Professional Documents

Culture Documents

EN Ds l10 12 br1172 en F 0517

EN Ds l10 12 br1172 en F 0517

Uploaded by

JankoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EN Ds l10 12 br1172 en F 0517

EN Ds l10 12 br1172 en F 0517

Uploaded by

JankoCopyright:

Available Formats

Standard Equipment/Optional Equipment Features

Steering system Lifting system

3 Proportional speed control varies truck 3 OptiLift mast control provides accura-

speed automatically in relation to the tiller te, fully proportional lifting as well as

angle for safe, comfortable and productive smooth and quiet operation

Standard Equipment 3 Soft landing of the forks protects load

operation

3 A Creep speed button ensures high mano- when lowering

Long tiller with low mounting point CAN-bus architecture euvrability in confined areas when ope- 3 Wide range of mast options available

Fibre-glass reinforced tiller and tiller head (Grivory®) Electromagnetic brake rating at low speeds with tiller in upright 3 Choice of standard or built-out carria-

position ge depending on application

Exxtral® motor and battery cover Automatic parking brake

3 End-of-stroke resistance on the tiller avoids 3 Initial lift on L12i ensures easy cros-

Creep speed control (L12, L12i) Cushion rubber drive wheel

Subject to modification in the interest of progress. Illustrations and technical details could include options and not binding for actual construc-

accidental, abrupt braking sing of ramps and dock levellers

Proportional speed control (L12, L12i) Single polyurethane load wheels 3 Soft tiller fold-back slows down the tiller

End-of-stroke resistance Fork length: 1150 mm when returning into upright position, avoi-

ding the tiller snapping on the motor cover

Storage compartments Width over forks: 560 mm

OptiLift® proportional lift system (L10, L12, L12i) Initial lift (L12i)

Hand protection at rear of mast Built-in or built-out fork carriage

(polycarbonate or steel mesh) Protection to -10°C

Multi-function display with hourmeter including scheduled Vertical 2 PzS-B battery change (L10B, L10, L12)

maintenance, fault code and battery discharge indicator Vertical 3 PzS-B battery change (L12i)

Key switch or LFM Go (PIN-code access) Horn AC motor & Booster effect Tiller & Tiller head Working station & Display

AC motor Clipboard 3 Powerful, smooth-running 1.2 kW AC 3 Off-set, ergonomic Grivory® tiller head 3 Wide, deep storage compartment for

motor ensures safety and visibility shrink wrap, pens, markers etc.

Linde LAC controller

3 Traction speed adjustable up to 3 Long tiller with low mounting point 3 Durable and long lasting Exxtral®

Electric Pallet Stackers 6 km/h, laden or unladen

3 Booster effect provides higher torque

provides safety clearance between

operator and chassis

motor and battery cover

3 Multi-function display as standard

Capacity 1000 - 1200 kg when additional power is needed

3 No roll-back on hill starts

3 Wrap-around hand protection

3 Comfortable controls, operable with

with hourmeter including scheduled

maintenance, fault code and battery

L10B, L10, L12, L12i Series 1172

either hand and gloves discharge indicator

tions. All dimensions subject to usual tolerances.

Optional Equipment

Drive wheels: polyurethane, wet grip, non marking cushion, Linde Connected Solutions:

treaded cushion ac:access control (PIN or RFID Dual), an:usage analysis and

Load wheels: Tandem polyurethane, tandem polyurethane dt:crash detection Safety

greasable Cold store protection to -35°C The hand guards of the off-centred tiller head effectively

Alternative fork lengths and widths Automatic battery watering system shield hands and keep the operator safely within the truck’s

Load backrest Built-in charger contours with excellent visibility through the mast. The long Braking system Chassis Maintenance and

Creep speed control (L10) High frequency charger tiller mounted low down on the chassis ensures ample safety 3 Highly efficient electro-magnetic brake 3 Compact, rounded shape avoids CAN-bus architecture

applied by moving tiller to fully up or snagging 3 Zero maintenance, moisture and

Proportional speed control (L10) clearance between operator and truck. down position 3 Highly resistant, robust steel dust-proof 1.2 kW AC motor

