Professional Documents

Culture Documents

Balikci 1997

Balikci 1997

Uploaded by

César DaerCopyright:

Available Formats

You might also like

- User S Manual: Four & Six One and Two Litre Tank Galvanic PlantsDocument24 pagesUser S Manual: Four & Six One and Two Litre Tank Galvanic PlantsTacha Von LammNo ratings yet

- Structural Materials For Fission & Fusion Energy: Zinklesj@ornl - GovDocument8 pagesStructural Materials For Fission & Fusion Energy: Zinklesj@ornl - GovVanina GiselaNo ratings yet

- Tailored Preparation Methods of Tio Anatase, Rutile, Brookite: Mechanism of Formation and Electrochemical PropertiesDocument7 pagesTailored Preparation Methods of Tio Anatase, Rutile, Brookite: Mechanism of Formation and Electrochemical PropertiesNov IndaNo ratings yet

- Emerging Applications of IntermetallicsDocument8 pagesEmerging Applications of IntermetallicsSahar RajaNo ratings yet

- Ceramic Materials For Energy Conversion and StoragDocument15 pagesCeramic Materials For Energy Conversion and StoragoystNo ratings yet

- 1 OnlineDocument11 pages1 Onlinenaar.bouchra2020No ratings yet

- Materials Today: Proceedings: Gaurav Prashar, Hitesh VasudevDocument5 pagesMaterials Today: Proceedings: Gaurav Prashar, Hitesh Vasudevnagaraj patilNo ratings yet

- Cold Spray Technology in Nuclear Energy Applications: A Review of Recent AdvancesDocument27 pagesCold Spray Technology in Nuclear Energy Applications: A Review of Recent AdvancesFieldaarr 181No ratings yet

- Corrosion Protection of Stainless Steel by Polysiloxane Hybrid Coatings PreparedDocument13 pagesCorrosion Protection of Stainless Steel by Polysiloxane Hybrid Coatings Preparedsinafarajpoor.sfNo ratings yet

- Hot Corrosion Behavior of Commercial Alloys in Thermal Energy Storage Material of Molten MgCl2 - KCL - NaCl Under Inert AtmosphereDocument9 pagesHot Corrosion Behavior of Commercial Alloys in Thermal Energy Storage Material of Molten MgCl2 - KCL - NaCl Under Inert AtmospheremanishtubNo ratings yet

- Materials SinteringDocument7 pagesMaterials Sinteringjose mirandaNo ratings yet

- Nanocoatings: Randa Abdel-KarimDocument37 pagesNanocoatings: Randa Abdel-KarimEnrique FrancoNo ratings yet

- Creep Resistant Aluminium Alloys and Their Applications: Materials Science and Technology February 2003Document14 pagesCreep Resistant Aluminium Alloys and Their Applications: Materials Science and Technology February 2003Oscar OrdazNo ratings yet

- Materials Challenges in Nuclear EnergyDocument24 pagesMaterials Challenges in Nuclear EnergyW.t. HanNo ratings yet

- Preprints202305 1599 v1Document15 pagesPreprints202305 1599 v1Aicepyrre MetGod MortelNo ratings yet

- Water Chemistry in Fusion Cooling System PDFDocument19 pagesWater Chemistry in Fusion Cooling System PDFmohamed yousefNo ratings yet

- Microwave Sintering of W-18cu and W-7ni-3cu AlloysDocument5 pagesMicrowave Sintering of W-18cu and W-7ni-3cu AlloysAvijit MondalNo ratings yet

- Journal of Energy Storage: SciencedirectDocument23 pagesJournal of Energy Storage: Sciencedirecttahreem hussainNo ratings yet

- Fire LoadingDocument57 pagesFire LoadingvinayNo ratings yet

- Full 112Document56 pagesFull 112vinayNo ratings yet

- Macro-Microporous Carbon With A Three-Dimensional Channel From Waste Sun Flower Seed ShellDocument9 pagesMacro-Microporous Carbon With A Three-Dimensional Channel From Waste Sun Flower Seed ShellMuhamad SuharNo ratings yet

- Steam Reforming of Methane Over Ni Catalyst in Micro-Channel ReactorDocument9 pagesSteam Reforming of Methane Over Ni Catalyst in Micro-Channel ReactorWassachol SumarasinghaNo ratings yet

- Jin 2017Document14 pagesJin 2017abdul basitNo ratings yet

- Liquid Metal As A Heat Transport Fluid For Thermal Solar Power ApplicationsDocument10 pagesLiquid Metal As A Heat Transport Fluid For Thermal Solar Power ApplicationsRadu CristianNo ratings yet

