Professional Documents

Culture Documents

Durafrax 2000 Alumina en 1039 Tds

Durafrax 2000 Alumina en 1039 Tds

Uploaded by

shuyang zhangOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Durafrax 2000 Alumina en 1039 Tds

Durafrax 2000 Alumina en 1039 Tds

Uploaded by

shuyang zhangCopyright:

Available Formats

MATERIAL PROPERTIES

DURAFRAX® 2000

Durafrax® 2000, Saint-Gobain’s ultra fine-grain, Pre-engineering and advanced processing

high grade alumina, is made from exceptionally techniques enable Saint-Gobain to manufacture

pure, uniformly controlled alpha aluminum oxide Durafrax® 2000 in a variety of geometries from

and is engineered to be one of the best wear simple to complex shapes. Combined with the

materials available for fine particle abrasion. appropriate attachment method, Durafrax® 2000

Durafrax® 2000 is our most economical and can overcome temperature limitations, impact,

frequently specified wear resistant material. and abrasion problems in many different

Durafrax® 2000 offers excellent mechanical industrial environments.

properties, superior wear resistance, and good

To learn more about Durafrax® 2000 wear

corrosion performance.

systems and products, please contact your Saint-

Gobain representative.

Property SI Units English Units

Chemical Analysis

Alumina Oxide (Al2O3) 90% 90%

Silicon Oxide (SiO2) 6% 6%

Others 4% 4%

Grain Size 3.4 µm 118—158 µin

Bulk Density 3.52 g/cm3 215 lbs./ft.3

Young’s Modulus (MoE) 20 °C 270 GPa 39 × 106 psi

Vickers Hardness 20 °C 9 GPa 1.31 × 106 psi

Shear Modulus 20 °C 110 GPa 16 × 106 psi

Modulus of Rupture RT 275 MPa 39.9 × 103 psi

Compressive Strength 20 °C 1.77 GPa 256 × 103 psi

Fracture Toughness 20 °C 3.75 MP3a·m½

Thermal Conductivity 20 °C 18.0 W/m·K 124 (BTU·in)/(hr·ft2·°F)

Thermal Expansion 30 °C—1500 °C 8.3 × 10-6/°C 4.6 × 10-6/ºF

Thermal Shock Resistance ∆Tc 250 °C 482 °F

Maximum Use Temperature 1,250 °C 2,282 °F

Apparent Porosity 0% 0%

Surface Finish (As Fired) 1.6 µm 63 µin

All of the above statements, recommendations, suggestions and data concerning the subject material are SAINT-GOBAIN CERAMIC MATERIALS

based on laboratory and field results, and although we believe the same to be reliable, we expressly do not 4702 Route 982

represent, warrant or guarantee the accuracy, completeness or reliability of same, of the material, or the LATROBE, PA 15650 USA

result to be obtained from the use thereof. Nor do we warrant that any such use, either alone or in combina- Phone: (1) 724 539-6000

tion with other materials, shall be free of the rightful claim of any third party by way of INFRINGEMENT (1) 800 438-7237

or the like, and Saint-Gobain Ceramic Materials DISCLAIMS ALL WARRANTIES, EXPRESSED Fax: (1) 724 539-6070

OR IMPLIED OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Internet: www.wrt.saint-gobain.com

e-mail: wrtinfo@saint-gobain.com

You might also like

- ASTM D516 11 Sulfatos en Agua PDFDocument4 pagesASTM D516 11 Sulfatos en Agua PDFAnonymous cc2JqvpI70% (1)

- Navier-Stokes Equations PDFDocument3 pagesNavier-Stokes Equations PDFbobNo ratings yet

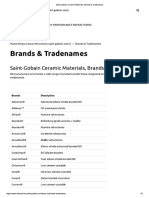

- Saint Gobain Norfrax RBDocument1 pageSaint Gobain Norfrax RBJavier Enrique Toro YentzenNo ratings yet

- Premium PLA - TDS - FormfuturaDocument1 pagePremium PLA - TDS - FormfuturaRui MatiasNo ratings yet

- TDS - Premium PLADocument1 pageTDS - Premium PLAMOHAMMED REKIKNo ratings yet

- EasyFil PLA - TDS - Formfutura PDFDocument1 pageEasyFil PLA - TDS - Formfutura PDFRui MatiasNo ratings yet

