Professional Documents

Culture Documents

Control Ball and Globe

Control Ball and Globe

Uploaded by

Arif FaturohmanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Control Ball and Globe

Control Ball and Globe

Uploaded by

Arif FaturohmanCopyright:

Available Formats

Technology Comparison of Control Ball and Globe Valves

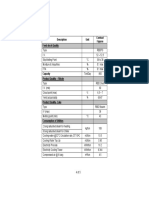

Attribute Control Ball Valve Globe Valve Advantage Reason

Quadratic (with characterization) Equal percent to design temp.

BAS controller expects flow

Flow Characteristics Linear (full port) Linear Globe

from valve at low signal

Delayed opening / early close-off Continuous from start

Fixed minimum flow results in 50:1 = 2% steps (HON) Small sizes are the most

Rangeability

1. Low TDR at low Cv 100:1 (Siemens claim) Globe common applications and

(turn-down ratio)

2. High TDR at high Cv Maximum 25:1 (JCI) need high TDR

Operating Differential 20 – 25 psid for characterized ports 20 – 25 psid for quiet operation 20+ psid is not typical of

——

Pressure (plate distortion) (cavitation at low flow) control valve applications

High with low Torque actuators Inversely proportional to Cv, and Globe is comparable

Close-Off Differential (water pressure aids sealing) proportional to actuator force in small sizes

Control Ball

Pressure

Capable of dead-heading pumps* Pressure balanced is high PB more expensive

ANSI Class IV (< 0.01% Cv) @ A port ANSI Class III w/ small metal seats Less leakage reduces

Seat Leakage (Does not apply to B port without ANSI Class IV with resilient seat and Control Ball energy use with chilled

seals) larger metal seated valves water

Resilient material on metal seat

Plated brass ball and stem Stainless steel ball and stem Long term performance

Trim

Brass plug on brass seat —— of ball valve in automatic

(internal construction)

control unknown

Rubber and Teflon stem O-rings Stainless steel plug on SS seat

Low pressure (full port only) Low pressure Greater versatility. Equal %

Steam Ratings Globe

—— High pressure flow available with globe

Lower installed cost with no

Cv Ratings Multiple Cv’s per valve size Multiple Cvs @ 1/2" size Ball

loss of control capability

Lower installed cost with no

Line Size Piping Line size piping with lower Cv Reducers often needed > 1/2" Ball

loss of control capability

1/2" – 3" Threaded 1/2" – 3" Threaded ANSI 150

Pipe Sizes 2-1/2" – 6" ANSI 125 and 250 Globe Wider applications

4" – 6" ANSI 125 Flanged

Flanged

Combo mixing/diverting Mixing models Easier to select. Piping

3-Way Body Styles Control Ball

B port seal required for tight close-off Diverting models different mixing & diverting

Low profile at large sizes Large profile at large sizes Control Ball

Physical Size Depends on application

APPENDICES

Relatively large in 1/2" pipe Small size in 1/2" pipe Globe

Floating/2-position, modulating Floating/2-position, modulating ——

Control Inputs Depends on application

Some pneumatic actuators available Large linear pneumatic installed base Globe

N/O or N/C by actuator position N/O or N/C up to 3" Globe needs higher power

Fail Safe Operation Control Ball

Stay-in-place Stay-in-place actuators

Requires unions for valve access B.V. must be removed

Valve Serviceability In-line serviceable Globe

VBN stems replaceable from piping

CE Preference Growing with time Well established Globe Familiar technology (habit)

Contractor Preference Valve comes with actuator Actuator selection separate Control Ball Easier to select

Actuator Selection Match valve and damper DCAs Requires linkage for DCAs Control Ball Added cost for globe valve

*Pumps require pressure cut-offs or supply-return differential pressure regulators to avoid pump seal damage and potential leakage that can result without flow-through. Unless

used in end-of-line-service, control valves do not need to close off against full pump head.

349

You might also like

- Ultra - 300lx Service ManualDocument577 pagesUltra - 300lx Service ManualKerri Puglisi Caputo100% (1)

- Eaton Vickers ValvesDocument16 pagesEaton Vickers ValvesJuan Miranda100% (1)

- Cargo Oil Pump TurbineDocument16 pagesCargo Oil Pump TurbineNikolay KirovNo ratings yet

- Anti Cavitation Low Noise Cage Guided Control Valve Series 1200Document15 pagesAnti Cavitation Low Noise Cage Guided Control Valve Series 1200Ibra HimNo ratings yet

- C Series: Cage Design Control ValvesDocument6 pagesC Series: Cage Design Control ValvesKuldeep28883No ratings yet

- Proportional Flow Controller Poppet Type, Pilot-Operated, Normally Closed SAE-16 Cartridge - 350 Bar PWS16Z-01Document2 pagesProportional Flow Controller Poppet Type, Pilot-Operated, Normally Closed SAE-16 Cartridge - 350 Bar PWS16Z-01Michał A.No ratings yet

