Professional Documents

Culture Documents

Solutions Profile: Using Fuzzy Logic in Logix

Solutions Profile: Using Fuzzy Logic in Logix

Uploaded by

pfalencarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Solutions Profile: Using Fuzzy Logic in Logix

Solutions Profile: Using Fuzzy Logic in Logix

Uploaded by

pfalencarCopyright:

Available Formats

SOLUTIONS PROFILE ADVANCED PROCESS CONTROL

USING FUZZY LOGIC IN LOGIX

BASIC SYSTEM FEATURES

• Library of components

• Hierarchical fuzzy systems

• No limits on number of inputs, outputs,

terms and rules

• Several methods for the fuzzy system

analysis

• Export fuzzy systems to Logix Add-On

Instructions (.L5X XML files)

• Import fuzzy systems from Add-On

Instructions

• Online monitoring and tuning of fuzzy

Add-On Instructions in running Logix

controllers

APPLICATION SCOPE

RSLogix 5000™ FuzzyDesigner is a software package for designing fuzzy logic

• Advanced applications in industrial algorithms for Logix controllers.

automation

Fuzzy logic allows engineers to exploit their expert knowledge and heuristics

• Intelligent control systems represented in the form of vague linguistic IF-THEN implication rules and

transfer it to a function block.

• Process diagnostics

FuzzyDesigner allows engineers to enhance the functionality of existing or new

• Decision-making and expert systems

control and decision making systems in various branches of industry. The fuzzy

• Intelligent monitoring systems system designed and generated by FuzzyDesigner might be used in control

systems as a direct nonlinear fuzzy-rule based controller or intelligent gain

• Forecasting systems scheduler (fuzzy supervisor) of PID or state feedback controllers. Fuzzy logic

solutions are especially useful for controlling complex systems where standard

PID control fails.

FuzzyDesigner generates Add-On Instruction (AOI) in L5X file format. The

user can then import the fuzzy AOI into RSLogix 5000 projects. Fuzzy AOI’s,

like any other AOI, can be used by any of the programming languages (Function

Block Diagram, Ladder Logic, or Structured Text). Finally, FuzzyDesigner allows

the user to online monitor and tune the fuzzy AOI directly in the running Logix

controller.

Add-On Fuzzy Instruction in Logix

RSLOGIX5000 FUZZYDESIGNER

FuzzyDesigner includes a library of

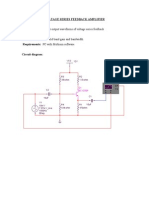

components from which a fuzzy system CASE STUDY

performing nonlinear input-output WET BLENDING PROCESS IN FOOD INDUSTRY

mapping can be designed. Hierarchical

structure enables the designer to

decompose a complex fuzzy system into

smaller and simpler parts, which reduces

the internal complexity of a fuzzy model

and results in fewer fuzzy rules and easier

insight into the system operation.

FuzzyDesigner offers several methods for

fuzzy system analysis. Simulation mode

allows you to watch the influence of

individual component values. 2D and 3D

graphs with many options allow insight

into the complex nonlinear mappings

realized by the fuzzy algorithm. Control system for the technology of wet parameters does not satisfy control

blend food processing consists of many requirements for the whole spectrum of

control loops. Any attempts for using applied recipes. One of the solutions,

standard PID control of the product which satisfies the requirements in wide

temperature were not successful due to range of operating conditions, is a

effect of the disturbance variables and nonlinear PI controller with scheduled

significant transportation delay between gains using expert fuzzy rules based on

the control action and its effect on applied recipe and other operating

temperature. A single setting of controller conditions.

OTHER CASE STUDIES

FUZZY SUPERVISED PID • Thermal Test Chamber

CONTROLLER • Intelligent Filter

• Diagnosis of a Motor Conditions

• Egg Wash Machine

• Anti-sway Crane Control

• Coupled Drives

Contact Rockwell Automation to learn

how RSLogix5000 FuzzyDesigner

software and our advanced process

control solutions team can help improve

performance of your manufacturing

plants.

