Professional Documents

Culture Documents

Work Sheet WIM Aviation AIRCRAFT ELECTRICAL SERVICING: REMOVE AND INSTALL ANTI-COLLISION LIGHTS

Work Sheet WIM Aviation AIRCRAFT ELECTRICAL SERVICING: REMOVE AND INSTALL ANTI-COLLISION LIGHTS

Uploaded by

e-Office Virtual SystemOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Work Sheet WIM Aviation AIRCRAFT ELECTRICAL SERVICING: REMOVE AND INSTALL ANTI-COLLISION LIGHTS

Work Sheet WIM Aviation AIRCRAFT ELECTRICAL SERVICING: REMOVE AND INSTALL ANTI-COLLISION LIGHTS

Uploaded by

e-Office Virtual SystemCopyright:

Available Formats

AKADEMI ERA GEMILANG

12-2, JALAN TASIK RAJA LUMU L

SEKSYEN U4/L

40150 SHAH ALAM, SELANGOR

KERTAS KERJA

( WORK SHEET )

KOD DAN NAMA

TP-060-3:2013

PROGRAM /

AIRCRAFT MAINTENANCE OPERATION

PROGRAMME CODE &

NAME

TAHAP / LEVEL 3 (TIGA)

KOD PROGRAM, KOD

DAN TAJUK UNIT

KOMPETENSI/ TP-060-3:2013-C05

PROGRAMME CODE, AIRCRAFT ELECTRICAL SERVICING

COMPETENCY UNIT

CODE AND TITLE

1. THE PRINCIPLE AND THEORY OF AIRCRAFT

ELECTRICAL SYSTEM MAINTENANCE

NOMBOR AKTIVITI 2. IDENTIFY ELECTRICAL SYSTEM SERVICING

KERJA DAN REQUIREMENT

PENYATAAN / WORK

ACTIVITIES NUMBER 3. PREPARE TOOLS, EQUIPMENT AND MATERIALS

AND STATEMENT 4. REMOVE AIRCRAFT ELECTRICAL COMPONENT.

5. INSTALL AIRCRAFT ELECTRICAL COMPONENT

Muka Surat / Page : 1

NO. KOD / CODE NO. TP-060-3:2013-C05/K(3/6)

Drpd / of : 11

TAJUK/TITLE: REMOVE AND INSTALL ANTI-COLLISION LIGHTS

TUJUAN PEMBELAJARAN/INSTRUCTIONAL AIMS:

Pelatih-pelatih mesti boleh / Trainees should be able to:

1. Perform system component and operational check

2. Identify probability cause of malfunction and retification action

3. Diassemble and assemble anti-collision lights

Muka Surat / Page : 2

NO. KOD / CODE NO. TP-060-3:2013-C05/K(3/6)

Drp / of : 11

AKADEMI ERA GEMILANG akademieragemilang@gmail.com

Muka Surat / Page : 3

NO. KOD / CODE NO. TP-060-3:2013-C05/K(3/6)

Drp / of : 11

ARAHAN/ INSTRUCTION :

The trainees are required to perform the operational check, disassemble and

assemble anti-collision lights. Assumed that the anti-collision malfunction and the

defect cause is anti-collision are unserviceable, remove and replace the anti-collision

lights and perform the operational checkout with the tools and equipment provided

and take all necessary safety and precaution while operating the equipment.

AKADEMI ERA GEMILANG akademieragemilang@gmail.com

Muka Surat / Page : 4

NO. KOD / CODE NO. TP-060-3:2013-C05/K(3/6)

Drp / of : 11

LUKISAN, DATA DAN JADUAL/ TOOLS, EQUIPMENT AND MATERIAL :

AKADEMI ERA GEMILANG akademieragemilang@gmail.com

Muka Surat / Page : 5

NO. KOD / CODE NO. TP-060-3:2013-C05/K(3/6)

Drp / of : 11

Firgure 1: Disassembly / Assembly Anti-collision light

Figure 2: Lighting Schematic Diagram

PERALATAN, PERKAKASAN DAN BAHAN/ TOOLS, EQUIPMENT AND MATERIAL

AKADEMI ERA GEMILANG akademieragemilang@gmail.com

Muka Surat / Page : 6

NO. KOD / CODE NO. TP-060-3:2013-C05/K(3/6)

Drp / of : 11

KUANTITI

BIL MATERIAL MEASUREMENT

(Bahan:Calon)

