Professional Documents

Culture Documents

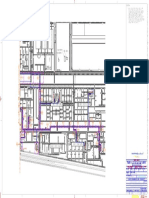

Notes:: Expansion Joint Butt Construction Joint Butt Construction Joint

Notes:: Expansion Joint Butt Construction Joint Butt Construction Joint

Uploaded by

billCopyright:

Available Formats

You might also like

- Empirical Formula of Silver Oxide LabDocument4 pagesEmpirical Formula of Silver Oxide LabGold Hunter0% (1)

- Abg 225-325Document202 pagesAbg 225-325martin_powell_1591% (11)

- AsdsdDocument14 pagesAsdsdbillNo ratings yet

- Copia Di Sanofi Aventis PDFDocument13 pagesCopia Di Sanofi Aventis PDFFrancesca D'AngeloNo ratings yet

- ActiMat Installation Guide SmallDocument3 pagesActiMat Installation Guide Smallgerardo manuel canto barreraNo ratings yet

- Process Buildings Building CodeDocument2 pagesProcess Buildings Building CodebillNo ratings yet

- Cbrating EquipmentDocument4 pagesCbrating EquipmentbillNo ratings yet

- CAL-CECL-M06 ChecklistDocument2 pagesCAL-CECL-M06 ChecklistbillNo ratings yet

- Codes and Standards: Lead Engineer (E) : ProjectDocument1 pageCodes and Standards: Lead Engineer (E) : ProjectbillNo ratings yet

- General Specifications: Specification: Checking Level: Project: Engineer (E) : Checker (C)Document2 pagesGeneral Specifications: Specification: Checking Level: Project: Engineer (E) : Checker (C)billNo ratings yet

- PPS, Storage & Interconnecting Ina-Industrija Nafte D.D.: Inspection and Test Plan (Itp)Document2 pagesPPS, Storage & Interconnecting Ina-Industrija Nafte D.D.: Inspection and Test Plan (Itp)torrentee5216No ratings yet

- MK Ted 210011 enDocument1,008 pagesMK Ted 210011 enDiana AkmaliahNo ratings yet

- Installation Practices FOR Cable Raceway Systems: The Okonite CompanyDocument56 pagesInstallation Practices FOR Cable Raceway Systems: The Okonite CompanyharlyganNo ratings yet

- 3tf ContactorDocument25 pages3tf Contactorpadminitt100% (1)

- A29 B FPS VB 065012 001 - 00 PDFDocument1 pageA29 B FPS VB 065012 001 - 00 PDFbillNo ratings yet

- Caterpillar SpecSizer vs. Generac Power Design Pro - Feature ComparisonDocument8 pagesCaterpillar SpecSizer vs. Generac Power Design Pro - Feature ComparisonBrahim BbdNo ratings yet

- TCXD 27. 1991 / Installation of Electric Equipments in Dwellings and Public Building - Design StandardDocument20 pagesTCXD 27. 1991 / Installation of Electric Equipments in Dwellings and Public Building - Design StandardtrungjindoNo ratings yet

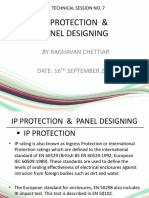

- Forms of SeperationDocument24 pagesForms of SeperationRagesh ChettiarNo ratings yet

- Utility Pole CatalogDocument13 pagesUtility Pole Catalogm_afuni80No ratings yet

- Guide To Forms of SeperationDocument32 pagesGuide To Forms of SeperationHồ ThànhNo ratings yet

- Lattice Steel Towers and Steel PolesDocument7 pagesLattice Steel Towers and Steel PolesMaruf HasanNo ratings yet

- SC348-ME-FDN-006 - RE - Foundation DrawingDocument6 pagesSC348-ME-FDN-006 - RE - Foundation DrawingsajanNo ratings yet

- 0488a0vvgc001 06Document73 pages0488a0vvgc001 06AlienshowNo ratings yet

- Street Light LevelsDocument1 pageStreet Light LevelsMandip PokharelNo ratings yet

- Va2 - Concrete Standard DrawingDocument10 pagesVa2 - Concrete Standard DrawingHiepNo ratings yet

- UBW RequirementsDocument33 pagesUBW RequirementsJayce TangNo ratings yet

- Lightning ProtectionDocument9 pagesLightning Protectioncharitha RanwalaNo ratings yet

- 000 215 1221 A04 31mar05Document11 pages000 215 1221 A04 31mar05Felipe FloresNo ratings yet

- Lvcatesgv enDocument152 pagesLvcatesgv endavidoff29No ratings yet

- 141-000-MI-CN-PLN-0005 Code-3Document35 pages141-000-MI-CN-PLN-0005 Code-3um erNo ratings yet

- Cural Steel Material Takeoff ChecklistDocument2 pagesCural Steel Material Takeoff ChecklistbillNo ratings yet

- Checklist For 33kV Bus Duct Structure Design & DrawingDocument4 pagesChecklist For 33kV Bus Duct Structure Design & DrawingRupesh KhandekarNo ratings yet

- Drainage Installation ProccedureDocument2 pagesDrainage Installation ProccedureAtef MohamedenNo ratings yet

- Prisma PDocument36 pagesPrisma PNATHANNo ratings yet

- Po # 7096-Mfsd-Prime Ac Industries (L.L.C)Document6 pagesPo # 7096-Mfsd-Prime Ac Industries (L.L.C)Saleh El-hawaryNo ratings yet

- J910-YQ02-P0ZEN-140941 - Typical Installation Cable Raceway - Rev.2 (AWC)Document7 pagesJ910-YQ02-P0ZEN-140941 - Typical Installation Cable Raceway - Rev.2 (AWC)Devy MangimbaNo ratings yet

- Battery EeeDocument27 pagesBattery EeeNaisarg ChauhanNo ratings yet

- Discrimination CurveDocument6 pagesDiscrimination Curvemilekitic2005No ratings yet

- Ode0000 STSP 0074 1Document14 pagesOde0000 STSP 0074 1pabvalenNo ratings yet

- Battery Load Profile-ModelDocument3 pagesBattery Load Profile-ModelMandip PokharelNo ratings yet

