Professional Documents

Culture Documents

Ultra-Tec Cable Railing

Ultra-Tec Cable Railing

Uploaded by

AbeanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ultra-Tec Cable Railing

Ultra-Tec Cable Railing

Uploaded by

AbeanCopyright:

Available Formats

Ultra-tec® Cable Railing www.wagnercablerailing.

com

OVERVIEW OF FEATURES Ultra-tec® Cable Railing System was

Railing frame components can be specified in a variety of created to address the deficiencies

encountered in using standard ten-

WAGNERAIL

materials: steel and stainless steel pipe; stainless steel flat sioning mechanisms for cable barri-

SYSTEM

bar; structural tubing; and wood. Please note that the er railings – sharp edges on retain-

Ultra-tec® Cable Railing System is not recommended for ers; long, bulky fittings; and

use with aluminum pipe or tube. uneven, hand-crimped shanks.

Standard marine turnbuckles and

Type 316 stainless steel cable and hardware are used. stud fittings with exposed nuts and

Due to the increased amounts of nickel and the addition of threads were the norm because that

molybdenum, type 316 stainless steel has excellent resist- was all that was available – until

ance to atmospheric and corrosive conditions. now.

RAILING

GLASS

Ultra-tec's® exclusive Invisiware® hardware is hidden

inside the end posts making it virtually invisible. We also

offer hardware that is visible when installed but with Railing styles shown in the Ultra-tec® Design &

smooth, rounded corners. More compact than awkward Fabrication Guide for Metal Framed

turnbuckles intended for other uses, all hardware has Railings – available online – are made

been designed specifically for pedestrian cable railings. available to design professionals and

steel fabricators. The guide is useful

All Ultra-tec® Cable Railing System hardware can be in designing a properly constructed

RAILING

CABLE

swaged in the field by using one of our portable swaging cable railing. It highlights attractive

tools. Swaging in the field permits intermediate post and pre-engineered metal frame styles

that utilize standard off the shelf

braces to be bored just slightly larger than the diameter of materials. Included are drawings

the cable being used since only the cable will have to pass and specifications that will ensure

through. If purchased pre-swaged, the intermediate posts that the frame will perform successful-

and braces have to be bored to allow for the larger diam- ly when all cables are properly ten-

SPIRAL STAIRS

BALCONIES

eter of the swaged fitting to pass through the intermediate sioned.

post or brace.

If desired, fittings can be swaged onto one or both of the

cable ends at the factory. New Ultra-tec Push-Lock fit- Exclusive Ultra-tec® Cable Railing Hardware is

tings simplify installation – requiring only one end be pre- designed especially for cable railings.

swaged with a tensioner and the other end field cut and Invisiware® terminals can be concealed

assembled. within the railing end post. These pre-

cision machined Type 316 stainless

ALUMINUM

RAILINGS

By using our pre-tensioning tool, runs of up to 150 feet steel fittings are engineered to inter-

and longer can be achieved while maintaining tight cable face with standard frame compo-

tension using Ultra-tec® hardware. nents detailed in our Design &

Fabrication Guide for Metal Framed

Refer to installation instructions on page 259 to 271. Railings. Ultra-tec® railing hard-

ware can be factory swaged by us or

Note: Due to the effects of thermal expansion and contraction, max- field swaged by the customer, using

imum run for exterior railings is 100 feet. an Ultra-tec® portable swaging tool.

BRASS / SS

New Push-Lock fittings now make field

FITTINGS

installation even easier.

The Ladder Effect

The 2000 International Residential Code (IRC) stated that

guardrails shall not be constructed with horizontal members or

other ornamental pattern that results in a ladder effect. The ladder

effect has never been a part of the International Building Code

(IBC).

A Cable Rail Sample Pack is available

The ladder effect was removed from the IRC during the 2001 code at a modest cost. It contains: 3/16" cable;

cycle and it was noted in the 2001 IRC supplement. The current Invisiware® Receiver, Radius Ferrule,

2006 IRC and IBC contain no reference to the ladder effect. Adjust-A-Body® with Hanger Bolt; Clip-

However, many local code authorities are using older codes On Stop and Fixed Jaw; Fixed Tab

based on BOCA – the creator of the ladder effect wording – and Weld Fitting; Weld Receiver,

the 2000 IRC. Many local code inspectors are not aware of the Grommets, and Threaded Tab. Order

2001 change and may reject guardrailings with infills they interpret Part Number CRSAMPLE.

as creating a ladder effect.

It will take time for the 2001 IRC supplement and the newer 2003

and 2006 model codes to trickle down to the local levels. In the

meantime, be prepared to address this issue should it come up in

your area.

Wagner / Braun • 888.243.6914 • 414.214.0444 • FAX: 414.214.0450 • www.wagnercompanies.com

48

www.wagnercablerailing.com Ultra-tec® Cable Railing Invisiware®

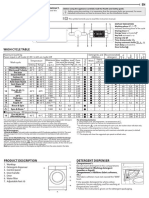

INVISIWARE® RECEIVER – TENSIONING DEVICE Delrin Post

Washer

Type 316 Stainless Steel Invisiware Receiver Swaged Threaded Stud

A tensioning device is hidden

WAGNERAIL

SYSTEM

inside the end post with only the

head of the Receiver exposed on the Allen Head

outside of the post. The inside is Cable

Counterbored Hole

female-threaded to accept the male- On Pipe Only

threaded Invisiware® Swaging Stud that is attached to the cable. The Pipe Actual Cable Use with

Size Size Size L D H T S Stud # Stainless

head of the Receiver is broached for an Allen wrench. To tension the

cable, insert the Allen wrench and rotate the Receiver around the 1 /4"

1

1.660" /8" 1.56" .437" /16" /16-24 .537" CRS4

1 3 5

CRR612

male threads on the Swaging Stud. This will draw the Swaging Stud 11/4" 1.660" 3

/16" 1.56" .437" 3/16" 5/16-24 .537" CRS6 CRR612

further inside the Receiver as you continue to turn it with the Allen 11/2" 1.900" 1

/8" 1.81" .437" 3/16" 5/16-24 .537" CRS4 CRR622

RAILING

11/2" 1.900" 3

/16" 1.81" .437" 3/16" 5/16-24 .537" CRS6 CRR622

GLASS

wrench.

11/2" 1.900" 1

/4" 1.81" .531" 7/32" 7/16-20 .646" CRS8 CRR822

Pipe ends are counterbored so the full perimeter of the head of the 2" 2.375" 1

/8" 2.30" .437" 3/16" 5/16-24 .537" CRS4 CRR642

Receiver will rest on a flat surface in the pipe. The head rests on the 2" 2.375" 3

/16" 2.30" .437" 3/16" 5/16-24 .537" CRS6 CRR642

outside wall of a flat-sided post. A plastic washer is included and 2" 2.375" 1

/4" 2.30" .531" 7/32" 7/16-20 .646" CRS8 CRR842

acts as a scratch resistant barrier between the Receiver head and 1" × 2"† 1/8" 3.03" .437" 3/16" 5/16-24 .537" CRS4 CRR652

the post. 1" × 2"† 3/16" 3.03" .437" 3/16" 5/16-24 .537" CRS6 CRR652

2" × 2" 1

/8" 2.03" .437" 3/16" 5/16-24 .537" CRS4 CRR632

2" × 2" 3/16" 2.03" .437" 3/16" 5/16-24 .537" CRS6 CRR632

RAILING

CABLE

2" × 2" 1

/4" 2.03" .531" 7/32" 7/16-20 .646" CRS8 CRR832

Swaged Stud 1" × 3"† 1/8" 3.03" .437" 3/16" 5/16-24 .537" CRS4 CRR652

1" × 3"† 3/16" 3.03" .437" 3/16" 5/16-24 .537" CRS6 CRR652

31/2" × 31/2"* 1/8" 3.56" .437" 3/16" 5/16-24 .537" CRS4 CRR662

31/2" × 31/2"* 3/16" 3.56" .437" 3/16" 5/16-24 .537" CRS6 CRR662

Invisiware * Nominal 4 × 4 wood post – 31/2" × 31/2" actual.

†

Receiver Use as double posts with spacer shown on page 58.

SPIRAL STAIRS

Spacer

BALCONIES

H T

Pipe, Tube Double Post with Spacer

or Wood Post

D

Invisiware® Receivers can be used in a horizontal position on stair end posts that have

a pitch up to 35 degrees. This eliminates the need to bore hardware holes at an angle

on stair runs. S

INVISIWARE® RADIUS FERRULE

ALUMINUM

RAILINGS

Type 316 Stainless Steel

For use on the fixed, non-tensioning end of the cable, often in com- L

bination with the Invisiware® Receiver on the tensioning end. When D

installed, the fitting is hidden inside the end post with only the

head exposed on the outside of the end post. Externally, it looks

the same as the Invisiware® Receiver, but costs much less. S

Pipe ends are counterbored, so the full perimeter of the head of

the Radius Ferrule will rest on a flat surface in the pipe. The head rests on the outside

BRASS / SS

FITTINGS

wall of a flat-sided post. A plastic A

Post

washer is included and acts as a Swaged Radius

scratch resistant barrier between Ferrule

Washer

the Radius Ferrule head and the Cable

Cable

post. Size D* L* S A Stainless

/8"

1

.250" .750" .537" .437" CRRF4

For pipe and square tube railing only. The

Radius Ferrule should not be used on rectan-

3

/16" .250" .750" .537" .437" CRRF6

Counterbored 1

/4" .375" 1.00" .646" .531" CRRF8

gular, double post construction.