Other options available on request 3 Automatic braking on releasing traction construction 3 CAN-bus architecture enables fast,

Performance Reliability butterfly or by reversing direction 3 Low chassis skirt protects operator‘s easy access to all truck data

3 Truck slows before coming to a stop, feet 3 Individually adjustable parameters via

The combination of a new AC motor and Linde LAC digi- Despite their visual appeal, these pallet stackers are rugged

remaining under total control at all diagnostic plug

tal controller makes these pallet stackers highly efficient. and durable. The mast channels are made from high grade times 3 Rapid and convenient access to main

Operating parameters can be adjusted to match any applica- rolled steel sections for strength and durability. Strong and components via front service panel

tion. The OptiLift mast control assures accurate, fully propor- long-lasting Exxtral® motor and battery cover protect the tech-

tional lifting as well as smooth and quiet operation. nical compartment from outside shocks. In addition, a built-out

fork carriage with thinner forks is available to protect the mast

Comfort when handling gitterboxes.

Li-ION technology Li-ION batteries All controls on the ergonomic tiller head can be easily ope-

Fast Full Charge - specific lithium-ion battery compartment: 1,8kWh-3,6kWh rated by either hand. A Creep speed button offers utmost Service

Printed in Germany 121.e.4.0517.IndF.Ki

Opportunity Charging (24V/82-164Ah) manoeuvrability in confined areas. Proportional speed auto- It is not just about the truck in operation: a maintenance-free

Fast Intermediate Charging Optimized 24V-Li-ION charger - v90: 1,8kWh (82 Ah) - matically alters traction speed in relation to the truck/ope- AC motor maximises uptime, reducing operating costs. All truck

Maintenance Free v160: 3,6kWh (164 Ah) rator distance. Finished in tactile materials, these stackers data is immediately and easily accessible to the service engi-

Long Lifetime deliver accurate load handling for better productivity. neer via CAN-bus architecture. Fast, easy access to all internal

Good performance in Cold Store components ensures service tasks are completed with a mini-

Linde Material Handling GmbH, Postfach 10 01 36, 63701 Aschaffenburg, Germany

mum of delay. Phone +49.60 21.99-0, Fax +49.60 21.99-15 70, www.linde-mh.com, info@linde-mh.com

Technical Data according to VDI 2198

1.1 Manufacturer LINDE LINDE LINDE LINDE

1.2 Manufacturer‘s type designation L12i L10B / [L10B ION] 1)

L10 / [L10 ION] 1)

L12 / [L12 ION] 1)

1.2a Series 1172 1172 1172 1172

Characteristics

1.3 Power unit Battery Battery Battery Battery

1.4 Operation Pedestrian Pedestrian Pedestrian Pedestrian

1.5 Load capacity/Load Q (t) 1.2 1.0 1.0 1.2

1.6 Load centre distance c (mm) 600 600 600 600

1.8 Axle centre to fork face x (mm) 780 / 709 2) 3) 715 4) 695 3) 695 3)

1.9 Wheelbase y (mm) 1362 / 1291 2) 1157 [1177] 1) 1157 [1177] 1) 1157 [1177] 1)

2.1 Service weight (kg) 909 708 788 788

Weights

2.2 Axle load with load, front/rear (kg) 744 / 1365 617 / 1091 [616 / 1092] 654 / 1134 [653 / 1135] 671 / 1317 [669 / 1319]