- Effect of Tempering On The Microstructure and Mechanical Properties of Low Carbon Low Alloy Martensitic SteelDocument6 pagesEffect of Tempering On The Microstructure and Mechanical Properties of Low Carbon Low Alloy Martensitic SteelMuhammad Rizki Ash-ShidiqNo ratings yet

- Graphene Oxide Modified Lini Co MN O As Cathode Material For Lithium Ion Batteries and Its Electrochemical PerformancesDocument14 pagesGraphene Oxide Modified Lini Co MN O As Cathode Material For Lithium Ion Batteries and Its Electrochemical Performancesआदित्य नारायण सिंहNo ratings yet

- Corrosion Resistance of Aluminum Alloy 2198 For Different Ageing 2022Document7 pagesCorrosion Resistance of Aluminum Alloy 2198 For Different Ageing 2022Ahmad MustopaNo ratings yet

- A Review On Thermal Barrier Coatings andDocument9 pagesA Review On Thermal Barrier Coatings andFreddy FernandezNo ratings yet

- ArtículoDocument10 pagesArtículoJosé Ma MuNo ratings yet

- Comparison of The Structural and Electrochemic MNMC FAMDocument10 pagesComparison of The Structural and Electrochemic MNMC FAMadalid contrerasNo ratings yet

- Materials Today: Proceedings: M. Mathanbabu, D. Thirumalaikumarasamy, P. Thirumal, M. AshokkumarDocument7 pagesMaterials Today: Proceedings: M. Mathanbabu, D. Thirumalaikumarasamy, P. Thirumal, M. AshokkumarShivareddy KondakindiNo ratings yet

- Low Temperature Co-Fired Ceramics With Ultra-Low Sintering Temperature A ReviewDocument20 pagesLow Temperature Co-Fired Ceramics With Ultra-Low Sintering Temperature A ReviewMeiliza HastutiNo ratings yet

- Hydrogen Production by Ammonia Decomposition Over Ruthenium Supported On SiC CatalystDocument10 pagesHydrogen Production by Ammonia Decomposition Over Ruthenium Supported On SiC CatalystMónica MejíaNo ratings yet

- Joining of Ti6Al4V To Al2O3 Using NanomultilayersDocument15 pagesJoining of Ti6Al4V To Al2O3 Using NanomultilayersMarcionilo NeriNo ratings yet

- Solar Energy Materials and Solar CellsDocument12 pagesSolar Energy Materials and Solar CellsÁngel GarcíaNo ratings yet

- Damage Characteristics and Microstructure Response of Steel Alloy Q235B Subjected To Simulated Lightning CurrentsDocument7 pagesDamage Characteristics and Microstructure Response of Steel Alloy Q235B Subjected To Simulated Lightning CurrentsRiyadh ZakiNo ratings yet

- Advantages of High Temperature MaterialsDocument20 pagesAdvantages of High Temperature MaterialsDeep MohantaNo ratings yet

- Heat Transfer Transient Analysis On The Fire Proofing Coating Applications For Structural SteelDocument32 pagesHeat Transfer Transient Analysis On The Fire Proofing Coating Applications For Structural SteelInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Journal Homepage: - : IntroductionDocument16 pagesJournal Homepage: - : IntroductionIJAR JOURNALNo ratings yet

- Enhanced Numerical Tool To Evaluate Steel Ladle Thermal LossesDocument10 pagesEnhanced Numerical Tool To Evaluate Steel Ladle Thermal LossesKhaled BOUALINo ratings yet

- Damage - and - Performance - Assessment - of - Protective - Coatings - On - Turbine - BladesDocument24 pagesDamage - and - Performance - Assessment - of - Protective - Coatings - On - Turbine - BladesRafael Garcia IllescasNo ratings yet

- Comparative Studyofthe Electrostatic Charging Tendencybetween Synthetic Esterand Mineral OilDocument10 pagesComparative Studyofthe Electrostatic Charging Tendencybetween Synthetic Esterand Mineral OilTalhi MamaNo ratings yet

- Ni-Co MOF With Channel StructureDocument11 pagesNi-Co MOF With Channel StructureBilal KhalidNo ratings yet

- Materials Science & Engineering A: I. Mejía, A.E. Salas-Reyes, J. Calvo, J.M. CabreraDocument19 pagesMaterials Science & Engineering A: I. Mejía, A.E. Salas-Reyes, J. Calvo, J.M. CabreraCésar CastañedaNo ratings yet

