Professional Documents

Culture Documents

Rsu - Rear Suspension Trasera

Rsu - Rear Suspension Trasera

Uploaded by

iohammorilloCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rsu - Rear Suspension Trasera

Rsu - Rear Suspension Trasera

Uploaded by

iohammorilloCopyright:

Available Formats

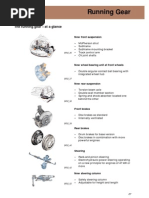

SUSPENSION

RSU

A

B

SECTION

REAR SUSPENSION C

RSU

CONTENTS

PRECAUTION ............................................... 2 REMOVAL AND INSTALLATION ................ 8 F

PRECAUTIONS ................................................... 2 REAR SHOCK ABSORBER .............................. 8

Precaution for Supplemental Restraint System Exploded View .......................................................... 8 G

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN- Removal and Installation .......................................... 8

SIONER" ................................................................... 2 Inspection ................................................................. 9

Precaution for Suspension ........................................ 2 Disposal ...................................................................10

H

PREPARATION ............................................ 3 COIL SPRING ................................................... 11

Exploded View .........................................................11

PREPARATION ................................................... 3 Removal and Installation .........................................11 I

Commercial Service Tools ........................................ 3 Inspection ................................................................12

SYMPTOM DIAGNOSIS ............................... 4 REAR SUSPENSION BEAM ............................ 13

Exploded View .........................................................13 J

NOISE, VIBRATION AND HARSHNESS Removal and Installation .........................................13

(NVH) TROUBLESHOOTING ............................. 4 Inspection ................................................................14

NVH Troubleshooting Chart ...................................... 4 K

SERVICE DATA AND SPECIFICATIONS

PERIODIC MAINTENANCE .......................... 5 (SDS) ............................................................ 15

REAR SUSPENSION ASSEMBLY ..................... 5 SERVICE DATA AND SPECIFICATIONS L

Inspection .................................................................. 5

(SDS) ................................................................. 15

WHEEL ALIGNMENT .......................................... 6 Wheel Alignment (Unladen*1) .................................15

Wheelarch Height (Unladen*) ..................................15 M

Inspection .................................................................. 6

Revision: May 2013 RSU-1 2014 Versa Note

PRECAUTIONS

< PRECAUTION >

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000009499797

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precaution for Suspension INFOID:0000000008969581

• When installing rubber bushings, the final tightening must be carried out under unladen conditions with tires

on ground. Spilled oil might shorten the life of rubber bushings. Be sure to wipe off any spilled oil.

- Unladen conditions mean that fuel, engine coolant and lubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

• After servicing suspension parts, be sure to check wheel alignment.

• Self-lock nuts are not reusable. Always use new ones when installing. Since new self-lock nuts are pre-oiled,

tighten as they are.

• The tightening surface must be kept free of oil/grease.

• When jacking up the vehicle with a floor jack, never hang the jack on the suspension beam.

Revision: May 2013 RSU-2 2014 Versa Note

PREPARATION

< PREPARATION >

PREPARATION A

PREPARATION

Commercial Service Tools INFOID:0000000009499798

B

Tool name Description

C

Power tool Loosening nuts, screws and bolts

RSU

PIIB1407E

Revision: May 2013 RSU-3 2014 Versa Note

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

< SYMPTOM DIAGNOSIS >

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart INFOID:0000000009499799

Use chart below to find the cause of the symptom. If necessary, repair or replace these parts.

RSU-8, RSU-11, RSU-13

RSU-8, RSU-11, RSU-13

RSU-12

RSU-8

RSU-6

RAX-4

WT-42

WT-41

BR-7

Reference

—

Shock absorber deformation, damage or deflection

Bushing or mounting deterioration

Improper installation, looseness

Possible cause and SUSPECTED PARTS

Incorrect wheel alignment

Suspension looseness

Parts interference

ROAD WHEEL

Spring fatigue

REAR AXLE

BRAKE

TIRE

Noise × × × × × × × × × ×

Shake × × × × × × × × ×

Vibration × × × × × × ×

Symptom REAR SUSPENSION

Shimmy × × × × × × × × ×

Shudder × × × × × × ×

Poor quality ride or handling × × × × × × × × ×

×: Applicable

Revision: May 2013 RSU-4 2014 Versa Note

REAR SUSPENSION ASSEMBLY

< PERIODIC MAINTENANCE >

PERIODIC MAINTENANCE A

REAR SUSPENSION ASSEMBLY

Inspection INFOID:0000000009499800

B

COMPONENT PART

Check the mounting conditions (looseness, backlash) of each component. Verify the component conditions C

(wear, damage) are normal.

