Professional Documents

Culture Documents

DIN 82 Randalinare PDF

DIN 82 Randalinare PDF

Uploaded by

tamasraduOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DIN 82 Randalinare PDF

DIN 82 Randalinare PDF

Uploaded by

tamasraduCopyright:

Available Formats

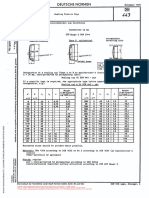

UDC 681.945 DEUTSCHE NORMEN 免费标准网(www.freebz.

net)

January 1973 标准最全面

I EN

Knurls

Rändel

I

I

82

Dimensions i n mm

Manufacturing methods using

Denomination and representation h u r l i n g r o l l s according t o DIN 403

Knurl with grooves p a r a l l e l t o axia Knurl RAA

--`,,,,``,,`,`,,,`,`,```````,``-`-`,,`,,`,`,,`---

Detail T Workpie

i

t

c

--IA Section A-A

I

0 Knurling r o l l AA

o

Knur? RAA Knur? RAA

drkpiece 4 lorkpie Workpiec

A

I

Knurling r o l l BL \

Knurling roll^

s w i v e l l e d 30°,

e w i v e l l e d 30'

Left-hand h u r l Section B-6

Workpie

.-E

c

C Knurling r ó l l BR Knurl& r o l l AA

.-cm Workpiece

s w i v e l l e d 30°

- 2

3

2 Knurl RBR

x n

€BR

dorkp

KnurlingI roll BL \

Knurling r o l l AA

s w i v e l l e d 30°

-

Continued on pages 2 to 4

Explanations on page 4

Alleinverkauf der Normblätter durch Beuth VerlagGmbH, Berlin 30 und Köln DIB 82 engl. Preisgr.

免费标准网(www.freebz.net) 无需注册 即可下载

免费标准网(www.freebz.net) 标准最全面

PaEe 2 DIN 82

Manufacturing methode using

m Denomination arid repreeentation b u r l i n g r o l l e according t o DIN 40:

- Leit-hand/rigùt-hand h u r l , pointe raised' )

Section 0-0

RGE

üoripie ce

I

Knurling roll 81 hurling roll11

swivelled 30'

Leit-hand/right-hand hurl, pointe indented*)

Section F-F

section G-G Knurl RGV

1

Detail x

RGU

Workpi

/

burling roll GE

Yorkpiec.

-4G

-

--`,,,,``,,`,`,,,`,`,```````,``-`-`,,`,,`,`,,`---

Croes-knurl, points raised

Section H-H

Knurl RKE

/

tKE Y

Detail Sec tion J-J

U

J

/

Uorkp iec e hurling r o l l KV

--i

J

-

'1 Previous denomination "Diamond hurling"

2 , Previous denomination "Negative diamond hurling"

免费标准网(www.freebz.net) 无需注册 即可下载

免费标准网(www.freebz.net) 标准最全面

D I N 82 Page 3

Denomination and representation Manufacturing methods using

h u r l i n g r o l l s accordingtoDIN 405

Cross-knurl, p o i n t s indented

Section K- K

Knurl RKV

I

Section L-L

Workpi

/

Knurling r o l l KE

Designation of a left-hand/right-hand

(08):

knurl, p o i n t s r a i s e d (Type RGE) with p i t c h t

Knml RGE 08 DIN 82

- 0.8 mm

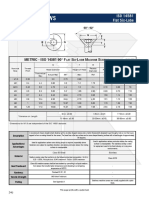

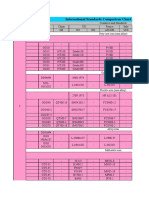

2. Dimensions

-----------_---

2.1. P r o f i l e an&

P r o f i l e angle a

90°.

.,

I f necessary, knurls can a l s o be made with p r o f i l e angle a 105O. i n t h i s case, t h e designa- -

t i o n reads, e. f o r a left-hand/rlght-hand

t = 0.8 mm (087 and p r o f i l e angle a 105O (105):

Knurl RGE O8 105 D I N 82

-

knurl, pointe r a i s e d (Type RGE) with p i t c h

-

'Po minimize t h e number of lmurling r o l l e required f o r making t h e knurls, t h e knurl p i t c h e s t

are l i m i t e d t o t h e nominal values

0.5 0.6 0.8 1 1.2 1.6 m.