- The Application of Monoliths For Gases Phase Catalytic ReactionsDocument8 pagesThe Application of Monoliths For Gases Phase Catalytic ReactionsManh CuongNo ratings yet

- Hydrothermal Synthesized Rugby-Like LiNi0.5Co0.2Mn0.3O2 CathodeDocument7 pagesHydrothermal Synthesized Rugby-Like LiNi0.5Co0.2Mn0.3O2 CathodeAnwar NurharyantoNo ratings yet

- Metals 12 00165Document21 pagesMetals 12 00165anjuabrahamNo ratings yet

- High-Temperature Corrosion in Waste-To-Energy BoilDocument8 pagesHigh-Temperature Corrosion in Waste-To-Energy Boilryan sandiNo ratings yet

- MST PaperDocument12 pagesMST PaperFaris fakhryNo ratings yet

- Temperature and Lithium Concentration Gradient Caused Inhomogeneous Plating in Large-Format Lithium-Ion CellsDocument9 pagesTemperature and Lithium Concentration Gradient Caused Inhomogeneous Plating in Large-Format Lithium-Ion CellsMiguel Andres Gracia ZubillagaNo ratings yet

- IP Influence of Temp On ZnNi Dep. Cyclic Voltametry 2020Document11 pagesIP Influence of Temp On ZnNi Dep. Cyclic Voltametry 2020Sorin SorinNo ratings yet

- RR3000和CMSX 4单晶高温合金的高温氧化行为 PDFDocument9 pagesRR3000和CMSX 4单晶高温合金的高温氧化行为 PDFhk esatonNo ratings yet

- Composite Structure Failure Analysis Post Lithium-Ion Battery FireDocument16 pagesComposite Structure Failure Analysis Post Lithium-Ion Battery FireDav KhNo ratings yet

- Art 4-Etching and Heating TreatmentDocument8 pagesArt 4-Etching and Heating TreatmentVictor MerlanoNo ratings yet

- Energies 11 00572Document18 pagesEnergies 11 00572Shreesha KumarNo ratings yet

- Welding of Ni Based Alloys For Energy Applications, J. DuPont WJDocument15 pagesWelding of Ni Based Alloys For Energy Applications, J. DuPont WJdeweyj1No ratings yet

- Nickel Super Alloy INCONEL 713LC - Structural Characteristics After Heat TreatmentDocument9 pagesNickel Super Alloy INCONEL 713LC - Structural Characteristics After Heat TreatmentelmiraNo ratings yet

- Journal of Power Sources: Aalok Gaitonde, Amulya Nimmagadda, Amy MarconnetDocument6 pagesJournal of Power Sources: Aalok Gaitonde, Amulya Nimmagadda, Amy Marconnetmuhammad mohamadNo ratings yet

- Optimal Design of Heating Elements Sheathed With INCOLOY Superalloy 800Document13 pagesOptimal Design of Heating Elements Sheathed With INCOLOY Superalloy 800Maxwel Silva DiasNo ratings yet

- Power Plant MaterialsDocument0 pagesPower Plant MaterialsAli KhalilNo ratings yet

- Radiographic Examination Report: Report No: Gtcl/Libra/Bkb800Mmscfd/Rt-0016 Client: Gas Transmission Company LTDDocument1 pageRadiographic Examination Report: Report No: Gtcl/Libra/Bkb800Mmscfd/Rt-0016 Client: Gas Transmission Company LTDMd Ashikur RahmanNo ratings yet

- Tie Bars Vs Dowel BarsDocument1 pageTie Bars Vs Dowel Barstally3tally100% (1)

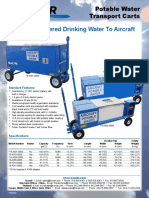

- Potable Water Transport CartsDocument1 pagePotable Water Transport CartsProvincial AirwaysNo ratings yet

- Tensile and Chemical Analyses of Selected Steel Bars Produced in NigeriaDocument6 pagesTensile and Chemical Analyses of Selected Steel Bars Produced in NigeriaSalih MohayaddinNo ratings yet

- 64-2103 Tweco Smoke Master MIGDocument4 pages64-2103 Tweco Smoke Master MIGcarlosNo ratings yet

- Ship Construction and Structure by Azaruddin MominDocument147 pagesShip Construction and Structure by Azaruddin MominNaman joshi100% (2)

- PS-10-17 en AqDocument16 pagesPS-10-17 en Aq.xNo ratings yet

- Llave Wilson PDFDocument30 pagesLlave Wilson PDFC. Perez herreraNo ratings yet

- Xlpe Insulated Power Cables PDFDocument47 pagesXlpe Insulated Power Cables PDFsouheil boussaidNo ratings yet