Logix is trademark of Rockwell Automation.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication EMSE00-BR009A-EN-E – September 2006 Copyright ©2006 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.

You might also like

- Programmable Logic Controllers (PLCS) For Automation and Process ControlDocument2 pagesProgrammable Logic Controllers (PLCS) For Automation and Process ControlYashveer TakooryNo ratings yet

- Louis C. Westphal - Handbook of Control Systems Engineering-Springer Science (2001)Document1,073 pagesLouis C. Westphal - Handbook of Control Systems Engineering-Springer Science (2001)Engin50% (2)

- Logix Architecture: (Confidential - For Internal Use Only)Document71 pagesLogix Architecture: (Confidential - For Internal Use Only)ABVSAINo ratings yet

- Advanced Process Control Instructions With LogixDocument13 pagesAdvanced Process Control Instructions With LogixAzito JumNo ratings yet

- Recent Successful Fuzzy Logic Applications in Industrial AutomationDocument7 pagesRecent Successful Fuzzy Logic Applications in Industrial Automationjhosset20112539cNo ratings yet

- Fuzzy ControlDocument37 pagesFuzzy Controltecav94114No ratings yet

- 193 At001 - en PDocument24 pages193 At001 - en PMauricio Oropeza CabreraNo ratings yet

- Sequencemanager: Logix Controller-Based Batch and Sequencing SolutionDocument4 pagesSequencemanager: Logix Controller-Based Batch and Sequencing SolutionYang Gul LeeNo ratings yet

- Design and Implementation of PID Controller in ProDocument6 pagesDesign and Implementation of PID Controller in ProBAGAS ADIYATMA Mahasiswa PNJNo ratings yet

- Fuzzy Control System Design: Module 2 ObjectivesDocument38 pagesFuzzy Control System Design: Module 2 ObjectivesopwekkiNo ratings yet

- PID Controllers CPC400Document12 pagesPID Controllers CPC400EliasNo ratings yet

- Control Performance Monitor Taiji Pid Loop Tuning: Product Information NoteDocument2 pagesControl Performance Monitor Taiji Pid Loop Tuning: Product Information NotemelvokingNo ratings yet

- Product Data Sheet Agileops Alarm ManagementDocument9 pagesProduct Data Sheet Agileops Alarm ManagementAdbul SamadNo ratings yet

- 1761 MicroLogix Application (1761-AP001A-EN-P Nov 02)Document2 pages1761 MicroLogix Application (1761-AP001A-EN-P Nov 02)jishyNo ratings yet

- Speed Control of DC MachineDocument5 pagesSpeed Control of DC MachineNoorAhmedNo ratings yet

- Logix Br001 en PDocument36 pagesLogix Br001 en PJorge Xavier Avila VillacísNo ratings yet

- Plantpax® MPC: Model Predictive Control ProductDocument2 pagesPlantpax® MPC: Model Predictive Control ProductJuan Esteban Benjumea BenjumeaNo ratings yet

- Product Data Sheet Agileops Alarm Management Software Emerson en 4914072Document9 pagesProduct Data Sheet Agileops Alarm Management Software Emerson en 4914072guillermo guzmanNo ratings yet

- Leaflet Easy and Smart Control en PDFDocument12 pagesLeaflet Easy and Smart Control en PDFjad oussamaNo ratings yet

- PlasmaPro 80Document8 pagesPlasmaPro 80zelanNo ratings yet

- Design and Implementation of PID ControlDocument6 pagesDesign and Implementation of PID Controlmuhammad shahbazNo ratings yet

- CL03 - Studio 5000 Logix Designer Basics Lab ROKTechED 2016Document14 pagesCL03 - Studio 5000 Logix Designer Basics Lab ROKTechED 2016Antony ChumpitazNo ratings yet

- Programmable Logic ControllerDocument4 pagesProgrammable Logic ControllerBlack PigeonNo ratings yet