1 Cement (type 44) - 1:1

KUANTITI

BIL TOOLS / EQUIPMENT MEASUREMENT

(Bahan:Calon)

1 Multimeter Unit 1:1

2 Spanner3/8 inch Unit 1:1

3 Spanner 5/8 Unit 1:1

4 Philips screwdriver Unit 1:1

5 Flat head screwdriver Unit 1:1

6 Side cutter Unit 1:1

7 Crimping tool Unit 1:1

8 External power unit Unit 1:20

9 Aircraft unit 1:20

AKADEMI ERA GEMILANG akademieragemilang@gmail.com

Muka Surat / Page : 7

NO. KOD / CODE NO. TP-060-3:2013-C05/K(3/6)

Drp / of : 11

LANGKAH

BUTIRAN KERJA/DETAILS

KERJA/STEPS

SIKAP, KESELAMATAN DAN PERSEKITARAN/ ATTITUDE,

SAFETY AND ENVIRONMENTAL

Attitude:

i. Clearly / precise in interpreting basic requirements on

aircraft maintenance

ii. Systematic in evaluating the requirement on aircraft

maintenance

iii. Meticulous in interpreting task card.

iv. Precise in performing task vis-a-vis aircraft manual

maintenance guideline.

Safety:

i. Always use appropriate Personal Protective Equipment

(PPE).

ii. Ensure safe working area.

iii. Comply with aircraft safety procedures.

Environmental:

i. Comply with environmental legislative, rules and regulations.

1. Perform system 1.1 PERFORM OPERATIONAL CHECK

component and i. Connect dc external Power.

operational check ii. Engage overhead control panel POS LTS and No. 2

junction box BEACON LT POWER FWD and AFT circuit

breakers.

iii. Place EXTERIOR LIGHTS MASTER SWITCH to ON

and OFF/ANTI-COLL switch to ANTI- COLL. Aft

anticollision lights shall turn and go on.

iv. Place FWD ROT LT switch to NORM. Forward

anticollision lights shall turn and go on.

v. Place FWD ROT LT switch OFF. Forward anti-collision

light stops turning and goes off. Aft anti-collision

‐ light remains on and turning.

AKADEMI ERA GEMILANG akademieragemilang@gmail.com

Muka Surat / Page : 8

NO. KOD / CODE NO. TP-060-3:2013-C05/K(3/6)

Drp / of : 11

LANGKAH

BUTIRAN KERJA/DETAILS

KERJA/STEPS

2. Identify probability

cause of malfunction

and retification action

3. Disassemble and 3.1 PERFORM DISASSEMBLY:

assemble anti-collision a. Unscrew and separate lens and cover from base (17,

AKADEMI ERA GEMILANG akademieragemilang@gmail.com

Muka Surat / Page : 9

NO. KOD / CODE NO. TP-060-3:2013-C05/K(3/6)

Drp / of : 11

LANGKAH

BUTIRAN KERJA/DETAILS

KERJA/STEPS

lights figure 5-3).

b. Remove retaining (6) from base by loosening screws

(14) and sliding clips (15) back to clear the retaining

ring. Remove lamp(7)

c. Remove contact block (22) and phenolic shim (21)

from base.

d. Disconnect wires (12, 23, and 24), remove screws

and remove contact spring (10), and support leaf

springs (11).

e. Disconnect wiring from disconnect plug (16).

f. Disconnect wiring from beacon motor contacts at

post (9). Remove posts (9 and 26) by removing

washer, nuts (19), and rubber washer (18).

g. Remove gasket (8) from base.

h. Remove tens (46) from cover (5) by removing the

screws and nuts (4), and spring clips (34).

i. Remove motor mount.

j. Loosen setscrews (45) and remove reflector (44).

k. Remove resistor (35) from contact plate (33)'

Remove tap (37) from resistor.

l. Remove cover (48) and insulator (49) from motor

(51). Disconnect wire of radio noise filter (38) from

motor.

m. Remove radio noise filter from mounting bracket

(40). Disconnect wire from tap at filter.

n. Remove shaft (42), plate (43), and mounting bracket.

o. Remove motor (51). Remove worm gear (54) by

loosening setscrews (53). Disconnect wiring and

remove capacitor (50).

p. Remove bracket (30). Remove gear (29) from

intermediate gear (31) by loosening setscrews (28).

