Professional Documents

Culture Documents

Minimum Design Metal Temperature Results

Minimum Design Metal Temperature Results

Uploaded by

GOWTHAM0 ratings0% found this document useful (0 votes)

14 views1 pageThe document provides results from minimum design metal temperature (MDMT) calculations for a vessel component. Key details include:

- The required thickness is 29.88 mm with a temperature reduction of 3°F.

- Post weld heat treatment is required for the element/joint.

- Elliptical head material is SA-516 Grade 70 for use between 40-50°F and 500°F.

- Calculations were performed for the knuckle portion of the vessel.

Original Description:

FDDF

Original Title

FDGEOGJREG (6)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides results from minimum design metal temperature (MDMT) calculations for a vessel component. Key details include:

- The required thickness is 29.88 mm with a temperature reduction of 3°F.

- Post weld heat treatment is required for the element/joint.

- Elliptical head material is SA-516 Grade 70 for use between 40-50°F and 500°F.

- Calculations were performed for the knuckle portion of the vessel.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

14 views1 pageMinimum Design Metal Temperature Results

Minimum Design Metal Temperature Results

Uploaded by

GOWTHAMThe document provides results from minimum design metal temperature (MDMT) calculations for a vessel component. Key details include:

- The required thickness is 29.88 mm with a temperature reduction of 3°F.

- Post weld heat treatment is required for the element/joint.

- Elliptical head material is SA-516 Grade 70 for use between 40-50°F and 500°F.

- Calculations were performed for the knuckle portion of the vessel.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

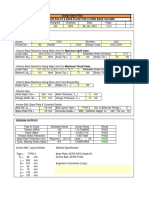

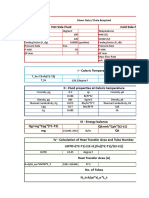

Minimum Design Metal Temperature Results:

Govrn. thk, tg = 34, tr = 30.8, c = 3.2 mm., E* = 1

Thickness Ratio = tr * (E*)/(tg - c) = 1, Temp. Reduction = 0 °F

Note:

Post Weld Heat Treatment is required for this Element/Joint and it was

specified as being heat treated.

Elliptical Head From 40 To 50 SA-516 70 , UCS-66 Crv. D at 500 °F

TOP HEAD

Material UNS Number: K02700

Required Thickness due to Internal Pressure [tr]:

Max. Allowable Working Pressure at given Thickness, corroded [MAWP]:

Less Operating Hydrostatic Head Pressure of 0.533 psig

Maximum Allowable Pressure, New and Cold [MAPNC]:

Actual stress at given pressure and thickness, corroded [Sact]:

Straight Flange Required Thickness:

Straight Flange Maximum Allowable Working Pressure:

Less Operating Hydrostatic Head Pressure of 0.533 psig

Factor K, corroded condition [Kcor]:

Percent Elong. per UCS-79, VIII-1-01-57 (75*tnom/Rf)*(1-Rf/Ro) 10.401 %

Note: Please Check Requirements of UCS-79 as Elongation is > 5%.

MDMT Calculations in the Knuckle Portion:

Govrn. thk, tg = 34, tr = 29.88, c = 3.2 mm., E* = 1

Thickness Ratio = tr * (E*)/(tg - c) = 0.97, Temp. Reduction = 3 °F

°

°

You might also like

- Design of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateDocument2 pagesDesign of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateAbhishek SinglaNo ratings yet

- Calculation of Earthing Sys.Document12 pagesCalculation of Earthing Sys.Rania Fathy Mohammed100% (4)

- Conduction Cooling For Chassis and Circuit BoardsDocument41 pagesConduction Cooling For Chassis and Circuit BoardsKadir Bozdemir100% (1)

- Cable Design Calculations (Air)Document8 pagesCable Design Calculations (Air)Inayat HathiariNo ratings yet

- Cable Design Calculations (Direct Burial & Short Circuit Current)Document19 pagesCable Design Calculations (Direct Burial & Short Circuit Current)Inayat Hathiari0% (1)

- Design Heat Exchanger Shell and Tube TheDocument8 pagesDesign Heat Exchanger Shell and Tube ThezatamaqeelNo ratings yet