- Spigot Product Spec Sheet 1614023137Document1 pageSpigot Product Spec Sheet 1614023137Cojuhari SergiuNo ratings yet

- Cold Rolling Mills CatalogDocument12 pagesCold Rolling Mills CatalogAshish GoyalNo ratings yet

- Sae 1080Document1 pageSae 1080bharathi_pmNo ratings yet

- AMS 2759-8 Ion NitridingDocument12 pagesAMS 2759-8 Ion NitridingIvy LiNo ratings yet

- The History of MoneyDocument5 pagesThe History of MoneyAdriana MartinsNo ratings yet

- ASTM Cross Reference Chart: Carbon SteelDocument1 pageASTM Cross Reference Chart: Carbon SteelMurat UzunNo ratings yet

- 1.6523 20nicrmo2-2 - Aisi 8620Document3 pages1.6523 20nicrmo2-2 - Aisi 8620zhenyupanNo ratings yet

- PolyGhard 2000Document3 pagesPolyGhard 2000Luis Felipe Dominguez RuizNo ratings yet

- Pipe FactsDocument30 pagesPipe FactsMekhmanNo ratings yet

- Fitter Sem3 TTDocument134 pagesFitter Sem3 TTPooja7 7No ratings yet

- L3-1 Drilling & Other Workshop ProcessesDocument27 pagesL3-1 Drilling & Other Workshop Processeskalahanmoonga82No ratings yet

- Day 34Document4 pagesDay 34Marcial Jr. MilitanteNo ratings yet

- Catalogo General KFDocument32 pagesCatalogo General KFMiguel FNo ratings yet

- Usw Review PaperDocument23 pagesUsw Review PaperRahul KumarNo ratings yet

- Cold Thermal Insulation SpecificationDocument13 pagesCold Thermal Insulation SpecificationCameliaNo ratings yet

- Chapter VI Inspection, Examination, and TestingDocument12 pagesChapter VI Inspection, Examination, and TestingFlorin TrNo ratings yet

- Powder Forged (PF) Ferrous Materials: Standard Specification ForDocument10 pagesPowder Forged (PF) Ferrous Materials: Standard Specification ForDanZel DanNo ratings yet

- CNC Lathe List: Item CK0640 CK0660 CK0680Document10 pagesCNC Lathe List: Item CK0640 CK0660 CK0680MUHAMMAD NAUMANNo ratings yet

- Rebar EngineeringDocument6 pagesRebar EngineeringSylvestre UbaNo ratings yet

- Rovalve Fig 215 Slide Gate Valve 2-24 InchDocument4 pagesRovalve Fig 215 Slide Gate Valve 2-24 InchCapacitacion TodocatNo ratings yet

Balikci 1997

Balikci 1997

Uploaded by

César DaerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Balikci 1997

Balikci 1997

Uploaded by

César DaerCopyright:

Available Formats

24/09/2010 Format for Print Page

ISI Web of Knowledge

Page 1 (Articles 1 -- 1)

[1]

Record 1 of 1

Author(s): Balikci, E; Raman, A; Mirshams, RA

Title: Influence of various heat treatments on the microstructure of polycrystalline IN738LC

Source: METALLURGICAL AND MATERIALS TRANSACTIONS A-PHYSICAL METALLURGY AND

MATERIALS SCIENCE, 28 (10): 1993-2003 OCT 1997

Language: English

Document Type: Article

KeyWords Plus: NICKEL-BASE SUPERALLOY; DEFORMATION; PHASE; TEMPERATURE; DEPENDENCE;

DIFFUSION; GROWTH

Abstract: IN738LC is a modem, nickel-based superalloy utilized at high temperatures in aggressive environments.

Durability of this superalloy is dependent on the strengthening of gamma' precipitates. This study focuses on the

microstructural development of IN738LC during various heat treatments. The 1120 degrees C/2 h/accelerated air-

cooled (AAC) solution treatment, given in the literature, already produces a bimodal precipitate microstructure,

which is, thus, not an adequate solutionizing procedure to yield a single-phase solid solution in the alloy at the outset.

However, the 1235 degrees C/4 h/water quenched (WQ) solution treatment does produce the single-phase condition.