The nominal diameter d l s t a t e d i n t h e workshop drawing i s the outside diameter of t h e fin-

ished knurl; t h i s dimension i s a function of the design.

---------------------

2.4. I n i t i a l diameter d2

The i n i t i a l diameter d of t h e workpiece p r i o r t o h u r l i n g muet be smaller than the nominal

diameter d l , because t i e i n i t i a l diameter undergoes enlargement through displacement of t h e

m a t e r i a l during the h u r l i n g operation.

The i n i t i a l diameter d2 for h u r l e with p r o f i l e angle a = 90° can be c a l c u l a t e d from t h e f o r -

mulae i n t h e Table below, depending on t h e type of knurl and t h e s i a e of pitch.

The f a c t o r s i n the fonuulae, however, do n o t take i n t o account t h e rounding of t h e grooves

r e s u l t i n g from t h e h u r l i n g operation or t h e s p e c i f i c p r o p e r t i e s of the materiale t o be

knurled.

Type of k n u r l

I I n i t i a l diameter

d2- I

RAA Knurl v i t h grooves parallel t o axis

RBL Left-hand k n u r l d l -0,5 t

RBR Right-hand k n u r l

RGE Left-hand/right-hand knurl, p o i n t s d l -0.67 t

raised

RGV Left-hand/right-hand knurl, p o i n t s dl -0.33 t

indented

RKE Cross-knurl, p o i n t s r a i s e d d l -0,67 t

I RKV Cross-knurl, p o i n t s indented I d l -0.33 t I

--`,,,,``,,`,`,,,`,`,```````,``-`-`,,`,,`,`,,`---

免费标准网(www.freebz.net) 无需注册 即可下载

免费标准网(www.freebz.net) 标准最全面

Page 4 DIB 82

References to further etandards

DIB 403 h u r l i n g rolls

DIB 8583 Sheet 5 Production method compression foming; inipreeaing, c l a s s i f i c a t i o n , defini-

tions

Explanations

Compared with t h e January 1940 issue of DIN 82, t h e standard denomination "knurl" has been adopted f o r

a l l types, s i n c e t h e previous denominations "diamond knurling" and "negative diamond knurlíng" vere not

used c o n a i a t e n t l y , and hence d i f f i c u l t i e a a r o s e i n t h e choice of toola. Some type8 of knurl have been

given b r i e f e r denominations, auch ea left-hand h u r l , right-hand k n u r l , left-hand/right-hand b u r l .

The type l e t t e r symbols assigned t o t h e various types provido both for b e t t e r d i f f e r e n t i a t i o n and a l s o

y i e l d a code deaienation f o r use in e l e c t r o n i c d a t a processing. The l e t t e r R d i f f e r e n t i a t e s t h e b u r l a

-

Zrom t h e h u r l i n g r o l l e (aee DIN 403). t h e second l e t t e r (A, E, (i and K) d e s i g n a t e s t h e b a s i c type.

v h i l e t t h e t h i r d l e t t e r (A p a r a l l e l t o axia, L

marks t h e d i r e c t i o n and form of t h e groovea.

-

left-hand, E right-hand, E - -

raised, Y -

indented)

The h e l i x cingle o f Types BB, BL. GE and QV is f i x e d a t standard value of .

'03 The p r o f i l e an&e is

-

n o m a l l y a = 90°, but, I f necessary, knurls with a p r o f i l e a = 10.50 giving a s h a l l o u e r depth can -

The p i t c h t -

be made. This s p e c i a l c a s e must be s t a t e d in t h e designation.

2 mæ has been discontinued becauBe it is s c a r c e l y uaed in p r a c t i c e . S i m i l a r l y , no attempt

haa been made t o c o r r e l a t e p i t c h v i t h uorkpiece diameter, s i n c e recommendations made e a r l i e r have n o t

proved s u i t a b l e i n a11 f i e l d s of a p p l i c a t i o n and hence t h s i r adoption in a c t u a l p r a c t i c e has been l i m -

ited.