Hole In Pipe

* After Swaging

INVISIWARE® SWAGING STUD

1 3

Type 316 Stainless Steel /2" /4"

Swaged on the end of the cable, this part is used with

the Invisiware® Receiver or the Invisiware® Welded * After

Receiver. When installed, it is completely hidden Swaging

inside the fitting, so you won’t ever see any unat- Cable

tractive swaging marks. The threaded surface is coat- Size D* Thread Stainless

ed with a baked-on molybdenum based dry film lubricant to prevent the threads from

1

/8" .250" 5

/16-24 CRS4

galling when tensioned and in extreme environments.

3

/16" .250" 5

/16-24 CRS6

1

/4" .375" 7

/16-20 CRS8

Wagner / Braun • 888.243.6914 • 414.214.0444 • FAX: 414.214.0450 • www.shopwagner.com

49

Ultra-tec® Cable Railing Push-LockTM Fittings www.wagnercablerailing.com

NEW!

FIELD INSTALLED PUSH-LOCKTM H ! K !

US OC

WAGNERAIL

FITTINGS MAKE CABLE RAILINGS

P L

SYSTEM

EASY TO INSTALL

NO FIELD SWAGING!

Cables come with a tensioner on one end. Install

the tensioner on one end post, then cut the cable

to length. Slip the Push-Lock fitting into the other

end post or mount it with the tab to the outside of

the post.

RAILING

GLASS

Push the cable into the Push-Lock fitting,

tension the cable and you’re done.

Note: Push-Lock Tool Kit is required – see

page 60.

EASY TO ORDER – EASY TO INSTALL

Select the tensioners you wish to use and provide the length of each of your cable runs on the worksheet shown on page 61. The cables will

be shipped with tensioners swaged on one end and bare cable on the other end. Pre-cut cable will be approximately 3" longer than required

RAILING

CABLE

to allow for potential fraying. Cut each cable to a final length on site and push it into the opening in the Push-Lock fitting.

PUSH-LOCKTM FOR LEVEL RUNS

Type 316 Stainless Steel .435" .537"

SPIRAL STAIRS

BALCONIES

Cable For Wood Post

Size Stainless Use Washer #

1

/8" CRPL4 CR716SAE

/16"

3

CRPL6 CR716SAE 1.56"

These Push-Lock fittings with rounded ends are used on level runs. They rest in a hole in the end post. When used with an end post 1-1/2"

or more in thickness, the Push-Lock fitting is hidden inside the end post with only the head exposed on the outside of the post. Pipe ends are

counterbored, so the full perimeter of the head will rest on a flat surface in the pipe. A plastic washer is included and acts as a scratch-resist-

ALUMINUM

RAILINGS

ant barrier between the Push-Lock fitting and a metal post. The head rests on the outside wall of a flat-sided metal post or on a stainless steel

washer on a wooden post. For wood applications, also order part number CR716SAE Washer.

PUSH-LOCKTM FOR STAIRS OR SEVERE PITCHES

Type 316 Stainless Steel

BRASS / SS

.435"

FITTINGS

.313"

2.45"

These fittings have a 1⁄4-28 threaded eye end and are for use on stairs. They

attach to a wood end post with a CRLE6 shown on page 51. For metal

posts, use a Fixed Tab or Threaded Tab. Mount with a CRSC6 Screw.

Cable Use with For Wood Post For Stainless Post For Steel Post

Size Stainless Screw # Use Lag Eye # Use Fixed Tab # Use Threaded Tab # Use Threaded Tab #

1

/8" CRPLTE4 CRSC6 CRLE6 CRFT65B CRTT6B CRFT65A

/16"

3

CRPLTE6 CRSC6 CRLE6 CRFT65B CRTT6B CRFT65A

SCREWS Cable Size Screw Size Stainless

Type 316 Stainless Steel 1

/8" 1

/4-28 × 1/2" CRSC6

For use with threaded fittings, as noted. 3

/16" 1

/4-28 × 1/2" CRSC6

1

/4" 3

/8-24 × 3/4" CRSC8

Wagner / Braun • 888.243.6914 • 414.214.0444 • FAX: 414.214.0450 • www.wagnercompanies.com

50

www.wagnercablerailing.com Ultra-tec® Cable Railing Invisiware®

INVISIWARE® THREADED TAB 5

/16"

Type 316 Stainless Steel

WAGNERAIL

Here’s a real time and money-saver.

SYSTEM

The Invisiware® Threaded Tab

screws into a drilled and tapped hole 3

on the inside wall of the end post. /8"

You save the expense of welding

tees or tabs onto your end post,

for mounting Adjust-A-Jaw® or

Adjust-A-Body™ Tensioners or Ultra-tec® Fixed Jaws. Cable

Size H S T A B L Stainless

Recommended only when you are using a minimum schedule 80 /8" .265" .500" .233"/.229" .813" .313" 1.250" CRTT6B

1

pipe end post or a square or rectangular steel end post with a min-

RAILING

3

/16" .265" .500" .233"/.229" .813" .313" 1.250" CRTT6B

GLASS

imum .250" wall. 1

/4" .390" .625" .295"/.285" 1.250" .375" 1.625" CRTT8B

INVISIWARE® EXTENDED LENGTH THREADED TAB Cable

Extended length, same Size Stainless

as above except there is /8"

1

CRTT6BL

no need to thread the 3

/16" CRTT6BL

hole in your end post. 1

/4" CRTT8BL 1.05

Cut to desired length and secure to end post with acorn nut and

thread sealant or Lido-Weld Adhesive – see page 39. Acorn Nut – CRAN37524S – is included.

RAILING

CABLE

H

INVISIWARE® FIXED TAB

D

Steel or Stainless Steel

Welded into an end post to

L S

make a strong tab for use

SPIRAL STAIRS

in mounting an Adjust-A-

BALCONIES

Jaw® or Adjust-A-Body™

T

Tensioner or Ultra-tec® Fixed Jaw. The Invisiware® Fixed Tab is

cut to length as necessary, inserted in a hole drilled through the

post and welded to the outside wall. The welded surface is then Cable

ground to the post’s original contour, thus hiding the weld. Size D H S T L Steel Stainless

1

/8" .375" .265" .44" .233"/.229" 3.11" CRFT65A CRFT65B

3

/16" .375" .265" .44" .233"/.229" 3.11" CRFT65A CRFT65B

1

/4" .562" .390" .68" .295"/.285" 3.00" CRFT85A CRFT85B

ALUMINUM

RAILINGS

INVISIWARE® WELDED RECEIVER

T

Steel or Stainless Steel

A fixed end, non-tensioning

device, the Invisiware® Welded

Receiver provides a sturdy,

threaded receptacle in the end 2.82" D

post for an Invisiware® Swaging

Stud. The Invisiware® Welded

BRASS / SS

FITTINGS

Receiver is cut to length as necessary, inserted in a hole drilled Cable Use with

through the post and welded to the outside wall. The welded sur- Size D T Stud # Steel Stainless

face is then ground to the post’s original contour, thus hiding the 1

/8" .437" 5

/16-24 CRS4 CRWR65A CRWR65B

weld. 3

/16" .437" 5

/16-24 CRS6 CRWR65A CRWR65B

1

/4" .531" 7

/16-20 CRS8 CRWR85A CRWR85B

ULTRA-TEC® LAG EYE

Type 304 Stainless Steel

A convenient, easy-to-install means for attaching an Adjust-A-Jaw®

or Adjust-A-Body™ Tensioner or Ultra-tec® Fixed Jaw to a wood

post.

For use with a minimum 4 × 4 nominal wood post.

Cable

Size G T L P Stainless

/8"

1

.233"/.229" .253" 1.50" .50" CRLE6

3

/16" .233"/.229" .253" 1.50" .50" CRLE6

1

/4" .295"/.285" .385" 2.00" .68" CRLE8

Wagner / Braun • 888.243.6914 • 414.214.0444 • FAX: 414.214.0450 • www.shopwagner.com

51

Ultra-tec® Cable Railing Adjust-A-BodyTM www.wagnercablerailing.com

ADJUST-A-BODY™ WITH THREADED EYE TENSIONER Body

Type 316 Stainless Steel T Nut

Ferrule Cable

Similar to the Adjust-A-

WAGNERAIL

SYSTEM

Jaw® Tensioner, except

it costs a lot less B

than the clevis-style S

Adjust-A-Jaw® Tensioner. See the tabulated drawing to deter- E Ln Lr

Lt

mine how to interface this fitting with your end post or use our Fixed

A

Tab or Threaded Tab fittings shown on page 51 of this catalog.

Tension with an open-end wrench.

Note: Order ferrule and screw separately.

RAILING

Cable Use with Use with

GLASS

Size E A B S T Lt Ln Lr D Screw # Ferrule # Stainless

/8"

1 1

/4-28 .233"/.229" .500" .44" 5

/16-24 2.00" .375" 2.75" .500" CRSC6 CRF4 CRAJTE6

3

/16" 1

/4-28 .233"/.229" .500" .44" 5

/16-24 2.00" .375" 2.75" .500" CRSC6 CRF6 CRAJTE6

1

/4" 3

/8-24 .295"/.285" .844" .68" 7

/16-20 2.50" .500" 3.00" .625" CRSC8 CRF8 CRAJTE8

RAILING

CABLE

ADJUST-A-BODY™ WITH HANGER BOLT TENSIONER Nut Body Ferrule Cable

(Order Separately)

Type 316 Stainless Steel Hanger Bolt

SPIRAL STAIRS

BALCONIES

Lp

Similar to the Adjust-A-Jaw® Tensioner, except it screws right into

your wooden end post. No need for special mounting hardware. A

For use with a minimum 4 × 4

sleek, economical tensioning device that is easy to install, adjusts nominal wood post

with an open-end wrench. Now available with a 11/2" longer hanger

bolt for 1/8" or 3/16" cable. *Longer shaft – Lp – for use when

mounting post has a fascia covering.