2.3 Axle load without load, front/rear (kg) 643 / 266 5) 518 / 190 572 / 216 572 / 216

3.1 Tyres rubber, SE, pneumatic, polyurethane V+P/P 6) V+P/P 6) V+P/P 6) V+P/P 6)

3.2 Tyre size, front Ø 230 x 75 Ø 230 x 75 Ø 230 x 75 Ø 230 x 75

Wheels/Tyres

3.3 Tyre size, rear 2x Ø 85 x 85 2x Ø 85 x 100 2x Ø 85 x 100 2x Ø 85 x 100

3.4 Auxiliary wheels (dimensions) Ø 140 x 54 Ø 140 x 54 Ø 140 x 54 Ø 140 x 54

3.5 Wheels, number front/rear (x = driven) 1x + 1 / 2 1x + 1 / 2 1x + 1 / 2 1x + 1 / 2

3.6 Track width, front b10 (mm) 518 518 518 518

3.7 Track width, rear b11 (mm) 380 380 380 380

4.2 Height of mast, lowered h1 (mm) 1996 2390 1940 1940

4.3 Free lift h2 (mm) 150 1912 150 150

4.4 Lift h3 (mm) 2424 1912 2924 2924

4.5 Height of mast, extended h4 (mm) 4868 2390 3402 3402

4.6 Initial lift h5 (mm) 130 - - -

4.9 Height of tiller arm in operating position, min/max h14 (mm) 650 / 1190 650 / 1190 650 / 1190 650 / 1190

4.15 Height, lowered h13 (mm) 86 86 86 86

Dimensions

4.19 Overall length l1 (mm) 1907 7) 1768 [1788] 1) 7) 1788 [1808] 1) 7) 1788 [1808] 1) 7)

4.20 Length to fork face l2 (mm) 757 618 [638] 1) 638 [658] 1) 638 [658] 1)

4.21 Overall width b1/b2 (mm) 800 800 800 800

4.22 Fork dimensions DIN ISO 2331 s/e/l (mm) 65 x 180 x 1150 8) 65 x 180 x 1150 8) 65 x 180 x 1150 8) 65 x 180 x 1150 8)

4.24 Width of fork carriage b3 (mm) 534 534 534 534

4.25 Fork spread b5 (mm) 560 560 560 560

4.32 Ground clearance, centre of wheelbase m2 (mm) 20 / 150 2) 30 30 30

4.34.1 Aisle width for pallets 1000 × 1200 crossways Ast (mm) 2480 (2061) / 2437 (2061) 2) 9) 10) 11)

2324 (1945) [2344 (1965)] 9) 10) 1)

2333 (1965) [2353 (1985)] 9) 10) 1)

2305 (1937) [2325 (1957)] 9) 10) 1)

Masts (L10/L12) (in mm) 1462 E 1912 E 2024 S 2424 S 2924 S 3324 S 3824 S 4224 S

4.34.2 Aisle width with pallet 800 x 1200 along forks Ast (mm) 2421 (2261) / 2403 (2261) 2) 9) 10) 11)

2289 (2145) [2309 (2165)] 9) 10) 1)

2304 (2165) [2324 (2185)] 9) 10) 1)

2276 (2137) [2296 (2157)] 9) 10) 1)

Lift h3 1462 1912 2024 2424 2924 3324 3824 4224

4.35 Turning radius Wa (mm) 1641 / 1570 2) 11) 1460 [1480] 1) 1460 [1480] 1) 1432 [1452] 11) 1)

Lift + fork height h3+h13* 1547 1997 2109 2509 3009 4309 3909 4309

5.1 Travel speed, with/without load (km/h) 6/6 6/6 6/6 6/6

Height lowered h1* 1940 2390 1490 1690 1940 2140 2390 2590

5.2 Lifting speed, with/without load (m/s) 0.11 / 0.225 0.09 / 0.2 0.1 / 0.2 0.11 / 0.225 Height raised h4 1943 2393 2502 2902 3402 3802 4302 4702

Performance

5.3 Lowering speed, with/without load (m/s) 0.4 / 0.3 0.23 / 0.23 0.35 / 0.35 0.4 / 0.3

Free lift h2 1462 1912 150 150 150 150 150 150

5.8 Maximum climbing ability, with/without load (%) 10.0 / 15.0 5.0 / 10.0 5.0 / 10.0 5.0 / 10.0

5.9 Acceleration time, with/without load (s) 8.3 / 7.0 8.0 / 7.0 8.0 / 7.0 8.3 / 7.0 Masts (L10/L12) (in mm) 2024 D 2424 D 2924 D 3324 D 3824 D 4224 D 3636 T 4386 T

5.10 Service brake Electro-magnetic Electro-magnetic Electro-magnetic Electro-magnetic Lift h3 2024 2424 2924 3324 3824 4224 3636 4386

