Professional Documents

Culture Documents

14Q Principle

14Q Principle

Uploaded by

Sakthy ArunaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

14Q Principle

14Q Principle

Uploaded by

Sakthy ArunaCopyright:

Available Formats

14 Quality Principles for the Value Stream

Value Stream

Q-Basics

1 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Value Stream Q-Basics

We want

our customers

to be satisfied!

2 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Principle 1

Stop Sign

Customer complaints are communicated

within the production site and, if possible,

displayed directly at the station in question.

Using problem-solving techniques, they are

processed in a fast and systematic manner.

The supply chain is promptly informed.

3 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Principle 1

Stop Sign

A STOP sign process with all of the 8D elements is

displayed on the shop floor.

A standard review process involving the

production/logistics management and quality

management takes place.

The decision to end the STOP sign process is taken by

production/logistics management after a review of the

measures’ effectiveness.

It is necessary to ensure that customer complaints are

communicated quickly over the entire supply chain from

supplier to customer.

4 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Principle 2

Andon Cord

In the event of deviations in quality or if

control limits are exceeded in the value

stream (source, make, deliver), the employee

needs to stop the process or escalate.

5 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Principle 2

Andon Cord

There is a systematics (e.g. Andon cord, blocking/

escalation process, reaction plan) in place that allows

the operator, if he notices deviations, to choose to

prevent the passing-on / further processing of parts (by

stopping/blocking) and to escalate immediately.

Deviations can occur if control limits are exceeded, and

also based on subjective observations (for example, the

power screwdriver is not running smoothly, material has

been funneled into the incorrect chute, or the associate

is not working to the standards set, label badly readable

or incomplete).

After stopping the system there needs to be a well-

defined process governing the restarting and release of

the system by shop floor management.

6 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Principle 3

Instructions

Safety, health, production, and inspection

instructions are complied with.

5S standards are put in place and observed.

7 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Principle 3

Instructions

The work, production and inspection instructions are

clearly visible at every work place. A consistent set of

symbols is available. If appropriate, the right/left hand

movement becomes evident from the instruction. The

failure modes from the FMEA and special characteristics

from the control plan are taken into account. Detailed

photos support the process.

There is a feedback loop in place that ensures the

consistency of the control plan, FMEA, and directions.

Health and safety instructions are carried out according

to the plan. Participation is compulsory and will be

documented.

All deviations regarding safety, work, production and

inspection instructions or safety and health briefings

shall be resolved using the 8D method.

8 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Principle 4

Process Parameters

The target values/tolerances for all

stated process parameters are observed.

9 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Principle 4

Process Parameters

All process parameters (e.g. press-in force, maximum

storage time) that affect product quality are clearly

defined and systematically checked on basis of the

control plan. All required inspection criteria are

implemented according to specification.

Process validations are performed to determine whether

target values/tolerances of the defined parameters have

been observed. Deviations are systematically recorded

and eliminated permanently.

10 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Principle 5

Measurement/Test Equipment

Measuring and test equipment is defined,

and monitoring intervals are observed.

11 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Principle 5

Measurement/Test Equipment

The type of measuring and test equipment (e.g. gages,

scanners) incl. auxiliary means and its uses is defined

for all processes in the control plans.

All measuring and test equipment is calibrated and only

utilized within the permissible inspection interval.

The inspection status of the measuring and test

equipment is recognizable at its place of usage (e.g.

marked by inspection certificate sticker, tag).

In case of suspected malfunctions/damages this has to

be notified.

12 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Principle 6

Check the Checker

The “check the checker” principle is applied,

and the “checker’s” suitability is ensured.

13 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Principle 6

Check the Checker

The suitability of processes used to prevent or detect

errors (e.g. camera-monitored processes, sensor-based

measurements, inspection processes, scanning of

labels) needs to be checked according to a predefined

standard.

Possible errors, such as loading the incorrect camera

software/testing program or incorrect MAE software

versions/updates, entry of wrong inspection parameters,

or improper sensor calibration, need to be prevented by

carrying out the inspection. These inspection processes,

need to be evaluated using appropriate methods (e.g.

