Professional Documents

Culture Documents

Electrode Comparision

Electrode Comparision

Uploaded by

AnilCopyright:

Available Formats

You might also like

- WPS ISO 15609 TemplateDocument1 pageWPS ISO 15609 TemplateSatish Keskar100% (5)

- WPS ISO 15609 TemplateDocument1 pageWPS ISO 15609 TemplateSatish Keskar100% (5)

- Cu ZN 15 TombacDocument2 pagesCu ZN 15 TombacPetrus UngureanuNo ratings yet

- MTC JSPLDocument2 pagesMTC JSPLAnil0% (1)

- En 10204 - 3.1 & 3.2Document1 pageEn 10204 - 3.1 & 3.2Anil100% (1)

- What Is RAID Control PDFDocument6 pagesWhat Is RAID Control PDFAhmedNo ratings yet

- OK AristoRod 69Document2 pagesOK AristoRod 69joao guilhermeNo ratings yet

- Purus 46: Mig/Mag Wires (Gmaw) Mild Steel WiresDocument1 pagePurus 46: Mig/Mag Wires (Gmaw) Mild Steel WiresYudhveer GrewalNo ratings yet

- MAT 1210 MCGB - Data Sheet For Suppliers Old MAT No.: 121Document1 pageMAT 1210 MCGB - Data Sheet For Suppliers Old MAT No.: 121MohamedNo ratings yet

- M.M.A. Welding Electrode: Classifications & ApprovalsDocument1 pageM.M.A. Welding Electrode: Classifications & ApprovalscwiksjNo ratings yet

- Wb35S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb35S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Wb1500e Eni CiDocument1 pageWb1500e Eni CicwiksjNo ratings yet

- 25crmo4: Steel GradeDocument3 pages25crmo4: Steel GradeCristian Stiven Martinez GonzalezNo ratings yet

- STK 400Document5 pagesSTK 400Nizar NazriNo ratings yet

- A.S.T.M. B584-09a: WWW - Okendo.mxDocument4 pagesA.S.T.M. B584-09a: WWW - Okendo.mxShariq KhanNo ratings yet

- Technical Report (CSF-81TM)Document5 pagesTechnical Report (CSF-81TM)matiasg.sanchezv95No ratings yet

- 38 MN VS6Document2 pages38 MN VS6Pramod NautiyalNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Wb4606e E312-17Document1 pageWb4606e E312-17cwiksjNo ratings yet

- E10018d2-Eng LINCOLNDocument1 pageE10018d2-Eng LINCOLNBenfil ViernezNo ratings yet

- AW60Document1 pageAW60Fitra VertikalNo ratings yet

- 42crmo6 : Steel GradeDocument2 pages42crmo6 : Steel GradeYonas Dwiananta YuwonoNo ratings yet

- 38 MN VS6Document3 pages38 MN VS6Jaison JacobNo ratings yet

- Wb9009E M.M.A. Welding Electrode: Bs en 14700-2005: Efe2Document1 pageWb9009E M.M.A. Welding Electrode: Bs en 14700-2005: Efe2lathasri78No ratings yet

- Pamphlet MG-51T PDFDocument2 pagesPamphlet MG-51T PDFImmalatulhusnaNo ratings yet

- Last Updated: Jan 27, 2006Document2 pagesLast Updated: Jan 27, 2006박준용No ratings yet

- SC-71LHM Cored: Hyundai Welding Co., LTDDocument9 pagesSC-71LHM Cored: Hyundai Welding Co., LTDAmanSharmaNo ratings yet

- Wb76S M.M.A. Welding Electrode: Classifications & ApprovalsDocument1 pageWb76S M.M.A. Welding Electrode: Classifications & Approvalslathasri78No ratings yet

- C2700Document6 pagesC2700Andrew TanNo ratings yet

- Product Data Sheet OK Autrod 12.64: G 'Gas-Shielded Metal-Arc Welding'Document2 pagesProduct Data Sheet OK Autrod 12.64: G 'Gas-Shielded Metal-Arc Welding'Cem DufourNo ratings yet

