Professional Documents

Culture Documents

Spreader Beam Calculations: JOB NO:09025-01, Item no:K84-F-473/573 (STEAM GENERATOR)

Spreader Beam Calculations: JOB NO:09025-01, Item no:K84-F-473/573 (STEAM GENERATOR)

Uploaded by

Senthil KumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spreader Beam Calculations: JOB NO:09025-01, Item no:K84-F-473/573 (STEAM GENERATOR)

Spreader Beam Calculations: JOB NO:09025-01, Item no:K84-F-473/573 (STEAM GENERATOR)

Uploaded by

Senthil KumarCopyright:

Available Formats

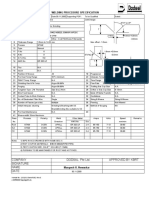

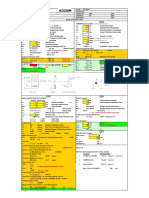

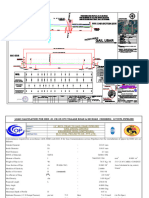

GULF HEAVY INDUSTRIES COMPANY

JOB NO:09025-01, Item no:K84-F-473/573(STEAM GENERATOR)

SPREADER BEAM CALCULATIONS

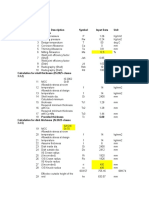

Input Data for Lifting Loads

Rated Load (Without Refractory,Riser D/Comer Pipes & including

exchanger components) F 169473 Kg

Imapct Factor I.F 2

No of Lifting Plates nL 2

Design Load (F x I.F) DL 338946 Kgs

Load per Lug (Dl/nL) PL 169473 Kgs

Allowable Stresses for Pipe

Pipe Material SA 106 Gr. B

2

Yield Stress 242 Mpa Sy 24.6 Kg/mm

Allow Bending Stress 0.66 x Sy 16.24 Kg/mm2

Allowable Stresses for Lifting / Bearing Plate

Lifting Plate / Bearing Plate Material SA 516 Gr.70

2

Yield Stress 262 Mpa Sy 26.7 Kg/mm

2

Allowable Tension Stress 0.6 x Sy 16.02 Kg/mm

Allowable Shear Stress 0.4 x Sy 10.68 Kg/mm2

Allowable Bearing Stress 0.75 x Sy 20.025 Kg/mm2

Allowable Stresses for Welds

U.T.S. at ambient temperature for weld material (Fu) : 42.19 Kg/mm2

Allowable stress in the weld 0.3 x Fu Syw 12.66 Kg/mm2

2

Allowable Tensile Stress in the Weld = 0.6 * Min. Yield Strength of weld SAW (T) 7.59 Kg/mm

2

Allowable Shear Stress in the Weld =0.4*Min.Yield Strength of weld SAW (S) 5.06 Kg/mm

2

Allowable Bending Stress in the Weld =0.4*Min.Yield Strength of weld SAW (B) 3.04 Kg/mm

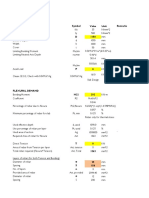

Input Data for Pipe

Length of Lift Pipe L1 3470 mm

ID of Lift Pipe Di 363.52 mm

Lift Pipe Thickness tt 21.44 mm

OD of Pipe Do 406.4 mm

Eccentricity for Pipe (Dm/2) e 192.5 mm

Input Data for Lifting Plate

Thk of Lug tL 70 mm

Radius of Lug plate at Lift point R1 270 mm

Height of Lift Plate at center h 300 mm

Input Data for Bearing Pads

Thickness of Bearing Plate tp 20 mm

Radius of Bearing Plate R2 250 mm

Dia of Pin Hole in Lug D1 130 mm

Input Data for Welding

Depth Weld Between Lift Plate and Bearing Pad KP1 14.0 mm

Depth Weld Between Pipe and lifting plate KP2 10.0 mm

Weld Length for Pipe & Lifting Plate WL 400.0 mm

Weld Efficiency Ew 0.7

Check Lifting plate

Tensile Stress at Section B-B

Area under Tension for Lift Plate (AT1) 2 x [ tL x (R1 - D1/2) ] 28700 mm2

Area under Tension for Bearing Pads(AT2) 4 x [ tp x (R2 - D1/2) ] 14800 mm2

2 2

Tensile Stress PL / (AT1 + AT2) 3.90 Kg/mm < 16.02 Kg/mm

The Design is Safe

Shear Stress at Section A-A

Area under Shear for Lift Plate (AS1) [ tL x (R1 - D1/2) ] + [ (h x tL ) / 2] 24850 mm2