- Earthing Design Calculation: Project: Document No. DateDocument9 pagesEarthing Design Calculation: Project: Document No. Dateboopathy1705100% (1)

- MDMT Calculations in The Knuckle PortionDocument1 pageMDMT Calculations in The Knuckle PortionGOWTHAMNo ratings yet

- Govrn. THK, TG 38, TR 30.66, C 3.2 MM., E 1 Thickness Ratio TR (E ) / (TG - C) 0.881, Temp. Reduction 12 °F ° °Document1 pageGovrn. THK, TG 38, TR 30.66, C 3.2 MM., E 1 Thickness Ratio TR (E ) / (TG - C) 0.881, Temp. Reduction 12 °F ° °GOWTHAMNo ratings yet

- FormulaeDocument33 pagesFormulaeLcm TnlNo ratings yet

- Tor. Dish EndDocument4 pagesTor. Dish EndSiva ShankarNo ratings yet

- Makkah PSM2 Suction SideDocument4 pagesMakkah PSM2 Suction Sideniyamat89No ratings yet

- 230kv Cable Sizing 1Document6 pages230kv Cable Sizing 1Thirunavukkarasu VaratharajanNo ratings yet

- Element ThicknessDocument10 pagesElement ThicknesskhairulakbarNo ratings yet

- Ieee80 Step and Touch CalculationDocument24 pagesIeee80 Step and Touch Calculationwaleed.liaquat.kkNo ratings yet

- Calculation of Earthing System As Per Ieee 80Document10 pagesCalculation of Earthing System As Per Ieee 80Fateh Khemissi MilasNo ratings yet

- PV Elite 2012 R1 Licensee: Pressure Filename: 102 Horz Tank - Internal Pressure Calculations: Step: 3 7:29P Oct 5,2012Document7 pagesPV Elite 2012 R1 Licensee: Pressure Filename: 102 Horz Tank - Internal Pressure Calculations: Step: 3 7:29P Oct 5,2012isaacalvareztejanoNo ratings yet

- 03 CalDocument56 pages03 Calnatarajan RavisankarNo ratings yet

- Shell and Tube HE CalculationDocument16 pagesShell and Tube HE CalculationPradip ShindeNo ratings yet

- Equipment Design As Per Russian Norms - 20090218Document45 pagesEquipment Design As Per Russian Norms - 20090218vikas100% (1)

- Design Calculation: Larsen & Toubro LimitedDocument72 pagesDesign Calculation: Larsen & Toubro Limitedjm.mankavil6230No ratings yet

- Design Cold Form Section 24may20Document7 pagesDesign Cold Form Section 24may20ramesNo ratings yet

- T Header For AFC Calculation (PER UG-34) :, With The Limitation That Z Need Not Be Greater Than 2.5 (UG-34.B3)Document16 pagesT Header For AFC Calculation (PER UG-34) :, With The Limitation That Z Need Not Be Greater Than 2.5 (UG-34.B3)Pand AemonaEonNo ratings yet

- Samb Expand End PlateDocument5 pagesSamb Expand End PlateArbiNo ratings yet

- 6 Inch NB Nozzle Calculation Appendex 1-7Document11 pages6 Inch NB Nozzle Calculation Appendex 1-7SACHIN PATELNo ratings yet

- Design Steps For SlabsDocument7 pagesDesign Steps For SlabsdhanashekarVNo ratings yet

- Forces On Gantry-34Document5 pagesForces On Gantry-34vkjainabc100% (1)

- Base Plate DesignDocument32 pagesBase Plate DesignGautam Sharma50% (2)

- L 8 IhjnmklgfDocument27 pagesL 8 IhjnmklgfbrintopvNo ratings yet

- Beam To Column'S Flange Fixed Connection Type Bcff-1: 1-Design DataDocument5 pagesBeam To Column'S Flange Fixed Connection Type Bcff-1: 1-Design DataAchmad RifaiNo ratings yet

- Section VIII CalDocument19 pagesSection VIII CalPradeep Kothapalli100% (1)