FMEA).

Check-the-Checker-parts are included in the control of

inspection measurement and test equipment.

Generally speaking, mistake-proofing is always

preferable to error detection (e.g. Poka Yoke).

14 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Principle 7

Total Productive Maintenance

A maintenance standard is installed and

observed at every station.

15 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Principle 7

Total Productive Maintenance

The four-pillar TPM model, particularly the autonomous

and preventative maintenance, is instituted at every

machine, device, facility. This contains both the roles

and responsibilities for production and the supporting

areas.

Systematic damage and dirt built-up on machinery and

device components (e.g. workpiece carriers, storage

facilities, stackers) need to be consistently analyzed,

recognized, and remedied.

The restart after maintenance (see principle 9), has to

consider potential influences on product quality.

16 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Principle 8

Tools

Each tool has a defined service life; the

current status must be recognizable.

A quality evaluation must be carried out

during installation, removal or disassembly.

17 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Principle 8

Tools

Wear-prone tools with influence on product quality (e.g.

processing, assembly, molding tools, workpiece

fixtures/carriers) have been recorded and are controlled

(e.g. defined service lives, control on basis of product

characteristics, inspection during maintenance).

A warning system promptly displays when tools need to

be replaced or serviced.

Each tool needs to be inspected when installed,

removed or disassembled to check for recognizable

abnormalities (e.g. damage/wear and tear). In case of

deviations, it is necessary to follow measures to ensure

product quality is maintained.

18 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Principle 9

Restart

Restart after disruptions is clearly regulated

for all machinery and equipment.

19 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Principle 9

Restart

Each disruption to the continuous production process

(tool change, set-up, break, shift change, maintenance,

power failure, upgrade, MAE software update,

parameter changes) presents a potential risk to quality.

A predefined standard for post-restart is therefore

necessary. This should detail how to deal with products

in the process after a disruption.

All devices have been inspected according to a defined

standard for quality risks in connection with disruptions

(for example, an unplanned disruption to the welding

process, the injection molding process stops

unexpectedly, a product remains in thermal treatment for

too long, the silicone bead is exposed to the air for too

long). The standard also includes the analysis of critical

wear parts (for example, drill bits or welding electrodes).

Following longer disruptions (e.g. station upgrade,

control software update), it is necessary to newly

release the process.

Set-up processes, need to be evaluated using

appropriate methods (e.g. FMEA).

20 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Principle 10

Labeling

Products and containers are labeled

according to the set standard.

21 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Principle 10

Labeling

Outside the production flow:

White card with a red diagonal stripe: Product blocked;

Green card: Product after additional test back in

production flow and in good condition;

Yellow card: Product for rework;

Red card: Product is scrap;

White card: Product in good condition.

Rejected parts in the red box (scrap container).

Red boxes must be secured against unintended access

(e.g. by locking them, covering, spatial separation,

covering during transport).

Containers for rejects must be emptied in line with

In the entire value stream products must always standards and the parts must be analyzed.

have a clear status. Therefore, a consistent identi- Parts at the analysis station are spatially separated from

fication/labeling concept at the production site and the production flow and clearly identified.

adherence to the following rules are necessary. Only parts with the same status in the same container

Within the production flow: No good parts in the red box.

Filled boxes must always be labeled A blocking process for production and logistics is defined.

(e.g. card, sticker, RFID). Products are protected against environmental influences

(e.g. contamination) in line with regulations.

22 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Principle 11

Rework / Scrap

The handling of rejected parts and those

to be reworked is clearly regulated.

23 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Principle 11

Rework / Scrap

Basic rule: Inspection or processing of a part that,

contrary to the control plan, is removed from the

standard process, is rework.

If rework is unavoidable it takes place on an approved

device and is limited in time or quantity. A concession is

necessary.

A rework process that is permanently required must be

transferred to a standard process.

Sorting inspections require a

risk assessment,

description of the workplace,

work / inspection instruction.

They are approved by the responsible for production

and the responsible for quality.

