Professional Documents

Culture Documents

26-10 Drilling Test PDF

26-10 Drilling Test PDF

Uploaded by

David BumbaloughOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

26-10 Drilling Test PDF

26-10 Drilling Test PDF

Uploaded by

David BumbaloughCopyright:

Available Formats

26-10 Drilling Test

In this test, the questions relate to the common drilling operations - spot drilling, drilling and tapping. In the first

part, answer the general questions. The questions in the second part relate to the enclosed drawing. The objective

of this exercise is to evaluate the questions and/or the drawing and provide correct answers.

ò PART 1 - GENERAL QUESTIONS

1. Specify formula to calculate any spot drill depth: __________________________________________________

2. What is the drill point length for Æ1/2 drill with point angle of 135°? _________________________________

3 What is a reasonable metric chamfer used for deburring? __________________________________________

4. What is the constant used for drill length calculation for 118° tool point angle? _______________________

5. Define a tap drill:

_______________________________________________________________________________________________

6. Define a chamfer diameter:

_______________________________________________________________________________________________

7. What is the formula to calculate a tool point length of a drill with 118° tool point angle?

_______________________________________________________________________________________________

8. What is a reasonable amount of breakthrough for ½-13 tap? _______________________________________

9. What is the most common included angle of the standard drill point? ________________________________

10. In spot drilling, what is the relationship of the chamfer diameter and the Z-depth?

__________________________________________________________________________________________

Peter Smid CNC Programming Handbook 26-10 [ 1 ]

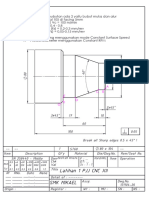

ò PART 2 - DRAWING RELATED QUESTIONS

65 15

10 (2) 8

Ø8

A B

Ø16

40

C

26

D E F G

8

M6

15 15 TYP 6

x1

38

(4)

Based on the drawing above, answer the following questions:

11. What is the programmed depth of holes A and B? ________________________________________________

12. If spindle speed for the tap is 560 r/min, what will the feedrate be? __________________________________

13. With a 2 mm breakthrough, what is the programmed depth of hole C? _____________________________

14. If 2,5 mm is required as a clearance, what is the R-level for spot drilling of holes D-G? _________________

15. Specify the X-coordinate of the hole F ____________________________________________________________

16. For holes A and B, the required chamfer is 0,35 mm - what is the depth of spot drill? __________________

17. What is the pitch of the tap for holes D-G? ________________________________________________________

Peter Smid CNC Programming Handbook 26-10 [ 2 ]

18. Which cycle will be used for spot drilling? _______________________________________________________

19. Calculate the chamfer diameter for the tapped holes _______________________________________________

20. Based on the answer in question 20, what will be the spot drill depth? _______________________________

21. Specify the tap drill size for holes D-G ____________________________________________________________

22. If a spot drill requires exactly 3 spindle revolutions, what is the dwell for 685 r/min? ___________________

23. Calculate spindle speed in r/min for 27 m/min surface speed and 16 mm drill _________________________

24. What is the drill point length of the tap drill? _____________________________________________________

25. Enter the complete program for tapping the four holes D-G (tapping only - use tool #7 and 460 r/min):

___________________________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

__________________________________________________________________________________________

Peter Smid CNC Programming Handbook 26-10 [ 3 ]

You might also like

- STIHL 021 023 025 Parts DiagramDocument23 pagesSTIHL 021 023 025 Parts DiagramTodd Lukes100% (6)

- Colonialism Impact On Caribbean EducationDocument2 pagesColonialism Impact On Caribbean Educationpretty_stefy80% (5)

- Tortort Manufacturing 80% Milled Receivers AK47Document6 pagesTortort Manufacturing 80% Milled Receivers AK47David BumbaloughNo ratings yet

- 40 Rabbana Duas - Duas With Rabbanah PDFDocument6 pages40 Rabbana Duas - Duas With Rabbanah PDFRoscii RulezNo ratings yet

- Ariel Start-Up Check List (Er-10.4.0)Document6 pagesAriel Start-Up Check List (Er-10.4.0)Jose RattiaNo ratings yet

- Alba SP LIST For DAE 16 & DAE 16 LDocument26 pagesAlba SP LIST For DAE 16 & DAE 16 Ldrmasster100% (3)