- Submittal Rev 2Document264 pagesSubmittal Rev 2Haythamberg AhmedNo ratings yet

- Civil 2019 v22 Release NoteDocument25 pagesCivil 2019 v22 Release NoteNilay GandhiNo ratings yet

- General Brochure eDocument6 pagesGeneral Brochure eShafeek GhreebNo ratings yet

- WEBFORGE BrochureDocument39 pagesWEBFORGE Brochurefreddielisto100% (1)

- Detail B: Page 1 of 2Document5 pagesDetail B: Page 1 of 2namasralNo ratings yet

- Calculus Report6031 20210702 055202Document25 pagesCalculus Report6031 20210702 055202Balamurugan ArumugamNo ratings yet

- Material Requisition For Protection Relay and Control Panel (Power Block and SS-329)Document11 pagesMaterial Requisition For Protection Relay and Control Panel (Power Block and SS-329)billNo ratings yet

- OS6450 AOS 6.6.4.309 R01 Release NotesDocument54 pagesOS6450 AOS 6.6.4.309 R01 Release NotesДмитрий ВасильевNo ratings yet

- Hih 060216Document337 pagesHih 060216Asif IqbalNo ratings yet

- Double Ground Fault ProtectionDocument17 pagesDouble Ground Fault ProtectionAnonymous xBi2FsBxNo ratings yet

- PV Carport With EVDocument2 pagesPV Carport With EVAra AkramNo ratings yet

- Civ GD Q68922 21Document1 pageCiv GD Q68922 21Adhe L ShethiadyNo ratings yet

- Oil City Division: Rev. Description Date BY CH'KDocument1 pageOil City Division: Rev. Description Date BY CH'KHendrias ari sujarwoNo ratings yet

- Ical Panels MCB Cable Size Calculation 1.1.15Document29 pagesIcal Panels MCB Cable Size Calculation 1.1.15abdulnadeemuddinNo ratings yet

- BLNG Ce 818010298560001Document66 pagesBLNG Ce 818010298560001Venkatesh PrasathNo ratings yet

- LY and LZ ExplainedDocument31 pagesLY and LZ ExplainedJatinTankNo ratings yet

- Tech GuideDocument153 pagesTech Guideact_rahul53No ratings yet

- Appendix B Wind LoadsDocument17 pagesAppendix B Wind LoadsJayabalan R KNo ratings yet

- Diseño de Subestaciones PDFDocument33 pagesDiseño de Subestaciones PDFalfredoNo ratings yet

- QAP Highmast1Document1 pageQAP Highmast1Mohsin Mansoori100% (1)

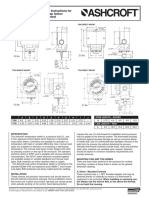

- T400, T700 Temp. Switch Installation and Maintenance ManualDocument2 pagesT400, T700 Temp. Switch Installation and Maintenance ManualHuan Trinh VanNo ratings yet

- Ansi b18.2.1 Hex Machine BoltDocument1 pageAnsi b18.2.1 Hex Machine BoltBharatNo ratings yet

- 66 LS 600h L / LS 600h (From Nov. 2009 Production) : Sliding RoofDocument1 page66 LS 600h L / LS 600h (From Nov. 2009 Production) : Sliding RoofWaleed AlshgaaaNo ratings yet

- SU-47 Parts 6mm Depron A4Document1 pageSU-47 Parts 6mm Depron A4vscribNo ratings yet

- The Rough Guide to Beijing (Travel Guide eBook)From EverandThe Rough Guide to Beijing (Travel Guide eBook)Rating: 2 out of 5 stars2/5 (1)

- Pa-St1203 001 PDFDocument1 pagePa-St1203 001 PDFbill100% (1)

- SEP PGB DFDDocument8 pagesSEP PGB DFDbillNo ratings yet

- FGGDFGDocument1 pageFGGDFGbillNo ratings yet

- Anchor Assembly (Epab) Schedule: VB-450974 001 M 01C A29 RestrictedDocument1 pageAnchor Assembly (Epab) Schedule: VB-450974 001 M 01C A29 RestrictedbillNo ratings yet

- AjhDocument1 pageAjhbillNo ratings yet

- Block #5 Block #4 Block #4 Block #5: DRAWING LIMIT N 9590.000Document1 pageBlock #5 Block #4 Block #4 Block #5: DRAWING LIMIT N 9590.000billNo ratings yet

- Secondary Road-J: DRAWING LIMIT N 9357.500Document1 pageSecondary Road-J: DRAWING LIMIT N 9357.500billNo ratings yet

- DesfdfdfdDocument1 pageDesfdfdfdbillNo ratings yet

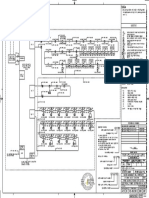

- Metering: StationDocument1 pageMetering: StationbillNo ratings yet

- Scope of Supply/Work For Protection Relay and Control PanelsDocument4 pagesScope of Supply/Work For Protection Relay and Control PanelsbillNo ratings yet

- Igc 002 (GSR) Igc 001 (Gfu) : Sub 055 Pib 055 SDB 055Document1 pageIgc 002 (GSR) Igc 001 (Gfu) : Sub 055 Pib 055 SDB 055billNo ratings yet

- A2 ZX XDocument9 pagesA2 ZX XbillNo ratings yet

- Material Requisition For Protection Relay and Control Panel (Power Block and SS-329)Document11 pagesMaterial Requisition For Protection Relay and Control Panel (Power Block and SS-329)billNo ratings yet

- Calculation Sheets: Saudi Arabian Oil CompanyDocument9 pagesCalculation Sheets: Saudi Arabian Oil CompanybillNo ratings yet

- Material Take-Off: Saudi Arabian Oil CompanyDocument4 pagesMaterial Take-Off: Saudi Arabian Oil CompanybillNo ratings yet

- J95 Q Doc Ve 028210 - 000 - 0 PDFDocument68 pagesJ95 Q Doc Ve 028210 - 000 - 0 PDFbillNo ratings yet