Scrap must be disposed of in line with the standard and

unauthorized further use of these products must be

prevented (for example, by destroying them).

24 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Principle 12

Dropped Parts

Any products that fall on the floor,

into the machine or cannot be classified

must be scrapped.

25 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Principle 12

Dropped Parts

Each individual employee must adhere to this standard

regardless of what part of the organization he/she

belongs to or his/her position within the company.

In case of repeated occurrence the shop floor

management must be notified by the employee.

Repeat events are analyzed regarding systematic

causes and improvement measures are implemented.

Nonconforming products or products that cannot be

classified must be scrapped according to procedure.

26 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Principle 13

Correct Product

Only the correct product may be

provided for removal and assembly.

27 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Principle 13

Correct Product

Only the correct product may be available to the

associate at the time of assembly.

All other variants or versions that are stored at the

assembly station/workplace must not be accessible to

the employee (e.g. closed/covered containers).

If several variants need to be available (e.g. mating of

parts), an inspection takes place after the handling

operation.

28 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Principle 14

Remaining Items

The handling of remaining items/

quantities is clearly regulated.

29 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Principle 14

Remaining Items

Remaining quantities must be clearly labeled (e.g. white

card with part number, number of units, date, name,

remaining quantity in the comments field) and stored

securely (e.g. shelf for remaining items).

The “First In, First Out” principle must be observed.

Maximum storage times must not be exceeded.

Close attention must be paid to ensure tidiness and

cleanliness as the goods have yet to be placed in the

final packaging.

The quantity of remaining items must be taken into

consideration with regard to engineering change

requests.

30 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

Terms and Abbreviations

(for information only)

5S: Approach for improvement of order and cleanliness at the MAE: Machinery and Equipment

workplace described by 5 Japanese words all beginning with S

Poka Yoke (from Japanese): Method to avoid human mistakes,

8D: Method for structured problem solving in 8 steps resulting defects and passing on of nonconforming parts

Andon Cord: Term derived from Japanese for a system (e.g. rip RFID (radio-frequency identification): transmitter-receiver system

cord, switch, systematics) enabling an employee to stop a for contact-free identification of objects using electromagnetic

device.

waves

Audit (lat. hearing): systematic and independent investigation of

the actual state e.g. of a quality management system, production source, make, deliver: short descriptions for the main sections

process or product in comparison to the requirements of the value stream (purchase, production, delivery)

FMEA (Failure Mode and Effects Analysis): Analytical method to TPM: Total Productive Maintenance

identify failure modes of systems, products or processes and to

avoid them by appropriate measures VDA: German Association of the Automotive Industry

IPN: International Production Network GB/QM: Division / Head of Quality Management

ISO (International Organization for Standardization): worldwide HSE: Health, Safety, Environment

union of national standardization institutes for the development of

international standards

ISO/TS 16949: Summarizing technical specification of the

worldwide existing requirements of the automotive industry for

management systems, developed by the ISO

31 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

14 Quality Principles for the Value Stream

Value Stream

Q-Basics

32 Robert Bosch GmbH | May 2016

Edition 2.0

© Robert Bosch GmbH 2016. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights.

You might also like

- Families Schools and Communities Together For Young Children PDFDocument2 pagesFamilies Schools and Communities Together For Young Children PDFMisty17% (6)

- Aiag Cqi-9Document78 pagesAiag Cqi-9Jorge FernandezNo ratings yet

- Customer Specific Requirements Manual HMB 3Â EditionDocument40 pagesCustomer Specific Requirements Manual HMB 3Â EditionAline Cristina GobeNo ratings yet

- Tisax Technical Guide DekraDocument15 pagesTisax Technical Guide DekraMert AtayNo ratings yet

- Supplier Web Share Downloads CQI-15 Welding System AssessmentDocument50 pagesSupplier Web Share Downloads CQI-15 Welding System AssessmentMostafa Abd El Alem83% (6)

- Choral Speaking MoneyDocument2 pagesChoral Speaking Moneyyuvaranist60% (5)