Cable Use with

ALUMINUM

Size S T Ls Lp* Lt Loq Ln Lr D Ferrule # Stainless

RAILINGS

1

/8" 5

/16" 5

/16-24 1.50" .25" 2.00" 3.75" .375" 2.75" .500" CRF4 CRAJB6

1

/8" 5

/16" 5

/16-24 1.50" 1.75" 2.00" 5.25" .375" 2.75" .500" CRF4 CRAJB6L

3

/16" 5

/16" 5

/16-24 1.50" 25" 2.00" 3.75" .375" 2.75" .500" CRF6 CRAJB6

3

/16" 5

/16" 5

/16-24 1.50" 1.75" 2.00" 5.25" .375" 2.75" .500" CRF6 CRAJB6L

1

/4" 7

/16" 7

/16-20 2.00" .25" 2.50" 4.75" .500" 3.00" .625" CRF8 CRAJB8

BRASS / SS

FITTINGS

ADJUST-A-BODY™ WITH THREADED BOLT TENSIONER Nut Body Ferrule

Type 316 Stainless Steel (Order Separately) Cable

Similar to the Adjust-A-

Body™ With Hanger Bolt

Tensioner, it screws into

a drilled and tapped hole

in your steel end post and adjusts with an open end wrench. A real

money-saver because there is no need for special tees with holes,

welded on tabs or any other mounting device – and it’s about half

the price of the clevis-style Adjust-A-Jaw® Tensioner. Recommended for level runs and when you are using a minimum schedule 80 pipe end

post or a square or rectangular steel end post with a minimum .250" wall.

Cable Use with

Size S T Ls Lt Loq Ln Lr D Ferrule # Stainless

1

/8" 5

/16-24 5

/16-24 .375" 2.00" 2.62" .375" 2.75" .500" CRF4 CRAJT6

3

/16" 5

/16-24 5

/16-24 .375" 2.00" 2.62" .375" 2.75" .500" CRF6 CRAJT6

1

/4" 5

/16-24 7

/16-20 .375" 2.50" 3.12" .500" 3.00" .625" CRF8 CRAJT8

Wagner / Braun • 888.243.6914 • 414.214.0444 • FAX: 414.214.0450 • www.wagnercompanies.com

52

www.wagnercablerailing.com Ultra-tec® Cable Railing Adjust-A-BodyTM

ADJUST-A-BODY™ WITH CONCRETE BOLT TENSIONER Nut Body Ferrule

(Order Separately) Cable

Type 316 Stainless Steel

WAGNERAIL

Similar to the Adjust-A-

SYSTEM

Body™ With Hanger

Bolt Tensioner, it screws

into a Red Head brand concrete anchor – available from your indus-

trial supplier. It is an easy, practical way to attach your tensioner to

a concrete wall. Adjusts with an open end wrench.

Cable Red Head Brand Anchor* Use with

Size S T Ls Lt Loq Ln Lr D Steel Stainless Ferrule # Stainless

1

/8" 3

/8-16 5

/16-24 .750" 2.38" 3.44" .375" 2.75" .500" RL-38 SSRM-38 CRF4 CRAJAB6

RAILING

GLASS

3

/16" 3

/8-16 5

/16-24 .750" 2.38" 3.44" .375" 2.75" .500" RL-38 SSRM-38 CRF6 CRAJAB6

1

/4" 1

/2-13 7

/16-20 1.12" 2.50" 3.93" .500" 3.00" .625" RL-12 SSRM-12 CRF8 CRAJAB8

CABLE Cable Minimum Measuring Cable:

Size Breaking Strength Stainless The factory can cut cable and swage fittings on cables up to 60 feet

RAILING

CABLE

1

/8" 1,780 lbs CR4AS2 in length.

3

/16" 4,000 lbs CR6AS2

1

/4" 6,900 lbs CR8AS2 To measure cable when ordering pre-cut and swaged cable:

• Clearly identify fittings – by part number – that are to be used

Cable Construction: 1 × 19, Type 316 stainless steel cable. with the cable.

1 × 19 construction cable is engineered to hold static loads without • For Invisiware® Receiver, Radius Ferrule or Clip-On Stop hard-

stretching and it is relatively stiff. Left hand lay cable for use with all ware, measure from back side of the post.

SPIRAL STAIRS

Ultra-tec® Fittings • For Adjust-A-Jaw®, Adjust-A-BodyTM, Threaded Stud with Welded

BALCONIES

Design Parameters and Constraints: Cable has a very high ten- Receiver or Fixed Jaw hardware, measure from the inside sur-

sile strength and is a suitable in-fill material for a guardrail. Spacing face of the post .

between posts and/or braces should not exceed 42". • For Adjust-A-Jaw®, Adjust-A-BodyTM or Fixed Jaw hardware, you

Recommended maximum vertical spacing of 3" free opening may also measure from the center of the mounting hole.

between cables when they are installed. For most applications, 3/16" • Measure rail as if all are straight from tensioning post to anchor

diameter cable is recommended. post. If rail is on a slope, measure on the slope.

Other cable constructions can be used, such as 7 × 7 or 7 × 19, but they are rarely rec- Note: Re-spooling charges apply for orders under 5,000 feet.

ommended because of their elevated levels of stretch and lower breaking strengths in

ALUMINUM

comparison to 1 × 19 construction.

RAILINGS

Erik

4/4

BRASS / SS

FITTINGS

Wagner / Braun • 888.243.6914 • 414.214.0444 • FAX: 414.214.0450 • www.shopwagner.com

53

Ultra-tec® Cable Railing Adjust-A-JawTM www.wagnercablerailing.com

ADJUST-A-JAW® TENSIONER – CLEVIS STYLE Swaged Ferrule

Type 316 Stainless Steel (Order Separately)

The Adjust-A-Jaw®

WAGNERAIL

Body Cable

Lock Nut

SYSTEM

Tensioner is a precision

machined, sleek,

streamlined tensioning

device that is used where a high-tech look is desired. It is suitable

for level runs or stair pitches. The clevis portion of the fitting attach- Tighten Lock Nut with

es to the end post with a button head socket screw that threads Clevis Mounting

Screw Open End Wrench

directly into a tapped hole on one side of the clevis fitting.

Unlike common turnbuckles, the Adjust-A-Jaw® Tensioner has no

sharp edges, no crevices to collect dust and dirt, no large areas of

RAILING

GLASS

exposed threads or exposed swaged shanks, and nothing that will

scratch or snag. See the tabulated drawing to determine how to

interface this fitting with your end post, or use our Fixed Tab or

Threaded Tab fittings shown on page 51 of this catalog.

The Clevis has a male thread that mates with the female thread with- Closed

in the Body. The Invisiware® Swaging Ferrule is swaged onto the

cable and holds the cable inside the Body. The Body rotates on the

cable and provides a considerable amount of take-up during tension-

RAILING

CABLE

ing with an open-end wrench. After tensioning, the Lock Nut locks the One Side

assembly in place. Only

Open

Note: Order ferrule and screw separately.

Cable Closed Open Use with Use with

Size D E G K L L Ln Lr Screw # Ferrule # Stainless

SPIRAL STAIRS

BALCONIES

1

/8" .260" 1

/4-28 .260" .56" 4.30" 5.99" .375" 2.75" CRSC6 CRF4 CRAJ62

3

/16" .260" 1

/4-28 .260" .56" 4.30" 5.99" .375" 2.75" CRSC6 CRF6 CRAJ62

1

/4" .390" 3

/8-24 .313" .75" 4.87" 6.43" .500" 3.00" CRSC8 CRF8 CRAJ82

Ultra-tec® FIXED JAW Swaged Ferrule

Type 316 Stainless Steel Threaded Hole

Similar in appearance, the Ultra-Tec® Fixed Jaw is about one-half the

ALUMINUM

RAILINGS

Fixed Jaw

price of the clevis-style Adjust-A-Jaw® Tensioner. Where you do not Cable

need a tensioner on both ends of the cable run, the economical Ultra-tec® Fixed Jaw is

frequently used on the fixed, non-tensioning end of the cable with the clevis-style

Adjust-A-Jaw® Tensioner on the tensioning end.

The Ultra-tec® Fixed Jaw makes a very attractive fitting where a high-tech look is desired on

level runs as well as on pitches. The Invisiware® Swaging Ferrule is swaged onto the cable

and holds the cable inside the clevis.

BRASS / SS

See the tabulated drawing to determine how to interface this fitting with your end post, or use

FITTINGS

our Fixed Tab or Threaded Tab fittings shown on page 51 of this catalog.

One Side

Ultra-tec® Clip-on FIXED JAW for pre-swaged cable Only

Type 316 Stainless Steel

Same as our regular Ultra-tec® Fixed Jaw, except the cable Ferrule Clip

attaches with a special clip that is installed by hand. All fittings

are swaged on the cable at the factory, so no field swaging is required. An Adjust-A-Jaw® or

Adjust-A-Body™ style tensioner or Invisiware® Receiver is used on the opposite end. Order

using part numbers below and check with the factory to determine cable lengths to be pro-

vided with swaged fittings. Available for 1/8" and 3/16" cable only. Refer to Clip-On Stop on page

55. Note: Order ferrule and screw separately.

Cable Use with Use with Fixed Jaw Clip-On Fixed Jaw

Size D E G K L Screw # Ferrule # Stainless Stainless

1

/8" .260" 1

/4-28 .260" .56" 1.75" CRSC6 CRF4 CRFJ62 CRFJC2

/16"

3

.260" 1

/4-28 .260" .56" 1.75" CRSC6 CRF6 CRFJ62 CRFJC2

1

/4" .390" 3

/8-24 .313" .75" 2.12" CRSC8 CRF8 CRFJ82

Wagner / Braun • 888.243.6914 • 414.214.0444 • FAX: 414.214.0450 • www.wagnercompanies.com

54

www.wagnercablerailing.com Ultra-tec® Cable Railing

INVISIWARE® SWAGING FERRULE

Type 316 Stainless Steel Cable

The Invisiware® Swaging Ferrule is used to retain

WAGNERAIL

Size D* Stainless

SYSTEM

an Adjust-A-Jaw® or Adjust-A-Body™ Tensioner or 1

/8" .250" CRF4

D

an Ultra-tec® Fixed Jaw onto a piece of cable. 3

/16" .250" CRF6

When installed, the Ferrule is locked inside the fit- 1

/4" .375" CRF8

ting, so you never see unattractive swage marks *After Swaged

with an Invisiware® Swaging Ferrule.

