Professional Documents

Culture Documents

JHA Bolting Unbolting and Manual Lifting

JHA Bolting Unbolting and Manual Lifting

Uploaded by

Eric Ting100%(1)100% found this document useful (1 vote)

220 views4 pagesJHA Bolting Unbolting and Manual Lifting

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentJHA Bolting Unbolting and Manual Lifting

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

100%(1)100% found this document useful (1 vote)

220 views4 pagesJHA Bolting Unbolting and Manual Lifting

JHA Bolting Unbolting and Manual Lifting

Uploaded by

Eric TingJHA Bolting Unbolting and Manual Lifting

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 4

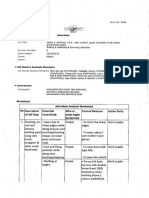

Job Hazard Analysis

Serial No:

Page | of 4

9240

UPSTREAM AREA NON MODULAR TIGA DOSH S/D ~ TO DO BOLTING & UNBOLTING

(INCL, SPADING & DE-SPADING) AND MANUAL LIFTING ACTIVITIES FOR ROSE

status: Submitted

yinfo

Job Tt

UNIT.

Revision Number 1

Date Created: o2jo9/2014

owner PDD/é

Author

¥ Job Hazard Analysis Members

Job Hazard Analysis Members Chai Set Lee (PLM/MLNG); Zainuddin Lili (PLM/MLNG); Sigo Sadok-Ilysse 6

Abdullah (PLM/MLNG); Michel Mering (PLM/MLNG); M Subki 8 Ahmad Fadzil

(PLM/MLNG); Farid Faliq Shukel (PLM/MLNG); M Aizam Mansor (PLM/MLNG); Lim

Hun Pin (PLM/MLNG); Tang Hing Tung (PLM/MLNG); Farah Bt Esran

(PLM/MLNG); Lim Chen Fong (PLM/MLNG)

Contractors

contractors: MAYSVILLE SON BHD

Worksheet

Job Hazard Analysis worksheet

No. ription of Job Step Potential ‘Who or what Control Measure Action

hazardiisk might be harmed Party

7 Manual bolting/ unbolting and\rong/ missed [Plant & Confirm with area WWSAWL

lservice stud bolts uit spading personnel perator prior to start

points land completion of work larea

(a) Spading, de-spading & perator

Ensure flange to be

hecking joints tightness fest noe cea

|b) Vessel & Strainers ag

lc) Rvs Verity tag from the

Ispade list drawing

|a) Spools & covers and etc Sudden release Workers and} Venting completely WL

[& presence of [properties nd N2 purge

hydrocarbon’ Area

(2) Pipe spool Verified gas test by [Operator

eT

KO) Heat exchangers I | |

Use copper hammer

(during non-gas free

ndition or advise by

ea Operator)

hitps://pww.sabahapps.petronas.com.my/nextg/mlng/jsa/Lists/Job%20Safety%20Analysis/P... 9/2/2014

Job Hazard Analysis, Page 2 of 4

jelease of trap [Workers To confirm system is hL

ressure ully Isolated

free

Double block and perator

bieed where applicable.

Slow break opening of

anges wedges open

the side opposite the

sssing area

IManual hers [To ensure correct SAL

handling, lposture during

swkwrard posturel botting/unbolting

lctivities

To ensure correct tools

the job

To conduct toolbox talk

job.

‘alling tools, boltWorkers and To use "Ready for WL

farespaear” [oma

Secure tools with

janyards.

Use canvas sheet

indemneath,

Loose tools keep in

container.

Barricades work area

ith proper signage at

ound level

Fiying particles [Personnel Barricade work area, \WWSIWL

No unauthorized entry

Use correct rated

hammer for the bolt.

gemnant fluids [Environment | To place adrip pan }WSIWL

lunderneath spade point

(0 contain any remnant

ids.

