Professional Documents

Culture Documents

BS 1449-1 Steel Plate, Sheet & Strip 1991

BS 1449-1 Steel Plate, Sheet & Strip 1991

Uploaded by

Saad Ayub0 ratings0% found this document useful (0 votes)

597 views20 pagesPart-1

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPart-1

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

597 views20 pagesBS 1449-1 Steel Plate, Sheet & Strip 1991

BS 1449-1 Steel Plate, Sheet & Strip 1991

Uploaded by

Saad AyubPart-1

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 20

BST BSaduNqEPTE

BRITISH STANDARD

SECHR.1 9b MM 42465 O256954

BS 1449:

Section 1.1:

1991

Steel plate, sheet and

strip

Part 1. Carbon and carbon-manganese plate, sheet and

strip

Section 1.1 General specification

‘Bes, bandos et foullards en acier leche und Blade

Parte I Tes, bandes ct feullards en acier au ‘Tel. leche ute Bdnder aus unegrtem

catbone ct au carbone-margantoe ‘Stahl und Mangarstaht

‘Section 1-1 Spécifieationspenales Abochit 1.1 Allgemelne Anforderongen

{the Beiiah Standards tnctation

\ fast0s 2008

"The folowing Bal references

relat to the werk on tis

Standart

(Gomme reference IW/10

Draft announced in BS! Nowe

Ait 1001

THBN 0 580 18670 7

Committees responsible for this

British Standard

‘The preparation of this British Standard was entrusted by the Iron und Steel

Standards Policy Committee (ISM/-) to Technical Commitioe ISM/10, upon

‘Which the following bodies were represented:

British Railways Board

British Steel Industry

Cold Rolled Sections Association

Society of Motor Manufacturers and Traders Limited

‘The following bodies were also represented In the drafting of the standard,

through subcommittoce and panels:

British Welded Steel Tube Association

Institution of Mechanical Engineers

National Association of Steel Stockholders

Amendments tesued since publication

‘Amd.No. [Date "Text affected

‘Copytight by the Brish Standards insttuion

FeiNov 09 11:80:07 2004

BSI BS*LWUqIPTAE SECx}.1 93 MM Rb24bG9 O2SL9SL 7 Ml

BS 1449 : Section 1,

1991

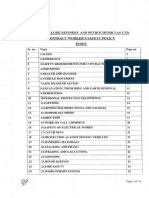

Corumittees responsible Inside front cover

Foreword, 2

i

ification

Introduction 4

Scope 4

Definitions 4

General 8

‘Steelmaking process 8

‘Chemical composition 8

Freedom from defects 8

‘Condition of material on delivery a

Number of testa o

9

4

9

a

9

9

9

BERD Soe Teme aene

16

16 Rotests ®

17 Surface finish and surface inspection 10

18 Edge conditions 20

19 Inspection 10

20 ‘blerances on dimensions and shape 10

21 Marking 10

Appendices

A Product analysis and permitted variations u

B_ Methods of teat ul

C__ Determination of r values

E

‘Symbols for material conditions 5

Symbols for surface finishes and surface Inspection 6

Summary of material grades, chemical campositions and types of

‘steel available 7

Edge conditions 10

‘Pennitted variations of product analysis from specified range.

Applicable to Killed (K) steels only IB

on eee

j

1 Bend test with the axis of the bend parallel to the direction of rolling 12

2 Bend test with the axis of the bend at, 90° to the direction of rolling 13.

3_Nomogram for determination of r values 16

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- BS 1449-2-1983-1999Document14 pagesBS 1449-2-1983-1999Saad AyubNo ratings yet

- Arcoplate ALLSTEINT FayreDocument4 pagesArcoplate ALLSTEINT Fayrevampiry1972No ratings yet

- Free Metal Craft PlansDocument30 pagesFree Metal Craft PlansEstuardoA80% (5)

- Electrical WorksDocument6 pagesElectrical WorksSaad AyubNo ratings yet

- Furnace OilDocument1 pageFurnace OilSaad AyubNo ratings yet

- Specification For Weldable Structural Steels: Find Similar ItemsDocument2 pagesSpecification For Weldable Structural Steels: Find Similar ItemsSaad AyubNo ratings yet

- U - Contractor - Workers - Safety - Policy PDFDocument39 pagesU - Contractor - Workers - Safety - Policy PDFSaad AyubNo ratings yet

- BS 1449-1 Steel Plate, Sheet & Strip 1983 PDFDocument39 pagesBS 1449-1 Steel Plate, Sheet & Strip 1983 PDFSaad Ayub0% (1)