6.1 Drive motor rating S2 60 min (kW) 1.2 1.2 1.2 1.2 Lift + fork height h3+h13* 2109 2509 3009 3409 3909 3409 3721 4471

6.2 Lift motor rating at S3 15% (kW) 2.5 0.9 1 2.5 Height lowered h1* 1490 1690 1940 2140 2390 2590 1690 1940

6.3 Battery according to DIN 43531/35/36 A,B,C,no no no no no Height raised h4 2502 2902 3402 3802 4302 4702 4118 4868

Drive

6.4 Battery voltage/rated capacity (5h) (V)/(Ah) 24 / 225 12) 24 / 180 [24 / 82] 1) 24 / 180 [24 / 82] 1) 24 / 180 [24 / 82] 1) Free lift h2 1012 1212 1462 1662 1912 2112 1212 1462

6.5 Battery weight (± 5%) (kg) 200 195 [51] 1)

195 [51] 1)

195 [51] 1) * Initial lift h5 = 130 mm

E=Simplex mast, S=Standard mast, D=Duplex mast, T=Triplex mast

6.6 Power consumption according to VDI cycle (kWh/h) 1 0.7 0.8 1

8.1 Type of drive unit LAC LAC LAC LAC

10.7 Sound pressure level LpAZ (at the driver’s seat) (dB(A)) 65 65 65 65

1) Figures in [ ] with Li-ION battery see line 6.4 5) Forks lowered

2) Without/with Initial lift 6) Solid rubber + polyurethane / polyurethane

3) With Simplex masts + 20 mm; with Triplex masts - 57 mm. Forks carriages with fork 7) with fork lenght l = 1000 mm l1 decreases of -150 mm.

thickness s = 60 mm, preferred while using gitter box, are also available: the x dimension 8) Optionally 65 x 180 x 1000

decreases of -44 mm for Simplex masts and -35 mm for Standard and Duplex masts. 9) Calculated with VDI 2198 (VDI 3597)

4) With Standard mast - 20 mm. Forks carriages with fork thickness s = 60 mm, preferred 10) Including a 200 mm (min.) operating aisle clearance.

while using gitter box, are also available: the x dimension decreases of -44 mm for 11) With creep speed = tiller in vertical position

Simplex masts and -35 mm for Standard mast. 12) Trough number 68

You might also like

- Service Manual STAR 8 - STAR 10 HaulotteDocument224 pagesService Manual STAR 8 - STAR 10 HaulotteJanko100% (2)

- Ch01 Solutions Review QuestionsDocument3 pagesCh01 Solutions Review QuestionsJankoNo ratings yet

- Hitachi Lx70 7Document5 pagesHitachi Lx70 7Tuấn AnhNo ratings yet

- Genie Service Manual GS 5390Document277 pagesGenie Service Manual GS 5390Janko100% (1)

- Maha Econ III 30 35 40 5 HL III 40 50 enDocument12 pagesMaha Econ III 30 35 40 5 HL III 40 50 enmillerNo ratings yet

- UpRight LX-31-41-50 Service Manual PDFDocument148 pagesUpRight LX-31-41-50 Service Manual PDFJankoNo ratings yet

- Types of Corrosion and Factors Influencing CorrosionDocument37 pagesTypes of Corrosion and Factors Influencing CorrosionBandita Datta71% (7)

- Standard Equipment/Optional Equipment Features: Electric Straddle Stacker Capacity 1000 - 1200 KG L10AS, L12ASDocument2 pagesStandard Equipment/Optional Equipment Features: Electric Straddle Stacker Capacity 1000 - 1200 KG L10AS, L12ASIker BasqueAdventureNo ratings yet

- Standard Equipment/Optional Equipment Features: Pedestrian Pallet Stacker Capacity 1400, 1600 and 2000 KG L14, L16, L20Document2 pagesStandard Equipment/Optional Equipment Features: Pedestrian Pallet Stacker Capacity 1400, 1600 and 2000 KG L14, L16, L20Amina ZukićNo ratings yet

- Standard Equipment/Optional Equipment Features: Pedestrian Double Stacker Capacity 600 KG - 800 KG D06, D08Document2 pagesStandard Equipment/Optional Equipment Features: Pedestrian Double Stacker Capacity 600 KG - 800 KG D06, D08Iker BasqueAdventureNo ratings yet