A microstructure with fine precipitates develops if solutionizing is carried out under 1200 degrees C/4 h/AAC

conditions. Agings at lower temperatures after 1200 degrees C4 h/AAC or 1250 degrees C/4 h/AAC or WQ

conditions yield analogous microstructures. Agings below similar to 950 degrees C for 24 hours yield nearly

spheroidal precipitates, and single aging for 24 hours at 1050 degrees C or 1120 degrees C produces cuboidal

precipitates. Two different gamma' precipitate growth processes are observed: merging of smaller precipitates to

produce larger ones (in duplex precipitate-size microstructures) and growth through solute absorption from the

matrix. Average activation energies for the precipitate growth processes are 191 and 350 kJ/mol in the ranges of 850

degrees C to 1050 degrees C and 1050 degrees C to 1120 degrees C, respectively, calculated using the precipitate

sizes from microstructures in the WQ condition, and 150 and 298 kJ/mol in the analogous temperature ranges,

calculated from precipitate sizes in the microstructures in the slow furnace-cooled condition.

Addresses: SOUTHERN UNIV,DEPT MECH ENGN,BATON ROUGE,LA 70813

Reprint Address: Balikci, E, LOUISIANA STATE UNIV,DEPT MECH ENGN,MAT SCI PROGRAM,BATON

ROUGE,LA 70803.

Cited Reference Count: 19

Times Cited: 33

Publisher: MINERALS METALS MATERIALS SOC

Publisher Address: 420 COMMONWEALTH DR, WARRENDALE, PA 15086

ISSN: 1073-5623

29-char Source Abbrev.: METALL MATER TRANS A

ISO Source Abbrev.: Metall. Mater. Trans. A-Phys. Metall. Mater. Sci.

Source Item Page Count: 11

Subject Category: Materials Science, Multidisciplinary; Metallurgy & Metallurgical Engineering

ISI Document Delivery No.: YA656

ISI Web of Knowledge

Page 1 (Articles 1 -- 1)

[1]

Acceptable Use Policy

Copyright © 2008 Thomson Reuters

pcs.isiknowledge.com/…/uml_view.cgi… 1/1

You might also like

- User S Manual: Four & Six One and Two Litre Tank Galvanic PlantsDocument24 pagesUser S Manual: Four & Six One and Two Litre Tank Galvanic PlantsTacha Von LammNo ratings yet

- Structural Materials For Fission & Fusion Energy: Zinklesj@ornl - GovDocument8 pagesStructural Materials For Fission & Fusion Energy: Zinklesj@ornl - GovVanina GiselaNo ratings yet

- Tailored Preparation Methods of Tio Anatase, Rutile, Brookite: Mechanism of Formation and Electrochemical PropertiesDocument7 pagesTailored Preparation Methods of Tio Anatase, Rutile, Brookite: Mechanism of Formation and Electrochemical PropertiesNov IndaNo ratings yet

- Emerging Applications of IntermetallicsDocument8 pagesEmerging Applications of IntermetallicsSahar RajaNo ratings yet

- Ceramic Materials For Energy Conversion and StoragDocument15 pagesCeramic Materials For Energy Conversion and StoragoystNo ratings yet

- 1 OnlineDocument11 pages1 Onlinenaar.bouchra2020No ratings yet

- Materials Today: Proceedings: Gaurav Prashar, Hitesh VasudevDocument5 pagesMaterials Today: Proceedings: Gaurav Prashar, Hitesh Vasudevnagaraj patilNo ratings yet

- Cold Spray Technology in Nuclear Energy Applications: A Review of Recent AdvancesDocument27 pagesCold Spray Technology in Nuclear Energy Applications: A Review of Recent AdvancesFieldaarr 181No ratings yet

- Corrosion Protection of Stainless Steel by Polysiloxane Hybrid Coatings PreparedDocument13 pagesCorrosion Protection of Stainless Steel by Polysiloxane Hybrid Coatings Preparedsinafarajpoor.sfNo ratings yet

- Hot Corrosion Behavior of Commercial Alloys in Thermal Energy Storage Material of Molten MgCl2 - KCL - NaCl Under Inert AtmosphereDocument9 pagesHot Corrosion Behavior of Commercial Alloys in Thermal Energy Storage Material of Molten MgCl2 - KCL - NaCl Under Inert AtmospheremanishtubNo ratings yet

- Materials SinteringDocument7 pagesMaterials Sinteringjose mirandaNo ratings yet

- Nanocoatings: Randa Abdel-KarimDocument37 pagesNanocoatings: Randa Abdel-KarimEnrique FrancoNo ratings yet

- Creep Resistant Aluminium Alloys and Their Applications: Materials Science and Technology February 2003Document14 pagesCreep Resistant Aluminium Alloys and Their Applications: Materials Science and Technology February 2003Oscar OrdazNo ratings yet