- NGDocument10 pagesNGbillNo ratings yet

- A29 S PLB Va 237774 001 PDFDocument1 pageA29 S PLB Va 237774 001 PDFbillNo ratings yet

- Prepared ForDocument125 pagesPrepared ForbillNo ratings yet

- DRAWING LIMIT N 9403.624: Saudi Arabian Oil CompanyDocument1 pageDRAWING LIMIT N 9403.624: Saudi Arabian Oil CompanybillNo ratings yet

- Saudi Aramco: Company General UseDocument2 pagesSaudi Aramco: Company General UsebillNo ratings yet

- Saudi Arabian Oil Company: TY P AX 9 0 0Document1 pageSaudi Arabian Oil Company: TY P AX 9 0 0billNo ratings yet

- Patrick. Adams@ Worleypar: Saudi Arabian Oil CompanyDocument1 pagePatrick. Adams@ Worleypar: Saudi Arabian Oil CompanybillNo ratings yet

- Saudi Arabian Oil Company: A29 P VA-284260 001Document1 pageSaudi Arabian Oil Company: A29 P VA-284260 001billNo ratings yet

- 19 SS329 Substation For Black Start & Essential / 13.8kV Emergency Black-Start Essentials Substation - IGCC Power BlockDocument4 pages19 SS329 Substation For Black Start & Essential / 13.8kV Emergency Black-Start Essentials Substation - IGCC Power BlockbillNo ratings yet

- A29 P LTG Va 240416 003 - 00 PDFDocument1 pageA29 P LTG Va 240416 003 - 00 PDFbillNo ratings yet

- A29 B FPS VB 065012 001 - 00 PDFDocument1 pageA29 B FPS VB 065012 001 - 00 PDFbillNo ratings yet

- Saudi Arabian Oil Company: LegendDocument1 pageSaudi Arabian Oil Company: LegendbillNo ratings yet

- Legend: Saudi Arabian Oil CompanyDocument1 pageLegend: Saudi Arabian Oil CompanybillNo ratings yet

- Complexing Capacity of Salicylaldoxime With Nickel and Zinc by Differential Pulse PolarographyDocument3 pagesComplexing Capacity of Salicylaldoxime With Nickel and Zinc by Differential Pulse PolarographyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Patent eDocument12 pagesPatent eivan de jesusNo ratings yet

- En 10168 Inspection InformationDocument12 pagesEn 10168 Inspection InformationStefano Squadrani100% (2)

- HACCPDocument47 pagesHACCPSujit Shandilya100% (1)

- UTAS-0030&UTAS-0035 Centrifuge Extractor EN 12697-1 ASTM D2172 AASHTO T16A Instruction BookDocument12 pagesUTAS-0030&UTAS-0035 Centrifuge Extractor EN 12697-1 ASTM D2172 AASHTO T16A Instruction BookCostel FloreaNo ratings yet

- Le Chatelier LabDocument3 pagesLe Chatelier LabDeep ManNo ratings yet

- Bejs Bridge Expansion Joint System Tech Data Sheet EmsealDocument3 pagesBejs Bridge Expansion Joint System Tech Data Sheet EmsealrenandNo ratings yet

- HW 1 SolutionsDocument6 pagesHW 1 SolutionsCJ KoretskovNo ratings yet

- Katalog Spesifikasi Produk GuardallDocument10 pagesKatalog Spesifikasi Produk GuardallhendrobamaNo ratings yet

- Tubesheet Cladding Baher 1648652344Document3 pagesTubesheet Cladding Baher 1648652344Sapan ShahNo ratings yet

- GRSP Presentation PDFDocument30 pagesGRSP Presentation PDFChaitanyaNo ratings yet

- 5.3. 402020-01391-08-PI-SPC-0002 Rev0 PDFDocument136 pages5.3. 402020-01391-08-PI-SPC-0002 Rev0 PDFsumit kumarNo ratings yet

- DeepFlex BrochureDocument4 pagesDeepFlex Brochureribeiro30No ratings yet

- Veetagrout V71 Instruction Manual - New Format V 2Document3 pagesVeetagrout V71 Instruction Manual - New Format V 2Alirio Ramirez VelasquezNo ratings yet

- International Standard: Safety of Primary and Secondary Lithium Cells and Batteries During TransportDocument7 pagesInternational Standard: Safety of Primary and Secondary Lithium Cells and Batteries During Transportp sangeerthNo ratings yet

- Chemistry Question Bank 2017 NewDocument22 pagesChemistry Question Bank 2017 Newஅன்புடன் அஸ்வின்No ratings yet

- Edexcel A Level Chemistry Unit 6 - January 2015Document16 pagesEdexcel A Level Chemistry Unit 6 - January 2015farahgraceNo ratings yet

- Notes FlamephotometryDocument19 pagesNotes FlamephotometryKaFiAliMirzaNo ratings yet

- Buffers and PH Adjusting AgentsDocument8 pagesBuffers and PH Adjusting AgentsJoão SantosNo ratings yet

- Chromatography NotesDocument3 pagesChromatography NotesJennifer HerediaNo ratings yet

- 9701 Y16 SP 4 PDFDocument22 pages9701 Y16 SP 4 PDFasipraw01No ratings yet

- Atoms and Molecules in 22 PagesDocument22 pagesAtoms and Molecules in 22 PagessandeepNo ratings yet

- Moisture Susceptibility of Asphalt MixturesDocument19 pagesMoisture Susceptibility of Asphalt Mixturesthanhnhat5521No ratings yet

- Good Nozzles Engineering-BookDocument84 pagesGood Nozzles Engineering-Booksbalu12674No ratings yet

- Gate 2011 Chemical SyllabusDocument2 pagesGate 2011 Chemical SyllabusVenkyNo ratings yet

- Lithological Terminology and DefinitionsDocument3 pagesLithological Terminology and DefinitionsJonathan ShimNo ratings yet

Notes:: Expansion Joint Butt Construction Joint Butt Construction Joint

Notes:: Expansion Joint Butt Construction Joint Butt Construction Joint

Uploaded by

billOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Notes:: Expansion Joint Butt Construction Joint Butt Construction Joint

Notes:: Expansion Joint Butt Construction Joint Butt Construction Joint

Uploaded by

billCopyright:

Available Formats

Preformed Joint

Filler (See Note #6)

Concrete D L

L L

Top Of Top Of Top Of

L/2

Transverse Joint Pavement Pavement L/2 L/2 Pavement

Approx. 3"

1 8

Plain Steel Dowel Bar

R

Steel Tie Bar Plain Steel Dowel

"

Longitudinal Joint

8"

R

3

1

Dowel Bars (See Note #3) 4" (See Note #7) Bar (See Note #8)

D

D

c

fi

af

D/2

D/2

D/2

D/2

Tr Metal Or

of

Tie Bars ion Plastic Cap

ct

ire

D

Approved Tie Bar Support 12"

Sheet Metal Bottom

Approved Dowel

Strip (See Note #8)

Support And Spacer

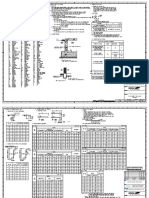

NOTES:

BUTT CONSTRUCTION JOINT EXPANSION JOINT BUTT CONSTRUCTION JOINT

1. For joint seal dimensions see Sheet 2. (See Note #6) (Used At Discountiuance Of Work)

2. For slabs poured simultaneously, tie bars may

be inserted in the plastic concrete by means Initial

1 1

8" Saw Cut Or 4" Max.

approved by the Engineer. L L

1 1

Formed Groove (Depth 4 to 3 D)

3. For Longitudinal Joints: L/2 1 L/2

8" Initial Cut

L

1 1

A. Tie bars are deformed #4 or #5 reinforcing Top Of Top Of (Depth 4 to 3 D)

L/2 Top Of

8"

steel bars meeting the requirements of Plain Steel Dowel Bar Pavement

Pavement Approx. 3" Plain Steel Dowel Bar

1

Specifications, Section 931. Pavement

(See Note #8)

(See Note #8)

B. Provide a standard load transfer tied joint 1

Parting Strip ( 4" Max. Thick)

with #4 bars 25" in length at 24" spacing Steel Tie Bar

or #5 bars 30" in length at 38" spacing. 1 1

(Depth 4 to 3 D)

(See Note #3)

4. Transverse joints are to be spaced at a

D

D

maximum of 15'. Dowels are required at

D/2

all transverse joints unless otherwise

D/2

D/2

Anticipated Anticipated

D/2

noted in the plans.

Break Break

5. Expansion joints to be placed on approaches

to bridges, at street intersections and other

locations indicated in the plans. Approved Tie

Anticipated Break

Bar Support

6. Punch clean holes in preformed joint filler

greater than bar diameter. LANE-TIE JOINT CONTRACTION JOINT CONTRACTION JOINT

(See Note #2) (Vibro Case Method) (Sawed Method)

7. Coat and lubricate plain steel dowel bars in

accordance with Specifications, Section 350.

LONGITUDINAL JOINTS TRANSVERSE JOINTS

8. Sheet metal bottom strips in accordance

with Specifications, Section 931.

DOWELS (LENGTH 18")

Pavement Thickness

Diameter

"D"

1 3

6"-6 2" 4"

1

7"-8 2" 1"

1 1

9"-10 2" 1 4"

1

≥11" 1 2"

3" Min. 3" Min.

3" To 9" 12" 12" 12" 12" 12" 12" 12" 12" 12" 3" To 9"

2" Min. 2" Min. Plastic

Plain Steel Dowel Bar Metal Plain Steel Dowel Bar

16"

16"

d

D

ID

ID

�

1

1

d

d+

d+

D/2

Puncture And Push Down Crimped Bar Stop

Plain Steel Dowel Bars

1 Bend Up Against End

8" On Both Sides

Of Pavement After

Sheet Metal Bottom Strip For

Forms Are Removed

45 AM

METAL PLASTIC Expansion Joints Only (See Note #9)

33:

9:

DOWEL BARS CAPS DOWEL BAR LAYOUT

10/12/2016

REVISIO N

LAST DESCRIPTION: INDEX SHEET

FY 2017-18

REVISION NO. NO.

CONCRETE PAVEMENT JOINTS

01/01/16 DESIGN STANDARDS 305 1of 4

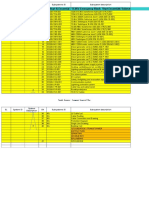

Saw Cut Or Formed Joint Backer Rod Placement Depth Joint Width

w 1 1 Saw Cut Or Formed Joint

1 1 8" to 4" 1 1

1 11

8" to 4" 4"Min., 32" Max. 8" to 4"

2" ± 8"

1

d

t

Joint Sealant Material To Be Sealant Bead Thickness

9 Joint Sealant Material To Be

1

16" Preformed Elastomeric

1

As Specified In The Plans

As Specified In The Plans

Compression Seal Joint Depth

Tape Bond Breaker

1 Saw Cut Or Parting Strip Backer Rod Bond Breaker

(w + 8") 1 1 Saw Cut Or Parting Strip

1

to

1

D

to D (D=Conc. Pavt. Thick.) 4 3

Existing Joint 4 3

Or Crack Not Required For Construction Joints. (D=Conc. Pavt. Thick.) Not

Required For Construction Joints

Or Existing Joints Or Cracks.

Note: Dimension w will be shown in the plans or

established by the Engineer based on field

conditions. Dimension d will be constructed

FOR NEW PROJECTS FOR NEW AND REHABILITATION PROJECTS

so that the shape factor w/t has a maximum

value of 2.0 and a minimum value of 1.0. PREFORMED ELASTOMERIC COMPRESSION SEAL BACKER ROD BOND BREAKER

FOR REHABILITATION PROJECTS

TAPE BOND BREAKER

CONCRETE-CONCRETE JOINTS

BACKER ROD BOND BREAKER

3 3

d = w = 4" Unless Specified Otherwise In The Plans d = w = 4" Unless Specified Otherwise In The Plans

(CONCRETE-CONCRETE JOINTS)

JOINT DIMENSIONS (INCHES)

Saw Cut Joint Saw Cut Joint

w w

1 1 1 1 SEALANT MINIMUM BACKER ROD

Concrete Pavement 8" to 4" Concrete Pavement 8" to 4" JOINT BACKER

Asphalt Shoulder Pavement Asphalt Shoulder Pavement BEAD JOINT PLACEMENT

WIDTH ROD DIA.