- Vee-Ball Designs V150, V200 and V300 Noise AttenuatorDocument6 pagesVee-Ball Designs V150, V200 and V300 Noise AttenuatorDatt NguyenNo ratings yet

- Seawater Service Pressure Relief Valve: ModelDocument2 pagesSeawater Service Pressure Relief Valve: ModelHemant RasamNo ratings yet

- 2-Way Flow Regulator, Pressure Compensated, Restrictive Style SAE-8 Cartridge - 350 Bar SR08-01Document2 pages2-Way Flow Regulator, Pressure Compensated, Restrictive Style SAE-8 Cartridge - 350 Bar SR08-01controlorNo ratings yet

- V5011N Two-Way Threaded Globe Valve: FeaturesDocument2 pagesV5011N Two-Way Threaded Globe Valve: FeaturesPabloNo ratings yet

- Valve Style Typical Availability Advantages DisadvantagesDocument2 pagesValve Style Typical Availability Advantages DisadvantagesArunNo ratings yet

- Brouchers 13Document6 pagesBrouchers 13safie147No ratings yet

- E5991-8 pwk12120wpDocument2 pagesE5991-8 pwk12120wpMarius MihaescuNo ratings yet

- Masoneilan - 21000Document24 pagesMasoneilan - 21000ppsutorNo ratings yet

- Series: Control ValvesDocument24 pagesSeries: Control ValvesGUSTAVONo ratings yet

- K3VL Presentation 2010 MDDocument15 pagesK3VL Presentation 2010 MDHamza Lashin100% (2)

- King 7470 Series DatasheetDocument2 pagesKing 7470 Series DatasheetMacro MediciónNo ratings yet

- Standard Pilot Assisted Load ControlDocument28 pagesStandard Pilot Assisted Load ControlOscar GuaricalloNo ratings yet

- Pressure Compensator Spool Valve, Direct-Acting Normally Closed Metric Cartridge - 350 BarDocument4 pagesPressure Compensator Spool Valve, Direct-Acting Normally Closed Metric Cartridge - 350 BarPaulo ArrudaNo ratings yet

- Páginas Extraídas de ACV-ZW209FPDocument1 pagePáginas Extraídas de ACV-ZW209FPJesus BarriNo ratings yet

- Artificial Lift - DMDocument34 pagesArtificial Lift - DMkrishNo ratings yet

- BHMN 21000 FS 31096C 0720 EnglishDocument2 pagesBHMN 21000 FS 31096C 0720 EnglishivomNo ratings yet

- Shear-Seal Directional Control Valve: Series 9000, 9020Document2 pagesShear-Seal Directional Control Valve: Series 9000, 9020francis_15inNo ratings yet

- By Pass (Valv Press Diff) RV18 & RV19Document2 pagesBy Pass (Valv Press Diff) RV18 & RV19Sergio DjbucaneroNo ratings yet

- Belimo B313 LRQX24-MFT Assembly En-UsDocument6 pagesBelimo B313 LRQX24-MFT Assembly En-UsRafael Souza PimentaNo ratings yet

- FCC Series 11 High Pressure Globe Control ValvesDocument15 pagesFCC Series 11 High Pressure Globe Control ValvesBASKARNo ratings yet

- Acv ZW205FPDocument3 pagesAcv ZW205FPSamy El-BeheryNo ratings yet

- Resilient Seated: CommercialDocument25 pagesResilient Seated: Commercialagung wijayaNo ratings yet

- Gea 31096 Masoneilan 21000 Series Valve Fact SheetDocument2 pagesGea 31096 Masoneilan 21000 Series Valve Fact SheetsaravananbscelecNo ratings yet

- API STD 53 Degasser Inspection RequirementsDocument1 pageAPI STD 53 Degasser Inspection RequirementsTerry SmithNo ratings yet

- D-Eeprb: 210 Bar - 75 LPMDocument2 pagesD-Eeprb: 210 Bar - 75 LPMhamdaNo ratings yet

- D Eeprb PDFDocument2 pagesD Eeprb PDFhamdaNo ratings yet

- Tom Wheatley Piston Check Valves BrochureDocument8 pagesTom Wheatley Piston Check Valves BrochureRandiRahmansyahNo ratings yet

- Model ZW209: Pressure Reducing ValveDocument4 pagesModel ZW209: Pressure Reducing ValveHai PhanNo ratings yet

- Pneumatically Operated With Manual Reset Deluge Valve For Freshwater and Seawater ServiceDocument2 pagesPneumatically Operated With Manual Reset Deluge Valve For Freshwater and Seawater ServicedmitosNo ratings yet

