Professional Documents

Culture Documents

5 AM Lab Manual 22 Oct 2017

5 AM Lab Manual 22 Oct 2017

Uploaded by

Shubham PoteOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5 AM Lab Manual 22 Oct 2017

5 AM Lab Manual 22 Oct 2017

Uploaded by

Shubham PoteCopyright:

Available Formats

Rajarambapu Institute of Technology, Rajaramnagar

Practical No 5

Title: Producing Tapered Turning job on CNC Turning Machine.

Learning Outcome:

1. Students will able to produce Taper Turning job on CNC Turning Machine.

Theory :

The applicable G codes for Taper Turning are G00 and G01. The rapid

traverse instruction (function) is given by G00. A rapid traverse instruction to

traverses the tool to the target point at maximum feed rate. It requires the

coordinates of the target point to be input with this code. G01 traverses the tool

along a linear taper path to the given target point with the feed rate input as

additional function. For Taper turning operation we have to simultaneously

change X & Z axis positions.

TY B Tech (Mech), Advanced Machining Lab (Code: ME3541) Page 1

Rajarambapu Institute of Technology, Rajaramnagar

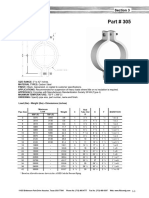

Figure No. 4:

[ Billet X50 Z80

Ref.pt.

Chuck

(X60,Z5)

Ø 50

Ø 20

M

50

80

Fig : Taper Turning.

TY B Tech (Mech), Advanced Machining Lab (Code: ME3541) Page 2

Rajarambapu Institute of Technology, Rajaramnagar

CNC Program :

[ Billet X50 Z80

O2000

Block

Command Comment

No.

Feed mm/rev., Metric units, Cutter

N10 G99 G21 G40 *

compensation cancle.

N20 G28 U0 W0 * Go to Home Position.

N30 M06 T0101 * Tool Change.

Spindle revolution in Clockwise direction

N40 M03 S2300 *

with 2300 rpm.

N50 G00 X60 Z5 M07 * Rapid to safe position and coolant on.

First Cutting Position for Taper Turning

N60 G01 X46 Z0 F1 *

with Feed.

Taper Turning to 50 mm length with

N70 G01 X50 Z-50 F.1 *

feed.

N80 G00 X60 Z5 * Rapid to Safe Position.

Second Cutting Position for Taper

N90 G01 X42 Z0 F1 *

Turning with Feed.

Taper Turning to 50 mm length with

N100 G01 X50 Z-50 F.1 *

feed.

N110 G00 X60 Z5 * Rapid to Safe Position.

N120 G01 X38 Z0 F1 * Third Cutting Position for Taper Turning

with Feed.

N130 G01 X50 Z-50 F.1 * Taper Turning to 50 mm length with

feed.

N140 G00 X60 Z5 * Rapid to Safe Position.

N150 G01 X34 Z0 F1 * Fourth Cutting Position for Taper

Turning with Feed.

TY B Tech (Mech), Advanced Machining Lab (Code: ME3541) Page 3

Rajarambapu Institute of Technology, Rajaramnagar

Block

Command Comment

No.

N160 G01 X50 Z-50 F.1 * Taper Turning to 50 mm length with

feed.

Nss170 G00 X60 Z5 * Rapid to Safe Position.

N180 G01 X30 Z0 F1 * Fifth Cutting Position for Taper Turning

with Feed.

N190 G01 X50 Z-50 F.1 * Taper Turning to 50 mm length with

feed.

N200 G00 X60 Z5 * Rapid to Safe Position.

N210 G01 X26 Z0 F1 * Sixth Cutting Position for Taper Turning

with Feed.

N220 G01 X50 Z-50 F.1 * Taper Turning to 50 mm length with

feed.

N230 G00 X60 Z5 * Rapid to Safe Position.

Seventh Cutting Position for Taper

N240 G01 X22 Z0 F1 *

Turning with Feed.

Taper Turning to 50 mm length with

N250 G01 X50 Z-50 F.1 *

feed.

N260 G00 X60 Z5 * Rapid to Safe Position.

Eighth Cutting Position for Taper

N270 G01 X20 Z0 F1 *

Turning with Feed.

Taper Turning to 50 mm length with

N280 G01 X50 Z-50 F.1

feed.

N290 G00 X60 Z5 * Rapid to safe position.

N300 G28 U0 W0 * Return to reference position.

N310 M05 * Spindle off.

N320 M30 * Program end & rewind.