AKADEMI ERA GEMILANG akademieragemilang@gmail.com

Muka Surat / Page : 10

NO. KOD / CODE NO. TP-060-3:2013-C05/K(3/6)

Drp / of : 11

LANGKAH

BUTIRAN KERJA/DETAILS

KERJA/STEPS

3.2 PERFORM ASSEMBLY.

a. Install intermediate gear (31, figure 5-3) into bracket

(30). Install gear (29) on intermediate gear shaft and

secure with setscrews (28).Secure bracket (30) to

motor mount with screws.

b. Connect capacitor (50) to motor (51)' Secure worm

gear (54) to motor shaft using 6etscrews (53). Secure

motor to motor mount with screws.

c. Install shaft (42), plate (43), and mounting bracket

(40) to motor mount.

d. Secure radio noise filter (38) on mounting bracket

with screws. Connect filter wire to motor. Connect

wire from tap (37) to filter.

e. Secure cover (48) and insulator (49) to motor (51)

with screws.

f. Secure tap (37) resistor (35) with screws. Secure

resistor to contact plate (33) with screws.

g. Install reflector (44) on shaft (42), securing with

setscrews (45).

h. Connect motor to external source of power and set

reflector to rotate 45 rpm by adjusting tap on

resistor.

i. Secure motor on cover (5) with screws.

j. Install fens (46) on cover with spring clips (34) and

screws and nuts (4).

k. Install gasket (8) on base (17), using cement (C-44).

l. Install post (9 and 26) securing with rubber washer

(18) and washers and nuts (19). Connect wiring at

beacon motor contacts on post (9).

m. Connect wiring to disconnect plug (16).

n. Secure contact spring (10), support leaf springs (11),

AKADEMI ERA GEMILANG akademieragemilang@gmail.com

Muka Surat / Page : 11

NO. KOD / CODE NO. TP-060-3:2013-C05/K(3/6)

Drp / of : 11

LANGKAH

BUTIRAN KERJA/DETAILS

KERJA/STEPS

and wires (12, 23, and 24) to contact block (22) with

screws.

o. Secure phenolic shim (21) and contact block (22) to

base (17) with screws.

p. Install lamp (7) and retaining ring (6), securing with

clips (15) and screws (14).

q. Screw lens (46) and cover (5) to base.

1. What are the equipment required for operational check?

2. What are the material needed for installing gasket (8) on base (17)?

AKADEMI ERA GEMILANG akademieragemilang@gmail.com

Muka Surat / Page : 12

NO. KOD / CODE NO. TP-060-3:2013-C05/K(3/6)

Drp / of : 11

SENARAI SEMAK /CHECK LIST:

SENARAI SEMAK KERJA/CHECKLIST

Tidak

Bil Tahap Pencapaian/ Terima / Catatan/

Terima / Not

No. Level of Achievement Accepted Remark

Accepted

A. PROSES KERJA/WORK PROCESS

1. Tools and equipment prepared

System component and operational

2.

checked.

Probability cause of malfunction and the

3.

retification action identified

Anti-collision lights diassembled and

4.

assembled

B. HASIL KERJA/END RESULT - PRODUK/PERKHIDMATAN/KEPUTUSAN

System component and operational

1.

checked according to manual

Anti-collision lights diassembled and

2

assembled neatly

C. SIKAP/ ATTITUDE

1. Systematic in evaluating the requirement

on aircraft maintenance

2. Precise in performing task aircraft

maintenance.

D. KESELAMATAN & PERSEKITARAN / SAFETY & ENVIRONMENTAL

1. Comply with aircraft safety procedures.

.................................................. ....................................................

( Tandatangan dan Nama Pelatih ) (Tandatangan dan Nama Pengajar )

Trainee’s Name and Signature Instructor’s Name and Signature

AKADEMI ERA GEMILANG akademieragemilang@gmail.com

Muka Surat / Page : 13

NO. KOD / CODE NO. TP-060-3:2013-C05/K(3/6)

Drp / of : 11

Tarikh/Date: ____________________ Tarikh/Date:_________________

AKADEMI ERA GEMILANG akademieragemilang@gmail.com

You might also like

- Sop For Motor Changing JobDocument10 pagesSop For Motor Changing JobT S Virdi50% (2)

- AURTTK102 Student Assessment - TheoryDocument9 pagesAURTTK102 Student Assessment - TheoryDeymon Alejandro Pinzon NaranjoNo ratings yet

- Acrylic Material in OrthodonticsDocument48 pagesAcrylic Material in Orthodonticsdr_nilofervevai2360No ratings yet