- Materials Challenges in Nuclear EnergyDocument24 pagesMaterials Challenges in Nuclear EnergyW.t. HanNo ratings yet

- Preprints202305 1599 v1Document15 pagesPreprints202305 1599 v1Aicepyrre MetGod MortelNo ratings yet

- Water Chemistry in Fusion Cooling System PDFDocument19 pagesWater Chemistry in Fusion Cooling System PDFmohamed yousefNo ratings yet

- Microwave Sintering of W-18cu and W-7ni-3cu AlloysDocument5 pagesMicrowave Sintering of W-18cu and W-7ni-3cu AlloysAvijit MondalNo ratings yet

- Journal of Energy Storage: SciencedirectDocument23 pagesJournal of Energy Storage: Sciencedirecttahreem hussainNo ratings yet

- Fire LoadingDocument57 pagesFire LoadingvinayNo ratings yet

- Full 112Document56 pagesFull 112vinayNo ratings yet

- Macro-Microporous Carbon With A Three-Dimensional Channel From Waste Sun Flower Seed ShellDocument9 pagesMacro-Microporous Carbon With A Three-Dimensional Channel From Waste Sun Flower Seed ShellMuhamad SuharNo ratings yet

- Steam Reforming of Methane Over Ni Catalyst in Micro-Channel ReactorDocument9 pagesSteam Reforming of Methane Over Ni Catalyst in Micro-Channel ReactorWassachol SumarasinghaNo ratings yet

- Jin 2017Document14 pagesJin 2017abdul basitNo ratings yet

- Liquid Metal As A Heat Transport Fluid For Thermal Solar Power ApplicationsDocument10 pagesLiquid Metal As A Heat Transport Fluid For Thermal Solar Power ApplicationsRadu CristianNo ratings yet

- Effect of Tempering On The Microstructure and Mechanical Properties of Low Carbon Low Alloy Martensitic SteelDocument6 pagesEffect of Tempering On The Microstructure and Mechanical Properties of Low Carbon Low Alloy Martensitic SteelMuhammad Rizki Ash-ShidiqNo ratings yet

- Graphene Oxide Modified Lini Co MN O As Cathode Material For Lithium Ion Batteries and Its Electrochemical PerformancesDocument14 pagesGraphene Oxide Modified Lini Co MN O As Cathode Material For Lithium Ion Batteries and Its Electrochemical Performancesआदित्य नारायण सिंहNo ratings yet

- Corrosion Resistance of Aluminum Alloy 2198 For Different Ageing 2022Document7 pagesCorrosion Resistance of Aluminum Alloy 2198 For Different Ageing 2022Ahmad MustopaNo ratings yet

- A Review On Thermal Barrier Coatings andDocument9 pagesA Review On Thermal Barrier Coatings andFreddy FernandezNo ratings yet

- ArtículoDocument10 pagesArtículoJosé Ma MuNo ratings yet

- Comparison of The Structural and Electrochemic MNMC FAMDocument10 pagesComparison of The Structural and Electrochemic MNMC FAMadalid contrerasNo ratings yet

- Materials Today: Proceedings: M. Mathanbabu, D. Thirumalaikumarasamy, P. Thirumal, M. AshokkumarDocument7 pagesMaterials Today: Proceedings: M. Mathanbabu, D. Thirumalaikumarasamy, P. Thirumal, M. AshokkumarShivareddy KondakindiNo ratings yet

- Low Temperature Co-Fired Ceramics With Ultra-Low Sintering Temperature A ReviewDocument20 pagesLow Temperature Co-Fired Ceramics With Ultra-Low Sintering Temperature A ReviewMeiliza HastutiNo ratings yet

- Hydrogen Production by Ammonia Decomposition Over Ruthenium Supported On SiC CatalystDocument10 pagesHydrogen Production by Ammonia Decomposition Over Ruthenium Supported On SiC CatalystMónica MejíaNo ratings yet

- Joining of Ti6Al4V To Al2O3 Using NanomultilayersDocument15 pagesJoining of Ti6Al4V To Al2O3 Using NanomultilayersMarcionilo NeriNo ratings yet

- Solar Energy Materials and Solar CellsDocument12 pagesSolar Energy Materials and Solar CellsÁngel GarcíaNo ratings yet

- Damage Characteristics and Microstructure Response of Steel Alloy Q235B Subjected To Simulated Lightning CurrentsDocument7 pagesDamage Characteristics and Microstructure Response of Steel Alloy Q235B Subjected To Simulated Lightning CurrentsRiyadh ZakiNo ratings yet