SHOCK ABSORBER

Check the shock absorber for oil leaks or damage. Replace the components if necessary. D

RSU

Revision: May 2013 RSU-5 2014 Versa Note

WHEEL ALIGNMENT

< PERIODIC MAINTENANCE >

WHEEL ALIGNMENT

Inspection INFOID:0000000009499801

DESCRIPTION

Measure the wheel alignment under unladen conditions.

NOTE:

“Unladen conditions” means that fuel, engine coolant, and lubricants are full. Spare tire, jack, hand tools and

mats are in designated positions.

PRELIMINARY

Check the following:

1. Tires for improper air pressure and wear.

2. Road wheels for runout. Refer to WT-41, "Inspection".

3. Wheel bearing axial end play. Refer to RAX-10, "Wheel Bearing".

4. Shock absorber operation.

5. Each mounting part of suspension for looseness and deformation.

6. Rear suspension beam for cracks, deformation, and other damage.

7. Vehicle height (posture).

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed.

• This type of alignment is recommended for any NISSAN/INFINITI vehicle.

• The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

• The alignment machine itself should be capable of accepting any NISSAN/INFINITI vehicle.

• The alignment machine should be checked to ensure that it is level.

2. Make sure the alignment machine is properly calibrated.

• Your alignment machine should be regularly calibrated in order to give correct information.

• Check with the manufacturer of your specific alignment machine for their recommended Service/Cali-

bration Schedule.

THE ALIGNMENT PROCESS

IMPORTANT: Use only the alignment specifications listed in this Service Manual. Refer to RSU-15, "Wheel

Alignment (Unladen*1)".

1. When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Do NOT use these indicators.

• The alignment specifications programmed into your alignment machine that operate these indicators

may not be correct.

• This may result in an ERROR.

2. Most camera-type alignment machines are equipped with both "Rolling Compensation" method and

optional "Jacking Compensation" method to "compensate" the alignment targets or head units.

"Rolling Compensation" is the preferred method.

• If using the "Rolling Compensation" method, after installing the alignment targets or head units, push or

pull on the rear wheel to move the vehicle. Do not push or pull the vehicle body.

• If using the "Jacking Compensation" method, after installing the alignment targets or head units, raise

the vehicle and rotate the wheels 1/2 turn both ways.

NOTE:

Do not use the "rolling compensation" if you are using sensor-type alignment equipment.

• Follow all instructions for the alignment machine you're using for more information.

CAMBER INSPECTION

• Measure camber of both right and left wheels with a suitable alignment gauge.

Camber : Refer to RSU-15, "Wheel Alignment

(Unladen*1)".

• If it is out of the specification value, inspect and replace any damaged or worn rear suspension parts.

Revision: May 2013 RSU-6 2014 Versa Note

WHEEL ALIGNMENT

< PERIODIC MAINTENANCE >

TOTAL TOE-IN INSPECTION

Measure the total toe-in using following procedure. If it is out of the specification, inspect and replace any A

damaged or worn rear suspension parts.

WARNING:

• Always perform the following procedure on a flat surface. B

• Make sure that no person is in front of the vehicle before pushing it.

1. Bounce the rear of the vehicle up and down to stabilize the vehicle height (posture).

2. Push the rear wheel to move the vehicle straight ahead about 5 m (16 ft). C

3. Put a mark on the base line of the tread (rear side) of both tires

at the same height of hub center. These are measuring points.

