Professional Documents

Culture Documents

Impact Copolymer: For Injection Moulded Products

Impact Copolymer: For Injection Moulded Products

Uploaded by

Sanjay SharmaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Impact Copolymer: For Injection Moulded Products

Impact Copolymer: For Injection Moulded Products

Uploaded by

Sanjay SharmaCopyright:

Available Formats

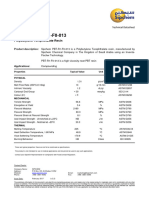

D120MA IMPACT COPOLYMER

FOR INJECTION MOULDED PRODUCTS

Repol D120MA is recommended for use in Injection Moulded processes where high impact strength is required. It is an ideal material

to use in compounding, automotive components, luggage shells etc. Repol D120MA contains antistatic agent that reduces static charge

build-up in products.

Typical Characteristics

Property Test Method Unit Typical Value*

Melt Flow Rate (230°C/2.16 kg) ASTM D1238 g/10 min 12

Tensile Strength at Yield (50 mm/min) ASTM D638 MPa 19

Elongation at Yield (50 mm/min) ASTM D638 % 10

Flexural Modulus (1% secant) ASTM D790A MPa ���

900

Notched Izod Impact Strength (23°C) ASTM D256 J/m ���

550

Heat Deflection Temperature (455 kPa) ASTM D648 °C 90

* Typical values, not to be taken as specification. All the mechanical properties as per ASTM D638 Type I specimen injection moulded in accordance with ASTM D4101

Applications

Automotive compounds

Regulatory Information

• Meets the requirements stipulated in IS 10910 on ‘Specification for Polypropylene and its Copolymers for safe use in contact with

foodstuff, pharmaceuticals, and drinking water’. Additives incorporated in this grade conform to the positive list of constituents

as prescribed in IS 10909. The grade and the additives incorporated in it also comply with the FDA:CFR Title 21,177.1520,

Olefin polymers

Storage Recommendations

• Bags should be stored in dry / closed conditions at temperatures below 50°C and protected from UV / direct sunlight

Reliance Industries Limited, Product - Application & Technology Group, PRTC,

Swastik Mill Compound, V. N. Purav Marg, Chembur, Mumbai-400 071. Tel.: +91-22-6767 7000. E-mail: polymer_patsupport@ril.com Website: www.ril.com

• The information and data presented herein is true and accurate to the best of our knowledge. No warranty or guarantee expressed or implied, is made regarding performance or otherwise. This

information and data may not be considered as a suggestion to use our products without taking into account existing patents, or legal provisions or regulations, whether national or international. • The user of

any information and/or data is advised to obtain the latest details from any of the offices of the company or its authorised agents, as the information and/or data is subject to change based on the research and

development work undertaken by the company.

�������������������

Updated as Of March 2009

You might also like

- FM Notes Vimp.Document212 pagesFM Notes Vimp.premiitr05No ratings yet

- SNNDNDNDDocument5 pagesSNNDNDNDRowena Remorosa Galay100% (1)

- Impact Copolymer: For Injection Moulded ProductsDocument1 pageImpact Copolymer: For Injection Moulded ProductsarthymanicNo ratings yet

- Im B120MADocument1 pageIm B120MAQUALITY MAYURNo ratings yet

- Reliance Relene HD50MA180Document1 pageReliance Relene HD50MA180MamdouhNo ratings yet

- Polysure PP RM30CRDocument1 pagePolysure PP RM30CRyansyafNo ratings yet

- Polypropylene Impact Co Polymer Injection Molding: Provisional Technical DatasheetDocument2 pagesPolypropylene Impact Co Polymer Injection Molding: Provisional Technical DatasheetMohit MohataNo ratings yet

- Polypropylene Homo Polymer Injection Molding: Provisional Technical DatasheetDocument2 pagesPolypropylene Homo Polymer Injection Molding: Provisional Technical DatasheetMohit MohataNo ratings yet

- Polysure PP RB02CRDocument1 pagePolysure PP RB02CRPiyush A JoshiNo ratings yet

- Tds H110maDocument2 pagesTds H110maShibu MohanNo ratings yet

- Polypropylene Impact Co Polymer Injection Molding: Provisional Technical DatasheetDocument2 pagesPolypropylene Impact Co Polymer Injection Molding: Provisional Technical DatasheetMohit MohataNo ratings yet

- Linear Low Density Polyethylene: Blown Film GradeDocument1 pageLinear Low Density Polyethylene: Blown Film GradeChetan BholeNo ratings yet

- Im B120MADocument1 pageIm B120MAPrashant MalikNo ratings yet

- HD M5306 PDFDocument2 pagesHD M5306 PDFmohamed1303No ratings yet

- Aramco PP HP30G Rev 20180116Document1 pageAramco PP HP30G Rev 20180116wulan kantiasihNo ratings yet

- Linear Low Density Polyethylene Injection MoldingDocument2 pagesLinear Low Density Polyethylene Injection MoldingakshayNo ratings yet