Formulae f o r c a l c u l a t i n g t h e i n i t i a l diameter of t h e workpiece a s a function of t h e type of k n u r l and

of t h e o u t s i d e diameter of t h e f i n i s h e d h u r l , which counts as t h e nominal diameter, a r e given. The re-

s u l t s obtained a r e only r e f e r e n c e values. however, s i n c e t h e s p e c i f i c p r o p e r t i e s of t h e m a t e r i a l s hare

not been taken i n t o account.

To f a c i l i t a t e t h e ChOOBing of h u r l i n g r o l l e aCCOrdin& t o DIN 403, t h e manufacturing methods s u i t a b l e

f o r each type of b u r l are indicated.

--`,,,,``,,`,`,,,`,`,```````,``-`-`,,`,,`,`,,`---

免费标准网(www.freebz.net) 无需注册 即可下载

You might also like

- Din332 PDFDocument4 pagesDin332 PDFmateo100% (2)

- Din 50979Document14 pagesDin 50979Bangali Singh100% (4)

- Asme B94.6-1984 (2014)Document24 pagesAsme B94.6-1984 (2014)Sevuga Rajan100% (1)

- Din 267 - 27Document18 pagesDin 267 - 27Ricardo Vitoriano100% (2)

- Asme B1.3-2007 (2017)Document24 pagesAsme B1.3-2007 (2017)jamie courney100% (1)

- DIN 76-1 - (2004) - Thread Run-Outs and Thread Undercuts For ISO Metric Threads As in DIN 13-1 PDFDocument5 pagesDIN 76-1 - (2004) - Thread Run-Outs and Thread Undercuts For ISO Metric Threads As in DIN 13-1 PDFnoraafshin100% (2)

- Din 13-1Document4 pagesDin 13-1Sankha Dasgupta100% (3)

- Din 443 PDFDocument1 pageDin 443 PDFLuciano Fontes100% (1)

- Din 8062-3 2009 PDFDocument10 pagesDin 8062-3 2009 PDFkoalaboi25% (4)

- Din 6930-2Document1 pageDin 6930-2murniNo ratings yet

- Asme B1.2 - 1983 PDFDocument189 pagesAsme B1.2 - 1983 PDFKristin Jones100% (1)

- Din 475Document4 pagesDin 475Sinan Chen100% (1)

- DT40 PDFDocument34 pagesDT40 PDFFrancisco Carlos TelesNo ratings yet

- Iso 1502 1996Document12 pagesIso 1502 1996Emaculata Monalisa0% (1)

- Knurling Profiles DIN 82Document3 pagesKnurling Profiles DIN 82mirzasinanovic100% (1)

- Iso 14581 CSK ScrewDocument1 pageIso 14581 CSK ScrewMitesh MakvanaNo ratings yet

- Cold Bending DIN 6935 (Eng)Document4 pagesCold Bending DIN 6935 (Eng)maik angelo0% (2)

- DIN125ADocument1 pageDIN125AManoj PatilNo ratings yet

- WX 100Document17 pagesWX 100anon_967426204100% (1)

- Din 6799Document1 pageDin 6799MarcoAntonioNo ratings yet

- BS en 12329 PDFDocument21 pagesBS en 12329 PDFSenthil Kumar GanesanNo ratings yet

- BS 57 (1951)Document23 pagesBS 57 (1951)dapsiduNo ratings yet

- Din 928 en PDFDocument1 pageDin 928 en PDFroyroverNo ratings yet

- IFI 2018 Book of Fastener Standards - TOCDocument7 pagesIFI 2018 Book of Fastener Standards - TOCMahmoud Al Homran0% (2)

- Ford Worldwide Fastener Standard: Printed Copies Are UncontrolledDocument7 pagesFord Worldwide Fastener Standard: Printed Copies Are Uncontrolledferhat aydoganNo ratings yet

- Din 8140-1 PDFDocument13 pagesDin 8140-1 PDFOSCAR VALENCIANo ratings yet

- Din en Iso 7089 2000-11Document8 pagesDin en Iso 7089 2000-11REKHANo ratings yet

- 6935 2011Document13 pages6935 2011Tufan Ünal100% (4)

- Douglas UFO DocsDocument275 pagesDouglas UFO DocsAndrew JohnsonNo ratings yet

- ISO 14583-01 - Hexalobular Socket Pan Head ScrewsDocument8 pagesISO 14583-01 - Hexalobular Socket Pan Head ScrewsGuillermo TorresNo ratings yet