- Compact Multipurpose Type Compatible With High-Voltage PulseDocument10 pagesCompact Multipurpose Type Compatible With High-Voltage PulseEko SutjiptoNo ratings yet

- Datasheet Sandvik 199l enDocument3 pagesDatasheet Sandvik 199l enpedro rojasNo ratings yet

- CuZn33 CatalogueDocument9 pagesCuZn33 CataloguefedericoNo ratings yet

- Purus 42 CFDocument2 pagesPurus 42 CFluisNo ratings yet

- Wb2318e E9018-MDocument1 pageWb2318e E9018-McwiksjNo ratings yet

- Product Data Sheet OK Autrod 12.51: G 'Gas-Shielded Metal-Arc Welding'Document2 pagesProduct Data Sheet OK Autrod 12.51: G 'Gas-Shielded Metal-Arc Welding'Filipe CordeiroNo ratings yet

- WB5525E ENiCrMo-5Document1 pageWB5525E ENiCrMo-5cwiksjNo ratings yet

- Product Specifications: Specifications For Continuous Cast ProductsDocument4 pagesProduct Specifications: Specifications For Continuous Cast ProductsvejanidbNo ratings yet

- SC-71MSR: Hyundai Welding Co., LTDDocument7 pagesSC-71MSR: Hyundai Welding Co., LTDRaviTeja BhamidiNo ratings yet

- Datasheet Sandvik 2283l en v2018!07!24 14 - 12 Version 1Document3 pagesDatasheet Sandvik 2283l en v2018!07!24 14 - 12 Version 1bhuvandesignNo ratings yet

- S355JRDocument3 pagesS355JRaabco.purchaseNo ratings yet

- Aaepl: TDC No. AAEPL/RM/lDocument2 pagesAaepl: TDC No. AAEPL/RM/lSandip PandeNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Wb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

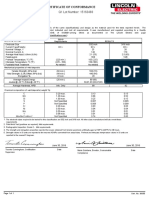

- Certificate of Conformance: Q1 Lot Number: 15163483Document1 pageCertificate of Conformance: Q1 Lot Number: 15163483interx00No ratings yet

- GW CSSRM2.CM - enDocument25 pagesGW CSSRM2.CM - enviniciustim9No ratings yet

- Automig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36Document1 pageAutomig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36satnamNo ratings yet

- High Conductivity Copper, Hard, UNS C10200 (MatWeb)Document3 pagesHigh Conductivity Copper, Hard, UNS C10200 (MatWeb)jlmeseguerNo ratings yet

- Aluminium Wrought AlloyDocument29 pagesAluminium Wrought AlloyRaj Kumar GiriNo ratings yet

- OK Tigrod 13.32Document1 pageOK Tigrod 13.32Paulo CorreiaNo ratings yet

- Din 2395-1Document4 pagesDin 2395-113393m210No ratings yet

- 1SMB5915BDocument3 pages1SMB5915Bafun02260709No ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- Cuzn37 Industrial RolledDocument6 pagesCuzn37 Industrial RolledcvgfgNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- Surface Mount Aluminum Electrolytic Capacitors: NACE SeriesDocument5 pagesSurface Mount Aluminum Electrolytic Capacitors: NACE SeriesNICCompNo ratings yet

- Steel Equivalent Table: en / BS To SAE - Page 1 of 20Document3 pagesSteel Equivalent Table: en / BS To SAE - Page 1 of 20LASCARZAMFIRESCUNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- WB56S E7016-1Document1 pageWB56S E7016-1cwiksjNo ratings yet

- CWC-BookletF1 10Document1 pageCWC-BookletF1 10satnamNo ratings yet

- CM-9CB TG-S9Cb US-9CbDocument3 pagesCM-9CB TG-S9Cb US-9Cbamit singhNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- What We Will CoverDocument4 pagesWhat We Will CoverAnilNo ratings yet

- WPS As Per ISO 15609 Ref.Document3 pagesWPS As Per ISO 15609 Ref.AnilNo ratings yet