- TDS B0155DDocument1 pageTDS B0155DtechnopackishvarlalNo ratings yet

- Aramco PP HP40G Rev 20180116Document1 pageAramco PP HP40G Rev 20180116wulan kantiasihNo ratings yet

- Polysure HDPE R0150SDocument1 pagePolysure HDPE R0150Syadavgirija30No ratings yet

- Re H200MKDocument1 pageRe H200MKnisargpatel766No ratings yet

- Y25GRDocument1 pageY25GRPiyush A JoshiNo ratings yet

- M12RR PDFDocument1 pageM12RR PDFJordan Rock100% (1)

- Low Density Polyethylene: Extrusion Coating and Film ApplicationsDocument1 pageLow Density Polyethylene: Extrusion Coating and Film ApplicationsMahadi Bachar MahamatNo ratings yet

- TDS F4600Document2 pagesTDS F4600tech.omNo ratings yet

- PP Block bc03bs DatasheetDocument1 pagePP Block bc03bs Datasheetphanplastic299No ratings yet

- TDS H019TGDocument2 pagesTDS H019TGkeyurmangnani2015No ratings yet

- Y35GRDocument1 pageY35GRPiyush A JoshiNo ratings yet

- Polypropylene Impact Co Polymer Injection MoldingDocument2 pagesPolypropylene Impact Co Polymer Injection MoldingMohit MohataNo ratings yet

- Ra R120MKDocument1 pageRa R120MKyansyafNo ratings yet

- PP Block bc03bsw DatasheetDocument2 pagesPP Block bc03bsw Datasheetphanplastic299No ratings yet

- R03RRDocument1 pageR03RRPiyush A JoshiNo ratings yet

- F03RRDocument1 pageF03RRPiyush A JoshiNo ratings yet

- High Density Polyethylene Injection MoldingDocument2 pagesHigh Density Polyethylene Injection MoldingQuality teamNo ratings yet

- P O L Y P R O P Y L E N E: Reliance Industries LimitedDocument1 pageP O L Y P R O P Y L E N E: Reliance Industries LimitedSiddheshNo ratings yet

- PP PP4-0R Polypropylene: Technical Data Sheet (TDS)Document1 pagePP PP4-0R Polypropylene: Technical Data Sheet (TDS)Jorge MedinaNo ratings yet

- Iocl-3030mg (U)Document1 pageIocl-3030mg (U)Vignesh SubramanianNo ratings yet

- TDS H020egDocument2 pagesTDS H020egkeyurmangnani2015No ratings yet

- Special Characteristics:: Innoplus Ll7420DDocument1 pageSpecial Characteristics:: Innoplus Ll7420DFahad MohamedNo ratings yet

- Low Density Polyethylene: For Injection Molding & Masterbatch ApplicationDocument1 pageLow Density Polyethylene: For Injection Molding & Masterbatch Applicationdharmendrasinh zalaNo ratings yet

- Polypropylene Homo Polymer BOPP Films: Provisional Technical DatasheetDocument2 pagesPolypropylene Homo Polymer BOPP Films: Provisional Technical DatasheetMohit MohataNo ratings yet

- Ube Nylon 5034bDocument1 pageUbe Nylon 5034bDiegoTierradentroNo ratings yet

- Iocl PPCP 8 Mfi 4080maDocument1 pageIocl PPCP 8 Mfi 4080mayaonik himmatramkaNo ratings yet

- TDS LC670 Eng 220216Document1 pageTDS LC670 Eng 220216AthonioMourinhoNo ratings yet

- Opal - Hdpe - 4Document2 pagesOpal - Hdpe - 4Piyush A JoshiNo ratings yet

- 3 Property H7900 EngDocument1 page3 Property H7900 EngMohit MohataNo ratings yet

- PP ARPP200-1 Black 14 Melt HomoDocument1 pagePP ARPP200-1 Black 14 Melt HomocountzeroaslNo ratings yet

- Linear Low Density Polyethylene Resin Special CharacteristicsDocument1 pageLinear Low Density Polyethylene Resin Special CharacteristicsFahad MohamedNo ratings yet

- Relene J1005FY20Document1 pageRelene J1005FY20Anuj Kumar SinghNo ratings yet

- Sipchem PBT-R1-F0-013: Polybutylene Terephthalate ResinDocument1 pageSipchem PBT-R1-F0-013: Polybutylene Terephthalate ResinTahir IqbalNo ratings yet

- Aramco PP HP30EGDocument2 pagesAramco PP HP30EGSayed FathyNo ratings yet

- H030SGDocument2 pagesH030SGLaxman AhirNo ratings yet

- SABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFDocument2 pagesSABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFvishal mehtaNo ratings yet

- Polypropylene Random Co Polymer Injection Molding & ISBM: Provisional Technical DatasheetDocument2 pagesPolypropylene Random Co Polymer Injection Molding & ISBM: Provisional Technical DatasheetMohit MohataNo ratings yet