- Msva ManualDocument207 pagesMsva Manualfudoken666No ratings yet

- Din 929 PDFDocument1 pageDin 929 PDFprathmesh238No ratings yet

- Press ReleaseDocument1 pagePress Releaseapi-457383597No ratings yet

- Web Application Development Dos and DontsDocument18 pagesWeb Application Development Dos and Dontsaatish1No ratings yet

- BS Iso Iec 07811-9-2015Document12 pagesBS Iso Iec 07811-9-2015Amer AmeryNo ratings yet

- VDA 4995 Management of Customer Documents Within The Supply Chain - Version 1 - 2018Document10 pagesVDA 4995 Management of Customer Documents Within The Supply Chain - Version 1 - 2018Victor VillegasNo ratings yet

- SscafDocument111 pagesSscafgabyroiceNo ratings yet

- Formel Q-Capability Version 6.0 Supplier Training - Product AuditDocument11 pagesFormel Q-Capability Version 6.0 Supplier Training - Product AuditVijay LadNo ratings yet

- Product Quality Target Study Plan (PQTSP) : Key Point(s)Document1 pageProduct Quality Target Study Plan (PQTSP) : Key Point(s)nicuNo ratings yet

- Introduction To MTripleP IMetalDocument21 pagesIntroduction To MTripleP IMetalKrishna Mohan T.RNo ratings yet

- QC 080000-2005 (2nd Ed) IECQ-HSPMDocument16 pagesQC 080000-2005 (2nd Ed) IECQ-HSPMISO Vintecom100% (1)

- US Tech Online - New Levels of Traceability For Electronics ManufacturingDocument4 pagesUS Tech Online - New Levels of Traceability For Electronics ManufacturingAbhijeet BokilNo ratings yet

- Iatf 16949 Quality Management System RequirementsDocument42 pagesIatf 16949 Quality Management System RequirementsKiki AditamaNo ratings yet

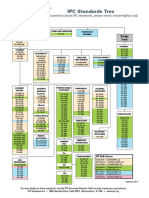

- IPC-SpecTree - IPC SpecTree 2014-09Document1 pageIPC-SpecTree - IPC SpecTree 2014-09edubrunno100% (1)

- PPAP 4th Edition (Errata Added)Document79 pagesPPAP 4th Edition (Errata Added)CHITHIRANNo ratings yet

- Send/Propose & General Releasing Tips: Version: IMDS Release 10.0Document39 pagesSend/Propose & General Releasing Tips: Version: IMDS Release 10.0Vanessa Alves Moreira100% (1)

- Validation PlanDocument2 pagesValidation PlandanielsasikumarNo ratings yet

- Stellantis Ex PSA Scorecard Quick Reference Guide July 2021Document3 pagesStellantis Ex PSA Scorecard Quick Reference Guide July 2021白子健No ratings yet

- Homologation and Self-CertificationDocument10 pagesHomologation and Self-CertificationAli Raza Virk100% (1)

- Process Capability Report Form06Document8 pagesProcess Capability Report Form06arunradNo ratings yet

- Dead Endclamp Failure AnalysisDocument26 pagesDead Endclamp Failure AnalysisRK KumarNo ratings yet

- DBL 9440 - 201912 - Englisch - Fasteners With Metric Thread Surface ProtectionDocument18 pagesDBL 9440 - 201912 - Englisch - Fasteners With Metric Thread Surface ProtectionEmir AkçayNo ratings yet

- Cqi 15Document1 pageCqi 15JanNo ratings yet

- Escalation MatrixDocument5 pagesEscalation MatrixRamya DivyaNo ratings yet

- 105-0009 - Capability and Performance StudiesDocument22 pages105-0009 - Capability and Performance StudiesthisisjineshNo ratings yet

- Checklist Question Support July 2015Document37 pagesChecklist Question Support July 2015Orbán NorbertNo ratings yet

- Fundamentals of ProgrammingDocument84 pagesFundamentals of ProgrammingmambearellaNo ratings yet