ULTRA-TEC® CLIP-ON STOP

RAILING

GLASS

Type 316 Stainless Steel Washer

For use in posts with cables cut and fittings Stop Clip

attached –preswaged – at the factory. No

/4"

field swaging is required. A special clip and

1

washer secure the Stop to the end post. 1"

Used on the non-tensioning end of the

cable. An Adjust-A-Jaw®, Adjust-A-Body™ Cable Size Post Material Washer Diam. Stainless

®

or Invisiware Receiver is used on the opposite end to tension the 1

/8" Wood .922" CRCOS4

RAILING

cable. Available for 3/16" and 1/8" diameter cable only. Includes Stop,

CABLE

1

/8" Metal .468" CRCOS4M

Washer and Clip. Refer to page 54 for Clip-On Fixed Jaw. 3

/16" Wood .922" CRCOS6

3

/16" Metal .468" CRCOS6M

ULTRA-TEC® CABLE GROMMETS Grommet Grommet

SPIRAL STAIRS

Cable Grommets are offered for popular cable diameters of 1/8", 3/16"

BALCONIES

Installation Tool

and 1/4". They help prevent rust in exterior applications or elsewhere

where moisture is a factor by providing a barrier between the cable

and the painted or powder coated surface through which the cable

is drawn when being installed.

Ultra-tec® Cable Grommets are installed – after the paint or powder

Large Lip Large Lip

coating is applied – into holes in intermediate posts, cable braces

and – in the case of the Invisiware® Radius Ferrule – into the end

post holes through which the cable exits. They are offered in black Order Cable Grommets by diameter of cable and post through which

ALUMINUM

UV resistant HDPE. the cable will be drawn. Sold in lots of 100. Specify quantity when

RAILINGS

ordering.

Intermediate Post Material End Post Material Intermediate Post Material Slotted

Not slotted for Stairways Using Radius Ferrule For Stairway Pitch Up To 37 Degrees

Cable 11/4" to 2" Square or Rect. Tube 1

/4" Cable 11/4" to 2" Square or Rect. Tube 11/4" to 2" Square or Rect. Tube 1/4" Cable

Size Pipe with .120" Wall Brace Pipe with .120" Wall Pipe with .120" Wall Brace

1

/8" or 3/16" CRGC61100 CRGC62100 CRGC64100 CRGC63100 CRGC64100 CRGIC61100 CRGIC62100 CRGIC64100

1

/4" CRGC81100 CRGC82100 CRGC84100 CRGC83100 CRGC84100 CRGIC81100 CRGIC82100 CRGIC84100

BRASS / SS

FITTINGS

Mike

1/33

Wagner / Braun • 888.243.6914 • 414.214.0444 • FAX: 414.214.0450 • www.shopwagner.com

55

Ultra-tec® Cable Railing Posts www.wagnercablerailing.com

PRE-DRILLED POSTS FOR WELDED ASSEMBLY

All posts are custom made based on customer provided, detailed shop drawings. Upon request, Wagner

can provide shop drawings – standard charges will apply.

WAGNERAIL

SYSTEM

• End Posts are drilled through or drilled and tapped on one side for use with

Invisiware® Threaded Tab.

• Intermediate Posts are provided with through holes.

Wagner can also customize your posts with counterbored holes, coped connec-

tions, special bends, or miters. Download a Post Order Form at www.wagnerca-

blerailing.com or Contact Wagner for pricing.

Intermediate Post

Material Options: Steel and Stainless Steel in sizes as indicated. When ordering,

Cable Brace

RAILING

note size of cable to be used. Wood posts – minimum 4 × 4 nominal lumber – are sup-

GLASS

End Post

plied by others.

CABLE BRACES

1

/4" × 1" Cable Braces are used to support the cables between End or Intermediate Posts. They keep the

cable from flexing excessively when a load is applied. Cable Braces are attached to the top rail and to

the lower mounting surface – either a bottom rail or deck. Download a Cable Brace Order Form at

www.wagnercablerailing.com

Pipe Size Tube Size Schedule Wall

11/4" 1.660" 40 .140"

RAILING

CABLE

11/4" 1.660" 80 .191"

11/2" 1.900" 40 .145"

11/2" 1.900" 80 .200"

2" 2.375" 40 .154"

2" 2.375" 80 .218"

1" × 2" .120"

1" × 3" .120"

SPIRAL STAIRS

BALCONIES

2" × 2" .120"

2" × 2" .250"

TYPICAL POST ASSEMBLY CONFIGURATIONS

These details are some of the more com- RECTANGULAR TUBE POST – WELDED ASSEMBLY

mon cable rail configurations. For com- End Post Cable Brace Intermediate Post End Post Cable Brace Intermediate Post

plete design and fabrication information,

a

a

please download Product Design and

Fabrication Guide for Metal Framed

ALUMINUM

RAILINGS

Railings at www.wagnercompanies.com/

cablerailing. Cable must be supported

every 42" mid run by either a Cable Brace

or Intermediate Post.

h

h

a

a

RECTANGULAR TUBE POST

End Post: Double 1" × 3" or 1" × 2" tube

31/2"

separated by stainless steel spacer with

BRASS / SS

FITTINGS

Invisiware® Fitting.

Cable Brace: 1/4" × 1" bar with through

holes for cable. SQUARE TUBE POST – WELDED ASSEMBLY

Intermediate Post: 1" × 3" or 1" × 2" tube End Post Cable Brace Intermediate Post End Post Cable Brace Intermediate Post

with through hole and grommets.

SQUARE TUBE POST

a

End Post: 2" × 2" tube with 1" × 2" top rail.

Cable Brace: 1/4" × 1" bar with through

holes for cable.

Intermediate Post: Double 1" × 2" tube

with through hole and grommets.

h

h

a

Building Code Issues:

To meet most code requirements restricting

31/2"

guard openings, cables are spaced

between 3" and 33/8" on center – depending

on frame construction.

Refer to page 248 for information regarding h cable a h cable a

the ladder effect. 361/2" 9 lines 3.10" 361/2" 10 lines 3.23"

421/2" 10 lines 3.36" 421/2" 12 lines 3.19"

Wagner / Braun • 888.243.6914 • 414.214.0444 • FAX: 414.214.0450 • www.wagnercompanies.com

56

www.wagnercablerailing.com Ultra-tec® Cable Railing Posts

PIPE OR ROUND TUBE POST PIPE OR ROUND TUBE POST – WELDED ASSEMBLY

End Post: 11/4" (1.660" OD), 11/2" (1.900" End Post Cable Brace Intermediate Post End Post Cable Brace Intermediate Post

OD), or 2" (2.375" OD), Schedule 80 pipe.

WAGNERAIL

Cable Brace: 1/4" × 1" bar, notched for pipe

SYSTEM

a

a

with through holes for cable.

Intermediate Post: Schedule 40 pipe with

through holes for cable.

h

90º FORMED ELBOWS

a

Pipe

a

Size r OD Steel Stainless

RAILING

11/4" 15/8" 1.660" 4434* 4654

GLASS

R

1 /2" 15/8" 1.900" 4464* 4684

31/2"

1

r

2" 1" 2.375" 410 459-1

*Note: These elbows have a visible seam.

For other elbows refer to pages 165 to 181.

Pipe h cable a Pipe h cable a

11/4" 361/2" 8 lines 3.30" 11/4" 361/2" 10 lines 3.17"

11/4" 421/2" 10 lines 3.24" 11/4" 421/2" 12 lines 3.14"

11/2" 361/2" 8 lines 3.24" 11/2" 361/2" 10 lines 3.15"

RAILING

11/2" 421/2" 10 lines 3.20" 11/2" 421/2" 12 lines 3.12"

CABLE

2" 361/2" 8 lines 3.14" 2" 361/2" 10 lines 3.10"

Seamed Elbow 2" 421/2" 10 lines 3.11" 2" 421/2" 11 lines 3.34"

COMPONENTS FOR THE ASSEMBLY OF TUBE CORNER SECTIONS CABLE TUBE

These stylish tube corner sections allow a change in direction without risk of damage to the

cables. At the same time, they offer the streamlined look of a continuous piece of cable – that

SPIRAL STAIRS

runs through the tube – and eliminates the cost and visual obstruction of additional mount- • Steel and Stainless Steel

BALCONIES

ing and tensioning hardware. • Drill 5⁄8" through hole in post and

chamfer one side for welding

These corner sections are provided as components: elbows, posts and cable tubes. Each • Insert Cable Tube into pre-drilled

post is custom designed per job requirements with holes pre-drilled to accept cable tubes. posts and weld into place.

Posts can also be provided pre-coped and in various styles and angles. All posts are custom Tubing Satin Finish

made based on customer provided, detailed shop drawings. Upon request, Wagner can pro- Diameter Steel Stainless

vide shop drawings – standard charges will apply. 5

⁄8" CR0113 CR0114.4

To use cable tubes, clear holes are drilled in the posts to accept these smaller diameter elbows.

The cable tubes are then inserted through the holes and welded into place. The cable may now

ALUMINUM

RAILINGS

be inserted through the tube providing a uniquely attractive fabrication.