- 1030MGDocument1 page1030MGaman1406krNo ratings yet

- Low Density Polyethylene: Lamination Film ApplicationsDocument1 pageLow Density Polyethylene: Lamination Film ApplicationsMahadi Bachar MahamatNo ratings yet

- Linear Low Density Polyethylene: Provisional Technical DatasheetDocument2 pagesLinear Low Density Polyethylene: Provisional Technical DatasheetMohit MohataNo ratings yet

- 3 Property R3450 EngDocument1 page3 Property R3450 EngMohit MohataNo ratings yet

- ASTM FL7100U Eng 240223Document1 pageASTM FL7100U Eng 240223MERVENo ratings yet

- Infino Pc-Abs Hp1000xa (Natural)Document1 pageInfino Pc-Abs Hp1000xa (Natural)Rhekron PlasticsNo ratings yet

- Mobil Special™ 20W-50 Mobil Special™ 20W-50 Mobil Special™ 20W-50 Mobil Special™ 20W-50Document2 pagesMobil Special™ 20W-50 Mobil Special™ 20W-50 Mobil Special™ 20W-50 Mobil Special™ 20W-50ENGINEER MONIRUJJAMANNo ratings yet

- Alomaishi Creep of High Strength Concrete PDFDocument20 pagesAlomaishi Creep of High Strength Concrete PDFSemih ArslanNo ratings yet

- Assignment - 1 - Fundamentals of Compressible FlowDocument1 pageAssignment - 1 - Fundamentals of Compressible FlowABHI THAKKARNo ratings yet

- Piezoelectric Quartz CrystalDocument4 pagesPiezoelectric Quartz CrystalPaper Mario FanNo ratings yet

- KNPC Project Spec - CP Design BasisDocument40 pagesKNPC Project Spec - CP Design Basis이선엽No ratings yet

- 1.1 Classification of Composite MaterialsDocument0 pages1.1 Classification of Composite MaterialsPhani GurijalaNo ratings yet

- Composite MaterialsDocument49 pagesComposite MaterialsKRISHNA trending statusNo ratings yet

- Lu-1 4982634Document6 pagesLu-1 4982634Gih-Keong LauNo ratings yet

- Recent Advances in Restorative MaterialsDocument357 pagesRecent Advances in Restorative MaterialsSanket Rane85% (20)

- Bmi Unit 1 To 5Document109 pagesBmi Unit 1 To 5sam08032004No ratings yet

- Pinho PHD ThesisDocument257 pagesPinho PHD ThesisaluruvamsiNo ratings yet

- 01-Intro MEMS History TrendsDocument19 pages01-Intro MEMS History TrendscmosNo ratings yet

- Materiale PiezoelectriceDocument68 pagesMateriale PiezoelectriceTanya WhiteNo ratings yet

- TECATEC™ - Product Family Thermoplastic Composites With Excellent StrengthDocument2 pagesTECATEC™ - Product Family Thermoplastic Composites With Excellent StrengthCésar CostaNo ratings yet

- An Study On Steel Fiber Reinforced ConcreteDocument26 pagesAn Study On Steel Fiber Reinforced ConcreteVìctòry Vèérá100% (1)

- M.E.S Indian School, Doha - Qatar Notes 2024 - 2025Document10 pagesM.E.S Indian School, Doha - Qatar Notes 2024 - 2025Rafiya95z MynirNo ratings yet

- Chemical Bonding and Molecular Structure - PYQ Chemistry Class 11 PDF DownloadDocument9 pagesChemical Bonding and Molecular Structure - PYQ Chemistry Class 11 PDF DownloadamreshNo ratings yet

- Phonon TECH PDFDocument26 pagesPhonon TECH PDFnaoufel1706No ratings yet

- Lab Report #1 Photoelectric EffectDocument8 pagesLab Report #1 Photoelectric EffectJohn FiveNo ratings yet

- Máquinas Pra DLCDocument43 pagesMáquinas Pra DLCrenatoeliegeNo ratings yet

- MCQ Thermal PDFDocument6 pagesMCQ Thermal PDFpriya dharshiniNo ratings yet

- Mechanical ASTM D2196Document1 pageMechanical ASTM D2196Vasa100% (1)

- Astm C892 - 00Document5 pagesAstm C892 - 00reneeNo ratings yet

- Fin TutorialDocument7 pagesFin TutorialmanasgartiaNo ratings yet

- Design of Magnesia-Spinel Bricks For Improved CoatDocument15 pagesDesign of Magnesia-Spinel Bricks For Improved CoatEbrahim BayoumiNo ratings yet

- Datasheet PA 12 Extended-6Document8 pagesDatasheet PA 12 Extended-6Lavin ZengNo ratings yet

- 10 Question PT QuizDocument3 pages10 Question PT Quizsafeer ahmadNo ratings yet

- Coursera Quiz 3Document4 pagesCoursera Quiz 3Miriam OntiverosNo ratings yet

- Assignment 5Document1 pageAssignment 5Pinakin GoreNo ratings yet