- PPAP Workbook 20220215Document43 pagesPPAP Workbook 20220215FRANCISCO JAVIER MALDONADONo ratings yet

- Vision: VDA Infosolutions Private LimitedDocument18 pagesVision: VDA Infosolutions Private LimitedsudhakaremcNo ratings yet

- Agilent Calibration FrequencyDocument6 pagesAgilent Calibration Frequencyzilangamba_s4535No ratings yet

- MX551200Zincatura Passivata StandardDocument7 pagesMX551200Zincatura Passivata StandardpopoNo ratings yet

- Education & Training Guidance Manual PDFDocument133 pagesEducation & Training Guidance Manual PDFKESHAVA PRASAD SNo ratings yet

- Krishna PPT - 22.07.23Document58 pagesKrishna PPT - 22.07.23Tushaar SethNo ratings yet

- SQMS Manual For Suppliers: 1. General InformationDocument87 pagesSQMS Manual For Suppliers: 1. General Informationlennad1No ratings yet

- Training Module Day Wise Day-1 To Day-6 New JoiningDocument23 pagesTraining Module Day Wise Day-1 To Day-6 New JoiningGirdhar SahuNo ratings yet

- MDSReport 1039818470Document154 pagesMDSReport 1039818470javier ortizNo ratings yet

- Excel Multi Level BOM Template and ExampleDocument20 pagesExcel Multi Level BOM Template and ExamplePacoNo ratings yet

- Software Test Report: Appendix To The PPA ReportDocument4 pagesSoftware Test Report: Appendix To The PPA ReportJuliaNo ratings yet

- Jep 113 BDocument10 pagesJep 113 BCezaryCezasNo ratings yet

- Module - 5 TQM (Mgmcet) FinalDocument31 pagesModule - 5 TQM (Mgmcet) FinalSiddharth PatilNo ratings yet

- System-Based, Customer-Centered Quality Plan For ManufacturersDocument9 pagesSystem-Based, Customer-Centered Quality Plan For ManufacturersmsbarretosNo ratings yet

- GS 90018-2Document27 pagesGS 90018-2Hatem ElbeziNo ratings yet

- Msa 4th Edition PDFDocument2 pagesMsa 4th Edition PDFSenthil KumarNo ratings yet

- Process Failure Mode and Effects Analysis: SEV OCC DETDocument15 pagesProcess Failure Mode and Effects Analysis: SEV OCC DETMomoZhNo ratings yet

- Testing Leather - Unit 1Document8 pagesTesting Leather - Unit 1Daniel MoralesNo ratings yet

- Jedec Standard: Els ServiçosDocument30 pagesJedec Standard: Els ServiçosEverton LuizNo ratings yet

- Sae J121M-2013Document5 pagesSae J121M-2013phan hoai nam PhanNo ratings yet

- RHB R6.3 Point ReleaseDocument20 pagesRHB R6.3 Point ReleaseJuan ReyesNo ratings yet

- CLEPA September 2018Document21 pagesCLEPA September 2018Tere ReyesNo ratings yet

- VDA 6.3-Analysis Tool: User ManualDocument23 pagesVDA 6.3-Analysis Tool: User ManualIstvan KisNo ratings yet

- GB8410 2006 enDocument46 pagesGB8410 2006 enDiego Camargo100% (1)

- What Is Your Company's Cost of Poor Quality (CoPQ) - Tools For Calculating and Reducing ItDocument4 pagesWhat Is Your Company's Cost of Poor Quality (CoPQ) - Tools For Calculating and Reducing ItfaidbNo ratings yet

- 4t GM1927-69 Drill Wide Matrix 01-JUN-06Document8 pages4t GM1927-69 Drill Wide Matrix 01-JUN-06alexNo ratings yet

- Groupe Renault - CSR V2020Document7 pagesGroupe Renault - CSR V2020OBSC PerfectionNo ratings yet

- WW1 ExpansionDocument43 pagesWW1 ExpansionReem AlkaabiNo ratings yet

- Presentation Sussex Conference (1st Year PHD Student)Document9 pagesPresentation Sussex Conference (1st Year PHD Student)vsavvidouNo ratings yet