For complete design and fabrication information, download our Product Design and Cable Tube

Fabrication Guide for Metal Framed Railings at www.wagnercablerailing.com.

ROUND TUBE OR PIPE CORNER POSTS

BRASS / SS

FITTINGS

Double Posts

Without Cable Tubes

90º ELBOW WITH TWO 2" TANGENTS

Pipe Tube

Size OD Steel Stainless

Pipe Tube Satin Finish • Steel and Stainless 11/4" 1.660" 5640 5656

R

Size Size Height Steel Stainless Steel r 11/2" 1.900" 5670 5690

11/4" 1.660" 36" CR166ST36 CR166SS36.4 • Welded tops and

• r = 4"

11/4" 1.660" 42" CR166ST42 CR166SS42.4 bases

• For other elbows, refer

11/2" 1.900" 36" CR190ST36 CR190SS36.4 • Manufactured to

to pages 166 to 180.

11/2" 1.900" 42" CR190ST42 CR190SS42.4 eliminate distortion

Wagner / Braun • 888.243.6914 • 414.214.0444 • FAX: 414.214.0450 • www.shopwagner.com

57

Ultra-tec® Cable Railing Mounting Options www.wagnercablerailing.com

MOUNTING PLATES

CABLE BRACE FLOOR PLATE

For installation details and mounting options using these compo-

• /4" Thick

1

WAGNERAIL

nents, refer to Cable Railing Mounting Options and Mounting

• For 1/4" × 1" Cable Braces

SYSTEM

Hardware Catalog available online or directly from Wagner.

• Countersunk for 3/8" mounting bolts.

Steel: 1018 Stainless Steel: Type 304 • Weld to cable brace from the back side

of the plate

Brace Size Steel Stainless

/4" × 1"

1

CRFLPCB CRFLPCBS

FASCIA MOUNTING PLATE WITH WELD SLOTS AND FOUR HOLES

RAILING

GLASS

• Four 7/16" holes for 3/8" mounting bolts.

• Attach to tube with 3/16" weld all around inside of 3/8" × 21/2" slot.

b • Weld to post from the back side.

• Use spacer shown below between posts for double post applications.

• Double posts with 1" spacer will use plate with two slots as noted below.

• 5" high.

Double Post Weld Steel Stainless

RAILING

Pipe Size Tube Size With 1" Spacer a b Slots 1018 Type 304

CABLE

1 /4"

1

1.660" 5" 6" 1 CRFAP4 CRFAP4S

11/2" 1.900" 5" 6" 1 CRFAP4 CRFAP4S

2" 2.375" 6" 7" 1 CRFAP5 CRFAP5S

1" × 3" 4" 5" 1 CRFAP1 CRFAP1S

3" × 3" 1" × 3" 6" 7" 2 CRFAP3 CRFAP3S

a 1" × 2" 4" 5" 1 CRFAP1• CRFAP1S

SPIRAL STAIRS

2" × 3" 1" × 2" 6" 7" 2 CRFAP3 CRFAP3S

BALCONIES

2" × 2" 5" 6" 1 CRFAP2 CRFAP2S

FLOOR PLATES SPACER

WITH CENTER HOLE FOR PIPE Only available in stainless steel. Insert between rectangular

tube posts.

• 1/4" Thick

ALUMINUM

• Countersunk for 1/4"

RAILINGS

mounting screws

• Weld to pipe from the

a

b back side

Spacer

Outside Steel Stainless

Pipe Size Diameter a b 1018 Type 304 Cable Diameter Wall Thickness Length Stainless

11/4" 1.660" 3" 21/2" CRFLP1M CRFLP1MS• 1

/8" 5

/8" .083" .970" CRSPCR6

BRASS / SS

11/2" 1.900" 3" 21/2" CRFLP2M CRFLP2MS 3

/16" 5

/8" .083" .970" CRSPCR6

FITTINGS

2" 2.375" 31/2" 31/2" CRFLP3M CRFLP3MS 1

/4" 7

/8" .035" .970" CRSPCR8

WASHERS

Available in Stainless Steel and Delrin® plastic.

FOR SQUARE OR RECTANGULAR TUBING Cable Outside Diam. Inside Diam. Stainless Delrin® Plastic

• Countersunk for 1/4" mounting screws. 1

/8" or 3/16" 59

/64" 15

/32" CR716SAE CRWR6B

• Use for square tube or rectangular tube. 1

/4" 11/16" 17

/32" CR050SAE CRWR8B

• Use spacer shown to the right between

posts for double post applications.

a • Butt weld to tube.

b BEVELED WASHERS

Stainless steel. For use with solid bar or

posts drilled at an angle.

Double Post Steel Stainless

Tube Size With 1" Spacer a b 1018 Type 304

1" × 3" 31/2" 3" CRFLP7M CRFLP7MS Cable Size

3" × 3" 1" × 3" 5" 31/2" CRFLP8M CRFLP8MS Angle /8" 1 3

/16" 1

/4"

1" × 2" 3" 21/2" CRFLP4M CRFLP4MS 30° - 33° CRBW326 CRBW326 CRBW328

2" × 3" 1" × 2" 5" 21/2" CRFLP6M CRFLP6MS 34° - 36° CRBW356 CRBW356 CRBW358

2" × 2" 4" 21/2" CRFLP5M CRFLP5MS 37° - 39° CRBW386 CRBW386 CRBW388

Wagner / Braun • 888.243.6914 • 414.214.0444 • FAX: 414.214.0450 • www.wagnercompanies.com

58

www.wagnercablerailing.com Ultra-tec® Cable Railing Wood Post Mounting

USING ULTRA-TEC® HARDWARE

WITH WOOD POSTS

These drawings illustrate some of the ways Ultra-tec® hard-

WAGNERAIL

SYSTEM

ware is used in wood end and corner posts. A minimum of a

nominal 4 × 4 (31/2" × 31/2" actual) is recommended for any

post where cable hardware is mounted.

Cables should be spaced on end posts on centers of no

more than 3.25", and the cable should be supported in some

fashion no more than every 42" along the cable run.

Cables can be cut and fittings swaged in the field using

Ultra-tec® swaging equipment – available for rent or pur-

chase.

RAILING

GLASS

With some hardware, the cable can be cut to customer pro-

vided lengths and the fittings swaged on at the factory thus

providing ready to install hardware.

Go to page 258 for more information on installing Ultra-tec

cable rail with wood posts.

Invisiware Invisiware

RAILING

Receiver with

CABLE

Radius Ferrule with Clip-On Stop

Stainless Washer Stainless Washer

Lag Eye Lag Eye

Fixed Jaw Adjust-A-Body TM Adjust-A-BodyTM with

with Hanger Bolt Threaded Eye

SPIRAL STAIRS

BALCONIES

INVISIWARE® RECEIVERS, RADIUS FERRULES AND CABLE SUPPORT

CLIP-ON STOP WITH WOODEN END POSTS 1

/4" × 1" flat bar.

The Invisiware® Receiver, Radius Ferrule and Clip-On Stop may be Available in Steel

used with wooden end posts. We recommend one of these ways to and Satin Finished Cable

accomplish this. Stainless Steel. Support

Surface Mount: Drill a hole in the post to accept the selected fitting

ALUMINUM

RAILINGS

such that the head sits on the outside of the post. Cable supports are

used to prevent the

Counter Bore: Drill a counter bored hole to accept the appropriate cable from biting into

fitting such that the head lies below the face of the post. the wood post – when

Stainless Steel washers – page 58 – are required. They are supplied tensioning – where the

with the Clip-On Stop but are to be purchased separately for the cable enters or exits at

Invisiware® Receiver and Radius Ferrule. an angle.

Refer to page 258 for installation information.

BRASS / SS

FITTINGS

Invisiware DRILL GUIDE

Use Drill Guide to locate and

Receiver

drill the pilot holes necessary

for your subsequent holes

and counter bores. Simply

clamp to post and drill. It is

Invisiware best to drill one side and

Radius Ferrule then the other. When

ordering, allow space for

clamps. 6" overall length

drill included that may

be used to drill your

Clip-On cable through holes.

Stop

Note: ACQ pressure treated lumber is now being used in many parts Download the Drill Guide Order Form and Cable Support Order

of the country. Use only stainless steel or galvanized hardware with Form from www.wagnercablerailing.com or contact Wagner.

ACQ treated lumber.

Wagner / Braun • 888.243.6914 • 414.214.0444 • FAX: 414.214.0450 • www.shopwagner.com

59

Ultra-tec® Cable Railing Tools www.wagnercablerailing.com

INSTALLATION TOOLS GROMMET INSTALLATION TOOLS

Cable can be provided pre-swaged or you may purchase the cable, tensioners and hardware Set of four for each

as components and swage the fittings prior to install. Tools are available for purchase or

WAGNERAIL

size and shape of

rental. Rental includes all tools required for installation except for an air compressor.

SYSTEM

grommet.

Before beginning your project, download the Design and Fabrication Guide at www.wagner-

cablerailing.com and review installation instructions on pages 258 to 271 of this catalog. Installation Tool CRGIT

MODEL 650 SWAGER AIR OVER HYDRAULIC PUMP

For 1/8" - 3/8" cable Air driven. Capable of delivering a maxi- LAG EYE DRIVER

Requires a hydraulic power source capa- mum of 10,000 psi. A 20 gallon minimum For driving Lag Eyes

ble of 10,000 psi. tank size is recommend- into wood posts. Lag

RAILING

ed. A functional pres-

GLASS

Eye not included.

sure regulator set at

100 psi maximum Lag Eye Driver CRDRIVERHB6N

is required – 90

psi minimum

to get swa- JAWED PLIERS WITH

ger to apply PRE-TENSIONER

full force – When tensioning, grip cable with special

otherwise Jawed Pliers to prevent damage to the

RAILING

CABLE

swaging cable. Pre-Tensioner can be used when

pump may be installing longer runs of Invisiware® since it

damaged. may have a minimum take-up.