Area under Tension for Bearing Pads(AS2) [ 2 x tp x (R2 - D1/2) ] + [ h x tp ] 13400 mm2

2 2

Shear Stress (T) PL / (AS1 + AS2) 4.43 Kg/mm < 10.68 Kg/mm

The Design is Safe

Pin Bearing Stress (Sp) PL/(D1 x (tL+2 x tp)) 11.85 Kg/mm2 < 20.03 Kg/mm2

The Design is Safe

Check Pipe

Lift Sling Angle (Minimum) Ø 30 degree

Vertical Component of Lift Load (Py) (PL x Sin Ø) 84737 Kgs

Moment (M) Py x e 16310082 Kg-mm

Section Modulus (Z) 0.098 ((Do^4-Di^4)/Do) 2366895 mm3

3

Polar section Modulus (Zp): 0.196 ((Do^4-Di^4)/Do) 4733790 mm

Bending Stress (Sb) M/Z 6.89 Kg/mm2 < 16.24 Kg/mm2

The Design is Safe

2 2

Torsional Shear Stress (St) M / Zp 3.45 Kg/mm < 16.02 Kg/mm

The Design is Safe

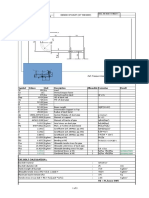

Check Welds

2

Welding Area for Bending (Aw) 4*WL*(0.707*KP2+tt ) 45616 mm

Distance from Load Center (d) y + WL/2 550 mm

Moment acting on welds (Mb) PL x d 93210150 Kg-mm

3

Section Modulus for the welds(Zw) 4 x WL / 3 85333333.3 mm3

2 2

Bending Stress in the Weld (Sbw) (Mb/Zw) 1.09 Kg/mm < 3.04 Kg/mm

The Design is Safe

Horiz.Component of lift Load (Ph) (PL x Sin Ø) 84737 Kgs

2 2

Shear Stress in the weld (Ssw) Ph / Ew x Aw 2.65 Kg/mm < 5.06 Kg/mm

The Design is Safe

Combined Maximum Tension in Weld (Stw) (Sbw/2 + sqrt((Sbw/2)^2 + Ssw^2)) 3.26 kg/mm2 < 7.59 Kg/mm2

The Design is Safe

Combined Maximum Shear In Weld (Ssw) sqrt((Sbw/2)2 + Ssw2) 2.71 kg/mm2 < 5.06 Kg/mm2

` The Design is Safe

Unity Check (Shear & Tension)

[ Stw / SAW(T) + Ssw / SAW(S) ] < 1 = [ 3.26 / 7.59 + 2.71 / 5.06 ]

0.96 < 1

The Design is Safe

Unity Check (Tension & Bending)

[ Stw / SAW(T) + Sbw / SAW(B) ] < 1 = [ 3.26 / 7.59 + 1.09 / 3.04 ]

0.79 < 1

The Design is Safe

You might also like

- ASME BPVC PCC-1 Torque PCC-1 WRC NPS44ACL150Document3 pagesASME BPVC PCC-1 Torque PCC-1 WRC NPS44ACL150datouyanshuNo ratings yet

- HDD Calc As Per PRCDocument8 pagesHDD Calc As Per PRClive4sankar50% (2)

- Drawing HandsDocument11 pagesDrawing Handsjefffm80% (5)

- Fixed Normal 575Document8 pagesFixed Normal 575mohanNo ratings yet

- Standard Shoe Verification Rev - ADocument19 pagesStandard Shoe Verification Rev - AballisnothingNo ratings yet

- 23132-E1A-XL-M: Spherical Roller BearingDocument2 pages23132-E1A-XL-M: Spherical Roller BearingvivianaNo ratings yet

- HDD Installation CalculationsDocument4 pagesHDD Installation Calculationslive4sankar100% (1)

- S.No Description Symbol Input Data Unit Design DataDocument2 pagesS.No Description Symbol Input Data Unit Design DataThiru AnanthNo ratings yet

- S.No Description Symbol Input Data Unit Design DataDocument2 pagesS.No Description Symbol Input Data Unit Design DataThiru AnanthNo ratings yet

- Description Symbol Value Unit RemarksDocument1 pageDescription Symbol Value Unit RemarksRakesh SapkotaNo ratings yet

- SFD & BMD PDFDocument1 pageSFD & BMD PDFRakesh SapkotaNo ratings yet

- SFD & BMD 01 PDFDocument1 pageSFD & BMD 01 PDFRakesh SapkotaNo ratings yet

- Part-Uhx (U-Tube) .Document5 pagesPart-Uhx (U-Tube) .AKSHAY BHATKARNo ratings yet

