Professional Documents

Culture Documents

Different

Different

Uploaded by

MohamedElAbbasyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Different

Different

Uploaded by

MohamedElAbbasyCopyright:

Available Formats

2.

Differential Sticking

As soon as differential sticking has been identified as the sticking mechanism pump at the maximum

allowable rate in an attempt to erode the filter cake. Work down to the stuck depth the maximum make

up torque (maximum for the type or types of pipe in the string) and attempt to maintain this torque at

depth. If this does not work then the procedure can be repeated a number of times.

If the pipe still does not come free then prepare to jar. Slow down the pumps to a minimum, or even

stop them. Slack off the string to the maximum set down weight for a long enough time period to trip

the jars. If the string still does not come free then maintain the string torque and continue jarring down

with the maximum trip load, still pumping very slowly or with the pumps off to maximise the

effectiveness of the down blow. If after 5-10 jar blows the string does not look as if it is going to come

free then continue jarring while making preparations to spot some sort of releasing pill or conduct “U”

tube operations.

Once the pipe is free rotate and work the string while circulating at the maximum rate to clear the hole

of any debris. Before continuing with drilling operations revaluate the mud properties to try and avoid

a recurrence of the problem.

2001, Datalog Technology

2000, Pipe Freeing Sheet, Randy Smith Training Schools

1997, Drillers Stuck Pipe Handbook, Colin Bowes & Ray Procter

You might also like

- Stuck PipeDocument1 pageStuck PipegatjeNo ratings yet

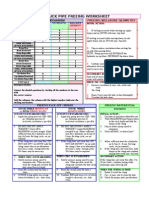

- Stuck Pipe Freeing WorksheetDocument1 pageStuck Pipe Freeing WorksheetAdeel NenseyNo ratings yet

- Pack OffDocument2 pagesPack OffMohammad RizwanNo ratings yet

- Surface Bumper Jar: Instruction Manual 4300Document9 pagesSurface Bumper Jar: Instruction Manual 4300GNo ratings yet

- Fishing Operations and ToolsDocument24 pagesFishing Operations and ToolsMohamedElAbbasy100% (2)

- API Bit Size - Casing ClearanceDocument1 pageAPI Bit Size - Casing ClearanceMohamedElAbbasyNo ratings yet

- Stuck Pipe ChartDocument3 pagesStuck Pipe ChartJorge Luis Ortiz100% (2)

- Stuck-Pipe-Poster V1Document2 pagesStuck-Pipe-Poster V1jaime lNo ratings yet

- DifferentDocument5 pagesDifferentTeodor Ioan Ghinet Ghinet DorinaNo ratings yet

- Stuck Pipe WorksheetDocument1 pageStuck Pipe WorksheetPashaakapaulNo ratings yet

- Stuck-Pipe-Poster V9rDocument2 pagesStuck-Pipe-Poster V9rjaime lNo ratings yet

- Stuck Pipe PosterDocument1 pageStuck Pipe PosterMoustafa AbdouNo ratings yet

- Stuck Pipe PosterDocument1 pageStuck Pipe Posterhooman_tehNo ratings yet

- If Over Pulls Are Encountered, Apply Max 15 MT Overpull RuleDocument1 pageIf Over Pulls Are Encountered, Apply Max 15 MT Overpull RuleEmma EmallyNo ratings yet

- Overview of The Drilling ProcessDocument16 pagesOverview of The Drilling ProcessCyril Jean-BaptisteNo ratings yet

- Differential StickingDocument1 pageDifferential StickingramyNo ratings yet

- Stuck Pipe Freeing Worksheet For UploadDocument1 pageStuck Pipe Freeing Worksheet For Uploadrverret100% (1)

- 13-Tripping & Reaming GuidelinesDocument16 pages13-Tripping & Reaming GuidelinessrikantaLee0% (1)

- Chapter 5 Drilling ProblemsDocument23 pagesChapter 5 Drilling ProblemsAlind doskyNo ratings yet

- 1 Problems Setting The Packer: Contingency ProceduresDocument1 page1 Problems Setting The Packer: Contingency ProceduresYougchu LuanNo ratings yet

- 1a. Pack Off in Deviated Holes: (Usually With Angles Greater Than 35)Document2 pages1a. Pack Off in Deviated Holes: (Usually With Angles Greater Than 35)MohamedElAbbasyNo ratings yet

- DipstickDocument3 pagesDipsticksiavash sarseparNo ratings yet

- Drilling 16 Inch Section - Best PracticesDocument2 pagesDrilling 16 Inch Section - Best PracticesYougchu Luan100% (2)

- Solids Induced Pack-Off Packing Off - First ActionsDocument4 pagesSolids Induced Pack-Off Packing Off - First ActionsBhagwal TravelsNo ratings yet

- Drilling With Casing 04Document15 pagesDrilling With Casing 04Dian Sikumbang100% (2)

- 5 Main Junk Basket TypesDocument7 pages5 Main Junk Basket TypesrahulNo ratings yet

- Separating Compounds by Column Chromatography PDFDocument2 pagesSeparating Compounds by Column Chromatography PDFsania fosterNo ratings yet

- Drilling Practice Stuck PipeDocument81 pagesDrilling Practice Stuck PipeAhmed Ajeeb100% (4)

- Val-Tex Valve Flush Procedure With High Lights - NDocument4 pagesVal-Tex Valve Flush Procedure With High Lights - Nmaminu1No ratings yet

- Sect 11Document8 pagesSect 11Anouckolympic mouloungui mamboundouNo ratings yet

- CT Stuck Pipe Procedures and ERPDocument3 pagesCT Stuck Pipe Procedures and ERPing.acarrera2024No ratings yet