- Check Valve Poppet Type Metric Cartridge - 350 Bar: Features FunctionDocument2 pagesCheck Valve Poppet Type Metric Cartridge - 350 Bar: Features FunctionDyna ClementeNo ratings yet

- 62-3078 3-Way ValveDocument4 pages62-3078 3-Way Valvesantosh yadavNo ratings yet

- HBE Anti FlashDocument3 pagesHBE Anti Flashinsult2injuryNo ratings yet

- Lmsection E6x060Document2 pagesLmsection E6x060Ηρακλης ΤσαπραζηςNo ratings yet

- Pressure Reducing - Relieving Valve PRFBDocument3 pagesPressure Reducing - Relieving Valve PRFBkocho79No ratings yet

- Piston Pump L09HVDocument2 pagesPiston Pump L09HVNOEL RODRIGUEZNo ratings yet

- Belimo B312B LRB24-SR Assembly En-UsDocument4 pagesBelimo B312B LRB24-SR Assembly En-UsDavid Martínez CarranzaNo ratings yet

- Valvula Neumatica Honeywell PC1Document8 pagesValvula Neumatica Honeywell PC1DAVIDNo ratings yet

- Models and SpecificationsDocument12 pagesModels and SpecificationsVentas AntofagastaNo ratings yet

- الباب الخامس مجارى الهواءDocument2 pagesالباب الخامس مجارى الهواءAbd AlhadiNo ratings yet

- Valve Selection PDFDocument5 pagesValve Selection PDFKamil MarszałekNo ratings yet

- 3-Way Flow Control Valves: 1 DescriptionsDocument6 pages3-Way Flow Control Valves: 1 Descriptionsmuhammad taufik rahmanNo ratings yet

- Needle Valves With and Without Reverse Flow Check Direct-Acting Inline Mounted - 350 Bar DV, DRV 20 To 40Document4 pagesNeedle Valves With and Without Reverse Flow Check Direct-Acting Inline Mounted - 350 Bar DV, DRV 20 To 40justice judgeNo ratings yet

- EG Valve Abbreviations SheetDocument1 pageEG Valve Abbreviations Sheetemadsafy20002239No ratings yet

- E BrochureDocument16 pagesE BrochureSankar sankarNo ratings yet

- Controlair Condensed CatalogueDocument6 pagesControlair Condensed CatalogueleandroNo ratings yet

- 2-And 3-Way Flow Control Valves: Series SR3CDocument8 pages2-And 3-Way Flow Control Valves: Series SR3CEbrahim AhmariNo ratings yet

- CT WKM Powrseal GateDocument28 pagesCT WKM Powrseal GatemoonanbuNo ratings yet

- Ekomat - WE4 10 Englisch PDFDocument10 pagesEkomat - WE4 10 Englisch PDFharianaNo ratings yet

- Electric Actuated Butterfly Valves: FeaturesDocument7 pagesElectric Actuated Butterfly Valves: FeaturesRicardo NapitupuluNo ratings yet

- Three-Way Threaded Globe Valve: FeaturesDocument4 pagesThree-Way Threaded Globe Valve: FeaturesmegdadNo ratings yet

- Data Sheet Avdo Automatic By-Pass Valve: ApplicationDocument4 pagesData Sheet Avdo Automatic By-Pass Valve: ApplicationganaaNo ratings yet

- Rate of Flow and Fuel Shut Off Valve: ModelDocument2 pagesRate of Flow and Fuel Shut Off Valve: Modelanon_867776278No ratings yet

- Metering Pumps: Ordering InformationDocument4 pagesMetering Pumps: Ordering InformationMohamed ImranNo ratings yet

- VT-BAYARD-Automatic Control Valves-FloatDocument8 pagesVT-BAYARD-Automatic Control Valves-Floatsiva ramakrishnanNo ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- ANSI Flange Pressure Temperature Reference ChartDocument1 pageANSI Flange Pressure Temperature Reference ChartArif FaturohmanNo ratings yet

- A. For DF Plant IV60: Description Unit Contract Figures Feed-Stock QualityDocument1 pageA. For DF Plant IV60: Description Unit Contract Figures Feed-Stock QualityArif FaturohmanNo ratings yet

- King IcariaDocument1 pageKing IcariaArif FaturohmanNo ratings yet

- Catalog Elpro Tray LadderDocument104 pagesCatalog Elpro Tray LadderArif Faturohman0% (1)

- Vibration Acceptance CriteriaDocument2 pagesVibration Acceptance Criteriairfanajai100% (1)

- Expansion Loop Sizes For Steel PipeDocument1 pageExpansion Loop Sizes For Steel PipeArif FaturohmanNo ratings yet

- Write Your Own OS KernelDocument32 pagesWrite Your Own OS KernelArif FaturohmanNo ratings yet