Minimum 1/4" ID air

hose with a 1/4" male pipe thread.

Note: Should you experience any leakage

Model 650 Swager CR650 during operation, discontinue use and

SPIRAL STAIRS

Rental Kit* CRWAGNER650 contact Wagner.

BALCONIES

Hydraulic Pump CRHP

MODEL 610 SWAGER

For 3/16" cable and smaller ELECTRIC HYDRAULIC 120V PUMP

Requires a hydraulic power source capable Increases swaging speed versus the Air

of 10,000 psi. Over Hydraulic Pump.

Jawed Pliers CRJP

Pre-tensioner w/Pliers:

ALUMINUM

RAILINGS

For 1/8" Cable CRPTP4

For 3/16" Cable CRPTP6

For 1/4" Cable CRPTP6

CABLE CUTTER

To be used to cut cable up to 1/4". Proper

Model 610 Swager CR610 leverage is required. Either lay cable on a

Rental Kit* CRWAGNER610 table below your waist or on the ground.

BRASS / SS

FITTINGS

* Rental kits include: Swager, Air Over Hydraulic Pump, Use both hands to operate.

Cable Gripping Pliers, Allen Wrench, Cable Cutter, Electric Hydraulic Pump CRHPE

Marking Pen, Radius Ferrule Gauge, Safety Glasses,

Grommet Tool Set, Instruction Manual and Tool Box.

RADIUS FERRULE/CLIP-ON STOP

GAUGE

Use this gauge to confirm that your fittings

CABLE TENSIONING GAUGE have been properly swaged. If the swaged

Check the tension on your cables with this fitting does not fit the appropriate slot, the Cable Cutter for 1/8" - 3/16" cable CRCC

simple to use gauge. fitting is not suitable for use. Cable Cutter for 1/4" cable CRCC12

PUSH-LOCK FITTING TOOL KIT

Kit includes the Cable Cutter and Jawed

Pliers.

/8" Cable

1

CR91

/16" - 1/4" Cable

3

CR90 Measuring Gauge CRMG Push-Lock Tool Kit CRPLTC

Wagner / Braun • 888.243.6914 • 414.214.0444 • FAX: 414.214.0450 • www.wagnercompanies.com

60

www.wagnercablerailing.com Ultra-tec® Cable Railing

CABLE RAILING WORKSHEETS We are presently working on an online configuration tool to assist in

Use these two worksheets to assist in determining the requirements determining pricing. We expect to have this in place by the middle of

for your application. Larger versions of these sheets may be down- 2007. Go to wagnercompanies.com for the latest information and

WAGNERAIL

loaded from our website. changes to this product line.

SYSTEM

Invisiware Receiver

Invisiware Swaging Stud Invis

iware

Rece

iver

RAILING

Invisiware Radius Ferrule Invis

GLASS

iware

Swa

Push-Lock Fitting ging

Stud

Clip-

Clip-On Stop On S

top

Invis

Adjust-A-Body with Concrete Bolt Tensioner iware

Radi

Adju us F

st-A- errul

e

RAILING

Body

CABLE

Adjust-A-Body with Hanger Bolt with

Thre

aded

Adjust-A-Body with Threaded Bolt Eye

and

Adju Thre

st-A- aded

Adjust-A-Jaw with Threaded Tab Body Tab

with

Hang

Fixe er Bo

Adjust-A-Jaw with Lag Eye d Ja lt

SPIRAL STAIRS

w wi

th La

BALCONIES

Push g Ey

Lock e

Fixed Jaw with Lag Eye with

Thre

aded

Inside to Inside Push Eye

-Loc and

Outside to Inside k wit Thre

h Th aded

read Tab

Outside to Outside ed E

Insid y e a

e to

Insid nd Lag E

Outs e ye

ide t

ALUMINUM

RAILINGS

Outs o Ins

ide t ide

o Ou

tside

BRASS / SS

FITTINGS

Photo courtesy of Don Duperault.

Wagner / Braun • 888.243.6914 • 414.214.0444 • FAX: 414.214.0450 • www.shopwagner.com

61

Cable Railing Installation Guide www.wagnercompanies.com

BEFORE YOU GET STARTED Cable Grip Locking Pliers. To grip the cable while tensioning the

end fittings without damaging the cable. (Available from the factory.)

Rail Finish

If your rail is to be painted, powder coated or otherwise finished in Push-Lock Tool Kit. Includes Cable Grip Pliers and Cable Cutter.

GENERAL

any way, we strongly recommend that you apply the finish after all

INFO

Wrenches. If installing Invisiware® Receivers, an Allen wrench to

holes are drilled and prior to stringing the cable. tension the cable. See chart for size.

Materials Required If installing Adjust-A-Jaw™ or Ajust-A-Body™ Tensioners, set of

If screws for mounting Adjust-A-Jaw™ or Adjust-A-Body™ with open-end wrenches from 1/4" through 111/16".

Threaded Eye Tensioners and Ultra-tec® Fixed Jaws were not

ordered from the factory, you will need one of the following screws Calipers, if you are swaging and installing Invisiware® Radius

for each of these items: Ferrules, you will need a means to measure the diameter of the

TECHNICAL

swaged fitting. (“go” gauges for this purpose are normally included

In areas prone to tampering, a permanent setting thread sealant is

INFO

with Ultra-tec® Portable Swagers when rented from the factory.)

recommended for use with screws.

Grommet Installation Tool and hammer if you will be installing

grommets.

Adjust-A-Jaw

or Adjust-A- Fixed Jaw Screw Screw Drills and Drill Bits as required, if installing in a wood railing – see

Body Part No. Part No. Required Part No. Wood Railings under “Measuring and Installing Cable – Horizontal

Railings.”

CRAJ62 or

CRFJ62 1

/4-28 X 1/2" CRSC6

BUILDING

CRAJTE6

CODES

Cable Diameter Receiver Used Hex Hole Size

CRAJ82 or CRFJ82

CRAJTE8

1

/8"

3

/8-24 X 3/4" CRSC8 CRR6 3

/16"

3

/16"

CRAJ122 CRFJ122

1

/4" CRR8 7

/32"

Tools Required

The tools listed here assume you will be swaging at least one end

SPECS

GUIDE

of the cable in the field using an Invisiware® Field Swager. If no field

5

/16"

CRR12 5

/16"

swaging is required, only those tools indicated with * may be

3

/8"

required. Most tools are available for purchase or rental.

Installing Grommets

IMPORTANT NOTE: If grommets are being used on intermediate

posts, cable braces, or in the cable exit hole of end posts, then

INSTALLATION

grommets should be installed before cable is run.

GUIDES

To install grommets, see figure below. Place the larger diameter of

the grommet onto the grommet installation tool and the smaller

diameter at the hole in the post. Tap the tool lightly with a hammer.

Grommet Grommet

Installation Tool

Cable Cutters. CRC9 for cables up to 3/16"; CRC12 for cables larg-

INDEX

er than 3/16".

Air Compressor. Minimum 5.8 cfm at 90 psi – not to exceed 140 Large Lip Large Lip

psi – and a minimum 20 gallon tank. Air pressure should be regu-

lated not to exceed 140 psi.

Ultra-tec® Portable Pneumatic/Hydraulic Swager. If you are rent- Installing Cable

ing one from Wagner, be sure to specify the uncoated diameter of MEASURING AND INSTALLING CABLE

the cable you are swaging, so the correct swager will be supplied. Horizontal Railings, Measuring Cable Lengths

Rented swagers generally come with most other special tools If you have ordered your cables cut to length from the factory, you

required to field swage and install cable, including hose fittings, can skip this section on Measuring Cable Length.

cable grip locking pliers, cable cutter, and go gauge for measuring A. Measure the length of the run from the outside of one termi-

the swaged diameter of Invisiware® Radius Ferrules. A pre-tension- nating end post to the outside of the other terminating end

er can also be furnished upon request. post. Over estimate as shown, when corners are involved.

Ultra-tec® Pre-tensioning Tool (optional). Since some Invisiware® See Figures A & B on next page. Note that Post “A” is always

hardware has a minimum of take-up on longer runs (over 30 feet) the first end to which hardware is attached. When only one

you may want to use a pre-tensioning tool. In ordering, be sure to end has a tensioning device (Invisiware® Receiver or Adjust-

specify the cable diameter you will be using it with. A-Jaw™ Tensioner), that tensioning device is attached to Post

“B” and the non-tensioning device is attached to Post “A”.

Post “B” is always a tensioning end.

Wagner / Braun • 888.243.6914 • 414.214.0444 • FAX: 414.214.0450 • www.wagnercompanies.com

258

www.wagnercompanies.com Cable Railing Installation Guide

3. Slide the washer over the body of the Radius Ferrule.

4. Feed the bare end of the cable through the hole in Post “A”

ERALINFO

GEN-

from the back side, until the fitting’s head with washer rests

GENERAL

against the back side of the post (or in the counterbore if

applicable).

Where Invisiware® Receivers are being used, swage the Stud

onto the end of the cable to be attached to Post “A” (see

“Swaging Instructions”).

TECHNICAL

1 3

/2" /4"

INFO

Where Adjust-A-Jaw™ or Adjust-A-Body™ Type Tensioners are

being used, slide the Body onto the cable and swage the Ferrule

onto the end of the cable to be attached to Post “A” (see “Swaging

BUILDING

Instructions”).

CODES

SPECS

GUIDE

Where Ultra-tec® Fixed Jaws are being used, slide the Fixed Jaw

onto the cable and swage the Ferrule onto the end of the cable to be

attached to Post “A” (see “Swaging Instructions”).

