Professional Documents

Culture Documents

RCC Rectangular Overhead Water Tank PDF

RCC Rectangular Overhead Water Tank PDF

Uploaded by

Akash GundaleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RCC Rectangular Overhead Water Tank PDF

RCC Rectangular Overhead Water Tank PDF

Uploaded by

Akash GundaleCopyright:

Available Formats

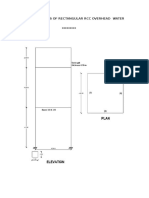

DESIGN & ANALYSIS OF RECTANGULAR RCC OVERHEAD WATER TANK

Data:

Size of water Tank 4.0m x4.0m x2.0m

Height of water tank from GL =8.0m

Water tank wall thickness =180mm

Size of column = 300 x 300 mm

Bracing beam =300 x 350mm

Concrete grade M30

Steel Fe 415 grade

1.Creation of Geometry :

File New Project Select Space Unit : Length =meters;

Force=KN; File Name=RCC overhead tank Next

Select Open Structure Wizard Finish.

Change to Frame Models from Truss models Select Bay frame and

double click on it.

Length X=4m No. bays =1

Height Y=10m No. of bays =3 click Bay 1=4m Bay2=4m Bay3=2m;

Width Z=4m No. bays=1

Apply Transfer model Click Yes Go to Front view icon (first view)

Select tank portion for surface modeling.

Isometric view Select surface meshing Quadrilateral meshing OK

Division=10 Apply . Do first bottom, side 1, side 2, side 3 and side 4. To

remove all beam elements, Select the tank portion except bottom of tank

Delete80 beams & associated Physical beams (if any) will be deletedOk.

Fig.1 Isometric view of the model

2. Member Properties :

Click General Define Rectangle YD=0.3m ZD=0.30m (column)

Add. YD=0.35m ZD=0.30m (Beams at top and bracing) Add Thickness Node

1 to 4 =0.18mAddClose.

High light column size 0.3 x 0.3 and select column portion by windowing

Assign to selected beam Assign Yes. High light beam size

0.35 x 0.30 and select tank bottom beam and tank middle bracing beam

Assign to selected beam Assign Yes. High light thickness and select tank

portion Assign to selected beam Assign Yes Close. De select the

member.

3.Supports :

Front view Click SupportCreate Fixed Add Click support 2 and bottom

most nodes of tank Assign to selected node AssignYes Close.

De select the nodes and change to beam cursor.

4. Loading :

Click Load & Definitions Click Load case details Add. Primary Number 1:

Loading type: none Title : load case 1 Add Close.

Click Load case 1Add.

For Bottom plate:

Click plate loads Pressure on full plate Pressure =-20 GYSelect

bottom plate of tank portion Assign to selected plates AssignYes .

Fig. 2 Bottom plate chosen

Fig. 3 Orientation of various sides of Plates

Left side wall:

Load case details Add.

Click plate loads Hydrostatic Select plates select left side plates

Done. W1 =-20 W2=-0.001 Y Local Z Add close.

Fig. 4 & 5 Left side plate chosen

Fig. 6 Left side plate load application

Fig. 7 Left side hydrostatic pressure diagram

Right side wall:

Load case details Add.

Click plate loads Hydrostatic Select plates Select right side plates Done.

W1 = 20 W2=0.001 Y Local Z Add Close.

Fig. 8 Right side plate chosen

Fig. 9 Rightside plate load application

Fig. 10 Rightside plate hydrostatic pressure application

Back side wall:

Load case details Add.

Click plate loads Hydrostatic Select plates select rear side wall plate Done.

W1 =- 20 W2= 0.001 Y Local Z Add Close.

Fig. 11 Back or rear side plate selection

Fig. 12 Rearside plate load application

Front side wall:

Load case details Add.

Click plate loads Hydrostatic Select plates Select front side wall plate

Done. W1=- 20 W2= 0.001 Y Local Z Add Close.