- Linde EN Ds t20 25sr br1154 en A 0517Document2 pagesLinde EN Ds t20 25sr br1154 en A 0517Nadeem AhmedNo ratings yet

- Tai Lieu Ki ThuatDocument2 pagesTai Lieu Ki ThuatNguyen HienNo ratings yet

- Standard Equipment /optional Equipment FeaturesDocument2 pagesStandard Equipment /optional Equipment FeaturesNadeem AhmedNo ratings yet

- Linde Pallet Trucks t25 Apsp t20 Apsp Series 131 7 SpecificationsDocument2 pagesLinde Pallet Trucks t25 Apsp t20 Apsp Series 131 7 SpecificationsEmadNo ratings yet

- Features Equipment: Electric Pallet Stackers Capacity 1400 and 1600 KG L14, L16/L14i, L16iDocument6 pagesFeatures Equipment: Electric Pallet Stackers Capacity 1400 and 1600 KG L14, L16/L14i, L16iBruno VazNo ratings yet

- Linde N20Document6 pagesLinde N20sindyNo ratings yet

- Linde EN Ds n20l Li br132 en C 0411Document6 pagesLinde EN Ds n20l Li br132 en C 0411Nadeem AhmedNo ratings yet

- Electric Man-Down Turret TruckDocument6 pagesElectric Man-Down Turret Truckwill wuNo ratings yet

- Linde EN Ds l14 16r br1174 en A 0617Document2 pagesLinde EN Ds l14 16r br1174 en A 0617Nadeem AhmedNo ratings yet

- Standard Equipment/Optional Equipment Features: Electric Reach Trucks Capacity 1400 KG - 1700 KG R 14 X, R 16 X, R 17 XDocument2 pagesStandard Equipment/Optional Equipment Features: Electric Reach Trucks Capacity 1400 KG - 1700 KG R 14 X, R 16 X, R 17 XKhhg AgddsNo ratings yet

- Linde EN Typ en Series1169 l10p l12p l14pDocument2 pagesLinde EN Typ en Series1169 l10p l12p l14pNadeem AhmedNo ratings yet

- Equipment Features: Electric Tow Tractor With Platform Capacity 3000 KG P30Document6 pagesEquipment Features: Electric Tow Tractor With Platform Capacity 3000 KG P30gananathansNo ratings yet

- Linde EN Ds t20s br144 en A 0507Document4 pagesLinde EN Ds t20s br144 en A 0507Nadeem AhmedNo ratings yet

- Machine EpirocDocument5 pagesMachine Epirochenrymejiam100% (1)

- Standard Equipment/Optional Equipment FeaturesDocument2 pagesStandard Equipment/Optional Equipment FeaturesBoy ScoutNo ratings yet

- Linde 356 H420Document6 pagesLinde 356 H420mahdiyamahdi743No ratings yet

- Standard Equipment/Optional Equipment Features: Electric Tow Tractor Capacity 25000 KG P 250Document2 pagesStandard Equipment/Optional Equipment Features: Electric Tow Tractor Capacity 25000 KG P 250jackson.santosgreentechNo ratings yet

- Linde EN Ds mt15 br1133 en A 0716Document2 pagesLinde EN Ds mt15 br1133 en A 0716Nadeem AhmedNo ratings yet

- Standard Equipment/Optional Equipment FeaturesDocument2 pagesStandard Equipment/Optional Equipment FeaturesAndrés RojasNo ratings yet

- T20 and T24 SP and APDocument2 pagesT20 and T24 SP and APLima PereiraNo ratings yet

- Linde EN Ds w20 br127 04 en B 0111Document2 pagesLinde EN Ds w20 br127 04 en B 0111Nadeem AhmedNo ratings yet

- Linde EN Ds v08 br1110 en B 0411Document2 pagesLinde EN Ds v08 br1110 en B 0411Nadeem AhmedNo ratings yet