- Advantages of High Temperature MaterialsDocument20 pagesAdvantages of High Temperature MaterialsDeep MohantaNo ratings yet

- Heat Transfer Transient Analysis On The Fire Proofing Coating Applications For Structural SteelDocument32 pagesHeat Transfer Transient Analysis On The Fire Proofing Coating Applications For Structural SteelInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Journal Homepage: - : IntroductionDocument16 pagesJournal Homepage: - : IntroductionIJAR JOURNALNo ratings yet

- Enhanced Numerical Tool To Evaluate Steel Ladle Thermal LossesDocument10 pagesEnhanced Numerical Tool To Evaluate Steel Ladle Thermal LossesKhaled BOUALINo ratings yet

- Damage - and - Performance - Assessment - of - Protective - Coatings - On - Turbine - BladesDocument24 pagesDamage - and - Performance - Assessment - of - Protective - Coatings - On - Turbine - BladesRafael Garcia IllescasNo ratings yet

- Comparative Studyofthe Electrostatic Charging Tendencybetween Synthetic Esterand Mineral OilDocument10 pagesComparative Studyofthe Electrostatic Charging Tendencybetween Synthetic Esterand Mineral OilTalhi MamaNo ratings yet

- Ni-Co MOF With Channel StructureDocument11 pagesNi-Co MOF With Channel StructureBilal KhalidNo ratings yet

- Materials Science & Engineering A: I. Mejía, A.E. Salas-Reyes, J. Calvo, J.M. CabreraDocument19 pagesMaterials Science & Engineering A: I. Mejía, A.E. Salas-Reyes, J. Calvo, J.M. CabreraCésar CastañedaNo ratings yet

- The Application of Monoliths For Gases Phase Catalytic ReactionsDocument8 pagesThe Application of Monoliths For Gases Phase Catalytic ReactionsManh CuongNo ratings yet

- Hydrothermal Synthesized Rugby-Like LiNi0.5Co0.2Mn0.3O2 CathodeDocument7 pagesHydrothermal Synthesized Rugby-Like LiNi0.5Co0.2Mn0.3O2 CathodeAnwar NurharyantoNo ratings yet

- Metals 12 00165Document21 pagesMetals 12 00165anjuabrahamNo ratings yet

- High-Temperature Corrosion in Waste-To-Energy BoilDocument8 pagesHigh-Temperature Corrosion in Waste-To-Energy Boilryan sandiNo ratings yet

- MST PaperDocument12 pagesMST PaperFaris fakhryNo ratings yet

- Temperature and Lithium Concentration Gradient Caused Inhomogeneous Plating in Large-Format Lithium-Ion CellsDocument9 pagesTemperature and Lithium Concentration Gradient Caused Inhomogeneous Plating in Large-Format Lithium-Ion CellsMiguel Andres Gracia ZubillagaNo ratings yet

- IP Influence of Temp On ZnNi Dep. Cyclic Voltametry 2020Document11 pagesIP Influence of Temp On ZnNi Dep. Cyclic Voltametry 2020Sorin SorinNo ratings yet

- RR3000和CMSX 4单晶高温合金的高温氧化行为 PDFDocument9 pagesRR3000和CMSX 4单晶高温合金的高温氧化行为 PDFhk esatonNo ratings yet

- Composite Structure Failure Analysis Post Lithium-Ion Battery FireDocument16 pagesComposite Structure Failure Analysis Post Lithium-Ion Battery FireDav KhNo ratings yet

- Art 4-Etching and Heating TreatmentDocument8 pagesArt 4-Etching and Heating TreatmentVictor MerlanoNo ratings yet

- Energies 11 00572Document18 pagesEnergies 11 00572Shreesha KumarNo ratings yet

- Welding of Ni Based Alloys For Energy Applications, J. DuPont WJDocument15 pagesWelding of Ni Based Alloys For Energy Applications, J. DuPont WJdeweyj1No ratings yet

- Nickel Super Alloy INCONEL 713LC - Structural Characteristics After Heat TreatmentDocument9 pagesNickel Super Alloy INCONEL 713LC - Structural Characteristics After Heat TreatmentelmiraNo ratings yet

- Journal of Power Sources: Aalok Gaitonde, Amulya Nimmagadda, Amy MarconnetDocument6 pagesJournal of Power Sources: Aalok Gaitonde, Amulya Nimmagadda, Amy Marconnetmuhammad mohamadNo ratings yet