D

RSU

F

SEIA0362E

4. Measure the distance (A) from the rear side. G

5. Push the rear wheel to move the vehicle slowly ahead and to

rotate the wheels 180 degrees (1/2 turn).

CAUTION: H

If the wheels have rotated more than 180 degrees (1/2 turn),

try the above procedure again from the beginning. Do not

push the vehicle backward.

6. Measure the distance (B) from the front side. I

Total toe-in : Refer to RSU-15, "Wheel Alignment

J

(Unladen*1)".

SFA234AC

Revision: May 2013 RSU-7 2014 Versa Note

REAR SHOCK ABSORBER

< REMOVAL AND INSTALLATION >

REMOVAL AND INSTALLATION

REAR SHOCK ABSORBER

Exploded View INFOID:0000000009499802

AWEIA0322ZZ

1. Cap 2. Piston rod lock nut 3. Washer

4. Bushing 5. Distance tube 6. Bound bumper cover

7. Bound bumper 8. Shock absorber 9. Rear suspension beam

Removal and Installation INFOID:0000000009499803

REMOVAL

1. Remove the rear shock absorber mask. Refer to INT-33, "Exploded View".

2. Remove the cap from the rear shock absorber.

3. Remove the piston rod lock nut (1).

NOTE:

To loosen the piston rod lock nut, hold the tip (A) of the piston

rod.

4. Remove the washer and the bushing.

JPEIB0241ZZ

5. Set a suitable jack under the rear suspension beam.

CAUTION:

• At this step, the jack must be set only for supporting the removal procedure. For details on jack-

ing up the vehicle, refer to GI-28, "Garage Jack and Safety Stand".

• Do not damage the rear suspension beam with the jack.

• Make sure the rear suspension beam is stable when using the jack.

6. Remove the lower shock absorber bolt.

7. Remove the rear shock absorber.

8. Remove the bushing, the distance tube, the washer, the bound bumper cover, and the bound bumper

from the shock absorber.

9. Inspect the components. Refer to RSU-9, "Inspection".

Revision: May 2013 RSU-8 2014 Versa Note

REAR SHOCK ABSORBER

< REMOVAL AND INSTALLATION >

INSTALLATION

Installation is in the reverse order of removal. A

• To install the bushings (1), securely insert the protrusion (A) into

the hole in the vehicle body.

B

D

JPEIB0240ZZ

• Install the washer (1) in the direction shown. RSU

: Bushing side

F

JPEIB0248ZZ

H

• Perform the final tightening of the bolts and nuts under unladen conditions with the tires on level ground.

• Hold the tip (A) of the piston rod. Tighten the piston rod lock nut (1) I

to the specification.

CAUTION:

Do not reuse the piston rod lock nut.

J

JPEIB0241ZZ L

• When installing the cap, securely engage the cap groove (A) with

the flange on the vehicle body. M

JPEIB0244ZZ

P

• After replacing the shock absorber, always follow the disposal procedure to discard the old shock absorber.

Refer to RSU-10, "Disposal".

Inspection INFOID:0000000009499804

INSPECTION AFTER REMOVAL

Revision: May 2013 RSU-9 2014 Versa Note

REAR SHOCK ABSORBER

< REMOVAL AND INSTALLATION >

Shock Absorber

Check the following items and replace the parts if necessary.

• Check the shock absorber for oil leaks, deformation, cracks, and other damage.

• Check the piston rod for damage, uneven wear, and distortion.

Bound Bumper, Bushing

Check for cracks and damage. Replace the parts if necessary.

Washer, Bound Bumper Cover, Distance Tube

• Check for cracks and damage. Replace the parts if necessary.

Disposal INFOID:0000000009499805

1. Set the shock absorber horizontally with the piston rod fully extended.

2. Drill a 2 – 3 mm (0.08 – 0.12 in) hole at the position ( ) from the

top as shown to release gas gradually.

CAUTION:

• Wear eye protection (safety glasses).

• Wear gloves.

• Be careful with metal chips or oil blown out by the com-

pressed gas.

NOTE:

• Drill vertically in this direction ( ).

• Drill directly to the outer tube avoiding brackets.