- Accounting For Plant Assets FinalDocument17 pagesAccounting For Plant Assets FinalAbdii Dhufeera100% (1)

- Machine Design Practice July 2019 Assignment IIT MadrasDocument39 pagesMachine Design Practice July 2019 Assignment IIT MadrasVishwajit HegdeNo ratings yet

- 34-10 Taper Pin MetricDocument1 page34-10 Taper Pin MetricDavid BumbaloughNo ratings yet

- Perimeter and CircumferenceDocument5 pagesPerimeter and CircumferenceHSC tutorNo ratings yet

- Panel Building-LearnersTakoradiDocument13 pagesPanel Building-LearnersTakoradiCollins KofiNo ratings yet

- Autocad: Time Pacific Institute Test Paper 40 MinsDocument2 pagesAutocad: Time Pacific Institute Test Paper 40 MinsArslan IrshadNo ratings yet

- Tool Function Q+A: # Answer 1Document2 pagesTool Function Q+A: # Answer 1David BumbaloughNo ratings yet

- P B S S L: Illow Lock ET Crew OCKDocument2 pagesP B S S L: Illow Lock ET Crew OCKDirafNo ratings yet

- NC P PDFDocument129 pagesNC P PDFrikiivoNo ratings yet

- Solidworks CSWP Practice - MergedDocument26 pagesSolidworks CSWP Practice - MergedJMcAz7No ratings yet

- Midterm Spring13Document10 pagesMidterm Spring13chemchemhaNo ratings yet

- M1 Ques Slide 1 - 1Document4 pagesM1 Ques Slide 1 - 1knizam1971No ratings yet

- Mold ChecklistDocument5 pagesMold ChecklistSelvaraj BalasundramNo ratings yet

- ME 321 Final Term Exam OBE Format - CLO MappingDocument7 pagesME 321 Final Term Exam OBE Format - CLO MappingSaad RasheedNo ratings yet

- Om - End Term-Sm - Jan 2022Document2 pagesOm - End Term-Sm - Jan 2022Priyam MrigNo ratings yet

- Gearbox Data Sheet: in Line Right AngleDocument1 pageGearbox Data Sheet: in Line Right Anglepenulis kata penulis kataNo ratings yet

- Sedis Conveyor Chains Catalogue PDFDocument236 pagesSedis Conveyor Chains Catalogue PDFAlexNo ratings yet

- VT FuzeDocument26 pagesVT Fuze郭芛宏No ratings yet

- Steel PlankDocument60 pagesSteel PlankNizam ShahNo ratings yet

- Shop Drawing Checklist Form - 201205240831047882Document2 pagesShop Drawing Checklist Form - 201205240831047882AlaaBadwyNo ratings yet

- Cm400dy 66HDocument3 pagesCm400dy 66HMiguel GalvánNo ratings yet

- Seatwork - Pump - Head Loss Due To FrictionDocument1 pageSeatwork - Pump - Head Loss Due To FrictionMarkJude MorlaNo ratings yet

- Annex 5 API 650 Storage Tanks Certificate of Compliance SampleDocument3 pagesAnnex 5 API 650 Storage Tanks Certificate of Compliance SampleLi LiuNo ratings yet

- Software CNC Lathe Machine Simulator © Virtlabs SoftwareDocument41 pagesSoftware CNC Lathe Machine Simulator © Virtlabs SoftwareJoao PedroNo ratings yet

- Coke Drum SpecDocument33 pagesCoke Drum SpecMahendra Rathore100% (1)

- Assignment GA and GB - ValvesDocument4 pagesAssignment GA and GB - Valvessthakur0703No ratings yet

- Alu Piston PUMPDocument24 pagesAlu Piston PUMPv8wfm8d8r7No ratings yet

- CAPE Building Mechanical Engineering Drawing Unit 1 Past Papers - 2005-2021 Options A B-Pages-7Document7 pagesCAPE Building Mechanical Engineering Drawing Unit 1 Past Papers - 2005-2021 Options A B-Pages-7DR. TECH Shemoy WellerNo ratings yet

- NC-Programming Manual For Turning Centers With Fanuc 30 Series ControlsDocument105 pagesNC-Programming Manual For Turning Centers With Fanuc 30 Series Controlsadnan.mustafic.mfNo ratings yet