- AS71051BDocument27 pagesAS71051Braviraj londhe100% (1)

- Pma C05Document9 pagesPma C05Nur ZaidanNo ratings yet

- IxawDocument4 pagesIxawyuvaraja 2219No ratings yet

- Starter/Generator Removal/Installation: M14/PPS/004Document3 pagesStarter/Generator Removal/Installation: M14/PPS/004Akash DeyNo ratings yet

- Assignment Sheet CidbDocument5 pagesAssignment Sheet CidbAnonymous V76nXvDAGNo ratings yet

- Practical Procedures: M14/PPS/002Document3 pagesPractical Procedures: M14/PPS/002Akash DeyNo ratings yet

- Practical Procedures: M14/PPS/002Document3 pagesPractical Procedures: M14/PPS/002Akash DeyNo ratings yet

- PW1100 FWD Mount Shackle Assembly Removal - Installation Schedule Issue-01, Rev 00Document15 pagesPW1100 FWD Mount Shackle Assembly Removal - Installation Schedule Issue-01, Rev 00Pradeep K s100% (1)

- Synchronous Control StarterDocument8 pagesSynchronous Control StarterNordiana ZulkifliNo ratings yet

- Kertas Kerja: Program'S Code & NameDocument5 pagesKertas Kerja: Program'S Code & NameHadi azfar channelNo ratings yet

- Pelan Mengajar Amali - Grinding Pro1Document7 pagesPelan Mengajar Amali - Grinding Pro1muhammad fakhrin shamsudinNo ratings yet

- SCHEME - E Fifth Semester (EE)Document54 pagesSCHEME - E Fifth Semester (EE)Yaser Shaikh0% (3)

- Form Desaign 4Document15 pagesForm Desaign 4andryan herjantoNo ratings yet

- New Me-5Document3 pagesNew Me-5kapun kumar nayakNo ratings yet

- Practical Procedures: M14/PPS/006Document5 pagesPractical Procedures: M14/PPS/006Akash DeyNo ratings yet

- Deliverable Task MAINTENANCE OF THE VEHICLE ELECTRICAL SYSTEMDocument8 pagesDeliverable Task MAINTENANCE OF THE VEHICLE ELECTRICAL SYSTEMScribdTranslationsNo ratings yet

- Universiti Kuala Lumpur: Assessment Brief and Verification Cover SheetDocument6 pagesUniversiti Kuala Lumpur: Assessment Brief and Verification Cover SheetAtzroulnizam AbuNo ratings yet

- PPS Module 13Document106 pagesPPS Module 13Akash DeyNo ratings yet

- Kertas Kerja: Kod Dan Nama ProgramDocument11 pagesKertas Kerja: Kod Dan Nama ProgramLeeNo ratings yet

- L4 Amali Cu4Document8 pagesL4 Amali Cu4PK K100% (1)

- Kelompok 3 - PTL RudderDocument6 pagesKelompok 3 - PTL RudderTaTayosNo ratings yet

- Quiz - 4 Final - AnswerDocument3 pagesQuiz - 4 Final - AnswerShuvro Sankar SenNo ratings yet

- Chantiers de L'Atlantique For MSC MSC 3 & 4 Electrical Propulsion Operator and Maintenance TrainingDocument40 pagesChantiers de L'Atlantique For MSC MSC 3 & 4 Electrical Propulsion Operator and Maintenance TrainingZoran PopovicNo ratings yet

- Check List For CraneDocument30 pagesCheck List For CraneMukesh Katarnavare100% (1)

- ITB3105 CASE Tools Lab: Record of Laboratory/ Practical Course WorkDocument40 pagesITB3105 CASE Tools Lab: Record of Laboratory/ Practical Course WorkSiddhantpsinghNo ratings yet

- Online Airline Ticket Reservation CompleteDocument40 pagesOnline Airline Ticket Reservation CompleteMishal Fathima100% (1)

- Lessons Learned From Launch Vehicle Avionics SystemsDocument10 pagesLessons Learned From Launch Vehicle Avionics Systemsdovesnest_inNo ratings yet

- Workshop Processes & PracticeDocument8 pagesWorkshop Processes & PracticeGavaine MattisonNo ratings yet

- SOP-14 AGEL-P02-SP02-Module Mounting Structure - Installation of MMSDocument159 pagesSOP-14 AGEL-P02-SP02-Module Mounting Structure - Installation of MMSVikas SinghNo ratings yet