• The gas is clear, colorless, odorless, and harmless. JPEIA0161ZZ

(A) : 20 – 30 mm (0.79 – 1.18 in)

3. Position the drilled hole downward and drain oil by moving the piston rod several times.

CAUTION:

Dispose of drained oil according to the law and local regulations.

Revision: May 2013 RSU-10 2014 Versa Note

COIL SPRING

< REMOVAL AND INSTALLATION >

COIL SPRING

A

Exploded View INFOID:0000000009499806

RSU

G

JPEIB0162ZZ

1. Upper rubber seat 2. Coil spring 3. Lower rubber seat

4. Rear suspension beam

H

Removal and Installation INFOID:0000000009499807

I

REMOVAL

1. Set a suitable jack under the rear suspension beam.

CAUTION: J

• At this step, the jack must be set only for supporting the removal procedure. For details on jack-

ing up the vehicle, refer to GI-28, "Garage Jack and Safety Stand".

• Do not damage the rear suspension beam with the jack. K

2. Remove the lower shock absorber bolts. Refer to RSU-8, "Exploded View".

3. Slowly lower the suitable jack. Remove the upper rubber seat, the coil spring, and the lower rubber seat

from the rear suspension beam. L

CAUTION:

Make sure the rear suspension beam is stable when using the jack.

4. Inspect the components. Refer to RSU-12, "Inspection".

M

INSTALLATION

Installation is in the reverse order of removal.

• Identify the upper side of the coil spring. N

: Upper side

NOTE: O

The top of the coil spring has a flat shape.

JSEIA0430ZZ

Revision: May 2013 RSU-11 2014 Versa Note

COIL SPRING

< REMOVAL AND INSTALLATION >

• Install the lower rubber seat (A) to the rear suspension beam

mounting hole (B).

• Match up lower rubber seat indentions and rear suspension beam

grooves and attach.

JPEIB0223ZZ

Inspection INFOID:0000000009499808

INSPECTION AFTER REMOVAL

Check the upper rubber seat, the lower rubber seat, and the coil spring for deformation, cracks, and damage.

Replace the parts if necessary.

Revision: May 2013 RSU-12 2014 Versa Note

REAR SUSPENSION BEAM

< REMOVAL AND INSTALLATION >

REAR SUSPENSION BEAM

A

Exploded View INFOID:0000000009499809

RSU

G

AWEIA0323ZZ

1. Rear suspension beam

H

Removal and Installation INFOID:0000000009499810

NOTE: I

When removing components such as hoses, tubes, lines, etc., cap or plug openings to prevent fluid from spill-

ing.

REMOVAL J

1. Remove the rear wheels and tires using power tools. Refer to WT-45, "Removal and Installation".

2. Disconnect the brake hoses from the rear suspension beam.

3. Remove the spindles and rear drum brake components. Refer to RAX-6, "Exploded View". K

4. Remove the wheel sensors and position the wheel sensor harnesses aside. Refer to BRC-106, "REAR

WHEEL SENSOR : Removal and Installation".

5. Disconnect the parking brake cables from the rear suspension beam and position the rear drum brake L

back plates aside with wire. Refer to RAX-6, "Exploded View".

6. Set a suitable jack under the rear suspension beam.

CAUTION: M

• At this step, the jack must be set only for supporting the removal procedure. For details on jack-

ing up the vehicle, refer to GI-28, "Garage Jack and Safety Stand".

• Do not damage the rear suspension beam with the jack. N

7. Remove the lower shock absorber bolts. Refer to RSU-8, "Exploded View".

8. Slowly lower the suitable jack. Remove the upper rubber seats, the coil springs, and the lower rubber

seats from the rear suspension beam. O

CAUTION:

Make sure the rear suspension beam is stable when using the jack.

9. Remove the rear suspension beam bolts.

P

10. Slowly lower the suitable jack. Remove the rear suspension beam from the vehicle.

11. Inspect the components. Refer to RSU-14, "Inspection".

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Do not reuse the rear suspension beam nuts.