THICKNESS DEPTH DEPTH

d

1 1 3 1

d

4 4 8 1 2

t

t

3 1 1 1 1

8 4 2 1 4 2

Joint Sealant Material To Be Joint Sealant Material To Be

1 1 5 1 1

As Specified In The Plans As Specified In The Plans 2 4 8 1 4 2

5 5 3 1 9

Tape Bond Breaker 8 16 4 1 2 16

1

Backer Rod Bond Breaker (w + 8") 3 3 3 5

4 8 1 1 4 8

7 7 1 3 11

8 16 1 8 1 4 16

1 1 3

1 2 1 4 2 4

1 1 3

>1 2 1 4+ 2+ 4

Unless otherwise indicated on the plans the joint width

BACKER ROD BOND BREAKER TAPE BOND BREAKER for new construction will be

1

4" for construction joints,

3

8" for all other joints.

For rehabilitation projects the joint width will be shown

FOR NEW AND REHABILITATION PROJECTS;

on the plans or established by the Engineer based on

EITHER TAPE OR BACKER ROD BOND BREAKER REQUIRED; field conditions.

SHOULDER MUST BE REPAIRED IF PROPER JOINT SHAPE

CAN NOT BE ATTAINED

CONCRETE-ASPHALT SHOULDER JOINTS

47 AM

33:

JOINT SEAL DIMENSIONS

9:

10/12/2016

REVISIO N

LAST DESCRIPTION: INDEX SHEET

FY 2017-18

REVISION NO. NO.

CONCRETE PAVEMENT JOINTS

07/01/00 DESIGN STANDARDS 305 2 of 4

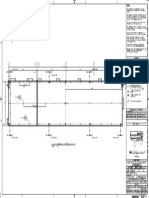

12" 12"

Spacer Bars A

Inside Face Of Slip Form

Guide Bar Fastened 6" 8"

Joint

16"

16"

7 7

Plastic Insert To Form 8" 8" 9

9

16" 16"

9

9

Hook Bolt Hex Bolt

D

B B

8"

D/2

5

2"

16"

Tie Wire

2"

Threaded

1

Staking Pin

1

Sleeve Guide Bar Fastened

To Form 1

7

8"

SECTION AA

Note: After the concrete has set to the extent that Anchor bolts shall be Grade C in accordance with ASTM A 307.

TOP VIEW

the Keyway will retain its shape, the hex

bolt and plastic insert shall be removed. Threaded sleeves shall develop the full strength of the bolt

The remaining portion of the hook bolt and meet the material and thread requirements of ASTM A 563.

assembly shall be installed immediately prior

to placing of concrete in the adjacent lane.

ALTERNATE KEYWAY AND HOOK BOLT SECTION BB

STEEL HOOK BOLT ASSEMBLY

CONTRACTION ASSEMBLY

12" 12"

Transverse Doweled

Contraction Joints Tied Longitudinal

Untied Keyed Joint Joints Spacer Bars C

R Tied Longitudinal

R Transverse Doweled

Joints Joint Seal Preformed

Expansion Joint

Joint Filler

Filler Support Tie

1 Tie Wire

8" R

1" D D

D

Sealer

D/2

1 Center Spacer Bar

4" Joint Filler

"D "

1:3 Slope Transverse Doweled

R

Untied Keyed Joint Contraction Joint

Leg Staking Pin

0.1 D

Transverse Doweled

Tied Longitudinal Untied Keyed Joint

Contraction Joints

Joints

SECTION CC Expansion Cap

0.25 D 0.375 D

C

TOP VIEW

KEYED JOINT JOINT LAYOUT JOINT LAYOUT

AT THRU INTERSECTION AT 'T' INTERSECTIONS Filler Support Wire

SECTION DD

JOINT ARRANGEMENT

NOTES EXPANSION ASSEMBLY

50 AM

1. Longitudinal joints will not be required for single lane pavement 14' or less in width. For entrance and exit ramp joint details, see Sheet 4. Note: Proprietary contraction and expansion assemblies may be used. Products shall be introduced to

33:

the State Construction Office in accordance with section (C) of the Product Evaluation Procedure.

9:

2. Arrangement of longitudinal joints are to be as directed by the Engineer.

1

3. All manholes, meter boxes and other projections into the pavement shall be boxed-in with 2" preformed expansion joint material.

10/12/2016

REVISIO N

LAST DESCRIPTION: INDEX SHEET

FY 2017-18

REVISION NO. NO.

CONCRETE PAVEMENT JOINTS

07/01/00 DESIGN STANDARDS 305 3 of 4

Longitudinal Joint Contraction Joint (Typ.)

12'

12'

3'M in.

3'M in.

3'M in.

*

*

PCC Gore Pavt.

501T

: aper

Longitudinal Joint Contraction Joint (Typ.)

3'M in.

12'

n

iln

ie

Ma 2-THRU LANES WITH SINGLE LANE ENTRANCE RAMP

mp

*

Ra v.

t

Pa

Pav.

t

*

Auxiliary Lane

r Transition From 12' to *

251T

: ape

Contraction Joint (Typ.) Wide Over 3 Slabs

12'

12'

ENTRANCE TAPER WITH AUXILIARY LANE

3'M in.

3'M in.

12'

*

Longitudinal Joint Contraction Joint (Typ.)

3'M in.

v.

t

e Pa

*

r

12'

Go

Transition From * to 12' PCC

*

Wide Over 3 Slabs

*

Longitudinal Joint Rate Va Auxiliary Lane

ri

es

av.

t

ln

ieP

Man

i Transition From * to 12' Wide Over 3 Slabs

v.

t

mp

Pa ENTRANCE RAMP WITH ADDED LANE

Ra

EXIT TAPER WITH AUXILIARY LANE

Contraction Joint (Typ.) Longitudinal Joint Contraction Joint (Typ.)

12'

12'

3'M in.

3'M in.

*

*

3'M in.

3'M in.

PCC Gore Pavt.