- Features Standard and Optional Equipment: Electric Pallet Stackers Capacity 1400 and 1600 KG L14Ap, L16Ap, L14Api, L16ApiDocument2 pagesFeatures Standard and Optional Equipment: Electric Pallet Stackers Capacity 1400 and 1600 KG L14Ap, L16Ap, L14Api, L16ApiBruno VazNo ratings yet

- Aisle Width E15 386Document6 pagesAisle Width E15 386Jankovski22 MaksNo ratings yet

- Linde EN Ds l14 16as Ap SP br131 en C 0411Document6 pagesLinde EN Ds l14 16as Ap SP br131 en C 0411Nadeem AhmedNo ratings yet

- Linde EN Ds p30 br132 en B 0411Document6 pagesLinde EN Ds p30 br132 en B 0411Nadeem AhmedNo ratings yet

- 175-Ton - 150 MT All Terrain Crane: Lattice Attachment Available in Hydraulic or Manual OffsetDocument4 pages175-Ton - 150 MT All Terrain Crane: Lattice Attachment Available in Hydraulic or Manual OffsetMatheus Pires PereiraNo ratings yet

- Equipment Features: Rider Seated Pallet Truck Capacity 2000 KG T 20 RDocument6 pagesEquipment Features: Rider Seated Pallet Truck Capacity 2000 KG T 20 RЕгор ЗNo ratings yet

- Minetruck MT65: Underground Truck With 65-Tonne Load CapacityDocument5 pagesMinetruck MT65: Underground Truck With 65-Tonne Load CapacityAlvaro Patricio Garcia AlfaroNo ratings yet

- 72 Ef 53Document2 pages72 Ef 53Robson belchiorNo ratings yet

- Minetruck MT42: Underground Truck With 42-Tonne Load CapacityDocument5 pagesMinetruck MT42: Underground Truck With 42-Tonne Load CapacityLucas Loyola GuzmanNo ratings yet

- Scooptram ST7: Underground Small Size Loader With 6.8-Tonne CapacityDocument5 pagesScooptram ST7: Underground Small Size Loader With 6.8-Tonne CapacityRomina MurgaNo ratings yet

- Fully Electric Stacker Brochure.Document6 pagesFully Electric Stacker Brochure.gopinadhNo ratings yet

- Standard Equipment/Optional Equipment FeaturesDocument2 pagesStandard Equipment/Optional Equipment FeaturesMarcio SilveiraNo ratings yet

- Linde RT Catalogue 2019Document2 pagesLinde RT Catalogue 2019anupthattaNo ratings yet

- Electric Reach Trucks Capacity 1000 - 2500 KGDocument2 pagesElectric Reach Trucks Capacity 1000 - 2500 KGwill wuNo ratings yet

- 9869 0023 01a Scooptram EST3.5 Technical Specification EN - LowDocument5 pages9869 0023 01a Scooptram EST3.5 Technical Specification EN - LowBhargav PagadalaNo ratings yet

- Series 1216 Data SheetDocument2 pagesSeries 1216 Data SheetSenthilKumarNo ratings yet

- EN Ds m10x M10xe br033 en A 0215Document2 pagesEN Ds m10x M10xe br033 en A 0215Nadeem AhmedNo ratings yet

- Smart-Lift en DigitalDocument3 pagesSmart-Lift en DigitalGonçalo EncarnaçãoNo ratings yet

- Grimme Masina de Recoltat CartofiDocument11 pagesGrimme Masina de Recoltat CartofiAdrian ChisNo ratings yet

- Standard and Optional Equipment Features: ActiveDocument6 pagesStandard and Optional Equipment Features: Activemike petersNo ratings yet

- Linde EN Ds N20vi Vli br1111 en B 0311Document6 pagesLinde EN Ds N20vi Vli br1111 en B 0311Nadeem AhmedNo ratings yet

- Standard Equipment/Optional Equipment FeaturesDocument2 pagesStandard Equipment/Optional Equipment FeaturesAsif JavedNo ratings yet

- Agrotron M: Evolving AgricultureDocument13 pagesAgrotron M: Evolving Agriculturejohn deereNo ratings yet