- Cable Capacity - Example Calculating 300 MMDocument7 pagesCable Capacity - Example Calculating 300 MMNedunuri.Madhav MurthyNo ratings yet

- 05 CalDocument53 pages05 Calnatarajan RavisankarNo ratings yet

- End Plate ConnectionDocument12 pagesEnd Plate ConnectioncklconNo ratings yet

- Weld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersDocument30 pagesWeld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersmishtinilNo ratings yet

- Internal CoilDocument2 pagesInternal CoilwhngomjNo ratings yet

- Design Input:: Design Sheet Title: Design of Anchor Bolts & Base Plate For A Fixed Base Column Ameya STDDocument4 pagesDesign Input:: Design Sheet Title: Design of Anchor Bolts & Base Plate For A Fixed Base Column Ameya STDSuryaSinghNo ratings yet

- Section VIII CalDocument21 pagesSection VIII CalRuben Samoel Barros RochaNo ratings yet

- Flange Bolt LoadDocument3 pagesFlange Bolt LoadSAMER OSMANNo ratings yet

- 02.2 Temperature FVDocument16 pages02.2 Temperature FVjovanivanNo ratings yet

- 250 HP Engine For Unmanned HelicopterDocument52 pages250 HP Engine For Unmanned HelicopteryanfengzhangNo ratings yet

- Anchor Bolt DesignDocument15 pagesAnchor Bolt Designamit8808No ratings yet

- UG-45 Minimum Nozzle Neck Thickness Requirement: (Int. Press.)Document1 pageUG-45 Minimum Nozzle Neck Thickness Requirement: (Int. Press.)Nerubian AssasinNo ratings yet

- 111Document3 pages111郑 凯伦 Tey Kai LoonNo ratings yet

- 220kV Beam - 1Document3 pages220kV Beam - 1k_arindam1No ratings yet

- Aspen HX Design ReportDocument78 pagesAspen HX Design ReportberylqzNo ratings yet

- Vassel DesignDocument5 pagesVassel DesignOsama JavedNo ratings yet

- Asme Sec 1 (Boiler)Document15 pagesAsme Sec 1 (Boiler)Arie MahendraNo ratings yet

- Process Design of CondenserDocument5 pagesProcess Design of CondenserVivek VĩvĕNo ratings yet

- Miter B1 ADocument55 pagesMiter B1 AFarid TataNo ratings yet

- E.3.2 - MDMT Using MathcadDocument2 pagesE.3.2 - MDMT Using MathcadrobertantoreniNo ratings yet

- HMT Answer 2 & 16 Marks HMTDocument85 pagesHMT Answer 2 & 16 Marks HMTChandra Sekar100% (3)

- Thermal Design of Heat ExchangerDocument9 pagesThermal Design of Heat ExchangerNaqqash SajidNo ratings yet

- Pile CAP Design Example + 2 PilesDocument3 pagesPile CAP Design Example + 2 PilesTharanga Pradeep100% (2)

- EC2 Beam Section DesignDocument3 pagesEC2 Beam Section Designikanyu79100% (1)

- Crack Width Cal-T Beam-Euro CodeDocument10 pagesCrack Width Cal-T Beam-Euro CodeGautham AllimuthuNo ratings yet

- sm3 058Document2 pagessm3 058Sadie HnatowNo ratings yet

- Insert/Set-in Nozzle No Pad, No Inside Projection Reinforcement CALCULATION, Description: N5ADocument1 pageInsert/Set-in Nozzle No Pad, No Inside Projection Reinforcement CALCULATION, Description: N5AGOWTHAMNo ratings yet

- PV Elite Is A Trademark of Intergraph Cadworx & Analysis Solutions, Inc. 2018Document1 pagePV Elite Is A Trademark of Intergraph Cadworx & Analysis Solutions, Inc. 2018GOWTHAMNo ratings yet

- Maximum Allowable Pressure For This Nozzle at This LocationDocument1 pageMaximum Allowable Pressure For This Nozzle at This LocationGOWTHAMNo ratings yet

- External Pressure Calculation Results: External Pressure CalculationsDocument1 pageExternal Pressure Calculation Results: External Pressure CalculationsGOWTHAMNo ratings yet