- NC-Programming Manual For Turning Centers With Fanuc 30 Series ControlsDocument129 pagesNC-Programming Manual For Turning Centers With Fanuc 30 Series ControlsThirugnanam Dhandayuthapani100% (1)

- 2nd-AXIS LOGIS Rev00Document1 page2nd-AXIS LOGIS Rev00Abdelfatah MohamedNo ratings yet

- Apocalypse Prevention, Inc.: Agility Smarts Spirit Strength VigorDocument2 pagesApocalypse Prevention, Inc.: Agility Smarts Spirit Strength VigorAtlas StormNo ratings yet

- 6002x FinalReview S2012Document77 pages6002x FinalReview S2012deepakhimmatNo ratings yet

- Vendor Equipment Review ChecklistDocument5 pagesVendor Equipment Review ChecklistRyanNo ratings yet

- Exercise 18: (All Questions Originally Set in Imperial Units.)Document26 pagesExercise 18: (All Questions Originally Set in Imperial Units.)Adam SinghNo ratings yet

- Shop Drawing Checklist Form 2Document2 pagesShop Drawing Checklist Form 2Ahmad Mahmoud AlshataratNo ratings yet

- Rack and Pinion IdentificationDocument1 pageRack and Pinion IdentificationSharmad Prabhu VerlekarNo ratings yet

- CNC Manual enDocument41 pagesCNC Manual enbeast manNo ratings yet

- Soal Latihan 1 PJJ - Sheet1Document1 pageSoal Latihan 1 PJJ - Sheet1Kristo Kroto CorpNo ratings yet

- Ieor 3Document2 pagesIeor 3Clash GodNo ratings yet

- BTE Internal Floating Roof Input Data Sheet: ST ND RDDocument1 pageBTE Internal Floating Roof Input Data Sheet: ST ND RDAhmet_Cullu_681No ratings yet

- Gear Cutters 01Document4 pagesGear Cutters 01Raúl MuñizNo ratings yet

- OR (7th&8th) Dec2017Document2 pagesOR (7th&8th) Dec2017Sailee AcharekarNo ratings yet

- Neff Data Sheet Komplet Katalog-EngDocument68 pagesNeff Data Sheet Komplet Katalog-Engspiketg82No ratings yet

- Commelectric DiscrepanciaDocument20 pagesCommelectric DiscrepanciaEnrique Paternina HernándezNo ratings yet

- Schreder OMNIFLOOD - 1 - 3 Installation Instructions RevdDocument3 pagesSchreder OMNIFLOOD - 1 - 3 Installation Instructions RevdgreghousemdNo ratings yet

- Coker DrumsDocument33 pagesCoker DrumsJosNo ratings yet

- Spindle Nose Data Sheet For ChuckDocument2 pagesSpindle Nose Data Sheet For ChuckPruthvi RajaNo ratings yet

- LKS SMK Tingkat Nasional Tahun 2023: ProjectDocument6 pagesLKS SMK Tingkat Nasional Tahun 2023: Projecthardiannurrasyid6No ratings yet

- ADC0809 With CKT, Flow CodeDocument8 pagesADC0809 With CKT, Flow CodeBhaskar Rao PNo ratings yet

- Emac Gold 2e Year 9 Ots Tests ch7 Indices Test ADocument8 pagesEmac Gold 2e Year 9 Ots Tests ch7 Indices Test Aapi-445198464No ratings yet

- 4.1 - 4.3 Quiz (2016)Document12 pages4.1 - 4.3 Quiz (2016)inizimijNo ratings yet

- 04 - DIA CS 07 12 CONTROL SWITCHES Standard Electric DiagramsDocument27 pages04 - DIA CS 07 12 CONTROL SWITCHES Standard Electric DiagramsĐình ThếNo ratings yet

- Engineering Action Request Form EPSDocument5 pagesEngineering Action Request Form EPSDomingo DiazNo ratings yet

- Final Exam - MicroeconomicsDocument3 pagesFinal Exam - MicroeconomicsRoseMarie MasongsongNo ratings yet

- 10 - 03 - 2021 - Me - R2016 / Chbcgs / Fe / Sem-1 / Mddlo1011 / Mech / Process Equipment Design/McqDocument8 pages10 - 03 - 2021 - Me - R2016 / Chbcgs / Fe / Sem-1 / Mddlo1011 / Mech / Process Equipment Design/Mcqkkingson18No ratings yet