Collect and put into

jesignated drum with

[Tripping hazard [Personnel Arrange tools and WL

pading, blind at safe

jistance.

| t

https://pww.sabahapps.petronas.com.my/nextg/mlng/jsa/Lists/Job%20Salety%20Analysis/P.... 9/2/2014

Job Hazard Analysis

Housekeeping at all

imes

‘Secure heavy and

ylindrical equipment

paso at

jovement / dropping

Page 3 of 4

2. |Lift, remove and install

f2) spool, hand hole cover,

hannel head & cover using

Imanual handling and chain

block

|!) Spades & spectacle blinds

Pinch point

rkers

Coordinate work,

ymmunicate in correct

jork sequence,

Koad under

nsion

(material fall

rom height)

rkers

Use cerified and

1pproved lifting gear

ind pulling gear with

correct SWL (purple

olor)

Competent rigger to

handle during lifting

fork

Barricade with proper

event un-authorized

ym entry

jnage the work area to]

WSL

Fall from height

rkers

To attend "WAH"

raining

Use "Ready for Use"

|caffola.

Use body harness.

(EN361 harness and

E1019 lanyard) and

sure 100% tie-off

nen working > 2

Imeters

Secure tools with

lanyard tie to permanent

structure.

Barricade work area

ind proper signage

SAL

GENERAL REQUIREMENTS.

1, Conduct Toolbox Talk prior to work start via PTW and JHA.

2. Ensure housekeeping is done at the end of work daily:

Reviewed by

https://pww.sabahapps.petronas.com.my/nextg/mIng/jsa/Lists/Job%20Safety%20Analysis/P... 9/2/2014

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- PDFDocument48 pagesPDFEric Ting100% (1)

- Ok-Venting & Charging of Nitrogen Accumulator at Terminal AreaDocument3 pagesOk-Venting & Charging of Nitrogen Accumulator at Terminal AreaEric TingNo ratings yet

- Ok-Hydraulic Oil Flushing at Terminal AreaDocument4 pagesOk-Hydraulic Oil Flushing at Terminal AreaEric TingNo ratings yet

- 4066-To Perform Hot Work Activities (Welding, Oxy Cutting, Grinding, Cutting, Heat Gun andDocument3 pages4066-To Perform Hot Work Activities (Welding, Oxy Cutting, Grinding, Cutting, Heat Gun andEric TingNo ratings yet

- 3922-MDR Project - Installation and Relocation Reposition of Lighting Fixture Including Testing at Module 5 PDFDocument3 pages3922-MDR Project - Installation and Relocation Reposition of Lighting Fixture Including Testing at Module 5 PDFEric TingNo ratings yet

- Petronas Technical Standards: Preparation of Process Flow Schemes and Process Engineering Flow SchemesDocument19 pagesPetronas Technical Standards: Preparation of Process Flow Schemes and Process Engineering Flow SchemesEric TingNo ratings yet

- Tank Info PDFDocument8 pagesTank Info PDFEric TingNo ratings yet

- JHA Bolting & Unbolting & Servicing ActivitiesDocument5 pagesJHA Bolting & Unbolting & Servicing ActivitiesEric TingNo ratings yet

- DOSH Shutdown RolesDocument4 pagesDOSH Shutdown RolesEric TingNo ratings yet

- Fired Boilers: 2.1 Design PrinciplesDocument6 pagesFired Boilers: 2.1 Design PrinciplesEric TingNo ratings yet

- Petronastechnicalstandards: Pipe SupportsDocument41 pagesPetronastechnicalstandards: Pipe SupportsEric TingNo ratings yet

- Em Piping ClassDocument25 pagesEm Piping ClassEric TingNo ratings yet

- Hempadur Multi-Strength GF 3587910170 En-UsDocument11 pagesHempadur Multi-Strength GF 3587910170 En-UsEric TingNo ratings yet

- The Rusty Chronicle - Issue 10 December 2005Document47 pagesThe Rusty Chronicle - Issue 10 December 2005Eric TingNo ratings yet