- LogbookDocument19 pagesLogbookNazimNo ratings yet

- Air BalancingDocument2 pagesAir BalancingPramod BhintedeNo ratings yet

- Automated Feed Handling System For Stamping Process: Chanvim Engineering Industries Pvt. LTDDocument28 pagesAutomated Feed Handling System For Stamping Process: Chanvim Engineering Industries Pvt. LTDmayank soniNo ratings yet

- WS 2 - (Kawalan Motor Mara Songsang)Document10 pagesWS 2 - (Kawalan Motor Mara Songsang)ZULHILMINo ratings yet

- MC 024 3 2012 C01KDocument5 pagesMC 024 3 2012 C01KHadi azfar channelNo ratings yet

- CAT Dimention Main BearingDocument16 pagesCAT Dimention Main BearingmkNo ratings yet

- Micom P132: Feeder Management and Bay ControlDocument796 pagesMicom P132: Feeder Management and Bay ControlHung Cuong PhamNo ratings yet

- 2006 US Army LessonPlans C01 Crane PMCS 27pDocument27 pages2006 US Army LessonPlans C01 Crane PMCS 27pLo Shun FatNo ratings yet

- Universiti Kuala Lumpur: Assessment Brief and Verification Cover SheetDocument12 pagesUniversiti Kuala Lumpur: Assessment Brief and Verification Cover SheetNaim NizamNo ratings yet

- M10 RewindingDocument124 pagesM10 RewindinggmnatigizawNo ratings yet

- Deck Crane 712Document712 pagesDeck Crane 712andriibarketNo ratings yet

- En An Ce / Co Nti Nu Ed: Data SheetDocument8 pagesEn An Ce / Co Nti Nu Ed: Data SheetReyes Aguilar MarioNo ratings yet

- AEL ProceduresDocument70 pagesAEL ProceduresGeorge OgbecheNo ratings yet

- Exp 3 - Forward Reverse StarterDocument7 pagesExp 3 - Forward Reverse StarterirfanNo ratings yet

- Check ListsDocument30 pagesCheck ListsAhmed Gomaa100% (1)

- 047-Testing of Electrical Protection PDFDocument13 pages047-Testing of Electrical Protection PDFVikrant Deshmukh0% (1)

- Ats 004-BDocument8 pagesAts 004-BRajesh Sharma PoudelNo ratings yet

- Form GMF Q-343A R3 Oral Assessment Guide For Aircraft Certifying StaffDocument6 pagesForm GMF Q-343A R3 Oral Assessment Guide For Aircraft Certifying StaffRenaldo Dwianto FbsNo ratings yet

- Practical Procedures: M14/PPS/001Document3 pagesPractical Procedures: M14/PPS/001Akash DeyNo ratings yet

- Practical Procedures: M14/PPS/001Document3 pagesPractical Procedures: M14/PPS/001Akash DeyNo ratings yet

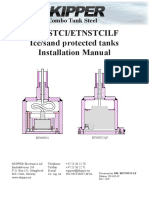

- Etnstci/Etnstcilf Ice/sand Protected Tanks Installation ManualDocument14 pagesEtnstci/Etnstcilf Ice/sand Protected Tanks Installation ManualRafael ReisNo ratings yet

- Practical Exercise Sheet: Phiếu Bài Tập Thực HànhDocument3 pagesPractical Exercise Sheet: Phiếu Bài Tập Thực Hànhcharltonbarnes011No ratings yet

- Ats 004-CDocument8 pagesAts 004-CRajesh Sharma PoudelNo ratings yet

- Planned Maintenance Procedure AMENDEDDocument5 pagesPlanned Maintenance Procedure AMENDEDwebsterchikambaNo ratings yet

- 2 - Plan Mengajar Teori Wiring SurfaceDocument10 pages2 - Plan Mengajar Teori Wiring SurfaceNur ZaidanNo ratings yet

- Practical Procedures: M14/PPS/003Document2 pagesPractical Procedures: M14/PPS/003Akash DeyNo ratings yet

- Week 9 AMT 4103 Learning Module 7Document16 pagesWeek 9 AMT 4103 Learning Module 7Ian SolomonNo ratings yet

- Micom (Areva)Document812 pagesMicom (Areva)Dario SalinasNo ratings yet

- Moonbase Blues BW v1Document2 pagesMoonbase Blues BW v1Станіслав Польськой100% (3)

- Crankcase Blowby, Measure PDF FORMATDocument51 pagesCrankcase Blowby, Measure PDF FORMATDARISON VINCENT100% (2)