- Product: Penetration Grade Bitumen Cutback MC 70 Packing: New Steel Drum 180 5Kgs / BulkDocument2 pagesProduct: Penetration Grade Bitumen Cutback MC 70 Packing: New Steel Drum 180 5Kgs / BulkvinayaiyappaNo ratings yet

- Technical Data Sheet: Product Name: Titanx™Document1 pageTechnical Data Sheet: Product Name: Titanx™PeitaçaNo ratings yet

- Volumic - FT - en - Cuivre80 UltraDocument1 pageVolumic - FT - en - Cuivre80 UltraKamel IfrahNo ratings yet

- RTP 2500 FR ADocument2 pagesRTP 2500 FR ASoopNo ratings yet

- TecamidDocument2 pagesTecamidTejas HuddarNo ratings yet

- Adhesive Transfer Tapes With Adhesive 200: Technical Data September, 2002Document4 pagesAdhesive Transfer Tapes With Adhesive 200: Technical Data September, 2002Reza AbdolahiNo ratings yet

- BESN Noir P20 TLDocument2 pagesBESN Noir P20 TLjuliushasan2No ratings yet

- Cabone Lorraine Sintering Brochure 2008Document6 pagesCabone Lorraine Sintering Brochure 2008Varun DodhiaNo ratings yet

- Thermal Transfer Polyester Label Material: Technical Data May 2017Document5 pagesThermal Transfer Polyester Label Material: Technical Data May 2017Sebastian BaenaNo ratings yet

- Sikadur 42 Gorut Palk LE - CaDocument2 pagesSikadur 42 Gorut Palk LE - Carobert benavidesNo ratings yet

- PP - Sasol - HKR 102Document2 pagesPP - Sasol - HKR 102Luis ArciaNo ratings yet

- Styrolution TDS400900250546Document2 pagesStyrolution TDS400900250546prabhat singhNo ratings yet

- WearresistantceramicsDocument4 pagesWearresistantceramicsMuhammad WajidNo ratings yet

- RTP 299 X 90078 SSC 63023Document2 pagesRTP 299 X 90078 SSC 63023kls.thorodinsonNo ratings yet

- Ultramid® B3S en SIDocument2 pagesUltramid® B3S en SImuamerNo ratings yet

- Pei 0270 RTP 2183Document2 pagesPei 0270 RTP 2183Vincent NguyenNo ratings yet

- en-Escorene-ultra-FL-00206Document2 pagesen-Escorene-ultra-FL-00206vituruchNo ratings yet

- Continental GorillaDocument1 pageContinental GorillabaglinoNo ratings yet

- Escorene Ultra LD728.61Document2 pagesEscorene Ultra LD728.61José Roberto LazoNo ratings yet

- Tritan TX1001Document2 pagesTritan TX1001qiongyao cuiNo ratings yet

- formfutura-tds-stonefilDocument1 pageformfutura-tds-stonefilMohamed BerzoukNo ratings yet

- Sika Nigeria - Sikadur 42 MP Slow v1Document7 pagesSika Nigeria - Sikadur 42 MP Slow v1willy iremNo ratings yet

- Styrolution TDS400700190196Document3 pagesStyrolution TDS400700190196asegundoferreiraNo ratings yet

- Hex Bonde A 9394 Structi L PDFDocument2 pagesHex Bonde A 9394 Structi L PDFFlorian Le MaoNo ratings yet

- Technical Data Sheet: Silcoset 151 1 Part Adhesive SealantDocument2 pagesTechnical Data Sheet: Silcoset 151 1 Part Adhesive SealantArun VaideeswaranNo ratings yet

- TOTAL Polystyrene 1441: Material DatasheetDocument3 pagesTOTAL Polystyrene 1441: Material DatasheetAlbert FortunatoNo ratings yet

- PEEKDocument2 pagesPEEKHugorong WongNo ratings yet

- F1 Model Block: Technical DatasheetDocument2 pagesF1 Model Block: Technical DatasheetRafael ObiciNo ratings yet

- Castrol Perfecto XDocument3 pagesCastrol Perfecto XHector Martin BarajasNo ratings yet

- Hojas TécnicasDocument2 pagesHojas TécnicasalejandrocharlescollNo ratings yet

- Ficha Técnica Hdpe (Sabic)Document2 pagesFicha Técnica Hdpe (Sabic)Luis LiraNo ratings yet