- Properties of Saturated SteamDocument4 pagesProperties of Saturated SteamArif FaturohmanNo ratings yet

- IP ClassificationDocument1 pageIP ClassificationArif FaturohmanNo ratings yet

- 2 Phase Stepper Motor PDFDocument2 pages2 Phase Stepper Motor PDFArif FaturohmanNo ratings yet

- Stepper Motor 28BJY 48 DatasheetDocument8 pagesStepper Motor 28BJY 48 DatasheetArif FaturohmanNo ratings yet

- Catalog Elpro Tray LadderDocument104 pagesCatalog Elpro Tray LadderArif Faturohman0% (1)

- Proper Grounding BondingDocument46 pagesProper Grounding BondingArif FaturohmanNo ratings yet

- Pump Calculations, Pump EquationsDocument3 pagesPump Calculations, Pump EquationsSpataru Marius0% (2)

- Proc Eng P&I DDocument60 pagesProc Eng P&I DGiang T LeNo ratings yet

- Data Sheet: Manifolds/Collectors and Hydraulic Pressure BalancersDocument4 pagesData Sheet: Manifolds/Collectors and Hydraulic Pressure BalancersHutan CatalynNo ratings yet

- Modeling Reference - Hydropneumatic TanksDocument19 pagesModeling Reference - Hydropneumatic Tankspca97No ratings yet

- Cummins Isde270 30 So40217 Parts CatalogueDocument10 pagesCummins Isde270 30 So40217 Parts CatalogueChen Caroline100% (1)

- WD Bredel 25 32 enDocument2 pagesWD Bredel 25 32 enMario CalvisiNo ratings yet

- Disassembly and Assembly: 2506-15 Industrial EngineDocument16 pagesDisassembly and Assembly: 2506-15 Industrial Engineمحمد اگریگوNo ratings yet

- Bomba Remachadora TKRDocument36 pagesBomba Remachadora TKRCarol CastillloNo ratings yet

- Drilling Fluids Technology Drilling FluidesDocument27 pagesDrilling Fluids Technology Drilling FluidesSouadHadjadjNo ratings yet

- p1 PD XL Service Lte 00062 3 C 0707 075 100 140Document42 pagesp1 PD XL Service Lte 00062 3 C 0707 075 100 140Bernardo Orozco LariosNo ratings yet

- Hvac1 Cond Pump 2004Document4 pagesHvac1 Cond Pump 2004maheshNo ratings yet

- Flow Measurement in Closed ConduitDocument65 pagesFlow Measurement in Closed ConduitjohnmayardNo ratings yet

- Holmatro Rescue Tools en 0917 LRDocument40 pagesHolmatro Rescue Tools en 0917 LRForum PompieriiNo ratings yet

- Hydrulic PressDocument3 pagesHydrulic PressShubhamNo ratings yet

- September 2011 IssueDocument102 pagesSeptember 2011 IssuePumper MagazineNo ratings yet

- Concrete Volute PumpsDocument8 pagesConcrete Volute PumpsvijayunityNo ratings yet

- Clayton Boiler PresentationDocument41 pagesClayton Boiler Presentationanon_297844545No ratings yet

- Operators Manual: Artificial LiftDocument25 pagesOperators Manual: Artificial LiftSam Ruge100% (1)

- JET 08 Cement Heads v1-1 2009 July 24 ForWeb 4127832 01 PDFDocument100 pagesJET 08 Cement Heads v1-1 2009 July 24 ForWeb 4127832 01 PDFOmkarGhori100% (1)

- G-Tech Rotary Lobe Pump OIM Manual PDFDocument23 pagesG-Tech Rotary Lobe Pump OIM Manual PDFGiorgiana Rosu100% (1)

- 30 Pneumatic Conveyors: Rs 110 Pneumatic Screw Pumps (FK Pumps)Document3 pages30 Pneumatic Conveyors: Rs 110 Pneumatic Screw Pumps (FK Pumps)Dilnesa EjiguNo ratings yet

- Manual Triplex PumpDocument45 pagesManual Triplex PumpSalineñoApasionado100% (1)

- 09 - 10 E Pumps PDFDocument8 pages09 - 10 E Pumps PDFWedneslao LopezNo ratings yet

- Friction Loss On SuctionDocument2 pagesFriction Loss On SuctionSathish LingamNo ratings yet

- Resolution MEPC 107Document33 pagesResolution MEPC 107rakis9069No ratings yet

- Kamatsu Pc228us Uslc-3e0Document8 pagesKamatsu Pc228us Uslc-3e0Piotr Gabryś Hi-this100% (2)

- V18N3 PDFDocument20 pagesV18N3 PDFMechanicNo ratings yet

- Pa34 Seneca 3 CheckDocument4 pagesPa34 Seneca 3 CheckMilanDronjakNo ratings yet