- Iso 7379Document2 pagesIso 7379Ahmed ElsafouryNo ratings yet

- Hexagon Socket Button Head Screw With Flange - IsO 7380-2Document9 pagesHexagon Socket Button Head Screw With Flange - IsO 7380-2Corneliu VilcuNo ratings yet

- Metric DIN 137 SpecDocument5 pagesMetric DIN 137 Specpradipbhosale81No ratings yet

- Din 8140-1Document5 pagesDin 8140-1main46prairieNo ratings yet

- Din 5480Document27 pagesDin 5480MiguelNo ratings yet

- Coating Standards-OverviewDocument10 pagesCoating Standards-Overviewwelington volpatto100% (1)

- Iso 2338Document6 pagesIso 2338stanyeah100% (2)

- ISO4762Document14 pagesISO4762Royal Mech (King)No ratings yet

- Din 13Document1 pageDin 13dedosimoesNo ratings yet

- Jis G4052-1979Document39 pagesJis G4052-1979RanjithkumarNo ratings yet

- Foreword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BDocument4 pagesForeword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BMarcelo KleinNo ratings yet

- International Standard: Cylindrical Gears For General and Heavy Engineering - Standard Basic Rack Tooth ProfileDocument10 pagesInternational Standard: Cylindrical Gears For General and Heavy Engineering - Standard Basic Rack Tooth ProfileGonzalo_Fernandez84100% (1)

- DIN 137 Type A, Spring Washers, CurvedDocument2 pagesDIN 137 Type A, Spring Washers, CurvedSteve1108No ratings yet

- Din 472 1981-09 PDFDocument12 pagesDin 472 1981-09 PDFSenthil Kumar GanesanNo ratings yet

- Din en 1561Document21 pagesDin en 1561Daniela Barbu100% (2)

- Iso 7380Document1 pageIso 7380Nisa_nisheNo ratings yet

- Din 13-51Document1 pageDin 13-51anks_raNo ratings yet

- EN1A - Mild SteelDocument2 pagesEN1A - Mild SteelSuyash TambeNo ratings yet

- DIN 7349 - Arruela Plana PDFDocument1 pageDIN 7349 - Arruela Plana PDFpierocarnelociNo ratings yet

- Din 933Document2 pagesDin 933Sugumar0% (1)

- Helical Coil Screw Thread Inserts: Free Running and Screw Locking (Metric Series)Document30 pagesHelical Coil Screw Thread Inserts: Free Running and Screw Locking (Metric Series)Joel Cielto100% (1)

- Artigo Stave de Ferro Fundido 1976Document14 pagesArtigo Stave de Ferro Fundido 1976Gabriel MáximoNo ratings yet

- Lammeren W P A.Wageningen B-Screw S.1969.TRANS PDFDocument49 pagesLammeren W P A.Wageningen B-Screw S.1969.TRANS PDFStefanoNo ratings yet

- A Simple Method For The Selection of Axial Fan Blade ProfilesDocument7 pagesA Simple Method For The Selection of Axial Fan Blade ProfilesVigiiNo ratings yet

- Tonar Katalog 0-11sDocument10 pagesTonar Katalog 0-11schampionNo ratings yet

- Sulzer 6rlb76 Me Diesel Engines SulzerDocument300 pagesSulzer 6rlb76 Me Diesel Engines SulzerJoseph AbrahamNo ratings yet

- Deburring Catalog 2011Document30 pagesDeburring Catalog 2011WVPNo ratings yet

- Investigations On Partial Penetration Welded NozzleDocument15 pagesInvestigations On Partial Penetration Welded NozzleAndres_Pastor1987No ratings yet

- Imi022 David Brown Technical Service Bulletins & Parts Bulletins Part 1Document151 pagesImi022 David Brown Technical Service Bulletins & Parts Bulletins Part 1Mauro SantanaNo ratings yet

- Making and metaphor: A discussion of meaning in contemporary craftFrom EverandMaking and metaphor: A discussion of meaning in contemporary craftGloria A. HickeyNo ratings yet