Revision: May 2013 RSU-13 2014 Versa Note

REAR SUSPENSION BEAM

< REMOVAL AND INSTALLATION >

• Perform the final tightening of the rear suspension beam nuts and bolts under unladen conditions with the

tires on level ground.

• Adjust the parking brake. Refer to PB-4, "Inspection and Adjustment".

• Fill the hydraulic brake system. Refer to BR-11, "Refilling".

• Bleed the hydraulic brake system. Refer to BR-12, "Bleeding Brake System".

• Complete the inspection. Refer to BR-11, "Inspection".

Inspection INFOID:0000000009499811

INSPECTION AFTER REMOVAL

Check the rear suspension beam for deformation, cracks or damage. Replace the parts if necessary.

INSPECTION AFTER INSTALLATION

1. Check the wheel sensor harness to be sure the connectors are fully seated.

2. Check the neutral position of the steering angle sensor. Refer to BRC-53, "Work Procedure".

3. Check the wheel alignment. Refer to RSU-6, "Inspection".

Revision: May 2013 RSU-14 2014 Versa Note

SERVICE DATA AND SPECIFICATIONS (SDS)

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS) A

SERVICE DATA AND SPECIFICATIONS (SDS)

Wheel Alignment (Unladen*1) INFOID:0000000009499812 B

Minimum −1° 55′ (−1.92°)

C

Camber

Nominal −1° 25′ (−1.42°)

Degree minute (Decimal degree)

Maximum −0° 55′ (−0.92°)

D

RSU

SFA234AC F

Minimum Out 2.0 mm (Out 0.079 in)

Distance (A - B) Nominal In 2.0 mm (In 0.079 in)

G

Maximum In 6.0 mm (In 0.236 in)

Total toe-in

Minimum Out 0° 45′ (Out 0.75°)

Angle (LH and RH)*2 Nominal In 0° 10′ (In 0.17°) H

Degree minute (Decimal degree)

Maximum In 0° 35′ (In 0.58°)

*1: Fuel, engine coolant, and lubricants are full. Spare tire, jack, hand tools, and mats are in designated positions.

I

*2: Since an adjustment mechanism is not included, the value of the left and right wheels must be used as the standard value.

Wheelarch Height (Unladen*) INFOID:0000000009499813

Unit: mm (in)

K

LEIA0085E

N

Tire size 185/65R15 195/55R16

Front (Hf) 690 (27.17) 687 (27.05)

Rear (Hr) 679 (26.73) 678 (26.69) O

*: Fuel, engine coolant, and lubricants are full. Spare tire, jack, hand tools, and mats are in designated positions.

Revision: May 2013 RSU-15 2014 Versa Note

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Vehicle Structures - Development of The Sports Car Chassis and Stiffness Analysis of The Westfield Sports CarDocument96 pagesVehicle Structures - Development of The Sports Car Chassis and Stiffness Analysis of The Westfield Sports CarWaynePrangnell100% (5)

- Chevrolet Tahoe Technical ManualDocument37 pagesChevrolet Tahoe Technical ManualFAKESIGNUPACCOUNTNo ratings yet

- Harris DX15 Main PDFDocument288 pagesHarris DX15 Main PDFiohammorilloNo ratings yet

- Workshop Manual: Sales Division Technical Network LeadershipDocument52 pagesWorkshop Manual: Sales Division Technical Network LeadershipAnonymous FjOY9y5DNo ratings yet

- VDCF03 - 02GB - DCF80-100 Workshop ManualDocument1,018 pagesVDCF03 - 02GB - DCF80-100 Workshop ManualANH LÊ100% (2)

- Manual de Servicio Motor 1600 Nissan Versa 2014Document21 pagesManual de Servicio Motor 1600 Nissan Versa 2014iohammorilloNo ratings yet

- FX50Document198 pagesFX50iohammorillo40% (5)

- Grid RetroDocument16 pagesGrid RetroiohammorilloNo ratings yet

- TCRP Report 57 - Track Design Handbook For Light Rail TransitDocument344 pagesTCRP Report 57 - Track Design Handbook For Light Rail TransitbcleeNo ratings yet