- A 972 - A 972M - 00 Qtk3mi9botcytq - PDFDocument4 pagesA 972 - A 972M - 00 Qtk3mi9botcytq - PDFSaad AyubNo ratings yet

- Hydrogen Induced Stress Cracking (DNV RP F112)Document25 pagesHydrogen Induced Stress Cracking (DNV RP F112)Guillaume BoyerNo ratings yet

- Asme Sa 234 Grade WPC PipesDocument1 pageAsme Sa 234 Grade WPC PipesFerroPipENo ratings yet

- WHP-SPM-011 Rev. C General Welding-NDE Specification Piping Shop-Field FabricationDocument26 pagesWHP-SPM-011 Rev. C General Welding-NDE Specification Piping Shop-Field Fabricationprihartono_dias100% (1)

- Soldering and Brazing: MENG16000: Design & Manufacture 1 Manufacturing ProcessesDocument10 pagesSoldering and Brazing: MENG16000: Design & Manufacture 1 Manufacturing ProcessesChen Zhi ShenNo ratings yet

- Preventingdelayedcracks in Ship WeldsDocument20 pagesPreventingdelayedcracks in Ship WeldsWahyu Nur ArifiantoNo ratings yet

- ISO Standards On Mech Test of MetalsDocument4 pagesISO Standards On Mech Test of MetalsDaniel MoreNoNo ratings yet

- BS en Iso 01514-2016Document22 pagesBS en Iso 01514-2016Krishna Vacha50% (2)

- Machine DesignDocument55 pagesMachine DesignJaypee Bucatcat0% (1)

- 3475 M T - Client: M/s Simplex Infrastructures LTD: DESIGN of Steflomet Metallic GUIDE BEARINGDocument2 pages3475 M T - Client: M/s Simplex Infrastructures LTD: DESIGN of Steflomet Metallic GUIDE BEARINGBume1938No ratings yet

- Properties of Engineering Materials 2Document12 pagesProperties of Engineering Materials 2Douglas Kufre-Abasi GilbertNo ratings yet

- Eco Materials Adviser Full Version Materials ListDocument116 pagesEco Materials Adviser Full Version Materials ListccooxxyyNo ratings yet

- Unit II PPT MT I Vol 1Document51 pagesUnit II PPT MT I Vol 1loganathanNo ratings yet

- Product Range 1 Hydraulic Hose FittingsDocument118 pagesProduct Range 1 Hydraulic Hose FittingsnursultanNo ratings yet

- Valency TableDocument1 pageValency TableRitesh SinghNo ratings yet

- Simplify Materials Selection: Your Guide To Making Choices That Reduce The Impact of CorrosionDocument37 pagesSimplify Materials Selection: Your Guide To Making Choices That Reduce The Impact of CorrosionInspection EngineerNo ratings yet

- fLAME TESTDocument6 pagesfLAME TESTkemcanaboNo ratings yet

- SOP-Piping Fabrication & InstallationDocument27 pagesSOP-Piping Fabrication & InstallationImtiaz Nusrat100% (6)

- Assembly2 Caster Complete 1Document1 pageAssembly2 Caster Complete 1lianaNo ratings yet

- Powder MetallurgyDocument8 pagesPowder MetallurgyPritamNo ratings yet

- Nagpur Cetp - Butibori - Member - ListDocument7 pagesNagpur Cetp - Butibori - Member - ListKv SatishNo ratings yet

- Chapter One - Introduction To Steel StructuresDocument8 pagesChapter One - Introduction To Steel StructuresJohn Philip Molina NuñezNo ratings yet

- Daftar Harga BesiDocument29 pagesDaftar Harga BesiBejo RaharjoNo ratings yet

- 2. CATALOGE POSCO (tôn bọc cách nhiệt)Document17 pages2. CATALOGE POSCO (tôn bọc cách nhiệt)Kiến Huy LưuNo ratings yet

- Cellular PrecipitationDocument24 pagesCellular PrecipitationRudi Yansah100% (1)

- ReportDocument28 pagesReportDipanshu KumarNo ratings yet

- ASTM Volume 02.02, September 2017 Aluminum and Magnesium AlloysDocument2 pagesASTM Volume 02.02, September 2017 Aluminum and Magnesium AlloysAnwarNo ratings yet

- GuidelinesDocument68 pagesGuidelinesPradeep KumarNo ratings yet

- BSI Standards For Welding InspectorDocument7 pagesBSI Standards For Welding InspectorAnonymous 1LrwaaONo ratings yet