- Prompting Science and Engineering Students in Practical TrigonometryFrom EverandPrompting Science and Engineering Students in Practical TrigonometryNo ratings yet

- The Complete Guide To Growing Corn in Containers - Garden and HappyDocument17 pagesThe Complete Guide To Growing Corn in Containers - Garden and HappyDavid BumbaloughNo ratings yet

- Exercises After Abdominal SurgeryDocument5 pagesExercises After Abdominal SurgeryDavid BumbaloughNo ratings yet

- HK94, MP5, Parts KitsDocument6 pagesHK94, MP5, Parts KitsDavid BumbaloughNo ratings yet

- 44-01 Machining With TailstockDocument1 page44-01 Machining With TailstockDavid BumbaloughNo ratings yet

- Scaling Function Q+A: # Answer 1Document2 pagesScaling Function Q+A: # Answer 1David BumbaloughNo ratings yet

- CNC Machining Q+A: # Answer 1Document2 pagesCNC Machining Q+A: # Answer 1David BumbaloughNo ratings yet

- 46-01 Horizontal MachiningDocument1 page46-01 Horizontal MachiningDavid BumbaloughNo ratings yet

- Scaling Exercise: Use T01 Ø20 End MillDocument1 pageScaling Exercise: Use T01 Ø20 End MillDavid BumbaloughNo ratings yet

- Feedrate Q+A: # Answer 1Document2 pagesFeedrate Q+A: # Answer 1David BumbaloughNo ratings yet

- 53-02 Locators PDFDocument1 page53-02 Locators PDFDavid BumbaloughNo ratings yet

- Verifying Programs Q+A: # Answer 1Document2 pagesVerifying Programs Q+A: # Answer 1David BumbaloughNo ratings yet

- 49-01 Documenting Programs Q+A PDFDocument1 page49-01 Documenting Programs Q+A PDFDavid BumbaloughNo ratings yet

- 53-03 Contour Points 1Document1 page53-03 Contour Points 1David BumbaloughNo ratings yet

- Trig Calculations: XY Contour Points On The Part Only, Along The Contour, Back To The StartDocument1 pageTrig Calculations: XY Contour Points On The Part Only, Along The Contour, Back To The StartDavid BumbaloughNo ratings yet

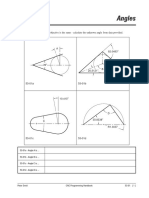

- Angles: in The Four Exercises, The Objective Is The Same - Calculate The Unknown Angle From Data ProvidedDocument1 pageAngles: in The Four Exercises, The Objective Is The Same - Calculate The Unknown Angle From Data ProvidedDavid BumbaloughNo ratings yet

- Unknown Radius: Chine Shop MagazineDocument1 pageUnknown Radius: Chine Shop MagazineDavid BumbaloughNo ratings yet

- Blend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDocument1 pageBlend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDavid BumbaloughNo ratings yet

- Machine Zero Return Q+A: # Answer 1Document2 pagesMachine Zero Return Q+A: # Answer 1David BumbaloughNo ratings yet

- Blend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDocument1 pageBlend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDavid BumbaloughNo ratings yet

- 22-01 Simple Linear Motion 1Document1 page22-01 Simple Linear Motion 1David BumbaloughNo ratings yet

- 22 00 IntroductionDocument2 pages22 00 IntroductionDavid BumbaloughNo ratings yet

- 23-03 Skipped Holes With ObstaclesDocument1 page23-03 Skipped Holes With ObstaclesDavid BumbaloughNo ratings yet

- 23-02 Trial Cut For Turning PDFDocument1 page23-02 Trial Cut For Turning PDFDavid BumbaloughNo ratings yet

- 23-02 Trial Cut For Turning PDFDocument1 page23-02 Trial Cut For Turning PDFDavid BumbaloughNo ratings yet

- 25-01 Fixed Cycles Q+A PDFDocument2 pages25-01 Fixed Cycles Q+A PDFDavid BumbaloughNo ratings yet

- Product Catalogue 2017 Food and Feed Analysis enDocument82 pagesProduct Catalogue 2017 Food and Feed Analysis enNelson AcostaNo ratings yet