- Shincoil CompressionDocument98 pagesShincoil CompressionVNK90No ratings yet

- Steel Conv Belt - 1800-ST2250-8+6 FR-LRR-TKIL-NK ProjectDocument1 pageSteel Conv Belt - 1800-ST2250-8+6 FR-LRR-TKIL-NK ProjectCaspian DattaNo ratings yet

- Flange Excel NewDocument26 pagesFlange Excel NewvikasNo ratings yet

- S.No Description Symbol Input Data Unit Design DataDocument2 pagesS.No Description Symbol Input Data Unit Design DataThiru AnanthNo ratings yet

- S.No Description Symbol Input Data Unit Design DataDocument2 pagesS.No Description Symbol Input Data Unit Design DataThiru AnanthNo ratings yet

- Symbol Values Unit Description Allowable Formulae Result: Eye Bolt CalculationDocument12 pagesSymbol Values Unit Description Allowable Formulae Result: Eye Bolt CalculationNaveen JeevaNo ratings yet

- Steel Beam SpreadsheetDocument27 pagesSteel Beam SpreadsheetHugh McGilveray100% (1)

- Beam DesignDocument2 pagesBeam DesignBilal A BarbhuiyaNo ratings yet

- Perhitungan Saddle Dan Lifting LugDocument18 pagesPerhitungan Saddle Dan Lifting LugAhmad FaujiNo ratings yet

- Monorail Stopper Design For 73-My-4412: Input DataDocument4 pagesMonorail Stopper Design For 73-My-4412: Input Datarajasekhar.cheruvu8635No ratings yet

- Jis G-3444Document10 pagesJis G-3444Maulana YusufNo ratings yet

- S.No Description Symbol Input Data Unit Design DataDocument1 pageS.No Description Symbol Input Data Unit Design DataThiru AnanthNo ratings yet

- Collets+BT Selon EN13121-3Document6 pagesCollets+BT Selon EN13121-3Ben Abdallah BecemNo ratings yet

- SRB DesignDocument3 pagesSRB DesignRam LangheNo ratings yet

- Flange DesignDocument4 pagesFlange DesignAshish SharmaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1023-1AA43-4AB4-ZDocument1 pageData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1023-1AA43-4AB4-ZFredericks ACNo ratings yet

- Combined Footing DesDocument7 pagesCombined Footing Desansar700No ratings yet

- Nozzle 1Document25 pagesNozzle 1Sasikumar JothiNo ratings yet

- ENG K22014 H-072 DR A 05 Rev A - Torque TighteningDocument10 pagesENG K22014 H-072 DR A 05 Rev A - Torque TighteningQuraisy AmriNo ratings yet

- HDD Calculation For Gas PipelineDocument3 pagesHDD Calculation For Gas Pipelinesamotavijaypal26No ratings yet

- Cleat Design - C-605Document4 pagesCleat Design - C-605shaishavNo ratings yet

- Flange ThicknessDocument29 pagesFlange ThicknessJafer SayedNo ratings yet

- Saddle Design at Operating ConditionDocument17 pagesSaddle Design at Operating ConditionGanesh Bhardwaj100% (2)

- Trunnion CalculationsDocument2 pagesTrunnion Calculationspmech consultantNo ratings yet

- Design Excel SheetDocument17 pagesDesign Excel SheetbuntyNo ratings yet

- Body Flange .PVDB FlangeDocument1 pageBody Flange .PVDB FlangeAnonymous aBg51lbe18No ratings yet

- Design For 3-Pile GroupDocument4 pagesDesign For 3-Pile GroupHemam PrasantaNo ratings yet

- Crack Width BS5400Document3 pagesCrack Width BS5400yuNo ratings yet

- EC2-BE-dubble Reinforced Beams SLS-crackwidth Rev6Document7 pagesEC2-BE-dubble Reinforced Beams SLS-crackwidth Rev6Dong LINo ratings yet

- Frame ConnectionsDocument14 pagesFrame ConnectionsShawkat Ali KhanNo ratings yet

- RC Tie Beam DesignDocument8 pagesRC Tie Beam DesignArfel BartianaNo ratings yet

- BS5400-R-C-Design-With-Crack-Width SampleDocument1 pageBS5400-R-C-Design-With-Crack-Width SampleAlden CayagaNo ratings yet

- Lifting Lug Calculation For Small Horizontal VesselDocument2 pagesLifting Lug Calculation For Small Horizontal Vesselmiteshpatel191100% (2)