Fig. 13 Frontside plate selection in top view

Fig. 14 Frontside plate hydrostatic load application

5. Analysis Type :

Click Analysis/print No print Add. Click post print Define commands

Analysis Results Add Close. Save the file before run the Analysis.

6. Analysis :

From Main Menu ` Analysis Run Analysis Done.

7. Result :

Go to post processing mode.

Click deflection and see the deflection Diagram.

Fig.15 Deflection diagram in top view

Fig. 16 Deflection diagram

Fig. 17 Front view deflection diagram

ResultsPlate Stress contour Loads & Results Load case: Load case 1

Stress type: Mx (local) Ok.

Fig. 18 BMD Mx top view

ResultsPlate Stress contour Loads & Results Load case: Load case 1

Stress type: My(local) Ok.

Fig. 19 Stress contour My (local)

ResultsPlate Stress contour Loads & Results Load case: Load case 1

Stress type: Max. Von Mis.Ok.

Fig. 20 Max Von Mises

Fig. 21 Von mises Isometric view

ResultsPlate Stress contour Loads & Results Load case: Load case 1

Stress type: Max. Absolute Ok.

Fig. 22 Max Absolute

Fig. 23 Max Absolute top view

Fig. 24 Max BMD in plates

Maximum BMD Right click Plate stress contour Table.

Fig. 25 Max BMD

Fig. 26 Plate stress contour table

Fig. 27 Summary

You might also like

- Leadership Skills of Satya NadellaDocument3 pagesLeadership Skills of Satya NadellaSai PrasannaNo ratings yet

- Etabs Tutorials ListDocument4 pagesEtabs Tutorials ListDanielNo ratings yet

- Staad Pro-Open ChannelDocument5 pagesStaad Pro-Open ChannelAnonymous nwByj9LNo ratings yet

- A Study On Customer Satisfaction at Rubber General Industry India PVT - LTD, CoonoorDocument9 pagesA Study On Customer Satisfaction at Rubber General Industry India PVT - LTD, CoonoorNavaneeth Vroon0% (1)

- Gillette SSI & SDIDocument6 pagesGillette SSI & SDImsampathramanujaNo ratings yet

- Astm A53 A53mDocument23 pagesAstm A53 A53mRaviprakash Chauhan100% (2)

- General Specifications For Road and Bridges, January 2005 of UgandaDocument307 pagesGeneral Specifications For Road and Bridges, January 2005 of UgandaSolomon BalemeziNo ratings yet

- Staad Pro-RCC Open ChannelDocument7 pagesStaad Pro-RCC Open ChannelV.m. RajanNo ratings yet

- RCC Rectangular Overhead Water TankDocument20 pagesRCC Rectangular Overhead Water TankV.m. RajanNo ratings yet

- Staad Pro-Solid Elements-Cantilever BeamDocument18 pagesStaad Pro-Solid Elements-Cantilever BeamV.m. RajanNo ratings yet

- Design of RCC Apartment Building Using Mirror Command DataDocument36 pagesDesign of RCC Apartment Building Using Mirror Command Datafharak patelNo ratings yet

- ETABS Example-RDocument39 pagesETABS Example-RAnonymous nwByj9LNo ratings yet

- Elevated Rectangular Water TankDocument3 pagesElevated Rectangular Water TankKesavan Dhurai100% (1)

- Wind Example-RDocument10 pagesWind Example-RV.m. RajanNo ratings yet

- Staad Basics: - Notes On The Effective Use of Staad-Pro Rel 3.1Document17 pagesStaad Basics: - Notes On The Effective Use of Staad-Pro Rel 3.1kardels100% (14)

- V. Load Generator - Response Spectrum IS 1893 2016: ReferenceDocument4 pagesV. Load Generator - Response Spectrum IS 1893 2016: ReferenceprantikduarahNo ratings yet

- Pile Cap DesignDocument7 pagesPile Cap Designmd. alaul azmirNo ratings yet

- Design of Overhead RCC Rectangular WaterDocument4 pagesDesign of Overhead RCC Rectangular WaterAhmed AwadNo ratings yet