- Fuzzy Module 2Document38 pagesFuzzy Module 2bkhoanvuNo ratings yet

- Product Profile: Rslogix 5000 Enterprise Series Programming SoftwareDocument4 pagesProduct Profile: Rslogix 5000 Enterprise Series Programming SoftwareAnonymous JwOs90v6TUNo ratings yet

- A Proven Solution For Any Challenge in Hydropower AutomationDocument2 pagesA Proven Solution For Any Challenge in Hydropower AutomationkamalNo ratings yet

- IntroductionDocument3 pagesIntroductionFrankline OchiengNo ratings yet

- Saia PCD Operating System: ControlsDocument12 pagesSaia PCD Operating System: ControlsnaceurmaNo ratings yet

- PB4501Document2 pagesPB4501parrastevens930No ratings yet

- RSLogix 5000Document36 pagesRSLogix 5000Er. Piush Jindal83% (6)

- Getting Started With The Logix5000 PIDE Function Block - PLCdevDocument11 pagesGetting Started With The Logix5000 PIDE Function Block - PLCdevAhmed OUADAHINo ratings yet

- Manual Máquina Extrol-6032Document12 pagesManual Máquina Extrol-6032Haxso Industrial ServiceNo ratings yet

- AB CLX Standard 4 Day Module1 5FDocument62 pagesAB CLX Standard 4 Day Module1 5FZaheer AbbasNo ratings yet

- Design of A Fuzzy Logic Process Controller For Flow ApplicationsDocument7 pagesDesign of A Fuzzy Logic Process Controller For Flow ApplicationstomakobNo ratings yet

- Infoplc Net KCL 20180405esag Studio5000v31kclDocument121 pagesInfoplc Net KCL 20180405esag Studio5000v31kclJorge JarrinNo ratings yet

- Excellence Expertise: Born FromDocument4 pagesExcellence Expertise: Born FromMỹ JumNo ratings yet

- 300570-Sta R Max3 Sell-SheetDocument4 pages300570-Sta R Max3 Sell-SheetABD ENOUR BOUALOULNo ratings yet

- PlantPAx™ Logix Batch & Sequence ManagerDocument4 pagesPlantPAx™ Logix Batch & Sequence ManagerYang Gul LeeNo ratings yet

- HTTPWWW Jamris Org012010saveas Phpquestjamrisno012010p08-19Document12 pagesHTTPWWW Jamris Org012010saveas Phpquestjamrisno012010p08-19agivereccNo ratings yet

- Bio Command SoftwareDocument4 pagesBio Command SoftwaregonrusticoNo ratings yet

- 01 SCADA TopkapiDocument6 pages01 SCADA TopkapiikhsanNo ratings yet

- TAPPI Paper Con 2011: DCS Embedded Condition Monitoring Erkki Jaatinen, MetsoDocument34 pagesTAPPI Paper Con 2011: DCS Embedded Condition Monitoring Erkki Jaatinen, MetsoDimas SetawanNo ratings yet

- R17 RoboticsDocument346 pagesR17 Roboticskiran babuNo ratings yet

- BMN Automation 2023 enDocument40 pagesBMN Automation 2023 enВладимирNo ratings yet

- Automation by Laukik P RautDocument46 pagesAutomation by Laukik P RautRutanshu LawhaleNo ratings yet

- BC Sigmapac enDocument16 pagesBC Sigmapac enEmiro Revilla CatariNo ratings yet

- DC Motor ProjetDocument13 pagesDC Motor ProjetArT MgMNo ratings yet

- RA Foundations - Studio 5000 and LogixDocument140 pagesRA Foundations - Studio 5000 and LogixAlonso Daniel Hurtado Centeno100% (1)

- RT 512 Level Control Trainer Gunt 1178 PDF 1 en GBDocument3 pagesRT 512 Level Control Trainer Gunt 1178 PDF 1 en GBAli HadiNo ratings yet

- DSP-Based Laboratory Implementation of Hybrid Fuzzy-PID Controller Using Genetic Optimization For High-Performance Motor DrivesDocument10 pagesDSP-Based Laboratory Implementation of Hybrid Fuzzy-PID Controller Using Genetic Optimization For High-Performance Motor DrivesJulián Peláez RestrepoNo ratings yet