2-THRU LANES WITH SINGLE LANE EXIT RAMP

Note: On single lane ramps, longitudinal joint to

Mai

nli

ne Pavt

. Ramp Pavt

. be constructed along centerline of ramp.

Contraction Joint (Typ.) Longitudinal Joint

12'

12'

12'

12'

3'M in.

3'M in.

12'

*

3'M in.

*

Auxiliary Lane PCC Gore Pavt.

Transition From * to 12' Wide Over 3 Slabs

12'

52 AM

*

33:

3-THRU LANES WITH AUXILIARY LANE AND 2-LANE EXIT RAMP

9:

Mai

nli

ne Pavt

. Ramp Pavt

.

10/12/2016

* 13' with tied Concrete Shoulders or 14' with Asphalt Shoulders. JOINT LAYOUT AT ENTRANCE AND EXIT RAMP TERMINALS

REVISIO N

LAST DESCRIPTION: INDEX SHEET

FY 2017-18

REVISION NO. NO.

CONCRETE PAVEMENT JOINTS

07/01/09 DESIGN STANDARDS 305 4 of 4

You might also like

- Empirical Formula of Silver Oxide LabDocument4 pagesEmpirical Formula of Silver Oxide LabGold Hunter0% (1)

- Abg 225-325Document202 pagesAbg 225-325martin_powell_1591% (11)

- AsdsdDocument14 pagesAsdsdbillNo ratings yet

- Copia Di Sanofi Aventis PDFDocument13 pagesCopia Di Sanofi Aventis PDFFrancesca D'AngeloNo ratings yet

- ActiMat Installation Guide SmallDocument3 pagesActiMat Installation Guide Smallgerardo manuel canto barreraNo ratings yet

- Process Buildings Building CodeDocument2 pagesProcess Buildings Building CodebillNo ratings yet

- Cbrating EquipmentDocument4 pagesCbrating EquipmentbillNo ratings yet

- CAL-CECL-M06 ChecklistDocument2 pagesCAL-CECL-M06 ChecklistbillNo ratings yet

- Codes and Standards: Lead Engineer (E) : ProjectDocument1 pageCodes and Standards: Lead Engineer (E) : ProjectbillNo ratings yet

- General Specifications: Specification: Checking Level: Project: Engineer (E) : Checker (C)Document2 pagesGeneral Specifications: Specification: Checking Level: Project: Engineer (E) : Checker (C)billNo ratings yet

- PPS, Storage & Interconnecting Ina-Industrija Nafte D.D.: Inspection and Test Plan (Itp)Document2 pagesPPS, Storage & Interconnecting Ina-Industrija Nafte D.D.: Inspection and Test Plan (Itp)torrentee5216No ratings yet

- MK Ted 210011 enDocument1,008 pagesMK Ted 210011 enDiana AkmaliahNo ratings yet

- Installation Practices FOR Cable Raceway Systems: The Okonite CompanyDocument56 pagesInstallation Practices FOR Cable Raceway Systems: The Okonite CompanyharlyganNo ratings yet

- 3tf ContactorDocument25 pages3tf Contactorpadminitt100% (1)

- A29 B FPS VB 065012 001 - 00 PDFDocument1 pageA29 B FPS VB 065012 001 - 00 PDFbillNo ratings yet

- Caterpillar SpecSizer vs. Generac Power Design Pro - Feature ComparisonDocument8 pagesCaterpillar SpecSizer vs. Generac Power Design Pro - Feature ComparisonBrahim BbdNo ratings yet

- TCXD 27. 1991 / Installation of Electric Equipments in Dwellings and Public Building - Design StandardDocument20 pagesTCXD 27. 1991 / Installation of Electric Equipments in Dwellings and Public Building - Design StandardtrungjindoNo ratings yet

- Forms of SeperationDocument24 pagesForms of SeperationRagesh ChettiarNo ratings yet

- Utility Pole CatalogDocument13 pagesUtility Pole Catalogm_afuni80No ratings yet

- Guide To Forms of SeperationDocument32 pagesGuide To Forms of SeperationHồ ThànhNo ratings yet

- Lattice Steel Towers and Steel PolesDocument7 pagesLattice Steel Towers and Steel PolesMaruf HasanNo ratings yet

- SC348-ME-FDN-006 - RE - Foundation DrawingDocument6 pagesSC348-ME-FDN-006 - RE - Foundation DrawingsajanNo ratings yet

- 0488a0vvgc001 06Document73 pages0488a0vvgc001 06AlienshowNo ratings yet

- Street Light LevelsDocument1 pageStreet Light LevelsMandip PokharelNo ratings yet

- Va2 - Concrete Standard DrawingDocument10 pagesVa2 - Concrete Standard DrawingHiepNo ratings yet

- UBW RequirementsDocument33 pagesUBW RequirementsJayce TangNo ratings yet

- Lightning ProtectionDocument9 pagesLightning Protectioncharitha RanwalaNo ratings yet

- 000 215 1221 A04 31mar05Document11 pages000 215 1221 A04 31mar05Felipe FloresNo ratings yet

- Lvcatesgv enDocument152 pagesLvcatesgv endavidoff29No ratings yet

- 141-000-MI-CN-PLN-0005 Code-3Document35 pages141-000-MI-CN-PLN-0005 Code-3um erNo ratings yet

- Cural Steel Material Takeoff ChecklistDocument2 pagesCural Steel Material Takeoff ChecklistbillNo ratings yet

- Checklist For 33kV Bus Duct Structure Design & DrawingDocument4 pagesChecklist For 33kV Bus Duct Structure Design & DrawingRupesh KhandekarNo ratings yet

- Drainage Installation ProccedureDocument2 pagesDrainage Installation ProccedureAtef MohamedenNo ratings yet

- Prisma PDocument36 pagesPrisma PNATHANNo ratings yet

- Po # 7096-Mfsd-Prime Ac Industries (L.L.C)Document6 pagesPo # 7096-Mfsd-Prime Ac Industries (L.L.C)Saleh El-hawaryNo ratings yet