- formfutura-tds-metalfilclassiccopperDocument1 pageformfutura-tds-metalfilclassiccopperMohamed BerzoukNo ratings yet

- 3M™ Scotchkote™ Fusion-Bonded Epoxy Coating XC-6171Document2 pages3M™ Scotchkote™ Fusion-Bonded Epoxy Coating XC-6171UEL IndNo ratings yet

- Titanpro 6531 MDocument1 pageTitanpro 6531 MErnesto CheguavaraNo ratings yet

- Deesa Pipe Gasket Catal - 230310 - 121140Document10 pagesDeesa Pipe Gasket Catal - 230310 - 121140Pietro MachadoNo ratings yet

- 2306 TDS Epoxy Antiskid CoatingDocument4 pages2306 TDS Epoxy Antiskid CoatingMeet NaikNo ratings yet

- Brilube ULTRA 2Document1 pageBrilube ULTRA 2Rodrigo PorcaroNo ratings yet

- Technical Data: Plastic Steel Putty (A)Document4 pagesTechnical Data: Plastic Steel Putty (A)francisNo ratings yet

- Datasheet Supersic Silicon Carbide 7062Document3 pagesDatasheet Supersic Silicon Carbide 7062clevercogNo ratings yet

- PA66 Ultramid A4H BASFDocument2 pagesPA66 Ultramid A4H BASFAlan MoraisNo ratings yet

- 76 Grasa Megaplex XD3Document2 pages76 Grasa Megaplex XD3Gustavo De Haro GonzálezNo ratings yet

- Hdpe HD 7845.30Document2 pagesHdpe HD 7845.30Cristian RodriguezNo ratings yet

- Mpact D143: Metallocene Linear Low Density PolyethyleneDocument1 pageMpact D143: Metallocene Linear Low Density PolyethyleneJulio GarcíaNo ratings yet

- OB693 - Dexron IIIDocument2 pagesOB693 - Dexron IIIArab Circle tallyNo ratings yet

- LLDPE Exxon 1001BUDocument2 pagesLLDPE Exxon 1001BULily LiNo ratings yet

- Ficha Tecnica Castrol Perfecto X RangeDocument3 pagesFicha Tecnica Castrol Perfecto X Rangeel pro jajaja GonzalezNo ratings yet

- TDS Engage 8200Document3 pagesTDS Engage 8200afernandezNo ratings yet

- Radiflam A Rv250 Af 375 BK: Product InformationDocument3 pagesRadiflam A Rv250 Af 375 BK: Product InformationLucas Valentim MendesNo ratings yet

- ALTECH ABS C 2017/500 GF17: Technical Data SheetDocument1 pageALTECH ABS C 2017/500 GF17: Technical Data SheetarmandoNo ratings yet

- Castrol Magna SW32Document2 pagesCastrol Magna SW32CHARLSTON BAPTISTANo ratings yet

- 3900 Prepreg SystemDocument5 pages3900 Prepreg SystemLiran KatzNo ratings yet

- Ficha Técnica Castrol Synthetic CT 320Document2 pagesFicha Técnica Castrol Synthetic CT 320el pro jajaja GonzalezNo ratings yet

- 226NDocument2 pages226NUmaibalanNo ratings yet

- 3M Scotchcast Resin 2130Document2 pages3M Scotchcast Resin 2130Dhrubajyoti BoraNo ratings yet

- Rubber Nanocomposites: Preparation, Properties, and ApplicationsFrom EverandRubber Nanocomposites: Preparation, Properties, and ApplicationsNo ratings yet

- 圣戈班陶瓷材料Document3 pages圣戈班陶瓷材料shuyang zhangNo ratings yet

- Energy Refractories Ammonia Methanol en 1004 TdsDocument2 pagesEnergy Refractories Ammonia Methanol en 1004 Tdsshuyang zhangNo ratings yet

- 评估气化炉耐火材料供应商 2014 - 8.2 - Saint - Gobain - Matthias - Schumannl PDFDocument15 pages评估气化炉耐火材料供应商 2014 - 8.2 - Saint - Gobain - Matthias - Schumannl PDFshuyang zhangNo ratings yet

- Technical Bulletin: Silicon Carbide Castable CementDocument3 pagesTechnical Bulletin: Silicon Carbide Castable Cementshuyang zhangNo ratings yet