- Aircraft Design Project Designing A Competitor Fighter AircraftDocument45 pagesAircraft Design Project Designing A Competitor Fighter AircraftKarthick. GNo ratings yet

- Surat Pengajuan PTSL Ke Pertanahan - BPNDocument58 pagesSurat Pengajuan PTSL Ke Pertanahan - BPNdeni hermawanNo ratings yet

- Pyp Teacher Cover LetterDocument7 pagesPyp Teacher Cover Letterafjwdkwmdbqegq100% (2)

- Davis Closes The Gap To Single Digits in First Post-Primary PollDocument84 pagesDavis Closes The Gap To Single Digits in First Post-Primary PollProgressTXNo ratings yet

- SUMMATIVE MUSIC AND ARTS With Answer KeyDocument2 pagesSUMMATIVE MUSIC AND ARTS With Answer KeyCath E RineNo ratings yet

- RBI - Report On Current and Finance 2005-06Document364 pagesRBI - Report On Current and Finance 2005-06_lucky_No ratings yet

- PCW Guidelines For Developing and Implementing Gender Responsive Programs and Projects 1993Document51 pagesPCW Guidelines For Developing and Implementing Gender Responsive Programs and Projects 1993Randell ManjarresNo ratings yet

- TERM II FA1 PBL - Grade 4Document1 pageTERM II FA1 PBL - Grade 4toteefruitw.prNo ratings yet

- Topper'S Choice Gpat Test Series: Pharma AddaDocument3 pagesTopper'S Choice Gpat Test Series: Pharma AddaVikash KushwahaNo ratings yet

- Nitin PawarDocument1 pageNitin PawarBOHEMIAN GAMINGNo ratings yet

- Membres Consell CSDocument2 pagesMembres Consell CSpersepNo ratings yet

- Writing Level 1 International School (Vol. 2) ENG 127: Mã môn họcDocument72 pagesWriting Level 1 International School (Vol. 2) ENG 127: Mã môn họcHồng TheNo ratings yet

- Anomalert Generator Anomaly Detector Datasheet-288496cDocument6 pagesAnomalert Generator Anomaly Detector Datasheet-288496cNaseer HydenNo ratings yet

- Prepositions of Time Test at / On / In: Exercise 1: Rules CheckDocument1 pagePrepositions of Time Test at / On / In: Exercise 1: Rules CheckOmar Sidi ElyNo ratings yet

- Sneaky Hypnosis PhrasesDocument4 pagesSneaky Hypnosis PhrasesRaiyanq67% (3)

- FINANCIAL ANALYSIS-HDFC-BankDocument112 pagesFINANCIAL ANALYSIS-HDFC-BankAbhijith V Ashok100% (1)

- Putting English Unit7Document12 pagesPutting English Unit7Jesus Alberto Dominguez Coronel100% (1)

- Sustainable Tourism, An Overview of The Concept Nad Its Position Relation To Conceptualization of TourismDocument24 pagesSustainable Tourism, An Overview of The Concept Nad Its Position Relation To Conceptualization of TourismalzghoulNo ratings yet

- Fonera Simpl Mini (FON2412A-B)Document36 pagesFonera Simpl Mini (FON2412A-B)luyckxj100% (1)

- Take Aim Spring 2008Document16 pagesTake Aim Spring 2008Felix GrosseNo ratings yet

- English Language 2001 WAEC Past Questions - MyschoolDocument1 pageEnglish Language 2001 WAEC Past Questions - Myschooldosumuahmod47No ratings yet

- 7.10 Environment and Fossils Through TimeDocument2 pages7.10 Environment and Fossils Through TimeWyatt KesterNo ratings yet

- Festo GrafcetDocument34 pagesFesto GrafcetSertug Başar50% (2)

- TC-P42XT50H: 42 Inch Class 720p Plasma HDTVDocument8 pagesTC-P42XT50H: 42 Inch Class 720p Plasma HDTVivonne73No ratings yet