- Blind Plate THK - Hydro PDFDocument3 pagesBlind Plate THK - Hydro PDFNaveen JeevaNo ratings yet

- Engineering Calculation Sheet Consulting EngineersDocument11 pagesEngineering Calculation Sheet Consulting EngineersJONAS NGNo ratings yet

- Design of Corbels, Brackets and NibsDocument3 pagesDesign of Corbels, Brackets and NibsBrij AkabariNo ratings yet

- EndPl MomConn LSDDocument54 pagesEndPl MomConn LSDsilroy d'saNo ratings yet

- 93 Qc20 J 414 Inlet NozzleDocument6 pages93 Qc20 J 414 Inlet NozzleHgagselim SelimNo ratings yet

- Moment Connection DesignDocument2 pagesMoment Connection DesignmaheshbandhamNo ratings yet

- Beam Column ConnectionDocument2 pagesBeam Column ConnectionHAZIRACFS SURATNo ratings yet

- Sudyrah, Station Design Calculation of Existing Steel Tank Inlet Connection N-1 Doc. No.96-QC20-J-414Document7 pagesSudyrah, Station Design Calculation of Existing Steel Tank Inlet Connection N-1 Doc. No.96-QC20-J-414Hgagselim SelimNo ratings yet

- 0.0bolt Torque Calculation - R0Document9 pages0.0bolt Torque Calculation - R0Darshan PanchalNo ratings yet

- H200141 - Calculation of Basering Rev 0 PDFDocument9 pagesH200141 - Calculation of Basering Rev 0 PDFSani Adipura WinataNo ratings yet

- Base Plate Design - Rev-0Document8 pagesBase Plate Design - Rev-0KINGSUK PALNo ratings yet

- HDD-LC-0001 Rev 0Document24 pagesHDD-LC-0001 Rev 0SAUGAT DUTTANo ratings yet

- PVDB 72Document1 pagePVDB 72Senthil KumarNo ratings yet

- PVDB PackingDocument1 pagePVDB PackingSenthil KumarNo ratings yet

- PVDB 71Document1 pagePVDB 71Senthil KumarNo ratings yet

- PVDB 75Document1 pagePVDB 75Senthil KumarNo ratings yet

- PVDM - Manual Part 3Document1 pagePVDM - Manual Part 3Senthil KumarNo ratings yet

- PVDM - Manual Part 1Document1 pagePVDM - Manual Part 1Senthil KumarNo ratings yet

- PVDM - Design of Base Plates LegsDocument1 pagePVDM - Design of Base Plates LegsSenthil KumarNo ratings yet

- PVDB - Force and MomentDocument1 pagePVDB - Force and MomentSenthil KumarNo ratings yet

- PVDM Part-4Document1 pagePVDM Part-4Senthil KumarNo ratings yet

- PVDM Part-1.3Document1 pagePVDM Part-1.3Senthil KumarNo ratings yet

- PVDM Part-1Document1 pagePVDM Part-1Senthil KumarNo ratings yet

- PVDM 3Document1 pagePVDM 3Senthil KumarNo ratings yet

- PVDM 15Document1 pagePVDM 15Senthil KumarNo ratings yet

- PVDM 20Document1 pagePVDM 20Senthil KumarNo ratings yet

- PVDM 17Document1 pagePVDM 17Senthil KumarNo ratings yet

- PV Base Plate With Center WebDocument1 pagePV Base Plate With Center WebSenthil KumarNo ratings yet

- PVDM 16Document1 pagePVDM 16Senthil KumarNo ratings yet

- PVDM 13Document1 pagePVDM 13Senthil KumarNo ratings yet

- Skirt Fireproofing:: Brick or Concrete Applied Inside and Outside of Skirt To Prevent Damage To Skirt in Case of FireDocument1 pageSkirt Fireproofing:: Brick or Concrete Applied Inside and Outside of Skirt To Prevent Damage To Skirt in Case of FireSenthil KumarNo ratings yet

- PVDM 12Document1 pagePVDM 12Senthil KumarNo ratings yet

- PV - Types of CoilDocument1 pagePV - Types of CoilSenthil KumarNo ratings yet

- PVDM 4Document1 pagePVDM 4Senthil KumarNo ratings yet

- PVDM 14Document1 pagePVDM 14Senthil KumarNo ratings yet

- PV - Sample Problem - 2Document1 pagePV - Sample Problem - 2Senthil KumarNo ratings yet

- PVDM 10Document1 pagePVDM 10Senthil KumarNo ratings yet

- PV - Coil SupportsDocument1 pagePV - Coil SupportsSenthil KumarNo ratings yet

- PV - Types of MountingsDocument1 pagePV - Types of MountingsSenthil KumarNo ratings yet