- Results Per UW-16.1:: Weld Size Calculations, Description: M1Document1 pageResults Per UW-16.1:: Weld Size Calculations, Description: M1GOWTHAMNo ratings yet

- Fdgeogjreg PDFDocument1 pageFdgeogjreg PDFGOWTHAMNo ratings yet

- Weld Load (W1) : : Strength of Connection Elements For Failure Path AnalysisDocument1 pageWeld Load (W1) : : Strength of Connection Elements For Failure Path AnalysisGOWTHAMNo ratings yet

- Max. Allowable Working Pressure at Given Thickness, Corroded (MAWP)Document1 pageMax. Allowable Working Pressure at Given Thickness, Corroded (MAWP)GOWTHAMNo ratings yet

- Note: The CG Is Computed From The First Element From Node: Shop/Field Installation OptionsDocument1 pageNote: The CG Is Computed From The First Element From Node: Shop/Field Installation OptionsGOWTHAMNo ratings yet

- Thickness Requirements Per UG-33 (A) (1) Do Not Govern The Required Thickness of This HeadDocument1 pageThickness Requirements Per UG-33 (A) (1) Do Not Govern The Required Thickness of This HeadGOWTHAMNo ratings yet

- Element and Detail Weights:: Miscellaneous Weight Percent: 10.0 %Document1 pageElement and Detail Weights:: Miscellaneous Weight Percent: 10.0 %GOWTHAMNo ratings yet

- V231-002 - Design CaseS1 S2 REV-C - OutDocument10 pagesV231-002 - Design CaseS1 S2 REV-C - OutGOWTHAMNo ratings yet

- Fdgeogjreg PDFDocument1 pageFdgeogjreg PDFGOWTHAMNo ratings yet

- PV Elite Is A Trademark of Intergraph Cadworx & Analysis Solutions, Inc. 2018Document1 pagePV Elite Is A Trademark of Intergraph Cadworx & Analysis Solutions, Inc. 2018GOWTHAMNo ratings yet

- Element Thickness, Pressure, Diameter and Allowable StressDocument1 pageElement Thickness, Pressure, Diameter and Allowable StressGOWTHAMNo ratings yet

- Elements Suitable For Internal Pressure.: PV Elite Is A Trademark of Intergraph Cadworx & Analysis Solutions, Inc. 2018Document1 pageElements Suitable For Internal Pressure.: PV Elite Is A Trademark of Intergraph Cadworx & Analysis Solutions, Inc. 2018GOWTHAMNo ratings yet

- MDMT Calculations in The Knuckle PortionDocument1 pageMDMT Calculations in The Knuckle PortionGOWTHAMNo ratings yet

- Asme BPVC - Ii.A-2017 Sa-530/Sa-530M: P2St/Dorsppd/2TDocument1 pageAsme BPVC - Ii.A-2017 Sa-530/Sa-530M: P2St/Dorsppd/2TGOWTHAMNo ratings yet

- Govrn. THK, TG 38, TR 30.66, C 3.2 MM., E 1 Thickness Ratio TR (E ) / (TG - C) 0.881, Temp. Reduction 12 °F ° °Document1 pageGovrn. THK, TG 38, TR 30.66, C 3.2 MM., E 1 Thickness Ratio TR (E ) / (TG - C) 0.881, Temp. Reduction 12 °F ° °GOWTHAMNo ratings yet

- Xy Coordinate Calculations:: PV Elite Is A Trademark of Intergraph Cadworx & Analysis Solutions, Inc. 2018Document1 pageXy Coordinate Calculations:: PV Elite Is A Trademark of Intergraph Cadworx & Analysis Solutions, Inc. 2018GOWTHAMNo ratings yet

- 4A104C Excel-Template - Heat-exchanger-Design p1 Si UnitsDocument1 page4A104C Excel-Template - Heat-exchanger-Design p1 Si UnitsGOWTHAMNo ratings yet

- 4A104C Excel-Template - Heat-exchanger-Design p1 Si UnitsDocument1 page4A104C Excel-Template - Heat-exchanger-Design p1 Si UnitsMustafa AlweshahiNo ratings yet