- J910-YQ02-P0ZEN-140941 - Typical Installation Cable Raceway - Rev.2 (AWC)Document7 pagesJ910-YQ02-P0ZEN-140941 - Typical Installation Cable Raceway - Rev.2 (AWC)Devy MangimbaNo ratings yet

- Battery EeeDocument27 pagesBattery EeeNaisarg ChauhanNo ratings yet

- Discrimination CurveDocument6 pagesDiscrimination Curvemilekitic2005No ratings yet

- Ode0000 STSP 0074 1Document14 pagesOde0000 STSP 0074 1pabvalenNo ratings yet

- Battery Load Profile-ModelDocument3 pagesBattery Load Profile-ModelMandip PokharelNo ratings yet

- Submittal Rev 2Document264 pagesSubmittal Rev 2Haythamberg AhmedNo ratings yet

- Civil 2019 v22 Release NoteDocument25 pagesCivil 2019 v22 Release NoteNilay GandhiNo ratings yet

- General Brochure eDocument6 pagesGeneral Brochure eShafeek GhreebNo ratings yet

- WEBFORGE BrochureDocument39 pagesWEBFORGE Brochurefreddielisto100% (1)

- Detail B: Page 1 of 2Document5 pagesDetail B: Page 1 of 2namasralNo ratings yet

- Calculus Report6031 20210702 055202Document25 pagesCalculus Report6031 20210702 055202Balamurugan ArumugamNo ratings yet

- Material Requisition For Protection Relay and Control Panel (Power Block and SS-329)Document11 pagesMaterial Requisition For Protection Relay and Control Panel (Power Block and SS-329)billNo ratings yet

- OS6450 AOS 6.6.4.309 R01 Release NotesDocument54 pagesOS6450 AOS 6.6.4.309 R01 Release NotesДмитрий ВасильевNo ratings yet

- Hih 060216Document337 pagesHih 060216Asif IqbalNo ratings yet

- Double Ground Fault ProtectionDocument17 pagesDouble Ground Fault ProtectionAnonymous xBi2FsBxNo ratings yet

- PV Carport With EVDocument2 pagesPV Carport With EVAra AkramNo ratings yet

- Civ GD Q68922 21Document1 pageCiv GD Q68922 21Adhe L ShethiadyNo ratings yet

- Oil City Division: Rev. Description Date BY CH'KDocument1 pageOil City Division: Rev. Description Date BY CH'KHendrias ari sujarwoNo ratings yet

- Ical Panels MCB Cable Size Calculation 1.1.15Document29 pagesIcal Panels MCB Cable Size Calculation 1.1.15abdulnadeemuddinNo ratings yet

- BLNG Ce 818010298560001Document66 pagesBLNG Ce 818010298560001Venkatesh PrasathNo ratings yet

- LY and LZ ExplainedDocument31 pagesLY and LZ ExplainedJatinTankNo ratings yet

- Tech GuideDocument153 pagesTech Guideact_rahul53No ratings yet

- Appendix B Wind LoadsDocument17 pagesAppendix B Wind LoadsJayabalan R KNo ratings yet

- Diseño de Subestaciones PDFDocument33 pagesDiseño de Subestaciones PDFalfredoNo ratings yet

- QAP Highmast1Document1 pageQAP Highmast1Mohsin Mansoori100% (1)

- T400, T700 Temp. Switch Installation and Maintenance ManualDocument2 pagesT400, T700 Temp. Switch Installation and Maintenance ManualHuan Trinh VanNo ratings yet

- Ansi b18.2.1 Hex Machine BoltDocument1 pageAnsi b18.2.1 Hex Machine BoltBharatNo ratings yet

- 66 LS 600h L / LS 600h (From Nov. 2009 Production) : Sliding RoofDocument1 page66 LS 600h L / LS 600h (From Nov. 2009 Production) : Sliding RoofWaleed AlshgaaaNo ratings yet

- SU-47 Parts 6mm Depron A4Document1 pageSU-47 Parts 6mm Depron A4vscribNo ratings yet

- The Rough Guide to Beijing (Travel Guide eBook)From EverandThe Rough Guide to Beijing (Travel Guide eBook)Rating: 2 out of 5 stars2/5 (1)

- Pa-St1203 001 PDFDocument1 pagePa-St1203 001 PDFbill100% (1)

- SEP PGB DFDDocument8 pagesSEP PGB DFDbillNo ratings yet

- FGGDFGDocument1 pageFGGDFGbillNo ratings yet

- Anchor Assembly (Epab) Schedule: VB-450974 001 M 01C A29 RestrictedDocument1 pageAnchor Assembly (Epab) Schedule: VB-450974 001 M 01C A29 RestrictedbillNo ratings yet

- AjhDocument1 pageAjhbillNo ratings yet

- Block #5 Block #4 Block #4 Block #5: DRAWING LIMIT N 9590.000Document1 pageBlock #5 Block #4 Block #4 Block #5: DRAWING LIMIT N 9590.000billNo ratings yet

- Secondary Road-J: DRAWING LIMIT N 9357.500Document1 pageSecondary Road-J: DRAWING LIMIT N 9357.500billNo ratings yet

- DesfdfdfdDocument1 pageDesfdfdfdbillNo ratings yet

- Metering: StationDocument1 pageMetering: StationbillNo ratings yet

- Scope of Supply/Work For Protection Relay and Control PanelsDocument4 pagesScope of Supply/Work For Protection Relay and Control PanelsbillNo ratings yet

- Igc 002 (GSR) Igc 001 (Gfu) : Sub 055 Pib 055 SDB 055Document1 pageIgc 002 (GSR) Igc 001 (Gfu) : Sub 055 Pib 055 SDB 055billNo ratings yet

- A2 ZX XDocument9 pagesA2 ZX XbillNo ratings yet

- Material Requisition For Protection Relay and Control Panel (Power Block and SS-329)Document11 pagesMaterial Requisition For Protection Relay and Control Panel (Power Block and SS-329)billNo ratings yet

- Calculation Sheets: Saudi Arabian Oil CompanyDocument9 pagesCalculation Sheets: Saudi Arabian Oil CompanybillNo ratings yet

- Material Take-Off: Saudi Arabian Oil CompanyDocument4 pagesMaterial Take-Off: Saudi Arabian Oil CompanybillNo ratings yet