- Design of Overhead RCC Rectangular TankDocument32 pagesDesign of Overhead RCC Rectangular TankVijayKrupaker100% (1)

- Design of RC Building - ExerciseDocument6 pagesDesign of RC Building - Exercisesajeerala100% (1)

- FLATE Slab DesignDocument16 pagesFLATE Slab DesignNikhil Poriya100% (1)

- Water Tank DesignDocument5 pagesWater Tank DesignYELLAMANDA SANKATINo ratings yet

- E TowerDocument2 pagesE TowerhannibalzzzzNo ratings yet

- Structure Analysis CheksDocument8 pagesStructure Analysis CheksEhsan ShNo ratings yet

- STAAD - Slab Design: Method 1: As Suro Mentioned, This Method Involves Specifying Design Parameters SuchDocument6 pagesSTAAD - Slab Design: Method 1: As Suro Mentioned, This Method Involves Specifying Design Parameters Suchsivasan10006098No ratings yet

- Design of Mat FoundationDocument13 pagesDesign of Mat FoundationdantezNo ratings yet

- Combined Footing For TwoDocument15 pagesCombined Footing For Twoer.praveenraj30No ratings yet

- Design of 10m Span RCC Slab CulvertDocument105 pagesDesign of 10m Span RCC Slab Culvertankkeshmundra10% (1)

- Manual Deisgn Shear WallDocument4 pagesManual Deisgn Shear WallQuality Design & ConstructionNo ratings yet

- Single Footing Design - SI UnitsDocument2 pagesSingle Footing Design - SI UnitsA.K.M Shafiq MondolNo ratings yet

- ProkonDocument7 pagesProkonmark7301158No ratings yet

- Etabs NotesDocument11 pagesEtabs Noteskarimunnisa sheikNo ratings yet

- 5-Design of Raft FoundationDocument2 pages5-Design of Raft FoundationheshamNo ratings yet

- Structural Analysis of Five-Storey Building: Location: Old Buswang, Kalibo, AklanDocument9 pagesStructural Analysis of Five-Storey Building: Location: Old Buswang, Kalibo, AklanRG T. IngallaNo ratings yet

- Deflection Flat SlabDocument4 pagesDeflection Flat SlabAjaykumar MistryNo ratings yet

- RCC Box Culvert - Methodology and Designs Including Computer MethodDocument31 pagesRCC Box Culvert - Methodology and Designs Including Computer Methodmohan1441No ratings yet

- Water TanksDocument59 pagesWater TanksSheikh_MutaharNo ratings yet

- Slab DesignDocument28 pagesSlab DesignUlasi IfeanyiNo ratings yet

- RCC Retaining WallSDocument23 pagesRCC Retaining WallSTarunNo ratings yet

- Analysis & Design of Multi Storeyed Buildings V.M.RAJAN, M.E. (Struct), FIE, Former CE/Civil/TANGEDCODocument25 pagesAnalysis & Design of Multi Storeyed Buildings V.M.RAJAN, M.E. (Struct), FIE, Former CE/Civil/TANGEDCOV.m. RajanNo ratings yet

- RCC Retaining WallDocument3 pagesRCC Retaining Wallsuganthi1711No ratings yet

- Design of Under Ground Circular Water TankDocument14 pagesDesign of Under Ground Circular Water Tankjitendra singh khichiNo ratings yet

- Design of Prestressed Circular Water TankDocument2 pagesDesign of Prestressed Circular Water TankVarun Singh Chandel33% (3)

- Balagata-Stage 1 DSN 13.3.2020Document109 pagesBalagata-Stage 1 DSN 13.3.2020Shankarappa NNo ratings yet

- Pile Footing Detailed Design CalculationDocument3 pagesPile Footing Detailed Design CalculationChris LeeNo ratings yet

- Interactive Design of Column RCC Column As Per IS-456 Using STAAD Analysis ResultsDocument4 pagesInteractive Design of Column RCC Column As Per IS-456 Using STAAD Analysis ResultsSudhakaran PilicodeNo ratings yet