- Insulating Fire Brick ProductsDocument3 pagesInsulating Fire Brick Productsshuyang zhang100% (1)

- Particles and Atoms MCQ TestDocument5 pagesParticles and Atoms MCQ TestVgyggNo ratings yet

- Q5 Assignment MEC551Document7 pagesQ5 Assignment MEC551iqbal2609No ratings yet

- Theoretical Investigations of Structural, Spectroscopic and Electron Collision Data of AcetoneDocument21 pagesTheoretical Investigations of Structural, Spectroscopic and Electron Collision Data of AcetoneVinayak SavarkarNo ratings yet

- Chemicals Zetag DATA Powder Zetag 7645 - 0410Document2 pagesChemicals Zetag DATA Powder Zetag 7645 - 0410PromagEnviro.comNo ratings yet

- IGCSE 14 MomentumDocument62 pagesIGCSE 14 MomentumMustayeen MahirNo ratings yet

- Bantubani ElectrodetechforbasemetalfurnacesDocument10 pagesBantubani ElectrodetechforbasemetalfurnacesSEETHARAMA MURTHYNo ratings yet

- TOPIC 1. Balancint of Rotating MassesDocument17 pagesTOPIC 1. Balancint of Rotating MassesOrbital TechNo ratings yet

- Comparing Pruv and Magnesium Stearate For External and Internal Lubrication During Rotary TabletingDocument1 pageComparing Pruv and Magnesium Stearate For External and Internal Lubrication During Rotary TabletingZeyad A AbdullahNo ratings yet

- First Quarter Summative Test 2Document2 pagesFirst Quarter Summative Test 2Zayn Daniel World of GamesNo ratings yet

- Effective MassDocument4 pagesEffective Massagnirailways100% (5)

- M1 Mega Revision JAN 21 PDFDocument6 pagesM1 Mega Revision JAN 21 PDFblob bleepNo ratings yet

- 3 Thick CylindersDocument21 pages3 Thick CylindersMalay ShahNo ratings yet

- Antimony LeachingDocument7 pagesAntimony LeachingAde SatriaNo ratings yet

- Chemistry Midterm ReviewDocument3 pagesChemistry Midterm ReviewAkarsh VelagapudiNo ratings yet

- Manual of Methods OF Analysis of Foods: Milk and Milk ProductsDocument197 pagesManual of Methods OF Analysis of Foods: Milk and Milk ProductsGajendra Singh Raghav100% (2)

- Wilo-FA (Product Catalogue)Document12 pagesWilo-FA (Product Catalogue)Ircham MaulanaNo ratings yet

- Processo de Injecao em Molde Muito BomDocument16 pagesProcesso de Injecao em Molde Muito BomFabiano SchincariolNo ratings yet

- 4th QTR Exam - G12-Gen Physics 2Document7 pages4th QTR Exam - G12-Gen Physics 2Anthony MontoyaNo ratings yet

- JEE Main 2022 (June 24 Evening Shift) Chemistry Question Paper With Solutions (PDF)Document61 pagesJEE Main 2022 (June 24 Evening Shift) Chemistry Question Paper With Solutions (PDF)BHOOMI BNo ratings yet

- Nota 6.1Document5 pagesNota 6.1ONG JUN YAO MoeNo ratings yet

- Jurnal 5 AyuDocument5 pagesJurnal 5 AyuAyu SuwarniNo ratings yet

- MR 341 Laguna 2Document81 pagesMR 341 Laguna 2Piotr BystryNo ratings yet

- Physics Solar and Lunar EclipseDocument10 pagesPhysics Solar and Lunar EclipseHemashreeNo ratings yet

- Savitha S. Panikar, PH.DDocument4 pagesSavitha S. Panikar, PH.Diboorose7No ratings yet

- 009 Paper1eDocument10 pages009 Paper1eFaizan AhmedNo ratings yet

- Oxidative Cleavage of Long-Chain Terminal Alkenes To Carboxylic AcidsDocument11 pagesOxidative Cleavage of Long-Chain Terminal Alkenes To Carboxylic AcidsMay PassarapornNo ratings yet

- PEE by Niraj Kandel - Student VersionDocument37 pagesPEE by Niraj Kandel - Student VersionNIRAJ KANDEL100% (1)

- FM Course SeminarDocument28 pagesFM Course Seminar2003 Akshar GotteNo ratings yet