- Using: Control ControlDocument6 pagesUsing: Control ControlRAJEEV RANJAN SILMANANo ratings yet

- Factorytalk® View Site Edition: Powerful, Scalable Visualization SolutionsDocument6 pagesFactorytalk® View Site Edition: Powerful, Scalable Visualization SolutionsJeremy AlfaroNo ratings yet

- 1736 Software For Programmable Automation ControllersDocument4 pages1736 Software For Programmable Automation Controllerssarkiss01No ratings yet

- Digitalization - Why Not Just Put It in The DCSDocument7 pagesDigitalization - Why Not Just Put It in The DCSajayvgNo ratings yet

- Auto LabDocument5 pagesAuto Labpssvasan108No ratings yet

- AB CLX Standard 4 Day Module1 5CDocument58 pagesAB CLX Standard 4 Day Module1 5CHassan RashadNo ratings yet

- AceDatasheet UserGuideDocument19 pagesAceDatasheet UserGuidealinupNo ratings yet

- Fuzzy Module 2Document38 pagesFuzzy Module 2Abel AbelNo ratings yet

- Ch.12 Programmable Logic ControllersDocument7 pagesCh.12 Programmable Logic ControllersMy QNNo ratings yet

- GAIN SCHEDULING CONTROLLER DESIGN FOR AN ELECTRIC DRIVE Final PDFDocument6 pagesGAIN SCHEDULING CONTROLLER DESIGN FOR AN ELECTRIC DRIVE Final PDFGlan DevadhasNo ratings yet

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- Training Systems For Drive Technology Power Electronics Electrical Machines CatalogDocument85 pagesTraining Systems For Drive Technology Power Electronics Electrical Machines CatalogpfalencarNo ratings yet

- Flight Line Service Manual For Rate Based AutopilotsDocument115 pagesFlight Line Service Manual For Rate Based AutopilotspfalencarNo ratings yet

- 440N Z, (Sensaguard) PDFDocument10 pages440N Z, (Sensaguard) PDFMarcio MullerNo ratings yet

- PLC Programming Made Easy FlyerDocument4 pagesPLC Programming Made Easy FlyerpfalencarNo ratings yet

- Altivar ATV IMC Drive Controller: Hardware GuideDocument72 pagesAltivar ATV IMC Drive Controller: Hardware GuidepfalencarNo ratings yet

- Altivar ProfibusDocument29 pagesAltivar ProfibustiagofelipebonesNo ratings yet

- Tcsmcnam3M002P: Product Data SheetDocument1 pageTcsmcnam3M002P: Product Data SheetpfalencarNo ratings yet

- PickMater 5 3HAC025829 001 - Revb - en PDFDocument292 pagesPickMater 5 3HAC025829 001 - Revb - en PDFpfalencarNo ratings yet

- Programmable Logic Controllers: PLC LanguagesDocument16 pagesProgrammable Logic Controllers: PLC LanguagespfalencarNo ratings yet

- NovaSensor NPH 081114 Low Pressure To 8Document4 pagesNovaSensor NPH 081114 Low Pressure To 8pfalencarNo ratings yet

- PLCDocument113 pagesPLCpfalencar0% (1)

- 06 Tech Modbus enDocument27 pages06 Tech Modbus enpfalencarNo ratings yet

- Facts and Theory of Air: For Industrial PneumaticsDocument74 pagesFacts and Theory of Air: For Industrial PneumaticspfalencarNo ratings yet

- PLC and System InterfacingDocument30 pagesPLC and System InterfacingpfalencarNo ratings yet

- PLC PresentationDocument58 pagesPLC PresentationpfalencarNo ratings yet

- MT P 20160901Document173 pagesMT P 20160901pfalencar0% (1)

- Honey Well Hvac Controls ManualDocument472 pagesHoney Well Hvac Controls Manualgohvicc100% (4)

- LCS Basics Revesion PDFDocument3 pagesLCS Basics Revesion PDFrajeshmholmukheNo ratings yet