- Production of Low Cost Self Compacting Concrete Using Bagasse AshDocument10 pagesProduction of Low Cost Self Compacting Concrete Using Bagasse AshENgřMuhăɱɱadRiǺzAhɱadNo ratings yet

- Kathy J Abbi Mccoy Kaylee Smith - Frugal Teacher AssignmentDocument4 pagesKathy J Abbi Mccoy Kaylee Smith - Frugal Teacher Assignmentapi-510126964No ratings yet

- CA903014E Coordination SPD MCB FusesDocument11 pagesCA903014E Coordination SPD MCB Fusesaji.isramboNo ratings yet

- IPL Cover LetterDocument1 pageIPL Cover LetterMauricio SaraviaNo ratings yet

- Velalar College of Engineering and TechnologyDocument47 pagesVelalar College of Engineering and TechnologyKartheeswari SaravananNo ratings yet

- Foxe - The Book of MartyrsDocument367 pagesFoxe - The Book of MartyrsBibliomania7No ratings yet

- Atividade 3º Ano Do Ensino Médio Inglês - Verbo To BeDocument3 pagesAtividade 3º Ano Do Ensino Médio Inglês - Verbo To Beerica vilane de souza guimaresNo ratings yet

- PR GroupDocument22 pagesPR GroupCeasar Ian MundalaNo ratings yet

- Pracres 2 Paralink Bookport Final Paper PDFDocument89 pagesPracres 2 Paralink Bookport Final Paper PDFRon Edward MedinaNo ratings yet

- State of The Art Chilled Water System Design Booklet - APP CMC076 ENDocument55 pagesState of The Art Chilled Water System Design Booklet - APP CMC076 ENMaxmore Karumamupiyo100% (2)

- 1989 Issue 5 - Moral Criticisms of The Market - Counsel of ChalcedonDocument5 pages1989 Issue 5 - Moral Criticisms of The Market - Counsel of ChalcedonChalcedon Presbyterian ChurchNo ratings yet

- Ref 15Document7 pagesRef 15giriNo ratings yet

- Ac 800 PDFDocument344 pagesAc 800 PDFJose Vicente CentellesNo ratings yet

- Research Aptitude Test (RAT) - Report: ObjectiveDocument4 pagesResearch Aptitude Test (RAT) - Report: ObjectiveDebasish JenaNo ratings yet

- TCS Beats Estimates With 16.2% Q1 Revenue Growth: Real Growth Not Possible Without Inclusiveness: PMDocument18 pagesTCS Beats Estimates With 16.2% Q1 Revenue Growth: Real Growth Not Possible Without Inclusiveness: PMf20213093No ratings yet

- Introduction To 6th Year JapaneseDocument3 pagesIntroduction To 6th Year JapaneseDavid McCartneyNo ratings yet

- CROSSWORDDocument4 pagesCROSSWORDMartyneJohnNo ratings yet

- ASSU Officers Reap Large Stipends: The Stanford DailyDocument8 pagesASSU Officers Reap Large Stipends: The Stanford Dailyeic4659No ratings yet

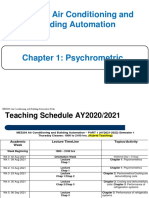

- ME5204: Air Conditioning and Building Automation NotesDocument36 pagesME5204: Air Conditioning and Building Automation Notesgattuso amberNo ratings yet

- Diagnostic Grade 12Document2 pagesDiagnostic Grade 12Jenelle de VeraNo ratings yet

- Heidenhain Ik 121v ManualDocument116 pagesHeidenhain Ik 121v ManualmasinemaNo ratings yet

- Dobby Shedding MechanismDocument21 pagesDobby Shedding MechanismAfjal Hossain Sujan100% (2)

- Forbidden Lands Legends and Adventurers 5th PrintingDocument40 pagesForbidden Lands Legends and Adventurers 5th PrintingRubens Beraldo PaulicoNo ratings yet

- PPQA OverviewDocument1 pagePPQA OverviewAkhil Kumar Chaudhary100% (2)

- MPOB PlanningDocument17 pagesMPOB PlanningRicha BabbarNo ratings yet

- PERDEV-Module-quarter 2 - Week 7Document12 pagesPERDEV-Module-quarter 2 - Week 7erica lamsen0% (1)