Professional Documents

Culture Documents

Cummins Bosch Manual Diesel Fuel Injection Pump Type Ve Rotary PDF

Cummins Bosch Manual Diesel Fuel Injection Pump Type Ve Rotary PDF

Uploaded by

Edin Raul Yalle Rafael89%(9)89% found this document useful (9 votes)

2K views56 pagesOriginal Title

Cummins Bosch Manual Diesel Fuel Injection Pump Type Ve Rotary.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

89%(9)89% found this document useful (9 votes)

2K views56 pagesCummins Bosch Manual Diesel Fuel Injection Pump Type Ve Rotary PDF

Cummins Bosch Manual Diesel Fuel Injection Pump Type Ve Rotary PDF

Uploaded by

Edin Raul Yalle RafaelCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 56

Diesel engine management

Diesel :

Distributor Fuel-Injection Pumps

Edition 94/95

Technical Instruction

BOSCH

t

Diesel

Distributor Fuel-Injection pumps

VE

the “green-house effect

9 lower than for the

the. past few years to. Suey

ower the particulate emissions which

though, would have been impossible.

Goer died «i te ve ‘pump

in’ passenger-car applications, th

engine responds immediately

the finest change in accelerator-pedal

setting, All points. which

the sophisticated handling qualities of

amodem-day autome

The Electronic Diesel Control. (EDO)

also plays a decisive role in the overall.

improvement of the —diese-engine

passenger

‘The following pages will deal with the

design and construction of the VE

distributor pump, and how it adapts

injected fuel quantity, sta

and duration of injection to the

different engine operating conditions.

sel engine i the ~ passenger car

Combustion in the diesel engine

The diesel engine 2

Distributor injection pumps VE

Fuel-injection systems,

fuel-injection technology 4

Fuel supply and delivery 8

Mechanical engine-speed control

(governing) 18

Injection timing 25

‘Add-on modules and shutoff

devices 28

Testing and calibration at

Electronic Diesel Control (EDC) _42

Peripheral equipment for

diesel fuel-injection systems

Nozzles and nozzle holders 48

Auxiliary starting devices for

diesel engines (starting aids 54

Combustion

in the diesel

‘engine

Combustion in the diesel

engine

The diesel engine

Diesel combustion principle

The diesel engine is a compression-

ignition (Cl) engine. Being as Cl engines

only draw in ait, they are able to

compress this to a level which is

considerably higher than that in the

sparicignition (SI) engine using an air-

fuel mixture. In addition, the SI engine is

also sensitive to knock. With its overall

efficiency figure, the diesel engine rates

fas the most efficient combustion engine

(CE). Large, slow-running models can

have efficiency figures of as much as

50% or even more. The resulting ow

fuel consumption, coupled with the low

level of pollutants in the exhaust gas

and the considerably reduced level of

noise, all serve to underline the diesel

engine's significance. The diesel engine

can utilise either the 4 or 2-stroke

principle. In automotive applications

though, diesels are practically always of

the 4-stroke type (Fig. 1)

Working cycle (4-stroke)

During the first stroke, the downward

movement of the piston draws. in

unthrottied air through the open intake

valve,

During the second stroke, the so-called

compression stroke, the air trapped in

the cylinder is compressed by the piston

which is now moving upwards. Com-

pression ratios are between 14:1 and

24:1. In the process, the air heats up to

temperatures around 800°C. At the end

of the compression stroke the nozzle

injects fuel into the heated air at press-

ures of up to 1500 bar.

Following the ignition delay, at the be-

ginning of the third stroke the finely

atomized fuel ignites as a result of auto-

ignition and bums almost completely.

‘The cylinder charge heats up even fur-

ther and the cylinder pressure increases

again. The energy released by the igni-

tion is applied to the piston.

The piston is forced downwards and the

combustion energy is transformed into

‘mechanical energy. In the fourth stroke,

Fig. 1: 4-stroke diesel engine

1 2

{induction soko, 2 Compression stroke, 9 Working stroke, 4 Exhaust stroke.

2 ‘

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shop Manual DL420A (Ingles) PDFDocument832 pagesShop Manual DL420A (Ingles) PDFEdin Raul Yalle Rafael100% (9)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- SG Operation ManualDocument51 pagesSG Operation ManualEdin Raul Yalle Rafael100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Case 580M Series 2 Backhoe Loader Parts Catalog PDF Manual PDFDocument1 pageCase 580M Series 2 Backhoe Loader Parts Catalog PDF Manual PDFEdin Raul Yalle RafaelNo ratings yet

- Elect. Eng. Control: Service Training MalagaDocument3 pagesElect. Eng. Control: Service Training MalagaEdin Raul Yalle Rafael100% (5)

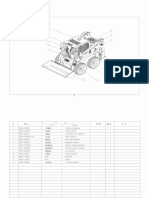

- DUMPER Serie - : Agria Hispania, S.ADocument97 pagesDUMPER Serie - : Agria Hispania, S.AEdin Raul Yalle RafaelNo ratings yet

- Controller P22000 PDFDocument157 pagesController P22000 PDFEdin Raul Yalle RafaelNo ratings yet

- VALVULA ALIVIO LINEAS 972G CatDocument8 pagesVALVULA ALIVIO LINEAS 972G CatEdin Raul Yalle RafaelNo ratings yet

- Hydraulic Hammer Parts ListDocument58 pagesHydraulic Hammer Parts ListEdin Raul Yalle RafaelNo ratings yet

- Changes Details Date Written Approved CE120163 Cooling Capacity Improvement 2012.09.14 Js - Cho HK - KimDocument23 pagesChanges Details Date Written Approved CE120163 Cooling Capacity Improvement 2012.09.14 Js - Cho HK - KimEdin Raul Yalle RafaelNo ratings yet

- 320C Causas de RecalentamientoDocument4 pages320C Causas de RecalentamientoEdin Raul Yalle RafaelNo ratings yet

- XG935-III - SO11701 Parts Catalogue (11-10-17)Document87 pagesXG935-III - SO11701 Parts Catalogue (11-10-17)Edin Raul Yalle Rafael100% (1)

- Assembly Procedure: Transmission CaseDocument14 pagesAssembly Procedure: Transmission CaseEdin Raul Yalle RafaelNo ratings yet

- Plano Electrico 972GDocument19 pagesPlano Electrico 972GEdin Raul Yalle Rafael100% (2)

- 153 Owner ManualDocument72 pages153 Owner ManualEdin Raul Yalle RafaelNo ratings yet

- Wiper RelayDocument2 pagesWiper RelayEdin Raul Yalle Rafael100% (1)

- Changes Details Date Written Approved CE120163 Cooling Capacity Improvement 2012.09.14 Js - Cho HK - KimDocument23 pagesChanges Details Date Written Approved CE120163 Cooling Capacity Improvement 2012.09.14 Js - Cho HK - KimEdin Raul Yalle RafaelNo ratings yet

- Controller P22000 PDFDocument157 pagesController P22000 PDFEdin Raul Yalle RafaelNo ratings yet

- WS50Parts Book KubotaDocument87 pagesWS50Parts Book KubotaEdin Raul Yalle RafaelNo ratings yet

- 7495 HF HydraCrowd AEHQ6519Document3 pages7495 HF HydraCrowd AEHQ6519Edin Raul Yalle Rafael100% (1)

- Cummins QSL-9 Operation and Maintenance Manual PDFDocument341 pagesCummins QSL-9 Operation and Maintenance Manual PDFEdin Raul Yalle Rafael100% (2)

- 330M Komatzu PDFDocument824 pages330M Komatzu PDFEdin Raul Yalle RafaelNo ratings yet