- PV - Coil Layout For Flat Bottom TanksDocument1 pagePV - Coil Layout For Flat Bottom TanksSenthil KumarNo ratings yet

- PV - Agitators and Mixers For Vessels and TanksDocument1 pagePV - Agitators and Mixers For Vessels and TanksSenthil KumarNo ratings yet

- PV - Impeller AuctionsDocument1 pagePV - Impeller AuctionsSenthil KumarNo ratings yet

- Moist Air Properties and Conditioning ProcessesDocument94 pagesMoist Air Properties and Conditioning Processespamsanchezmd100% (1)

- Life in The Glory RealmDocument5 pagesLife in The Glory RealmRaildo S PereiraNo ratings yet

- Cromatografi e TextDocument8 pagesCromatografi e TextRaunciucGianinaNo ratings yet

- 01 - Quality Basics in Business With Bosch - Ver3Document71 pages01 - Quality Basics in Business With Bosch - Ver3Seenivasagam SeenuNo ratings yet

- Mengistu 2016Document13 pagesMengistu 2016Dimas WahyuNo ratings yet

- Experimental Investigation On The Effects of Process Parameters of GMAW and Transient Thermal Analysis of AISI321 SteelDocument16 pagesExperimental Investigation On The Effects of Process Parameters of GMAW and Transient Thermal Analysis of AISI321 SteelumisaaadahNo ratings yet

- Medical Surgical Nursing 2 HighlightsDocument7 pagesMedical Surgical Nursing 2 HighlightsMatt Andrei P. SongcuanNo ratings yet

- DFT Study of CO2 and H2O Co-Adsorption On CarbonDocument17 pagesDFT Study of CO2 and H2O Co-Adsorption On CarbonRafael Ricardo Celin ManceraNo ratings yet

- Halong Bay and Hanoi 5 Days PDFDocument3 pagesHalong Bay and Hanoi 5 Days PDFmaheshnavamiNo ratings yet

- ICTP VaporPressureGroup 2 PDFDocument27 pagesICTP VaporPressureGroup 2 PDFHarySetiyawanNo ratings yet

- Office Automation LabDocument36 pagesOffice Automation Labvidyanjali collegeNo ratings yet

- Owner's Manual: 2012 ModelDocument481 pagesOwner's Manual: 2012 ModelparamerdasNo ratings yet

- Complete Block DesignsDocument80 pagesComplete Block DesignsTaddese GashawNo ratings yet

- cfd1 IntroDocument6 pagescfd1 IntrowhateverNo ratings yet

- MULTIPLE CHOICE. Read The Following Questions and Choose The Best Answer by Shading TheDocument14 pagesMULTIPLE CHOICE. Read The Following Questions and Choose The Best Answer by Shading ThePrince Mark BadilloNo ratings yet

- Roald Amundsen and The South PoleDocument11 pagesRoald Amundsen and The South PoleRhonda BushNo ratings yet

- Video and Imaging Solutions GuideDocument61 pagesVideo and Imaging Solutions GuideHemantkumar100% (1)

- Heizer Om10 Ism 00Document6 pagesHeizer Om10 Ism 00fireflyzzz0% (1)

- VM Vma: Rated RatedDocument6 pagesVM Vma: Rated RatedramyeidNo ratings yet

- Cell Structure and Organisation NotesDocument27 pagesCell Structure and Organisation NotesGift Blessed NgoveNo ratings yet

- Bladder CancerDocument3 pagesBladder CancerGhea Jovita SinagaNo ratings yet

- Cliping & Clamping of DiodesDocument19 pagesCliping & Clamping of DiodesashutoshvashistNo ratings yet

- Transportation ProblemDocument53 pagesTransportation ProblemJapa SonNo ratings yet

- Design Principles For Thick CylindersDocument18 pagesDesign Principles For Thick CylindersDinesh VaghelaNo ratings yet

- 4Document2 pages4Cedrick CapampanganNo ratings yet

- CW9 Identifying Functions 5Document2 pagesCW9 Identifying Functions 5Xavier BurrusNo ratings yet

- First Record of Eudiplozoon Nipponicum Goto, 1891Document1 pageFirst Record of Eudiplozoon Nipponicum Goto, 1891selmabegovicNo ratings yet

- Metallized Polyester Film Capacitors (MKT)Document44 pagesMetallized Polyester Film Capacitors (MKT)m3y54mNo ratings yet

- Pro Tip Catalogue 4 07Document28 pagesPro Tip Catalogue 4 07notengofffNo ratings yet