- Casting ProcessDocument72 pagesCasting ProcessFRO MusicNo ratings yet

- Sheet Metal OperationsDocument27 pagesSheet Metal OperationsbmvinayNo ratings yet

- Metal Forming Practise: SpringerDocument7 pagesMetal Forming Practise: SpringerHamed Okaf100% (1)

- Thread Geometry - Metric CoarseDocument4 pagesThread Geometry - Metric CoarseMociran FlorinNo ratings yet

- 08 Casting - ForgingDocument35 pages08 Casting - ForgingomkardashetwarNo ratings yet

- Design Optimization of Gating and FeedinDocument9 pagesDesign Optimization of Gating and FeedinJoao LuisNo ratings yet

- Metal-Casting Tomo 15Document8 pagesMetal-Casting Tomo 15CamilaAndreaGrijalbaNo ratings yet

- Caparo Price ListDocument20 pagesCaparo Price ListkutbiahtNo ratings yet

- Scew Thread IndexDocument3 pagesScew Thread IndexRyszardZNo ratings yet

- Me 333 - CastingDocument30 pagesMe 333 - CastingFarhan HasinNo ratings yet

- MU07 Rosca Americana Fina Unf Tecem PDFDocument1 pageMU07 Rosca Americana Fina Unf Tecem PDFmarcosNo ratings yet

- Broken Screw Removal SystemDocument16 pagesBroken Screw Removal SystemDJGGNo ratings yet

- Fed STD H28 20BDocument30 pagesFed STD H28 20BL FNo ratings yet

- DjjfsdhfjsDocument1 pageDjjfsdhfjsshreya patilNo ratings yet

- Hexagon Socket-Head Shoulder Screws: Fit: f9 Bare Steel 012.9Document1 pageHexagon Socket-Head Shoulder Screws: Fit: f9 Bare Steel 012.9HariNo ratings yet

- ForgingDocument58 pagesForgingSamir Bose100% (4)

- Compression Molding Is A Method ofDocument4 pagesCompression Molding Is A Method ofsathishpantaloonNo ratings yet

- MT Merged PDFDocument273 pagesMT Merged PDFavcNo ratings yet

- Module 4 - Bulk Deformation Processes in Metal WorkingDocument93 pagesModule 4 - Bulk Deformation Processes in Metal WorkingAmna OmerNo ratings yet

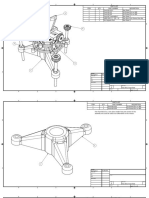

- Eric Fauteux 21/08/2021: Drawn Checked QA MFG Approved TitleDocument4 pagesEric Fauteux 21/08/2021: Drawn Checked QA MFG Approved Titleaz123654No ratings yet

- A-6 SolutionDocument2 pagesA-6 Solutionkishore nandyalaNo ratings yet

- Student Copy-Manufacturing Process SelectionDocument49 pagesStudent Copy-Manufacturing Process SelectionAnishMendisNo ratings yet

- Iron International StandardsDocument2 pagesIron International StandardsAmir MusaibNo ratings yet

- STPB740Document12 pagesSTPB740Antônio Rafael BatistaNo ratings yet

- Fundamentals of Casting - Part 2Document49 pagesFundamentals of Casting - Part 2Kavan PatelNo ratings yet

- Whitworth Tapered Pipe Thread DIN EN 10226-1, DIN EN 10226-2 Formerly Known As DIN 2999 BSPT (British Standard Tapered Pipe)Document1 pageWhitworth Tapered Pipe Thread DIN EN 10226-1, DIN EN 10226-2 Formerly Known As DIN 2999 BSPT (British Standard Tapered Pipe)LucianNechiforNo ratings yet

- Collodion and The Making of Wet-Plate NegativesDocument20 pagesCollodion and The Making of Wet-Plate NegativesAstrid PiepschykNo ratings yet

- BS 6615 Iso 8062-CT7Document2 pagesBS 6615 Iso 8062-CT7Purushothama Nanje GowdaNo ratings yet

- Guide To Screwthread Sizes - Page 1Document6 pagesGuide To Screwthread Sizes - Page 1squanerNo ratings yet

- U-2 Mechanical Working of MetalsDocument76 pagesU-2 Mechanical Working of Metalsapi-271354682No ratings yet