- List of En/Iso Standards: SR No Standard Description EditionDocument4 pagesList of En/Iso Standards: SR No Standard Description EditionAnilNo ratings yet

- Law of Mother Earth BoliviaDocument3 pagesLaw of Mother Earth Boliviarahul banerjeeNo ratings yet

- Rotorcraft Aerodynamics: Muhammad Abdullah Tahir 180101034 Aero 17 (A)Document15 pagesRotorcraft Aerodynamics: Muhammad Abdullah Tahir 180101034 Aero 17 (A)Abdullah CheemaNo ratings yet

- HEI Tech Sheet 110Document15 pagesHEI Tech Sheet 110Suganya LokeshNo ratings yet

- Textbook Pediatric Behavioral Nutrition Factors Environment Education and Self Regulation 1St Edition Areej Hassan Ebook All Chapter PDFDocument39 pagesTextbook Pediatric Behavioral Nutrition Factors Environment Education and Self Regulation 1St Edition Areej Hassan Ebook All Chapter PDFjanet.galloway812100% (8)

- Geometry - Olympiad Material BY DR SHYAM SUNDAR AGRAWALDocument67 pagesGeometry - Olympiad Material BY DR SHYAM SUNDAR AGRAWALdrssagrawalNo ratings yet

- Comm - Name Comm - Code Comm - WT Index20122013 I Primary Articles (A) - Food ArticlesDocument48 pagesComm - Name Comm - Code Comm - WT Index20122013 I Primary Articles (A) - Food ArticlesNavin SanjeevNo ratings yet

- Asme A13.1 - 1996Document27 pagesAsme A13.1 - 1996lohv100% (1)

- Material Balance PDFDocument31 pagesMaterial Balance PDFApril Joy HaroNo ratings yet

- Filipino BasicDocument21 pagesFilipino BasicReiko Nakayama100% (1)

- Quarter 3 - Las No. 1 (Week 5-7) Active Recreation (Street and Hip-Hop Dances) (Pe10Pf-Iiia-H-39, Pe10Pf-Lllc-H-45)Document11 pagesQuarter 3 - Las No. 1 (Week 5-7) Active Recreation (Street and Hip-Hop Dances) (Pe10Pf-Iiia-H-39, Pe10Pf-Lllc-H-45)hakkensNo ratings yet

- SCM and TQM: by Junaid ShaheedDocument8 pagesSCM and TQM: by Junaid ShaheedjunaidsNo ratings yet

- MCQ - AcousticsDocument16 pagesMCQ - AcousticsRomeo Espenida0% (1)

- Ex 4Document4 pagesEx 420-MCE-63 SYED HASSAN KUMAILNo ratings yet

- BSD-GL-HAL-HMS-100 - (Terms & Definitions)Document42 pagesBSD-GL-HAL-HMS-100 - (Terms & Definitions)Eduard GadzhievNo ratings yet

- Is-Cal01 Design Carbon Accounting On Site Rev.02Document6 pagesIs-Cal01 Design Carbon Accounting On Site Rev.02shoba9945No ratings yet

- The Normal DistributionDocument30 pagesThe Normal DistributionJohn Rich CaidicNo ratings yet

- Final Firefly Reading & Writing AnswerDocument70 pagesFinal Firefly Reading & Writing AnswerVamshidhar ReddyNo ratings yet

- Supplement Guide Memory FocusDocument41 pagesSupplement Guide Memory Focusgogov.digitalNo ratings yet

- Inbound 7104382368239826711Document51 pagesInbound 7104382368239826711katNo ratings yet

- UntitledDocument4 pagesUntitleddwky KrnwnNo ratings yet

- ASTM GradesDocument4 pagesASTM GradesSaurabh MundheNo ratings yet

- Brochure Keor S GBDocument8 pagesBrochure Keor S GBFernando CespedesNo ratings yet

- NT Seq DatabaseDocument4 pagesNT Seq DatabaseDevinder KaurNo ratings yet

- ProductSheet Iq200 Rackmount SatelliteModemDocument2 pagesProductSheet Iq200 Rackmount SatelliteModemAsim Penkar PenkarNo ratings yet