- J95 Q Doc Ve 028210 - 000 - 0 PDFDocument68 pagesJ95 Q Doc Ve 028210 - 000 - 0 PDFbillNo ratings yet

- NGDocument10 pagesNGbillNo ratings yet

- A29 S PLB Va 237774 001 PDFDocument1 pageA29 S PLB Va 237774 001 PDFbillNo ratings yet

- Prepared ForDocument125 pagesPrepared ForbillNo ratings yet

- DRAWING LIMIT N 9403.624: Saudi Arabian Oil CompanyDocument1 pageDRAWING LIMIT N 9403.624: Saudi Arabian Oil CompanybillNo ratings yet

- Saudi Aramco: Company General UseDocument2 pagesSaudi Aramco: Company General UsebillNo ratings yet

- Saudi Arabian Oil Company: TY P AX 9 0 0Document1 pageSaudi Arabian Oil Company: TY P AX 9 0 0billNo ratings yet

- Patrick. Adams@ Worleypar: Saudi Arabian Oil CompanyDocument1 pagePatrick. Adams@ Worleypar: Saudi Arabian Oil CompanybillNo ratings yet

- Saudi Arabian Oil Company: A29 P VA-284260 001Document1 pageSaudi Arabian Oil Company: A29 P VA-284260 001billNo ratings yet

- 19 SS329 Substation For Black Start & Essential / 13.8kV Emergency Black-Start Essentials Substation - IGCC Power BlockDocument4 pages19 SS329 Substation For Black Start & Essential / 13.8kV Emergency Black-Start Essentials Substation - IGCC Power BlockbillNo ratings yet

- A29 P LTG Va 240416 003 - 00 PDFDocument1 pageA29 P LTG Va 240416 003 - 00 PDFbillNo ratings yet

- A29 B FPS VB 065012 001 - 00 PDFDocument1 pageA29 B FPS VB 065012 001 - 00 PDFbillNo ratings yet

- Saudi Arabian Oil Company: LegendDocument1 pageSaudi Arabian Oil Company: LegendbillNo ratings yet

- Legend: Saudi Arabian Oil CompanyDocument1 pageLegend: Saudi Arabian Oil CompanybillNo ratings yet

- Complexing Capacity of Salicylaldoxime With Nickel and Zinc by Differential Pulse PolarographyDocument3 pagesComplexing Capacity of Salicylaldoxime With Nickel and Zinc by Differential Pulse PolarographyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Patent eDocument12 pagesPatent eivan de jesusNo ratings yet

- En 10168 Inspection InformationDocument12 pagesEn 10168 Inspection InformationStefano Squadrani100% (2)

- HACCPDocument47 pagesHACCPSujit Shandilya100% (1)

- UTAS-0030&UTAS-0035 Centrifuge Extractor EN 12697-1 ASTM D2172 AASHTO T16A Instruction BookDocument12 pagesUTAS-0030&UTAS-0035 Centrifuge Extractor EN 12697-1 ASTM D2172 AASHTO T16A Instruction BookCostel FloreaNo ratings yet

- Le Chatelier LabDocument3 pagesLe Chatelier LabDeep ManNo ratings yet

- Bejs Bridge Expansion Joint System Tech Data Sheet EmsealDocument3 pagesBejs Bridge Expansion Joint System Tech Data Sheet EmsealrenandNo ratings yet

- HW 1 SolutionsDocument6 pagesHW 1 SolutionsCJ KoretskovNo ratings yet

- Katalog Spesifikasi Produk GuardallDocument10 pagesKatalog Spesifikasi Produk GuardallhendrobamaNo ratings yet

- Tubesheet Cladding Baher 1648652344Document3 pagesTubesheet Cladding Baher 1648652344Sapan ShahNo ratings yet

- GRSP Presentation PDFDocument30 pagesGRSP Presentation PDFChaitanyaNo ratings yet

- 5.3. 402020-01391-08-PI-SPC-0002 Rev0 PDFDocument136 pages5.3. 402020-01391-08-PI-SPC-0002 Rev0 PDFsumit kumarNo ratings yet

- DeepFlex BrochureDocument4 pagesDeepFlex Brochureribeiro30No ratings yet

- Veetagrout V71 Instruction Manual - New Format V 2Document3 pagesVeetagrout V71 Instruction Manual - New Format V 2Alirio Ramirez VelasquezNo ratings yet

- International Standard: Safety of Primary and Secondary Lithium Cells and Batteries During TransportDocument7 pagesInternational Standard: Safety of Primary and Secondary Lithium Cells and Batteries During Transportp sangeerthNo ratings yet

- Chemistry Question Bank 2017 NewDocument22 pagesChemistry Question Bank 2017 Newஅன்புடன் அஸ்வின்No ratings yet

- Edexcel A Level Chemistry Unit 6 - January 2015Document16 pagesEdexcel A Level Chemistry Unit 6 - January 2015farahgraceNo ratings yet

- Notes FlamephotometryDocument19 pagesNotes FlamephotometryKaFiAliMirzaNo ratings yet

- Buffers and PH Adjusting AgentsDocument8 pagesBuffers and PH Adjusting AgentsJoão SantosNo ratings yet

- Chromatography NotesDocument3 pagesChromatography NotesJennifer HerediaNo ratings yet

- 9701 Y16 SP 4 PDFDocument22 pages9701 Y16 SP 4 PDFasipraw01No ratings yet

- Atoms and Molecules in 22 PagesDocument22 pagesAtoms and Molecules in 22 PagessandeepNo ratings yet

- Moisture Susceptibility of Asphalt MixturesDocument19 pagesMoisture Susceptibility of Asphalt Mixturesthanhnhat5521No ratings yet

- Good Nozzles Engineering-BookDocument84 pagesGood Nozzles Engineering-Booksbalu12674No ratings yet

- Gate 2011 Chemical SyllabusDocument2 pagesGate 2011 Chemical SyllabusVenkyNo ratings yet

- Lithological Terminology and DefinitionsDocument3 pagesLithological Terminology and DefinitionsJonathan ShimNo ratings yet