Professional Documents

Culture Documents

Oil Cause 050710 PDF

Oil Cause 050710 PDF

Uploaded by

bennimitzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oil Cause 050710 PDF

Oil Cause 050710 PDF

Uploaded by

bennimitzCopyright:

Available Formats

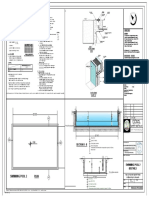

DEEPWATER

HORIZON WHAT HAPPENED ON THE

DEEPWATER HORIZON

On April 20, Deepwater Horizon was two days away from temporarily capping the oil well it had

drilled and handing off the pumping of the oil to a production platform or pipeline. But during

this disconnection process the rig suffered a blowout, caught fire and sank to the bottom.

Here is what went wrong:

GULF OF 2

MEXICO 1 THE CEMENT FAILS

RISER Cement is supposed to protect the THE CEMENTING PROCESS:

outside of the well pipe and is used

to seal off a well when needed.

Drill Drilling

pipe Casing mud

PROBLEM:

Either the primary or secondary Casing

Well is located cementing failed, pushing a huge

in 5,000 feet column of natural gas into the Cement Cement

BOP

of water 3 well pipe. plug

Cement

Cement

DRILL PIPE

Primary Secondary

Cement is pushed between the well When a well is to be temporarily

casings and the sediment layers that have abandoned, two plugs are cemented in

been drilled through. It protects the metal with drilling fluid between them.

wall from gas pressure and from gas Sometimes more plugs are used.

leaking up the outside of the well pipe.

THE WAY

IT IS

SUPPOSED

TO WORK: 2 SEAWATER IN THE RISER

Deepwater Horizon had begun to

remove the heavy column of drilling

mud that is the primary means of

controlling pressure inside a well.

Mud is pumped

THE USES OF MUD: down the drill

Ú During drilling, mud is pumped pipe from the rig

down the riser and well to the tip of

the drill. The mud then flows back up

The mud then

to rig, taking the drill shavings with it.

rises back to

Ú The weight of the mud maintains the rig carrying

well pressure so the oil does not shavings with it

WELL rise to the surface.

Ú The thickness of the mud can be

adjusted to deal with a “kick,” a

sudden surge of gas pressure.

DRILL PIPE AS

PROBLEM: IT DRILLS DOWN

When the cement failed, the TO OIL LAYER

natural gas rocketed to the

surface, as the weakened mixture

of mud and seawater did not have Drill bit

the pressure necessary to hold

the gas back. The gas exploded the

rig, killing 11 men and destroying

the rig.

THE BLOWOUT

Riser adapter

3

Until the well is

completely plugged,

PREVENTER FAILS Flex joint

the pressure from The BOP stack is a 450-ton series of PROBLEM:

a column of thick valves developed to prevent a

drilling mud keeps With only seconds to react, rig

gusher if the mud control is

natural gas and oil operators fired off the shear

overwhelmed.

in the ground ram, but it only partially

sheared the drill pipe. A joint

may have been in the way, or

TWO ANNULAR VALVES: the ram was fouled by pieces of

Closes in and seals on the casing or cement from the

drill pipe. Or if the drill blowout. For days, remotely

pipe is not in use, it closes operated robots tried to fire off

the open hole. Blue Yellow the ram manually, but failed.

control control

Thin line of pod pod

cement encases

a steel well pipe

TOP

PLUG

1

SHEAR RAM: The final

fail safe, it is designed

to close the well by

In a properly cutting through and

capped well sealing the drill pipe.

two large FOUR BLIND RAMS: But they are not

cement plugs Can withstand more designed to cut through

separated by pressure than joints where two drill

drilling mud annular valves over pipe sections connect.

are in place open holes. Not used Drill pipe

with a drill pipe in

Oil is 18,000 place. Two metal

BOTTOM feet below blocks close on each

PLUG the sea floor other, sealing the

well.

OIL LAYER

Wellhead Note: Man shown for scale.

connector BOP is located on the sea

floor 5,000 feet below the

surface.