B. Measure out cable on a relatively clean surface (see Figure

INSTALLATION

C above). A lawn or swept concrete surface would be fine.

GUIDES

C. Cut cable to length, using Cable Cutter.

NOTE: Make sure you have a positive holding device at the zero

end. Cutting the cables takes very little time. It is best to have one

person stand at the zero mark while another operates the cable cut-

ter at the cut mark.

Installing Cable

NOTE: If you are using Ultra-tec® “Clip-on” Fixed Jaws with

A. Unless already swaged, swage the fittings to be used on the Ferrule already swaged onto the cable or Ultra-tec® “Clip-

INDEX

Post “A” onto one end of the cut cables (See “Swaging on” Stops, you will have to feed the cable from the Post "B"

Instructions” section of these instructions). end through all intermediate posts to Post "A," before

NOTE: Where only one end of the cable has an adjusting fit- installing the Fixed Jaw onto the Post "A" end of the cable.

ting (Invisiware® Receiver or Adjust-A-Jaw™ Tensioner), we See “Ultra-tec® Clip-On Fixed Jaw Installation Instructions” or

recommend that you swage the unadjusting end, Post “A,” ”Ultra-tec® “Clip-on Stop Installation Instructions” elsewhere in

first (before the cables are strung) and the adjusting end, this guide for attaching the Fixed Jaw or “Clip-on Stop” to the

Post “B,” last (after the cables have been strung). cable.

Where Invisiware® Radius Ferrules will be used: B. String Cable through intermediate posts and braces to Post

1. Slide the Washer onto the cable. “B.” If you are using the Radius Ferrule, see Fig. M; for other

2. Swage the Radius Ferrule onto the end of the cable (see devices, see Fig. M-A (shown on next page).

“Swaging Instructions”). C. Attach fittings to end Post “A.”

Post If using Ultra-tec® Fixed Jaw, bolt the fitting to the tab, through

Swaged Radius the hole in the structural tee, or the lag eye (in wood post) on

Ferrule the end post, using the screws specified under “Materials

Washer

Cable Required.”

Counterbored

Hole In Pipe

Wagner / Braun • 888.243.6914 • 414.214.0444 • FAX: 414.214.0450 • www.shopwagner.com

259

Cable Railing Installation Guide www.wagnercompanies.com

Screw the lock nut onto the threads of the Clevis or Eye, then

hold the cable closely behind the body and turn the body by hand

a minimum of 8 turns onto the threaded end of the Clevis. (See

GENERAL

note)* Socket Nut Driver –

INFO

CRDRIVERHB6 – may be

used to facilitate tightening.

TECHNICAL

If you are installing into wood with a hanger bolt, screw the hang-

er bolt into a pre-drilled pilot hole in the post. Screw the lock nut

INFO

onto the threads of the bolt, then hold the cable closely behind

the body and turn the body by hand a minimum of 8 turns onto

the threaded end of the bolt. (See note*).

BUILDING

CODES

If using Adjust-A-Jaw™ or Adjust-A-Body™ with Threaded

Eye Tensioners:

If you are installing into a threaded hole in a metal post, screw the

bolt into the threaded hole in the post. Screw the lock nut onto the

threads of the bolt, then hold the cable closely behind the body

and turn the body by hand a minimum of 8 turns onto the thread-

SPECS

GUIDE

ed end of the bolt. (See note*).

INSTALLATION

GUIDES

If you are installing an Adjust-A-Body™ concrete anchor bolt end

into a concrete anchor bolt, screw the bolt into the threaded hole

in the anchor bolt. Screw the lock nut onto the threads of the bolt,

then hold the cable closely behind the body and turn the body by

hand onto the threaded end of the bolt at least 6 full turns. (See

INDEX

note*)

*NOTE: This will allow for maximum take-up. The fewer turns you

make at this step, the more thread that will be exposed when the

installation is complete. Each job is different, so we suggest that you

string and lightly tension one cable between end posts, to determine

how many turns you will make in turning the body onto the male

threaded end in order to minimize the amount of exposed thread at

both ends.

If using an Invisiware® Receiver, slide the washer over the body

of the Receiver, then feed the Receiver through the hole in back

of the post and into the hole on inside wall of the post (metal). If

you have a metal double post end post construction, be sure to

place spacers between the double posts, as you feed the fitting

If you are installing the tensioner using tabs, holes in a through. By hand, screw the Receiver onto the threaded Stud at

structural tee or lag eyes (in wood) attach the clevis portion least 6 full turns.

of the fitting to the tab, lag eye or through the hole in struc-

tural tee on the end post, using the screws specified under

“Materials Required.”

Wagner / Braun • 888.243.6914 • 414.214.0444 • FAX: 414.214.0450 • www.wagnercompanies.com

260

www.wagnercompanies.com Cable Railing Installation Guide

shown in relation to end Post “B” (see Figure R below for

steel posts, Figure RW below for wood posts). NOTE: this cut

mark will allow for maximum take-up. However, it may leave

GENERAL

more thread exposed than necessary after tensioning. This

INFO

length can be altered to achieve the most favorable results.

TECHNICAL

INFO

Receiver

CRR6 = .75

CRR8 = 1.00

CRR12 = 1.00

For wood posts, follow the same instructions, except you will

have to feed the cable – with the Stud swaged on the end –

through the post from the inside to meet the Receiver inside the

post, where you will turn the Receiver onto the Stud using an

BUILDING

Allen wrench.

CODES

If you are using Invisiware® Radius Ferrule, make sure the fitting

is through the hole in the back of the post with the head with

washer resting against the back side of the post (or in the coun-

terbore if applicable) as you proceed to the next step.

SPECS

GUIDE

INSTALLATION

GUIDES

CRR6

CRR8

D. Pull cable toward end Post “B.” Use Ultra-tec® Pre-tensioning

Tool, if required (see Figure S).

2. Swage Stud onto cable (see “Swaging Instructions” sec-

E. Attach fittings at end Post “B” tion in these instructions).

If installing Invisiware® Receiver at Post “B” 3. Slide the washer over the body of the Receiver, then feed

INDEX

NOTE: If installing Invisiware® Receiver on a stairway, see "Using the Receiver through the hole in the back of the post. If

Invisiware® Receivers on Stairways" before proceeding. you have a double post end post construction, be sure to

Fig. S

1. Cut Cable at Post “B” End. (Assumes cable is already

attached to Post “A.”) Mark and cut the cable at the location Double End Post Construction

Wagner / Braun • 888.243.6914 • 414.214.0444 • FAX: 414.214.0450 • www.shopwagner.com

261

Cable Railing Installation Guide www.wagnercompanies.com

place spacers between the double posts, as you feed the

fitting through. By hand, screw the Receiver onto the

swaged Stud at least 6 full turns. Do not tension cables

GENERAL

until all cables have been installed between end posts “A”

INFO

and “B.”

For wood posts using 3.50" long Receiver, follow the

same instructions CRAJ62

CRAJ82

4. Repeat above steps for each cable to be installed

CRAJ122

between end posts “A” and “B.”

CRAJTE6

TECHNICAL

5. After all the cables have been installed, tension the cable CRAJTE8

to approx. 400 lbs. by holding the cable (using cable grip

INFO

locking pliers) closely behind the Stud. Turn the Receiver

clockwise with an Allen Wrench. See “Tensioning

Cables” for sequence to use in tensioning cables.

BUILDING

CODES

CRAJB6

CRAJB8

SPECS

GUIDE

INSTALLATION

If installing Adjust-A-Jaw™ or Adjust-A-Body™ type tension-

GUIDES

er at Post “B”

1. Cut Cable at Post “B” End. (Assumes cable is already

attached to Post “A.”)If you are attaching the tensioner to a

tab, lag eye or hole in a structural tee, mark and cut the

cable at the location shown in relation to the center of the

mounting hole at Post ”B” (see Figure T). NOTE: this cut CRAJTB6

CRAJTB8

mark will allow for maximum take-up. However, it may leave

more thread exposed than necessary after tensioning. This

INDEX

length can be altered to achieve the most favorable results.

If the tensioner is mounted with the bolt screwed into a

wood post, a threaded hole in a metal railing, or a con-

crete anchor, mark and cut the cable at the location shown

in relation to end Post “B” (see Figures below). NOTE: this

cut mark will allow for maximum take-up. However, it may

leave more thread exposed than necessary after tension-

ing. This length can be altered to achieve the most favor-

able results.

Wagner / Braun • 888.243.6914 • 414.214.0444 • FAX: 414.214.0450 • www.wagnercompanies.com

262

www.wagnercompanies.com Cable Railing Installation Guide

2. Slide the Body onto the cable and swage the Ferrule onto If you are installing an Adjust-A-Body™ concrete anchor

the end of the cable (see “Swaging Instructions”). bolt end into a concrete anchor bolt, screw the bolt into the

threaded hole in the anchor bolt. Screw the lock nut onto

GENERAL

the threads of the bolt, then hold the cable closely behind

INFO

the body and turn the body by hand onto the threaded end

of the bolt at least 6 full turns.

3. Attach Tensioner to Post.

If you are installing the tensioner using tabs, holes in a

TECHNICAL

structural tee or lag eyes (in wood) attach the Clevis or

Eye portion of the fitting to the tab, lag eye or through the

INFO

hole in structural tee on the end post, using the screws

specified under “Materials Required.”

Fig. TC-2 FOR CONCRETE

BUILDING

CODES

4. Repeat the above steps for each cable to be installed. Do

not tension the cables, until all cables have been installed

between end posts “A” and “B.”