- Phy Investigatory Project Tangent GalvanDocument11 pagesPhy Investigatory Project Tangent Galvankomal mahelaNo ratings yet

- Methods of Data CollectionDocument49 pagesMethods of Data Collectionclain4u80% (5)

- 12 Production and Purification of Recombinant Glargine Insulin From Escherichia Coli BL-21 StrainDocument12 pages12 Production and Purification of Recombinant Glargine Insulin From Escherichia Coli BL-21 StrainAnand KumarNo ratings yet

- GE JVM1540 OTR MicrowaveDocument56 pagesGE JVM1540 OTR MicrowaveplasmapeteNo ratings yet

- Oxygenation: Nursing Fundamentals Focus ViiiDocument72 pagesOxygenation: Nursing Fundamentals Focus Viiiጀኔራል አሳምነው ፅጌ100% (1)

- Zero-B - NonDocument1 pageZero-B - Nonmaksudur4No ratings yet

- Code On Wages 2019 - NotesDocument3 pagesCode On Wages 2019 - NotesAnand ReddyNo ratings yet

- Pressure Conversion ChartDocument1 pagePressure Conversion Chartamarkore3486No ratings yet

- 03b Van Parijs 20141996 Two Dilemmas of The Welfare StateDocument6 pages03b Van Parijs 20141996 Two Dilemmas of The Welfare StateNela PetrováNo ratings yet

- 1 - Ne - b2 Sety Leksykalne U7iDocument1 page1 - Ne - b2 Sety Leksykalne U7iAneta WalejewskaNo ratings yet

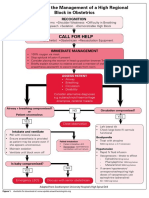

- Algorithm For The Management of A High Regional Block in ObstetricsDocument5 pagesAlgorithm For The Management of A High Regional Block in ObstetricsRaditya DidotNo ratings yet

- Rish Split Current TransformerDocument6 pagesRish Split Current TransformerluisNo ratings yet

- SCF PolyDocument7 pagesSCF PolyAde AnjaniNo ratings yet

- 3m Privacy Filter Screen Anti Glare Screen Protector Price List Singapore 2019Document32 pages3m Privacy Filter Screen Anti Glare Screen Protector Price List Singapore 2019Anchor Business & IT SolutionsNo ratings yet

- Antibiotic Drug Resistance PDFDocument700 pagesAntibiotic Drug Resistance PDFDiego RamosNo ratings yet

- ToxicologyDocument197 pagesToxicologyRichelle Dianne Ramos-Giang100% (6)

- Vegetarian Moussaka Recipe With Mushroom SauceDocument1 pageVegetarian Moussaka Recipe With Mushroom SauceMarija JesicNo ratings yet

- Ipm Fruit Crops 23022015 PDFDocument92 pagesIpm Fruit Crops 23022015 PDFprudhvi_hyd100% (1)

- Safai Karamchari Andolan and Ors Vs Union of India and Ors On 27 March, 2014Document14 pagesSafai Karamchari Andolan and Ors Vs Union of India and Ors On 27 March, 2014Velmurugan ElumalaiNo ratings yet

- DNA DR In-Class ActivitiesDocument15 pagesDNA DR In-Class ActivitiesCéline Engels100% (1)

- FND Sleep DisordersDocument10 pagesFND Sleep DisordersQuang VuNo ratings yet

- Earth and Life Science: Quarter 2 - Module 9DDocument15 pagesEarth and Life Science: Quarter 2 - Module 9DJessaNo ratings yet

- The Role of EEG in The Diagnosis and Classification of The Epilepsy Syndromes (Part 1)Document66 pagesThe Role of EEG in The Diagnosis and Classification of The Epilepsy Syndromes (Part 1)Rosmery VillaNo ratings yet

- 21 22 ĐỀ CƯƠNG ÔT 8 TUẦN HKI ANH 10 21 22Document12 pages21 22 ĐỀ CƯƠNG ÔT 8 TUẦN HKI ANH 10 21 22sangNo ratings yet

- The Five Elements ChartDocument6 pagesThe Five Elements ChartPaul Francis100% (9)

- EcoDocument7 pagesEcoSushma YonzenNo ratings yet

- Anterior Teeth Selection and Its ArrangementDocument48 pagesAnterior Teeth Selection and Its ArrangementAnonymous NFiQTb1No ratings yet