Note: Vertical height of water and sediment layers is to scale. Rig and drilling components are not. Source: Staff research EMMETT MAYER III AND DAN SHEA / THE TIMES-PICAYUNE

You might also like

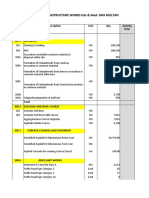

- Credit CardsDocument1 pageCredit CardsBiju Basheer C50% (6)

- BOQ DHA Multan Work PlanDocument8 pagesBOQ DHA Multan Work PlanHamza QayyumNo ratings yet

- Preface: Robert C. SmithDocument6 pagesPreface: Robert C. SmithDaniel DelgadoNo ratings yet

- PMS Building StructureDocument14 pagesPMS Building Structureejo.emonlineNo ratings yet

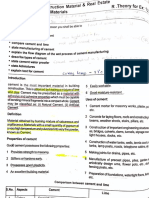

- Cement Chemistry and Cement Chemistry And: PR Immer LL PR Immer LLDocument8 pagesCement Chemistry and Cement Chemistry And: PR Immer LL PR Immer LLDanish KhanNo ratings yet

- Fencewall DesignDocument1 pageFencewall DesignNana BarimaNo ratings yet

- File3e - Propellants - and - Perf - Damage Stimgun PDFDocument4 pagesFile3e - Propellants - and - Perf - Damage Stimgun PDFLuis Alfonso EstebanNo ratings yet

- Cost Estimates NapolesDocument6 pagesCost Estimates NapolesJulie-Ann AutorNo ratings yet

- Front Elevation Rear Elevation: Scale: 1:100 M Scale: 1:100 MDocument1 pageFront Elevation Rear Elevation: Scale: 1:100 M Scale: 1:100 MLeonard Delos ReyesNo ratings yet

- Cementing (Sharing Knowledge)Document15 pagesCementing (Sharing Knowledge)Moh Syamsul BahriNo ratings yet

- Plate 2 FinalDocument1 pagePlate 2 Finalmadhuvanthis21No ratings yet

- Bill No. 8000 SlabDocument5 pagesBill No. 8000 SlabYedenekachew NigussieNo ratings yet

- ECRD - Relato OKDocument104 pagesECRD - Relato OKelvisNo ratings yet

- Bill No. 8000 BoxDocument5 pagesBill No. 8000 BoxYedenekachew NigussieNo ratings yet

- Methodology For FRP 2019Document3 pagesMethodology For FRP 2019Okada IndustryNo ratings yet

- Road No 04 Storm Pipe Laying 0+000 To 0+700 SR# Description Scope Unit Length Remarks 22.915Document8 pagesRoad No 04 Storm Pipe Laying 0+000 To 0+700 SR# Description Scope Unit Length Remarks 22.915UssamaLatifNo ratings yet

- Latilla 2007 Pre-Split Blasting To Modify Goaf BehaviourDocument7 pagesLatilla 2007 Pre-Split Blasting To Modify Goaf BehaviourjlatillaNo ratings yet

- DSD - Relining PDFDocument1 pageDSD - Relining PDFMorris KwokNo ratings yet

- Soak-Pit: Floor LatrineDocument3 pagesSoak-Pit: Floor LatrineAbijithNo ratings yet

- Materials and Construction - I: Lecture No. 3 Dated: 27/02/2020Document22 pagesMaterials and Construction - I: Lecture No. 3 Dated: 27/02/2020awais anjumNo ratings yet

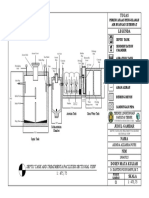

- Polly Septic TankDocument1 pagePolly Septic TankCollen Costa ShokoNo ratings yet

- TSE 10 07 00 1 FT - Doc AngDocument2 pagesTSE 10 07 00 1 FT - Doc AngEduardo CastilloNo ratings yet

- TB02 PVCPipe TrenchDocument2 pagesTB02 PVCPipe TrenchShwan SoraniNo ratings yet

- Adinda Azzahra Putri - 190407025 - Gambar PPABSDocument1 pageAdinda Azzahra Putri - 190407025 - Gambar PPABSAdinda Azzahra PutriNo ratings yet

- Ohwt Water Tank On Terrace Top.: Detail 05: Aluminium Alternating Tread Ladder, Used For Climbing OnDocument1 pageOhwt Water Tank On Terrace Top.: Detail 05: Aluminium Alternating Tread Ladder, Used For Climbing OnRajeshwari YeoleNo ratings yet

- Planning A Treatment Center: FloorplanDocument1 pagePlanning A Treatment Center: FloorplanbabakaroNo ratings yet

- Clay - NEW-Clay-Drainage-0616Document24 pagesClay - NEW-Clay-Drainage-0616AMOLNo ratings yet

- DAVAO P 1 2 Files MergedDocument2 pagesDAVAO P 1 2 Files MergedMarson JustinNo ratings yet

- B.O.Q For Okpala - Igwurita Km.17+500 - Ch43+510Document19 pagesB.O.Q For Okpala - Igwurita Km.17+500 - Ch43+510Chinenyike NnadiNo ratings yet