- Standard Equipment/Optional Equipment Features: Tractor P 20 Capacity 2000 KG Load Transporter W 04 Capacity 400 KGDocument2 pagesStandard Equipment/Optional Equipment Features: Tractor P 20 Capacity 2000 KG Load Transporter W 04 Capacity 400 KGjackson.santosgreentechNo ratings yet

- MSG97AL 722 Product Data BrochureDocument2 pagesMSG97AL 722 Product Data BrochureYAKOVNo ratings yet

- Urban Electric Pallet Truck Capacity 500 KG CiTi OneDocument2 pagesUrban Electric Pallet Truck Capacity 500 KG CiTi Onewill wuNo ratings yet

- Forklift LoadingsDocument2 pagesForklift LoadingsmilovanstanojevNo ratings yet

- PW98MR 8Document12 pagesPW98MR 8Бранко Нешић100% (2)

- BRO MAHA Alle Zwei-Saeulen en 2014-05-06Document16 pagesBRO MAHA Alle Zwei-Saeulen en 2014-05-06GaborNo ratings yet

- Wa150-5 Cen00264-02 201302Document4 pagesWa150-5 Cen00264-02 201302Ganta Zuliansyah Yusuf RachmanNo ratings yet

- ZW250 enDocument11 pagesZW250 enhaiccdk6No ratings yet

- Mitsubishi InverterDocument12 pagesMitsubishi InverterAgus Acho0% (1)

- Check Weigher: Revolutionizing Quality Control with Computer VisionFrom EverandCheck Weigher: Revolutionizing Quality Control with Computer VisionNo ratings yet

- Technical - Catalogue - 10 - 2017.PDF Insulation Panels ISOPANEL AccesoriesDocument117 pagesTechnical - Catalogue - 10 - 2017.PDF Insulation Panels ISOPANEL AccesoriesJankoNo ratings yet

- Katalog BefestigungstechnikDocument110 pagesKatalog BefestigungstechnikJankoNo ratings yet

- 2017 NEE Book Preview PDFDocument83 pages2017 NEE Book Preview PDFJankoNo ratings yet

- Purpose of Miniature Circuit Breakers MCBsDocument5 pagesPurpose of Miniature Circuit Breakers MCBsJankoNo ratings yet

- Cable Installation Guidelines: Business Unit Industrial ProjectsDocument8 pagesCable Installation Guidelines: Business Unit Industrial ProjectsJankoNo ratings yet

- Information: Double Decking System For CurtainsidersDocument12 pagesInformation: Double Decking System For CurtainsidersJankoNo ratings yet

- RivedilDocument132 pagesRivedilJankoNo ratings yet

- Revisions: ASCENT - Center For Technical KnowledgeDocument1 pageRevisions: ASCENT - Center For Technical KnowledgeJankoNo ratings yet

- CCMDocument5 pagesCCMJankoNo ratings yet

- Grundfos SP ManualDocument24 pagesGrundfos SP ManualJankoNo ratings yet

- GB GRUNDFOSS Controler PDFDocument38 pagesGB GRUNDFOSS Controler PDFJankoNo ratings yet

- Tyre Presentation PDFDocument29 pagesTyre Presentation PDFJankoNo ratings yet

- Eric.W. Abelquist - Decommissioning Health Physics - A Handbook For MARSSIM Users (Medical Physics Series) (2002)Document453 pagesEric.W. Abelquist - Decommissioning Health Physics - A Handbook For MARSSIM Users (Medical Physics Series) (2002)GabrielNo ratings yet

- Elna (Radial Thru-Hole) RLB SeriesDocument1 pageElna (Radial Thru-Hole) RLB Seriesjghjkhgkh87No ratings yet

- Transformer Testing 8Document1 pageTransformer Testing 8imcoolmailme2No ratings yet

- Multi Effect EvaporatorsDocument38 pagesMulti Effect EvaporatorsTajuddin ShaikNo ratings yet

- Answers & Solutions JEE (Main) - 2023 (Online) Phase-2: Memory BasedDocument15 pagesAnswers & Solutions JEE (Main) - 2023 (Online) Phase-2: Memory BasedSaήjaγKsNo ratings yet