- Pablocastillo PDFDocument44 pagesPablocastillo PDFPabloNo ratings yet

- Toro Homelite 3354-726Document8 pagesToro Homelite 3354-726Cameron ScottNo ratings yet

- A Clinical Audit Into The Success Rate of Inferior Alveolar Nerve Block Analgesia in General Dental PracticeDocument4 pagesA Clinical Audit Into The Success Rate of Inferior Alveolar Nerve Block Analgesia in General Dental PracticeGina CastilloNo ratings yet

- Relative Color Pickup of Three Different Knits and Predictive Dyeing Recipe FormulationDocument17 pagesRelative Color Pickup of Three Different Knits and Predictive Dyeing Recipe FormulationNguyễn Huy CườngNo ratings yet

- Environmental Science For AP Second EditionDocument61 pagesEnvironmental Science For AP Second Editionjoshua.little480100% (50)

Electrode Comparision

Electrode Comparision

Uploaded by

AnilOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrode Comparision

Electrode Comparision

Uploaded by

AnilCopyright:

Available Formats

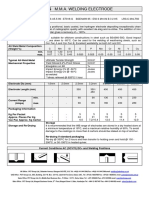

WB6000 M.I.G.

WELDING WIRE

Classifications AWS A5.18-05 : ER70S-6 BS EN ISO 14341-A:2008 : G46 4MG3 Si1

Product Description Copper Coated, Controlled Carbon-Manganese-Silicon steel solid MIG wire.

Applications Suitable for welding and repairing most C-Mn steels.

Wire Composition (Weight %) Cu

C Mn Si S P Ni Cr Mo (total)

min. 0.06 1.30 0.75 - - - - - -

max. 0.12 1.60 1.00 0.025 0.025 0.15 0.15 0.15 0.30

Typical All-Weld Metal Ultimate Tensile Strength N/mm² 530 min.

Mechanical Properties Yield Stress/0.2% Proof Stress N/mm² 460 min.

Elongation on 5D % 22 min.

Impact Energy CV @ -20°C Joules >80

Impact Energy CV @ -29°C Joules >60

Impact Energy CV @ -30°C Joules >55

Impact Energy CV @ -40C Joules >30

as-welded

Wire Dia (mm) 0.6mm 0.8/0.9mm 1.0mm 1.2mm 1.6mm 2.4mm 3.2mm

min. - 80 120 160 180 - -

Current Range

(Amps) max. - 180 240 260 300 - -

min. - 17 17 18 20 - -

Volt Range

(Volts) max. - 20 22 26 29 - -

Packaging Information

Kg Per Std Reel - 0.7/5/20 0.7/5/20 20 20 - -

Kg Per Bulk Reel 200 250 250 250

Storage

Storage It is recommended that the WB ranges of wires are stored in a dry heated store at a

minimum temperature of 18C, and a maximum relative humidity of 60%.

Gases Gas MIG Gas TIG

CO2 and Argon/CO2 mixture Argon

Flow Rate Flow Rate

12-16 l/min 8-12 l/min

Current Conditions DC+ and Welding Positions

You might also like

- WPS ISO 15609 TemplateDocument1 pageWPS ISO 15609 TemplateSatish Keskar100% (5)

- WPS ISO 15609 TemplateDocument1 pageWPS ISO 15609 TemplateSatish Keskar100% (5)

- Cu ZN 15 TombacDocument2 pagesCu ZN 15 TombacPetrus UngureanuNo ratings yet

- MTC JSPLDocument2 pagesMTC JSPLAnil0% (1)

- En 10204 - 3.1 & 3.2Document1 pageEn 10204 - 3.1 & 3.2Anil100% (1)

- What Is RAID Control PDFDocument6 pagesWhat Is RAID Control PDFAhmedNo ratings yet