- Automatic Generation Control of An Interconnected Power SystemDocument6 pagesAutomatic Generation Control of An Interconnected Power SystemSudhir KumarNo ratings yet

- A Frequency Domain PID Controller Design Method Using Direct Synthesis ApproachDocument11 pagesA Frequency Domain PID Controller Design Method Using Direct Synthesis ApproachTrần Kế HưngNo ratings yet

- Open-Loop vs. Closed-Loop Control SystemDocument6 pagesOpen-Loop vs. Closed-Loop Control SystemJaveria AfzalNo ratings yet

- State and Output Feedback Nonlinear Model Predictive Control: An OverviewDocument17 pagesState and Output Feedback Nonlinear Model Predictive Control: An OverviewShashank SrivastavaNo ratings yet

- Analysis of Missile Control SystemDocument21 pagesAnalysis of Missile Control SystemD.Viswanath100% (2)

- Kaddour Najim Control of Continuous Linear SystemsDocument11 pagesKaddour Najim Control of Continuous Linear SystemsChrislei RizzattiNo ratings yet

- Manual TC3 Temperature ControllerDocument46 pagesManual TC3 Temperature ControllerMinh Nhut LuuNo ratings yet

- B3-Signal Processing For RoboticsDocument16 pagesB3-Signal Processing For RoboticsJorge RodriguezNo ratings yet

- Control System FinalDocument200 pagesControl System FinalqwertyNo ratings yet

- Az PDFDocument132 pagesAz PDFAlan Barreras GastelumNo ratings yet

- ECE 411 Computer Lab 1Document9 pagesECE 411 Computer Lab 1Sekar PrasetyaNo ratings yet

- Advanced Control StrategiesDocument6 pagesAdvanced Control StrategiesHugo EGNo ratings yet

- Measurement & ControlDocument5 pagesMeasurement & ControlAsif PatelNo ratings yet

- Space Engineering Lab Manual MDocument43 pagesSpace Engineering Lab Manual Mmanikandan_murugaiahNo ratings yet

- 10 1 1 456 5401 PDFDocument14 pages10 1 1 456 5401 PDFSreehari RgNo ratings yet

- Voltage Series Feedback AmplifierDocument5 pagesVoltage Series Feedback AmplifierRavi Teja71% (7)

- Lec16 - Optimal ControlDocument13 pagesLec16 - Optimal Controljavadmousavi440No ratings yet

- (G) - LEC Feedback and OscillatorsDocument43 pages(G) - LEC Feedback and OscillatorsAngelino Pimentel100% (1)

- Design and Implementation of Energy Management System With Fuzzy Control For DC Microgrid SystemsDocument8 pagesDesign and Implementation of Energy Management System With Fuzzy Control For DC Microgrid SystemsAlamson SitanggangNo ratings yet

- 2 Tank System BondgraphDocument7 pages2 Tank System BondgraphSolemn AkkiNo ratings yet

- Design and Modeling of Multiple Tank Control For Fluid Circulation System Using Fuzzy Controller - Gwee Chiou Chin - TJ213.G83 2008Document27 pagesDesign and Modeling of Multiple Tank Control For Fluid Circulation System Using Fuzzy Controller - Gwee Chiou Chin - TJ213.G83 2008Halomoan Daniel100% (1)

- Notes Tee602 Bode Plot PDFDocument23 pagesNotes Tee602 Bode Plot PDFtansnvarmaNo ratings yet

- Candidates Are Required To Give Their Answers in Their Own Words As Far As Practicable. The Figures in The Margin Indicate Full MarksDocument3 pagesCandidates Are Required To Give Their Answers in Their Own Words As Far As Practicable. The Figures in The Margin Indicate Full MarksAdhikari SushilNo ratings yet

- Control Valves - inst2JNTU - 2014Document72 pagesControl Valves - inst2JNTU - 2014Sridhar GudapatiNo ratings yet

- Chapter 3Document71 pagesChapter 3akshay kalangadeNo ratings yet