5. After all the cables have been installed, tension the cable

(to approximately 400 lbs.) with an open end wrench,

holding the cable with cable grip locking pliers to prevent

it from rotating. See “Tensioning Cables” for sequence

SPECS

GUIDE

Screw the lock nut onto the threads of the Clevis or Eye, to use in tensioning cables.

then hold the cable closely behind the body and turn the 6. If tensioners are mounted to tabs, structural tees or lag

body by hand onto the threaded end of the Clevis at least eyes, tighten the mounting screws.

6 full turns.

INSTALLATION

GUIDES

If you are installing into wood with a hanger bolt, screw the

hanger bolt into a pre-drilled pilot hole in the post. Screw

the lock nut onto the threads of the bolt, then hold the

cable closely behind the body and turn the body by hand 7. On all installations, tighten the lock nut against the body of

onto the threaded end of the bolt at least 6 full turns. the fitting with an open end wrench.

INDEX

Socket Nut Driver –

CRDRIVERHB6 – may be NOTE: In areas prone to tampering, the use of permanent setting

used to facilitate tightening. thread sealant is recommended for mounting screws and lock nuts.

If you are installing into a threaded hole in a metal post,

screw the bolt into the threaded hole in the post. Screw

the lock nut onto the threads of the bolt, then hold the

cable closely behind the body and turn the body by hand

onto the threaded end of the bolt at least 6 full turns.

Wagner / Braun • 888.243.6914 • 414.214.0444 • FAX: 414.214.0450 • www.shopwagner.com

263

Cable Railing Installation Guide www.wagnercompanies.com

F. Tensioning cables

Using Lag Eye

NOTE: Tension in sequence, beginning with cable nearest center of Cable Diameter Drill Size

Part No.

GENERAL

post (see Figure V below).

INFO

/8"

1

CRLE6 17

/64"

3

/16 " CRLE6 17

/64"

TECHNICAL

/4"

1

CRLE8 3

/8"

INFO

Where Adjust-A-Body™ with Hanger Bolt Tensioners are being

used, drill holes in the end posts using the drill size shown on the fol-

lowing chart and screw the Hanger Bolt into the holes. Adjust-A-Body

will be mounted to the Hanger Bolts (see “Installing Cable”).

Using

BUILDING

Cable Diameter Adjust-A-Body Drill Size

CODES

Part No.

CRAJB6

/8"

1 13

/64"

CRAJB6L

CRAJB6

3

/16" 13

/64"

CRAJB6L

SPECS

GUIDE

/4"

1

CRAJB8 5

/16"

*Due to the differences in different types of woods, slightly smaller or

larger holes may be required for your particular application.

INSTALLATION

GUIDES

Following are illustrations of several hardware mounting alternatives

and some techniques for mounting hardware to the end posts.

For Wood Posts

INDEX

Options for Mounting Invisiware® Receivers

and Radius Ferrules.

When using Invisiware Receivers, Radius Ferrules and/or Clip-on Stops,

see the illustration below for different mounting options. Drill holes in

your end posts using sizes shown in the chart. Ultra-tec Receivers,

Radius Ferrules and Clip-on Stops will be mounted in the drilled holes.

Drilling Holes in End Posts for Cable Mounting Hardware The hole depth will depend upon the mounting option you choose and

the thickness of the post.

Where Ultra-tec® Fixed Jaws are being used, drill holes in the end

posts using the drill size shown on the following chart and screw Lag

Eyes into the holes. Fixed Jaws will be mounted to the Lag Eyes

(see “Installing Cable“).

Wagner / Braun • 888.243.6914 • 414.214.0444 • FAX: 414.214.0450 • www.wagnercompanies.com

264

www.wagnercompanies.com Cable Railing Installation Guide

relying on the shear strength of the nails or screws to support the

tension applied to the end post.

Configuration of any corners in a wood post design

GENERAL

INFO

At corners or turns of more than approximately 45 degrees, it is best

to terminate your runs in each direction with an end post (minimum

of a nominal 4x4). The following illustrations demonstrate how this

is done. One such corner, however, may be designed using two

posts on the corner and running the cables between the posts as

illustrated below.

TECHNICAL

INFO

*Note: Do not counterbore if you are using CRR662 (31/2" long)

Receivers in a 4x4 (31/2") post on a pitch.

For Counterbore

Drill Hole for Diam of Hole for

Cable, Threaded Diameter of Hole Flat Washer or

BUILDING

Cable Stud or Clip-On for Receiver or Use Stainless Clip-On Stop

CODES

Option Diameter Stop Radius Ferrule SAE Flat Washer Washer

A & B Mount: Receiver using 1

/8"

Flat Washer (See Note 11

/32" 29

/64" 7

/16" 15

/16"

below)

3

/16"

C & D Mount: Radius

Ferrule using Flat Washer

1

/4" 15

/32" 35

/64" 1

/2" 13/32"

1

/8"

E & F Mount: Clip-On Stop 17

/64" NA NA 15

/16"

3

/16"

Drilling Holes in Intermediate Posts and Cable Braces

SPECS

GUIDE

Hole Diameter Where Cables are supplied by Wagner

with fittings swaged on both ends

Hole Diameter Where

Studs/Ferrules are swaged in Using Ferrules for Clip-On Fixed

Cable Size the field Using Threaded Studs Jaws or Clip-On Stop

1

/8" 5

/32" 11

/32" 17

/64"

3

/16" 7

/32" 11

/32" 17

/64"

1

/4" 9

/32" 15

/32" 25

/64"

INSTALLATION

A stainless steel flat bar (Cable Support) with holes for the cable to

Wood Rail Applications

GUIDES

pass through is mounted on each surface where the cable enters or

A substantial end post is necessary, to prevent the end post from exits the post at an angle, to prevent the cable from biting into the

bending, which will cause the cables to sag. In wood, a minimum wood when it is tensioned. Cable Supports are available from

4x4 nominal – 31⁄2" square – end post is required. End posts must be Wagner.

securely fastened to the deck or other surface, to prevent the post

from coming loose with the forces applied through the tensioned

cables. Support members between end posts are also necessary. In

wood, we recommend support members running between posts,

such as a 2x4 secured to the inside of each post, so you are not

INDEX

We do not recommend using this type of corner post config-

uration on more than one corner between any two-end posts

(with tensioning hardware). When using this configuration,

you will need tensioning hardware on both ends of the run,

and you will need to tension the cables from both ends.

Wagner / Braun • 888.243.6914 • 414.214.0444 • FAX: 414.214.0450 • www.shopwagner.com

265

Cable Railing Installation Guide www.wagnercompanies.com

On a turn of less than approximately 45 degrees, you can run your a) Field cut and swage or factory cut and swage fittings on the

cables through a single post, but you will still need to use a Cable cables.

Support where the cable enters or exits the post at an angle, to pre- When the fittings are swaged on at the factory, some fittings are larg-

GENERAL

vent the cable from biting into the wood when it is tensioned. er in diameter than the size of the holes you want to drill in your inter-

INFO

Configuration of Single Wood Corner Post mediate members (posts or cable braces). The fittings illustrated

The following illustrations demonstrate how the hardware can be below, however, require relatively small holes in your intermediate

used on a single corner post. They also illustrate how some hard- members. If the hardware is swaged on at the factory and if the cable

ware can be countersunk into the post or mounted flush with the will pass through intermediate posts or cable braces, one end of

back of the post. Not all combinations are shown here. If the hard- each cable should have one of the following fittings. The holes in

ware and cable run all the way through the post in one direction, you your intermediate member will be drilled for the diameter of the

TECHNICAL

will need to use a hanger bolt end or hardware that is mounted to a swaged fitting passing through the intermediate member as shown

in the following illustrations:

INFO

lag eye for the perpendicular direction, as shown in the first three

illustrations that follow.

BUILDING

CODES

Clip-On Stop in End Post

Passing through Intermediate

SPECS

GUIDE

Clip-On Fixed Jaw in End Post

INSTALLATION

Passing through Intermediate

GUIDES

Invisiware Receiver in End Post

INDEX

Passing through Intermediate

Where the cable will not pass through any intermediate members,

you can order factory cut and swaged cables using any hardware.

You are not limited to the fittings shown above.

If your cables will be cut and the fittings swaged on at the factory, you

will need to provide the factory with measurements for your cable

runs after the posts have been installed. Contact the factory for the

measurements required.

Vertical Railings – for Metal Railings Only

If you have ordered your cables cut to length from the factory, you

can skip the steps indicated with * on measuring cable length and

Selection of Appropriate Hardware for Wood Posts swaging fittings onto cable.

In selecting hardware, you will need to consider a) whether you want A. *Measure the distance between the bottom of the top rail to

to field cut and swage the cables or have them factory cut and the top of the bottom rail and add 2.187" (23/16").

swaged; b) hardware preferences for end posts; c) how you wish to

configure your corners (if applicable); d) hardware used for stairs or

severe slopes.

Wagner / Braun • 888.243.6914 • 414.214.0444 • FAX: 414.214.0450 • www.wagnercompanies.com

266

www.wagnercompanies.com Cable Railing Installation Guide

G. Tension the cables (to approximately 400 lbs.) by holding the

Drilled and tapped holes to accept

Invisiware Threaded Studs

cable (using jawed pliers) closely above the Stud in the bot-

tom rail. Turn the Receiver clockwise with an Allen Wrench

GENERAL

from underneath the bottom rail. First, tension the cable near-

INFO

est the center point between posts and/or cable braces. Then,

tension the rest of the cables in sequence, by alternating from

one side of the center cable to the other, as you move out-

ward toward the posts and/or cable braces. (For tensioning

sequence illustration, see “Tensioning Cables” in preceding

Installing Cables Section of this guide.)

TECHNICAL

Before you begin swaging

INFO

NOTE: If you are using coated cable, be sure to strip the coating

Drilled holes to accept

Invisiware Receivers from the end of the cable before swaging.