- Stuck PigDocument1 pageStuck PigdakidofdaboomNo ratings yet

- Instructions For Use of Rotary EvaporatorDocument2 pagesInstructions For Use of Rotary EvaporatorJulia PasqualeNo ratings yet

- Stuck Pipe - Drilling ProblemDocument18 pagesStuck Pipe - Drilling ProblemaaputraNo ratings yet

- Instrumental Analysis in ResearchDocument271 pagesInstrumental Analysis in ResearchYap JackyNo ratings yet

- Boricon BOP TestDocument7 pagesBoricon BOP TestJosh SabimanNo ratings yet

- Dna ExtractionDocument3 pagesDna ExtractionCetura VillaruzNo ratings yet

- PBL Operation ProcedureDocument16 pagesPBL Operation Procedurekudturkar100% (1)

- Injection Molding - SHUT DOWNRESTARTDocument4 pagesInjection Molding - SHUT DOWNRESTARTAmit PatelNo ratings yet

- Pipe Sticking PDFDocument5 pagesPipe Sticking PDFAnimeshNo ratings yet

- Pipe Sticking: Differential Pressure and MechanicalDocument5 pagesPipe Sticking: Differential Pressure and MechanicalA JNo ratings yet

- How To Avoid Stuck Pipe in Hard or Soft CementDocument4 pagesHow To Avoid Stuck Pipe in Hard or Soft CementMohamed SouidiNo ratings yet

- 4 3qtr Inch PBL ProcedureDocument7 pages4 3qtr Inch PBL ProcedureAnonymous D9jw6iPYEhNo ratings yet

- 0 Intro STK Pipe PDFDocument10 pages0 Intro STK Pipe PDFNabil Benmakhlouf100% (9)

- Val-Tex Valve Flush Procedure With High Lights - N PDFDocument4 pagesVal-Tex Valve Flush Procedure With High Lights - N PDFgm_revankar39420% (1)

- Method Statement For Horizontal Four Flange Bladders Installation in TankDocument2 pagesMethod Statement For Horizontal Four Flange Bladders Installation in TankDong VanraNo ratings yet

- Fire PistonDocument10 pagesFire PistonCiovica Lucian CatalinNo ratings yet

- Packing For Centrifugal PumpsDocument4 pagesPacking For Centrifugal PumpsJitu Jena100% (1)

- Well Bore GeometryDocument2 pagesWell Bore GeometryMohamedElAbbasyNo ratings yet

- Instruction Manual SFL-GN 125Document8 pagesInstruction Manual SFL-GN 125Alok KumarNo ratings yet

- National Pump JET-PUMPDocument6 pagesNational Pump JET-PUMPOsamaNo ratings yet

- Core Barrel Running ProcedureDocument4 pagesCore Barrel Running Proceduremahesh_mzp1954No ratings yet

- Stuck Breaker PillDocument2 pagesStuck Breaker PillRohan ChunaraNo ratings yet

- General High Banker Instructions: AssemblyDocument9 pagesGeneral High Banker Instructions: AssemblyJesús DíazNo ratings yet

- Tube Replacement Instructions: CL/CLM & HECL/HECLM Models: Bryan BoilersDocument4 pagesTube Replacement Instructions: CL/CLM & HECL/HECLM Models: Bryan BoilersVictor Enrique Carmona AlvarezNo ratings yet

- LD2 Drilling Practices & Lessons Learned - A.boubeniaDocument8 pagesLD2 Drilling Practices & Lessons Learned - A.boubeniaAli BoubeniaNo ratings yet

- Allen, Laura - Greywater, Green Landscape - How To Install Simple Water-Saving Irrigation Systems in Your Yard-Storey Publishing (2017) - 8Document20 pagesAllen, Laura - Greywater, Green Landscape - How To Install Simple Water-Saving Irrigation Systems in Your Yard-Storey Publishing (2017) - 8Hector Alfredo Gutierrez RomeroNo ratings yet

- Tru - Wate Mud BalanceDocument2 pagesTru - Wate Mud BalanceClemente Serrudo UlpanaNo ratings yet

- Progressive PiggingDocument1 pageProgressive PiggingfedermNo ratings yet

- Crap, The Shitter Is Broke! -Or- How To Fix Common Problems With Your ToiletFrom EverandCrap, The Shitter Is Broke! -Or- How To Fix Common Problems With Your ToiletNo ratings yet

- SafetyDocument30 pagesSafetyMohamedElAbbasyNo ratings yet

- Grant Prideco Rotary Shoulder HandbookDocument112 pagesGrant Prideco Rotary Shoulder Handbookrlk2806No ratings yet

- DrillpipeDocument6 pagesDrillpipeMohamedElAbbasyNo ratings yet

- 1a. Pack Off in Deviated Holes: (Usually With Angles Greater Than 35)Document2 pages1a. Pack Off in Deviated Holes: (Usually With Angles Greater Than 35)MohamedElAbbasyNo ratings yet

- Well Bore GeometryDocument2 pagesWell Bore GeometryMohamedElAbbasyNo ratings yet

- 01 Pump SelectionDocument26 pages01 Pump SelectionMohamedElAbbasy100% (1)

- %core #1 %normalised SW %normalised Kro %normalised KRW %plotting The Data For This CoreDocument3 pages%core #1 %normalised SW %normalised Kro %normalised KRW %plotting The Data For This CoreMohamedElAbbasyNo ratings yet

- Koomey UnitDocument1 pageKoomey UnitMohamedElAbbasyNo ratings yet

- Mud 1Document5 pagesMud 1MohamedElAbbasyNo ratings yet

- Stuck Pipe PreventionDocument2 pagesStuck Pipe PreventionMohamedElAbbasyNo ratings yet

- Rig Component: Supply RealDocument3 pagesRig Component: Supply RealMohamedElAbbasyNo ratings yet