- Combined FootingDocument4 pagesCombined FootingSakar ShresthaNo ratings yet

- Project 2 ReportDocument26 pagesProject 2 Reportarjun kumarNo ratings yet

- JEC Prog - Design of CorbelDocument4 pagesJEC Prog - Design of CorbelAaron O'SullivanNo ratings yet

- Conical OH Water TankDocument17 pagesConical OH Water TankRam LangheNo ratings yet

- Circular Water Tank-1Document17 pagesCircular Water Tank-1Vikram ShahNo ratings yet

- RCC Circular Water TankDocument23 pagesRCC Circular Water TankV.m. RajanNo ratings yet

- Circular OH Water TankDocument24 pagesCircular OH Water TankV.m. RajanNo ratings yet

- Staad Pro and Circular SlabDocument10 pagesStaad Pro and Circular SlabP&D CIRCLE PWD0% (1)

- Staad Pro - DomeDocument9 pagesStaad Pro - DomeV.m. Rajan100% (1)

- Member Weight MethodDocument10 pagesMember Weight MethodV.m. RajanNo ratings yet

- Staad Pro-Circular Plate With A HoleDocument5 pagesStaad Pro-Circular Plate With A HoleV.m. RajanNo ratings yet

- Method 2 Seismic Analysis Using Member Weight MethodDocument11 pagesMethod 2 Seismic Analysis Using Member Weight MethodV.m. RajanNo ratings yet

- Staad Pro-Circular SlabDocument9 pagesStaad Pro-Circular SlabV.m. RajanNo ratings yet

- Analysis With Slab Modeling 1Document10 pagesAnalysis With Slab Modeling 1V.m. RajanNo ratings yet

- Staad-Seismic Coefficient 1 MethodDocument9 pagesStaad-Seismic Coefficient 1 MethodV.m. RajanNo ratings yet

- ETABS-Exmple Using Is 456Document33 pagesETABS-Exmple Using Is 456Shital ChaudhariNo ratings yet

- Staad Pro-Conical Shaped Slab With HoleDocument14 pagesStaad Pro-Conical Shaped Slab With HoleV.m. RajanNo ratings yet

- ETABS Exmple1Document33 pagesETABS Exmple1Anonymous nwByj9LNo ratings yet

- Mechanics of Aeronautical Solids, Materials and StructuresFrom EverandMechanics of Aeronautical Solids, Materials and StructuresNo ratings yet

- Press 'F9' Key To Calculate: Illustrated Here Is A Very Ill Conditioned EquationDocument3 pagesPress 'F9' Key To Calculate: Illustrated Here Is A Very Ill Conditioned EquationSRINIVAS DNo ratings yet

- Design of Footings: Load CombinationDocument10 pagesDesign of Footings: Load CombinationSRINIVAS DNo ratings yet

- Slide SlopeStabilityVerification PDFDocument327 pagesSlide SlopeStabilityVerification PDFSRINIVAS DNo ratings yet

- Appendix 1: Figure A1.1STAAD PRO Model of Shape Truss of Size 3m X 2mDocument9 pagesAppendix 1: Figure A1.1STAAD PRO Model of Shape Truss of Size 3m X 2mSRINIVAS DNo ratings yet

- Analysis of Double Howe Steel Truss & Cantilever Truss Using Ansys SoftwareDocument6 pagesAnalysis of Double Howe Steel Truss & Cantilever Truss Using Ansys SoftwareSRINIVAS DNo ratings yet

- Evaluation of Safe Bearing Capacity of Soil Foundation by Using Numerical Analysis MethodDocument7 pagesEvaluation of Safe Bearing Capacity of Soil Foundation by Using Numerical Analysis MethodSRINIVAS DNo ratings yet

- 2D and 3D Numerical Modeling of Combined PDFDocument45 pages2D and 3D Numerical Modeling of Combined PDFSRINIVAS DNo ratings yet

- Soil Improvement Works For An Offshore L PDFDocument12 pagesSoil Improvement Works For An Offshore L PDFSRINIVAS DNo ratings yet