- OK AristoRod 69Document2 pagesOK AristoRod 69joao guilhermeNo ratings yet

- Purus 46: Mig/Mag Wires (Gmaw) Mild Steel WiresDocument1 pagePurus 46: Mig/Mag Wires (Gmaw) Mild Steel WiresYudhveer GrewalNo ratings yet

- MAT 1210 MCGB - Data Sheet For Suppliers Old MAT No.: 121Document1 pageMAT 1210 MCGB - Data Sheet For Suppliers Old MAT No.: 121MohamedNo ratings yet

- M.M.A. Welding Electrode: Classifications & ApprovalsDocument1 pageM.M.A. Welding Electrode: Classifications & ApprovalscwiksjNo ratings yet

- Wb35S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb35S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Wb1500e Eni CiDocument1 pageWb1500e Eni CicwiksjNo ratings yet

- 25crmo4: Steel GradeDocument3 pages25crmo4: Steel GradeCristian Stiven Martinez GonzalezNo ratings yet

- STK 400Document5 pagesSTK 400Nizar NazriNo ratings yet

- A.S.T.M. B584-09a: WWW - Okendo.mxDocument4 pagesA.S.T.M. B584-09a: WWW - Okendo.mxShariq KhanNo ratings yet

- Technical Report (CSF-81TM)Document5 pagesTechnical Report (CSF-81TM)matiasg.sanchezv95No ratings yet

- 38 MN VS6Document2 pages38 MN VS6Pramod NautiyalNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Wb4606e E312-17Document1 pageWb4606e E312-17cwiksjNo ratings yet

- E10018d2-Eng LINCOLNDocument1 pageE10018d2-Eng LINCOLNBenfil ViernezNo ratings yet

- AW60Document1 pageAW60Fitra VertikalNo ratings yet

- 42crmo6 : Steel GradeDocument2 pages42crmo6 : Steel GradeYonas Dwiananta YuwonoNo ratings yet

- 38 MN VS6Document3 pages38 MN VS6Jaison JacobNo ratings yet

- Wb9009E M.M.A. Welding Electrode: Bs en 14700-2005: Efe2Document1 pageWb9009E M.M.A. Welding Electrode: Bs en 14700-2005: Efe2lathasri78No ratings yet

- Pamphlet MG-51T PDFDocument2 pagesPamphlet MG-51T PDFImmalatulhusnaNo ratings yet

- Last Updated: Jan 27, 2006Document2 pagesLast Updated: Jan 27, 2006박준용No ratings yet

- SC-71LHM Cored: Hyundai Welding Co., LTDDocument9 pagesSC-71LHM Cored: Hyundai Welding Co., LTDAmanSharmaNo ratings yet

- Wb76S M.M.A. Welding Electrode: Classifications & ApprovalsDocument1 pageWb76S M.M.A. Welding Electrode: Classifications & Approvalslathasri78No ratings yet

- C2700Document6 pagesC2700Andrew TanNo ratings yet

- Product Data Sheet OK Autrod 12.64: G 'Gas-Shielded Metal-Arc Welding'Document2 pagesProduct Data Sheet OK Autrod 12.64: G 'Gas-Shielded Metal-Arc Welding'Cem DufourNo ratings yet

- Compact Multipurpose Type Compatible With High-Voltage PulseDocument10 pagesCompact Multipurpose Type Compatible With High-Voltage PulseEko SutjiptoNo ratings yet

- Datasheet Sandvik 199l enDocument3 pagesDatasheet Sandvik 199l enpedro rojasNo ratings yet

- CuZn33 CatalogueDocument9 pagesCuZn33 CataloguefedericoNo ratings yet

- Purus 42 CFDocument2 pagesPurus 42 CFluisNo ratings yet

- Wb2318e E9018-MDocument1 pageWb2318e E9018-McwiksjNo ratings yet

- Product Data Sheet OK Autrod 12.51: G 'Gas-Shielded Metal-Arc Welding'Document2 pagesProduct Data Sheet OK Autrod 12.51: G 'Gas-Shielded Metal-Arc Welding'Filipe CordeiroNo ratings yet