TY B Tech (Mech), Advanced Machining Lab (Code: ME3541) Page 4

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Baku - Group - TourDocument4 pagesBaku - Group - TourZara Farooq SahiNo ratings yet

- Technicall Specification of 630 KVA, 11-0.415 KV Dry Type Outdoor Transformers.......... Dated. 31.08.2015Document25 pagesTechnicall Specification of 630 KVA, 11-0.415 KV Dry Type Outdoor Transformers.......... Dated. 31.08.2015spidervinoNo ratings yet

- Cost C. Test EM Question 03.03.2023 VI-1, VDI-1Document2 pagesCost C. Test EM Question 03.03.2023 VI-1, VDI-1harish jangidNo ratings yet

- 28-Tax-Capitol Wireless Inc vs. Provincial Treas. of BatangasDocument2 pages28-Tax-Capitol Wireless Inc vs. Provincial Treas. of BatangasJoesil Dianne SempronNo ratings yet

- 22 Passage 2 - Western Immigration of Canada Q14-26Document6 pages22 Passage 2 - Western Immigration of Canada Q14-26Cương Nguyễn DuyNo ratings yet

- 2018 Resume NVDocument1 page2018 Resume NVcourtney willsonNo ratings yet

- Resume Goutam AdwantDocument3 pagesResume Goutam AdwantGoutamNo ratings yet

- Pattern, Price and Time - Using Gann TheoryDocument29 pagesPattern, Price and Time - Using Gann TheoryRohitOhri44% (9)

- The Golden Fish Keeps A Promise StoryDocument2 pagesThe Golden Fish Keeps A Promise StoryDe Guzman Diane Marie B.No ratings yet

- The Moderating Effect of Ewom On The Perception of Service Quality and Repurchase Intension Relationship The Case of The West Bank RestaurantsDocument7 pagesThe Moderating Effect of Ewom On The Perception of Service Quality and Repurchase Intension Relationship The Case of The West Bank RestaurantsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- MDC Monthly Proposal Dec 2019Document2 pagesMDC Monthly Proposal Dec 2019Tushar Prakash ChaudhariNo ratings yet

- Embedded System DesignDocument22 pagesEmbedded System Designtrail meNo ratings yet

- Unit-3 - Garden Design (Pages-32)Document25 pagesUnit-3 - Garden Design (Pages-32)siva ramanNo ratings yet

- Pyrolysis of Plastic Waste - Opportunities and ChallengesDocument17 pagesPyrolysis of Plastic Waste - Opportunities and Challengesgavin meadeNo ratings yet

- When Caring Hurts: The Silence Burnout of SonographersDocument5 pagesWhen Caring Hurts: The Silence Burnout of SonographersCarlos BarradasNo ratings yet

- Good Operation and Maintenance Practice of Fresh Water Cooling TowersDocument20 pagesGood Operation and Maintenance Practice of Fresh Water Cooling TowersSimon LawNo ratings yet

- To Study The Impact of Technology On RecruitmentDocument9 pagesTo Study The Impact of Technology On RecruitmentInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Case FerreroDocument22 pagesCase FerreroGlyka K. RigaNo ratings yet

- Assignment Management System: Project Report OnDocument68 pagesAssignment Management System: Project Report OnAnuj Kumar SinghNo ratings yet

- Template For Submission of Papers To IETE Technical ReviewDocument6 pagesTemplate For Submission of Papers To IETE Technical ReviewTabassum Nawaz BajwaNo ratings yet

- A Call For A Temporary Moratorium On "The DAO"Document13 pagesA Call For A Temporary Moratorium On "The DAO"SoftpediaNo ratings yet

- Part 305 Heavy Pipe ClampDocument1 pagePart 305 Heavy Pipe ClampezhiljananiNo ratings yet

- Chart For Contraception:: PreventsDocument1 pageChart For Contraception:: PreventsAngelica May ClaritoNo ratings yet

- LAZUDAN ZEKRELLAH I. BSMT 2 BD WATCH 1 Semi Final Exam 1Document8 pagesLAZUDAN ZEKRELLAH I. BSMT 2 BD WATCH 1 Semi Final Exam 1Macxie Baldonado QuibuyenNo ratings yet

- Radiographic Technique 2: Ysmael O. Alip, RRTDocument81 pagesRadiographic Technique 2: Ysmael O. Alip, RRTMarts Rivera100% (1)

- Chapter 8 v8.1Document113 pagesChapter 8 v8.1ANTONYNo ratings yet

- Liquid Nitriding - ProcessDocument1 pageLiquid Nitriding - ProcesssivamettNo ratings yet

- Caterpillar D6Document3 pagesCaterpillar D6RasoolKhadibi100% (1)

- Behavioral Modeling of A Comparator Using Verilig-AMSDocument88 pagesBehavioral Modeling of A Comparator Using Verilig-AMSPriNo ratings yet