrinivasa Rao GNo ratings yet

- Lecture 6 1Document24 pagesLecture 6 1Dany LoboNo ratings yet

- Rules Thumb: Summary: P Z 90 TorrDocument9 pagesRules Thumb: Summary: P Z 90 TorrNdzalama RekotsoNo ratings yet

- rr310303 Thermal Engineering IIDocument9 pagesrr310303 Thermal Engineering IISRINIVASA RAO GANTANo ratings yet

- Tutorial - Transient ConductionDocument2 pagesTutorial - Transient Conduction219016536No ratings yet

- Ems TutorialDocument43 pagesEms TutorialJohn Eric Balarao Ferranco33% (3)

- Heat Transfer Jan2003 or 220852Document2 pagesHeat Transfer Jan2003 or 220852Nizam Institute of Engineering and Technology LibraryNo ratings yet

- Civil Engineer NotesDocument91 pagesCivil Engineer Notesishfaq hassanNo ratings yet

- Applied Thermodynamics QBDocument12 pagesApplied Thermodynamics QBapi-25999517100% (1)

- Heat Transfer in Polymer Composite Materials: Forming ProcessesFrom EverandHeat Transfer in Polymer Composite Materials: Forming ProcessesNicolas BoyardNo ratings yet

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"From EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"No ratings yet

- 3 Exiguobacterium Sp. LMNARJR 16S Ribosomal RNA Gene, Partial Sequence - Nucleotide - NCBI (9 Files Merged)Document9 pages3 Exiguobacterium Sp. LMNARJR 16S Ribosomal RNA Gene, Partial Sequence - Nucleotide - NCBI (9 Files Merged)api-3852712No ratings yet

- Modeling and Experimental Study For Winter Performance of An Earth To Air Heat Exchanger: An Alternative Energy Source For GreenhouseDocument14 pagesModeling and Experimental Study For Winter Performance of An Earth To Air Heat Exchanger: An Alternative Energy Source For Greenhouseapi-3852712No ratings yet

- Redundant Phrases Are Bad Habits Just Waiting To Take Control of Your Writing. Beware of The FollowingDocument3 pagesRedundant Phrases Are Bad Habits Just Waiting To Take Control of Your Writing. Beware of The Followingapi-3852712No ratings yet

- Life and Times in Engineering and Chemical EngineeringDocument15 pagesLife and Times in Engineering and Chemical Engineeringapi-3852712No ratings yet

- RSC Advances: PaperDocument10 pagesRSC Advances: Paperapi-3852712No ratings yet

- Lecture 34: Examples On Fixed and Fluidized BedsDocument5 pagesLecture 34: Examples On Fixed and Fluidized Bedsapi-3852712No ratings yet

- Chemical Engineering Journal: Chunhu Zhao, Xiaoping Zhang, Jiangling Ding, Yaru ZhuDocument10 pagesChemical Engineering Journal: Chunhu Zhao, Xiaoping Zhang, Jiangling Ding, Yaru Zhuapi-3852712No ratings yet

- Mass Transfer NotesDocument37 pagesMass Transfer Notesapi-3852712No ratings yet

- Made by Anurag Rao Dakshal PatelDocument10 pagesMade by Anurag Rao Dakshal Patelapi-3852712No ratings yet

- Ads or PtionDocument14 pagesAds or Ptionapi-3852712No ratings yet

- 02 WholeDocument148 pages02 Wholeapi-3852712No ratings yet

- Simulation of Air-Steam GasiDocument10 pagesSimulation of Air-Steam Gasiapi-3852712No ratings yet

- Flow Regimes and Flow Transitions in Liquid Fluidized BedsDocument18 pagesFlow Regimes and Flow Transitions in Liquid Fluidized Bedsapi-3852712No ratings yet

- Physico Chemical Properties of Biodiesel Manufactured From Waste Frying Oil Using Domestic AdsorbentsDocument10 pagesPhysico Chemical Properties of Biodiesel Manufactured From Waste Frying Oil Using Domestic Adsorbentsapi-3852712No ratings yet

- United Molasses Draft SurveyDocument35 pagesUnited Molasses Draft Surveyapi-3852712No ratings yet