- WB5525E ENiCrMo-5Document1 pageWB5525E ENiCrMo-5cwiksjNo ratings yet

- Product Specifications: Specifications For Continuous Cast ProductsDocument4 pagesProduct Specifications: Specifications For Continuous Cast ProductsvejanidbNo ratings yet

- SC-71MSR: Hyundai Welding Co., LTDDocument7 pagesSC-71MSR: Hyundai Welding Co., LTDRaviTeja BhamidiNo ratings yet

- Datasheet Sandvik 2283l en v2018!07!24 14 - 12 Version 1Document3 pagesDatasheet Sandvik 2283l en v2018!07!24 14 - 12 Version 1bhuvandesignNo ratings yet

- S355JRDocument3 pagesS355JRaabco.purchaseNo ratings yet

- Aaepl: TDC No. AAEPL/RM/lDocument2 pagesAaepl: TDC No. AAEPL/RM/lSandip PandeNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Wb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Certificate of Conformance: Q1 Lot Number: 15163483Document1 pageCertificate of Conformance: Q1 Lot Number: 15163483interx00No ratings yet

- GW CSSRM2.CM - enDocument25 pagesGW CSSRM2.CM - enviniciustim9No ratings yet

- Automig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36Document1 pageAutomig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36satnamNo ratings yet

- High Conductivity Copper, Hard, UNS C10200 (MatWeb)Document3 pagesHigh Conductivity Copper, Hard, UNS C10200 (MatWeb)jlmeseguerNo ratings yet

- Aluminium Wrought AlloyDocument29 pagesAluminium Wrought AlloyRaj Kumar GiriNo ratings yet

- OK Tigrod 13.32Document1 pageOK Tigrod 13.32Paulo CorreiaNo ratings yet

- Din 2395-1Document4 pagesDin 2395-113393m210No ratings yet

- 1SMB5915BDocument3 pages1SMB5915Bafun02260709No ratings yet

- Wb1700e Enicu-BDocument1 pageWb1700e Enicu-BcwiksjNo ratings yet

- Cuzn37 Industrial RolledDocument6 pagesCuzn37 Industrial RolledcvgfgNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- Surface Mount Aluminum Electrolytic Capacitors: NACE SeriesDocument5 pagesSurface Mount Aluminum Electrolytic Capacitors: NACE SeriesNICCompNo ratings yet

- Steel Equivalent Table: en / BS To SAE - Page 1 of 20Document3 pagesSteel Equivalent Table: en / BS To SAE - Page 1 of 20LASCARZAMFIRESCUNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- WB56S E7016-1Document1 pageWB56S E7016-1cwiksjNo ratings yet

- CWC-BookletF1 10Document1 pageCWC-BookletF1 10satnamNo ratings yet

- CM-9CB TG-S9Cb US-9CbDocument3 pagesCM-9CB TG-S9Cb US-9Cbamit singhNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- What We Will CoverDocument4 pagesWhat We Will CoverAnilNo ratings yet

- WPS As Per ISO 15609 Ref.Document3 pagesWPS As Per ISO 15609 Ref.AnilNo ratings yet

- List of En/Iso Standards: SR No Standard Description EditionDocument4 pagesList of En/Iso Standards: SR No Standard Description EditionAnilNo ratings yet

- Law of Mother Earth BoliviaDocument3 pagesLaw of Mother Earth Boliviarahul banerjeeNo ratings yet

- Rotorcraft Aerodynamics: Muhammad Abdullah Tahir 180101034 Aero 17 (A)Document15 pagesRotorcraft Aerodynamics: Muhammad Abdullah Tahir 180101034 Aero 17 (A)Abdullah CheemaNo ratings yet

- HEI Tech Sheet 110Document15 pagesHEI Tech Sheet 110Suganya LokeshNo ratings yet

- Textbook Pediatric Behavioral Nutrition Factors Environment Education and Self Regulation 1St Edition Areej Hassan Ebook All Chapter PDFDocument39 pagesTextbook Pediatric Behavioral Nutrition Factors Environment Education and Self Regulation 1St Edition Areej Hassan Ebook All Chapter PDFjanet.galloway812100% (8)