- Modelling and Simulation AssignmentDocument7 pagesModelling and Simulation AssignmentJoel ForbesNo ratings yet

- LANROVER - Air Suspension Compressor SoftwareDocument4 pagesLANROVER - Air Suspension Compressor SoftwareTung NguyenNo ratings yet

- Brochure Range Rover 2010Document44 pagesBrochure Range Rover 2010Beepin JeNo ratings yet

- Running Gear (Suspension, Steering, Brake System, Electrical System) For Skoda FabiaDocument17 pagesRunning Gear (Suspension, Steering, Brake System, Electrical System) For Skoda FabiakikouchaaNo ratings yet

- A Improved Hydro-Pneumatic Suspension: Mathematical Modeling and SimulationDocument6 pagesA Improved Hydro-Pneumatic Suspension: Mathematical Modeling and SimulationAhmadMoaazNo ratings yet

- Kinematics and Force Analysis TOMEJ-8-219Document5 pagesKinematics and Force Analysis TOMEJ-8-219Pedro PinheiroNo ratings yet

- Driveshaft and AxleDocument25 pagesDriveshaft and AxleClaudio Godoy GallegosNo ratings yet

- CBR1000RR 2010Document110 pagesCBR1000RR 2010LEONARDO100% (3)

- GR00003400 34Document26 pagesGR00003400 34Art Del R SalongaNo ratings yet

- Suspension and Frame Design in Formula SAE - SAE PaperDocument11 pagesSuspension and Frame Design in Formula SAE - SAE Paperamit_dceNo ratings yet

- Catalogo de Ensamble MBC-O 1119Document155 pagesCatalogo de Ensamble MBC-O 1119Julio Sauceda LongoriaNo ratings yet

- Belt Scale HandbookDocument28 pagesBelt Scale HandbookPercy TorresNo ratings yet

- Automobile Systems - 9057Document5 pagesAutomobile Systems - 9057Khushbu JoshiNo ratings yet

- Suspension SubsystemDocument29 pagesSuspension SubsystemAkhilesh KatdareNo ratings yet

- Wheel Loader: Engine Power 66,0 KW / 88,5 HP at 2.350 RPM Operating Weight 6.875 - 7.180 KG Bucket Capacity 1,05 - 1,80 MDocument12 pagesWheel Loader: Engine Power 66,0 KW / 88,5 HP at 2.350 RPM Operating Weight 6.875 - 7.180 KG Bucket Capacity 1,05 - 1,80 MJimmyNo ratings yet

- ZW310 3.4-4.2 Cum PDFDocument11 pagesZW310 3.4-4.2 Cum PDFSriram NambiNo ratings yet

- Kinshofer KM920!12!921 EngDocument1 pageKinshofer KM920!12!921 EngSaša StankovićNo ratings yet

- New Text DocumentDocument6 pagesNew Text DocumentsadsdNo ratings yet

- Hitachi Wheel Loader ZW90Document7 pagesHitachi Wheel Loader ZW90Leandro SalNo ratings yet

- Shock Absorber ReportDocument48 pagesShock Absorber ReportGiani Siva Prasad Sabbavarapu33% (6)

- Automotive Chassis 2Document360 pagesAutomotive Chassis 2Mohammmed Farooq100% (1)

- Siemens PLM Using Nonlinear Flexible Bodies in Multibody Simulation WP 50012 A22 Tcm1023 258268Document11 pagesSiemens PLM Using Nonlinear Flexible Bodies in Multibody Simulation WP 50012 A22 Tcm1023 258268Aerospace0908No ratings yet

- Spring Rates, Wheel Rates, Motion Ratios and Roll Stiffness Session 5Document43 pagesSpring Rates, Wheel Rates, Motion Ratios and Roll Stiffness Session 5Vijay Pawar100% (1)

- Chassis, Aerodynamics and FeaDocument25 pagesChassis, Aerodynamics and FeaSivaPrasad Chekri100% (1)

- Coach & Wagon BogiesDocument156 pagesCoach & Wagon BogiesAmanpreet Singh100% (1)