- Proposed CulvertsDocument1 pageProposed CulvertsDagl GoroNo ratings yet

- BN Dutta Septic TankDocument4 pagesBN Dutta Septic TankJeevan NaikNo ratings yet

- Draughtsman Civil Materials: CementDocument4 pagesDraughtsman Civil Materials: CementHARIJITH K SNo ratings yet

- 11 RoofDocument1 page11 RoofShane BiliNo ratings yet

- Swimming Pool 2: Section B - BDocument1 pageSwimming Pool 2: Section B - BTahirJabbarNo ratings yet

- U HalliburtonDocument3 pagesU Halliburtonanas soufNo ratings yet

- 671 VonKrugerDocument10 pages671 VonKrugerBagus Tri Ardaya ArdayaNo ratings yet

- Date BOQ Description of Work Unit Name of The Contractor Work PlaceDocument70 pagesDate BOQ Description of Work Unit Name of The Contractor Work Placeyashas sNo ratings yet

- 905 029 2 Grouting enDocument12 pages905 029 2 Grouting enAnıl ÖzpirinçiNo ratings yet

- UMADEVIDocument1 pageUMADEVImanohar kNo ratings yet

- Major Noel HouseDocument27 pagesMajor Noel Houseeduard bulanonNo ratings yet

- 3 - Plane - Wind FenceDocument1 page3 - Plane - Wind FenceRamesh GaurNo ratings yet

- Manhole Section PDFDocument1 pageManhole Section PDFjaipalNo ratings yet

- Glo Backfill TBM Tunnel Boring MachinesDocument8 pagesGlo Backfill TBM Tunnel Boring Machinesjpantazis1975No ratings yet

- Perforating With Water Control Boosts Production 1,470%Document2 pagesPerforating With Water Control Boosts Production 1,470%Israel Arias GonzálezNo ratings yet

- RAWL KEM Data SheetDocument2 pagesRAWL KEM Data Sheetbrian1mugadzaNo ratings yet

- 4N Tapping Band NewDocument2 pages4N Tapping Band NewAkshat Engineers Private LimitedNo ratings yet

- Water TankDocument3 pagesWater TankAlfred LochanNo ratings yet

- Brochures - Bronze Roof Drains PDFDocument2 pagesBrochures - Bronze Roof Drains PDFAakash KumarNo ratings yet

- Ucep Gazipur Tvet Institute: Total Manpower Count: 5 8 0 0 0 0 0 0 0 0 3 3 0 0 0 0Document1 pageUcep Gazipur Tvet Institute: Total Manpower Count: 5 8 0 0 0 0 0 0 0 0 3 3 0 0 0 0Ah RashedNo ratings yet

- Diaghragm Wall 2Document8 pagesDiaghragm Wall 2aramsayed100% (1)

- Pipe 03Document5 pagesPipe 03jb.dqaNo ratings yet

- Insert 02 Practical Assignment 2Document1 pageInsert 02 Practical Assignment 2panashekadangobt2201No ratings yet

- Arapuni Dam (Wharmby Et Al, ANZGS 2007)Document6 pagesArapuni Dam (Wharmby Et Al, ANZGS 2007)Nick WharmbyNo ratings yet

- AluminumDocument1 pageAluminumyoussefnabil929No ratings yet

- Atienza, Arjay M. ST - Anne College Lucena Inc.: Second Floor Plumbing Plan (Sanitary Works)Document1 pageAtienza, Arjay M. ST - Anne College Lucena Inc.: Second Floor Plumbing Plan (Sanitary Works)Atienza ArjayNo ratings yet

- 05 Metode KerjaDocument19 pages05 Metode Kerjaahmad maulidiNo ratings yet

- DBT273 Study MaterialDocument32 pagesDBT273 Study MaterialnatNo ratings yet

- Se PFD 001Document1 pageSe PFD 001mNo ratings yet

- Volume V A - Technical Specification For Civil WorksDocument128 pagesVolume V A - Technical Specification For Civil WorksRudra Pratap SinghNo ratings yet

- Bridge Deck Construction - Insitu With Void Formers & Post-TensionedDocument1 pageBridge Deck Construction - Insitu With Void Formers & Post-TensionedengrmasgharNo ratings yet

- Smacna DamperDocument7 pagesSmacna Dampermoming1No ratings yet

- 8643 IOM 300 and 400 SeriesDocument7 pages8643 IOM 300 and 400 SeriesBiju Basheer CNo ratings yet

- Printable Page - WiMaxDocument1 pagePrintable Page - WiMaxBiju Basheer CNo ratings yet