- Stabilization of Expansive Soil Using Fly Ash: A Dissertation Submitted byDocument72 pagesStabilization of Expansive Soil Using Fly Ash: A Dissertation Submitted byVARUN RANANo ratings yet

- Flowmeter DatasheetDocument8 pagesFlowmeter DatasheetBhoopendra SinghNo ratings yet

- Type Test InduscabosDocument11 pagesType Test InduscabosAntonio GresiaNo ratings yet

- Tibetan Reiki ManualDocument15 pagesTibetan Reiki ManualSudhanshu Goswami100% (2)

- Mid TermDocument11 pagesMid TermMaha TharwatNo ratings yet

- 0625 w16 Ms 32Document10 pages0625 w16 Ms 32yuke kristinaNo ratings yet

- Colfax Mechanical Seal LeakageDocument4 pagesColfax Mechanical Seal Leakagesoumya19800000000No ratings yet

- Witricity: Devon GrecoDocument7 pagesWitricity: Devon GrecoGorishsharmaNo ratings yet

- Ameren Service DropDocument12 pagesAmeren Service DropZoe WheeleyNo ratings yet

- Multi-Parametric Instrument: Installation ManualDocument38 pagesMulti-Parametric Instrument: Installation ManualPaula SilvaNo ratings yet

- M101c - Costs&Benefits of Digital Technologies: Author: Prof. Dr. Meltem Ucal, KHAS, Turkey Ceren Takımlı, KHAS, TurkeyDocument18 pagesM101c - Costs&Benefits of Digital Technologies: Author: Prof. Dr. Meltem Ucal, KHAS, Turkey Ceren Takımlı, KHAS, Turkeymaia maiaNo ratings yet

- 950H, 962H and IT62H Wheel Loader Hydraulic System: Command Control SteeringDocument2 pages950H, 962H and IT62H Wheel Loader Hydraulic System: Command Control SteeringTeofilo Paredes CosmeNo ratings yet

- A Fan For All Seasons A Fan For All Seasons: CirculationDocument84 pagesA Fan For All Seasons A Fan For All Seasons: CirculationshaikhbwcNo ratings yet

- GP 2 Lesson 2.1-2.2Document31 pagesGP 2 Lesson 2.1-2.2Jescelle PetonioNo ratings yet

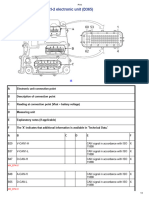

- CAN Connections of PMCI-2 Electronic Unit (D365)Document3 pagesCAN Connections of PMCI-2 Electronic Unit (D365)Oscar De la fuenteNo ratings yet

- Ocv Aerio N SwiftDocument6 pagesOcv Aerio N SwiftagusNo ratings yet

- KIA KIA KIA: 1.descriptionDocument5 pagesKIA KIA KIA: 1.descriptionhugos31No ratings yet

- Fault Codes: Address: Postal Address: Phone: Fax: E-Mail: HomepageDocument3 pagesFault Codes: Address: Postal Address: Phone: Fax: E-Mail: HomepageLudmila CroitoruNo ratings yet

- Internal Combustion Engines: MET 101 Basic Mechanical EngineeringDocument30 pagesInternal Combustion Engines: MET 101 Basic Mechanical EngineeringAnish RulesNo ratings yet

- S7000DDDocument52 pagesS7000DDisrafilNo ratings yet

- Prof. M.K Gandhi: A Project Report OnDocument87 pagesProf. M.K Gandhi: A Project Report OnShivani AwasthyNo ratings yet

- Stakehoders Presentation On CTBCM - NEPRA - 240622Document35 pagesStakehoders Presentation On CTBCM - NEPRA - 240622Waqas MasoodNo ratings yet

- InTech-Equivalent Circuit and Calculation of Its Parameters of Magnetic Coupled Resonant Wireless Power Transfer PDFDocument17 pagesInTech-Equivalent Circuit and Calculation of Its Parameters of Magnetic Coupled Resonant Wireless Power Transfer PDFMaria Lavinia IordacheNo ratings yet

- Physics Lab - Rectification and Smoothing of An A.C. VoltageDocument8 pagesPhysics Lab - Rectification and Smoothing of An A.C. Voltageaben100% (1)