- Design and Performance of Soft Ground Im PDFDocument16 pagesDesign and Performance of Soft Ground Im PDFSRINIVAS DNo ratings yet

- Powerone, Power Supply 48V Rectifier Module (Aspiro XR08.48)Document3 pagesPowerone, Power Supply 48V Rectifier Module (Aspiro XR08.48)Riky FitriadiNo ratings yet

- Presentacion Chasqui Montana (1671)Document23 pagesPresentacion Chasqui Montana (1671)Edwin Abregú LeandroNo ratings yet

- F Horarios Uct Nacional Civil 2021-2Document17 pagesF Horarios Uct Nacional Civil 2021-2Jean Carlos Peña CalleNo ratings yet

- Contrabalance Walvoil CC10ADocument3 pagesContrabalance Walvoil CC10AMatias Oñate ArriagadaNo ratings yet

- Trajectory 2Document5 pagesTrajectory 2Sreelal SreeNo ratings yet

- Green Engine Seminar Report PDFDocument22 pagesGreen Engine Seminar Report PDFJitendra Panwar100% (1)

- Developments in Science and Technology Are Fundamentally Altering The Way People LiveDocument3 pagesDevelopments in Science and Technology Are Fundamentally Altering The Way People LiveJanRayEnriqueNo ratings yet

- Online PMP Training - Online PMP Certification - Online Project Management Courses - PMP Training OnlineDocument10 pagesOnline PMP Training - Online PMP Certification - Online Project Management Courses - PMP Training Onlinealdridge39No ratings yet

- Computation Complexity LCTN - Laszlo LovaszDocument169 pagesComputation Complexity LCTN - Laszlo LovaszAnikNo ratings yet

- Understanding Common-Mode SignalsDocument11 pagesUnderstanding Common-Mode SignalsRabshaqaNo ratings yet

- Zhejiang Sanye Catelogue-Fittings2019Document80 pagesZhejiang Sanye Catelogue-Fittings2019Danyang YUNo ratings yet

- Munnangi Sea Foods Private LimitedDocument77 pagesMunnangi Sea Foods Private LimitedDevaraj SubrmanayamNo ratings yet

- Special Tools Special Tools: Instruction No Part. No. Instruction No Part. NoDocument47 pagesSpecial Tools Special Tools: Instruction No Part. No. Instruction No Part. NoAlex SibirnayaNo ratings yet

- Alto Macro 2400 Manual de Usuario Amp de Potencia PDFDocument13 pagesAlto Macro 2400 Manual de Usuario Amp de Potencia PDFE GNo ratings yet

- Original MVC Pattern (Trygve Reenskaug 1979)Document11 pagesOriginal MVC Pattern (Trygve Reenskaug 1979)scribd@stevenfusco.comNo ratings yet

- Slab DesignDocument3 pagesSlab DesignMagdy BakryNo ratings yet

- TestKing 70-216 v23Document421 pagesTestKing 70-216 v23api-3705610100% (1)

- ECMVDocument2 pagesECMVardic wiraNo ratings yet

- Japan Energy Challenge An Invitation To Innovators-1.pdf0f - SDocument1 pageJapan Energy Challenge An Invitation To Innovators-1.pdf0f - SMarwan KhouryNo ratings yet

- 2124 4919 1 SMDocument13 pages2124 4919 1 SMISNAN NURDIANSYAHNo ratings yet

- Vivado HLS UpdateDocument35 pagesVivado HLS UpdateOmar RiganeNo ratings yet

- Community Connect HandoutDocument7 pagesCommunity Connect HandoutROHIT9044782102No ratings yet

- Learning From Failures: Case StudiesDocument71 pagesLearning From Failures: Case Studiesyedida v r aviswanadhNo ratings yet

- R7410402 Electronic Measurements & InstrumentationDocument4 pagesR7410402 Electronic Measurements & InstrumentationsivabharathamurthyNo ratings yet

- TELabDocument121 pagesTELabSrinu ReddyNo ratings yet