- Geometry - Olympiad Material BY DR SHYAM SUNDAR AGRAWALDocument67 pagesGeometry - Olympiad Material BY DR SHYAM SUNDAR AGRAWALdrssagrawalNo ratings yet

- Comm - Name Comm - Code Comm - WT Index20122013 I Primary Articles (A) - Food ArticlesDocument48 pagesComm - Name Comm - Code Comm - WT Index20122013 I Primary Articles (A) - Food ArticlesNavin SanjeevNo ratings yet

- Asme A13.1 - 1996Document27 pagesAsme A13.1 - 1996lohv100% (1)

- Material Balance PDFDocument31 pagesMaterial Balance PDFApril Joy HaroNo ratings yet

- Filipino BasicDocument21 pagesFilipino BasicReiko Nakayama100% (1)

- Quarter 3 - Las No. 1 (Week 5-7) Active Recreation (Street and Hip-Hop Dances) (Pe10Pf-Iiia-H-39, Pe10Pf-Lllc-H-45)Document11 pagesQuarter 3 - Las No. 1 (Week 5-7) Active Recreation (Street and Hip-Hop Dances) (Pe10Pf-Iiia-H-39, Pe10Pf-Lllc-H-45)hakkensNo ratings yet

- SCM and TQM: by Junaid ShaheedDocument8 pagesSCM and TQM: by Junaid ShaheedjunaidsNo ratings yet

- MCQ - AcousticsDocument16 pagesMCQ - AcousticsRomeo Espenida0% (1)

- Ex 4Document4 pagesEx 420-MCE-63 SYED HASSAN KUMAILNo ratings yet

- BSD-GL-HAL-HMS-100 - (Terms & Definitions)Document42 pagesBSD-GL-HAL-HMS-100 - (Terms & Definitions)Eduard GadzhievNo ratings yet

- Is-Cal01 Design Carbon Accounting On Site Rev.02Document6 pagesIs-Cal01 Design Carbon Accounting On Site Rev.02shoba9945No ratings yet

- The Normal DistributionDocument30 pagesThe Normal DistributionJohn Rich CaidicNo ratings yet

- Final Firefly Reading & Writing AnswerDocument70 pagesFinal Firefly Reading & Writing AnswerVamshidhar ReddyNo ratings yet

- Supplement Guide Memory FocusDocument41 pagesSupplement Guide Memory Focusgogov.digitalNo ratings yet

- Inbound 7104382368239826711Document51 pagesInbound 7104382368239826711katNo ratings yet

- UntitledDocument4 pagesUntitleddwky KrnwnNo ratings yet

- ASTM GradesDocument4 pagesASTM GradesSaurabh MundheNo ratings yet

- Brochure Keor S GBDocument8 pagesBrochure Keor S GBFernando CespedesNo ratings yet

- NT Seq DatabaseDocument4 pagesNT Seq DatabaseDevinder KaurNo ratings yet

- ProductSheet Iq200 Rackmount SatelliteModemDocument2 pagesProductSheet Iq200 Rackmount SatelliteModemAsim Penkar PenkarNo ratings yet

- Pablocastillo PDFDocument44 pagesPablocastillo PDFPabloNo ratings yet

- Toro Homelite 3354-726Document8 pagesToro Homelite 3354-726Cameron ScottNo ratings yet

- A Clinical Audit Into The Success Rate of Inferior Alveolar Nerve Block Analgesia in General Dental PracticeDocument4 pagesA Clinical Audit Into The Success Rate of Inferior Alveolar Nerve Block Analgesia in General Dental PracticeGina CastilloNo ratings yet

- Relative Color Pickup of Three Different Knits and Predictive Dyeing Recipe FormulationDocument17 pagesRelative Color Pickup of Three Different Knits and Predictive Dyeing Recipe FormulationNguyễn Huy CườngNo ratings yet

- Environmental Science For AP Second EditionDocument61 pagesEnvironmental Science For AP Second Editionjoshua.little480100% (50)