- Optimal Design of Heating Elements Sheathed With INCOLOY Superalloy 800Document13 pagesOptimal Design of Heating Elements Sheathed With INCOLOY Superalloy 800Maxwel Silva DiasNo ratings yet

- Power Plant MaterialsDocument0 pagesPower Plant MaterialsAli KhalilNo ratings yet

- Radiographic Examination Report: Report No: Gtcl/Libra/Bkb800Mmscfd/Rt-0016 Client: Gas Transmission Company LTDDocument1 pageRadiographic Examination Report: Report No: Gtcl/Libra/Bkb800Mmscfd/Rt-0016 Client: Gas Transmission Company LTDMd Ashikur RahmanNo ratings yet

- Tie Bars Vs Dowel BarsDocument1 pageTie Bars Vs Dowel Barstally3tally100% (1)

- Potable Water Transport CartsDocument1 pagePotable Water Transport CartsProvincial AirwaysNo ratings yet

- Tensile and Chemical Analyses of Selected Steel Bars Produced in NigeriaDocument6 pagesTensile and Chemical Analyses of Selected Steel Bars Produced in NigeriaSalih MohayaddinNo ratings yet

- 64-2103 Tweco Smoke Master MIGDocument4 pages64-2103 Tweco Smoke Master MIGcarlosNo ratings yet

- Ship Construction and Structure by Azaruddin MominDocument147 pagesShip Construction and Structure by Azaruddin MominNaman joshi100% (2)

- PS-10-17 en AqDocument16 pagesPS-10-17 en Aq.xNo ratings yet

- Llave Wilson PDFDocument30 pagesLlave Wilson PDFC. Perez herreraNo ratings yet

- Xlpe Insulated Power Cables PDFDocument47 pagesXlpe Insulated Power Cables PDFsouheil boussaidNo ratings yet

- Spigot Product Spec Sheet 1614023137Document1 pageSpigot Product Spec Sheet 1614023137Cojuhari SergiuNo ratings yet

- Cold Rolling Mills CatalogDocument12 pagesCold Rolling Mills CatalogAshish GoyalNo ratings yet

- Sae 1080Document1 pageSae 1080bharathi_pmNo ratings yet

- AMS 2759-8 Ion NitridingDocument12 pagesAMS 2759-8 Ion NitridingIvy LiNo ratings yet

- The History of MoneyDocument5 pagesThe History of MoneyAdriana MartinsNo ratings yet

- ASTM Cross Reference Chart: Carbon SteelDocument1 pageASTM Cross Reference Chart: Carbon SteelMurat UzunNo ratings yet

- 1.6523 20nicrmo2-2 - Aisi 8620Document3 pages1.6523 20nicrmo2-2 - Aisi 8620zhenyupanNo ratings yet

- PolyGhard 2000Document3 pagesPolyGhard 2000Luis Felipe Dominguez RuizNo ratings yet

- Pipe FactsDocument30 pagesPipe FactsMekhmanNo ratings yet

- Fitter Sem3 TTDocument134 pagesFitter Sem3 TTPooja7 7No ratings yet

- L3-1 Drilling & Other Workshop ProcessesDocument27 pagesL3-1 Drilling & Other Workshop Processeskalahanmoonga82No ratings yet

- Day 34Document4 pagesDay 34Marcial Jr. MilitanteNo ratings yet

- Catalogo General KFDocument32 pagesCatalogo General KFMiguel FNo ratings yet

- Usw Review PaperDocument23 pagesUsw Review PaperRahul KumarNo ratings yet

- Cold Thermal Insulation SpecificationDocument13 pagesCold Thermal Insulation SpecificationCameliaNo ratings yet

- Chapter VI Inspection, Examination, and TestingDocument12 pagesChapter VI Inspection, Examination, and TestingFlorin TrNo ratings yet

- Powder Forged (PF) Ferrous Materials: Standard Specification ForDocument10 pagesPowder Forged (PF) Ferrous Materials: Standard Specification ForDanZel DanNo ratings yet

- CNC Lathe List: Item CK0640 CK0660 CK0680Document10 pagesCNC Lathe List: Item CK0640 CK0660 CK0680MUHAMMAD NAUMANNo ratings yet

- Rebar EngineeringDocument6 pagesRebar EngineeringSylvestre UbaNo ratings yet

- Rovalve Fig 215 Slide Gate Valve 2-24 InchDocument4 pagesRovalve Fig 215 Slide Gate Valve 2-24 InchCapacitacion TodocatNo ratings yet