Professional Documents

Culture Documents

NUMBER: 3 2-09 S.M. REF.: Listed in Table ENGINE: DD Series DATE: March 2009

NUMBER: 3 2-09 S.M. REF.: Listed in Table ENGINE: DD Series DATE: March 2009

Uploaded by

Cuong Dinh0 ratings0% found this document useful (0 votes)

64 views6 pagesdetroi

Original Title

208-09

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentdetroi

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

64 views6 pagesNUMBER: 3 2-09 S.M. REF.: Listed in Table ENGINE: DD Series DATE: March 2009

NUMBER: 3 2-09 S.M. REF.: Listed in Table ENGINE: DD Series DATE: March 2009

Uploaded by

Cuong Dinhdetroi

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 6

NUMBER: 3 2–09 S.M. REF.

: Listed in Table ENGINE: DD Series DATE: March 2009

SUBJECT: SPN 723

ADDITIONS, REVISIONS, OR UPDATES

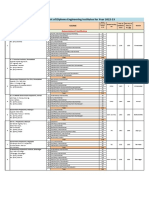

Publication Number Platform Section Title Change Page Number(s)

DDC-SVC-MAN-0029 EPA07 DD13, EPA07 74 SPN 723 SPN 723/FMI 8 and 74–7, 74–10

DD15 SPN 723/FMI 31 have

been revised.

NOTE: Page numbers are based on the most recent version of the individual publication and may be adjusted throughout the annual print cycle.

723/FMI 8

1. Use DDDL to insure that cranking speed is over 150 RPM. Is cranking speed over 150 RPM?

[a] Yes, go to next step.

[b] No, refer to section 3.3 "Defective Starter" to determine the cause of low crank speed.

2. Disconnect the camshaft position sensor harness connector.

3. Turn on the ignition (key ON, engine OFF).

4. Inspect the sensor harness for bent, spread, or corroded pins.

[a] If the pins are bent, spread, or corroded, repair as necessary.

[b] If connector shows no signs of damage, go to next step.

5. Measure the voltage between pin 1 and pin 3 on the harness side of the camshaft position sensor.

[a] If the voltage is greater than 4.5 volts, go to next step.

[b] If the voltage is less than 4.5 volts, go to step 7.

6. Measure the voltage between pin 2 and pin 3 on the harness side of the camshaft position sensor.

[a] If the voltage is less than 11.5 volts, repair the wire between pin 2 of the harness side of the

camshaft position sensor and pin 45 of the MCM 120-pin connector.

[b] If the voltage is greater than 11.5 volts, go to step 8.

7. Measure the voltage between pin 1 on the harness side of the camshaft position sensor and

engine ground.

[a] If the voltage is less than 4.5 volts, repair the wire between pin 1 of the harness side of the

camshaft position sensor and pin 82 of the MCM 120-pin connector.

[b] If the voltage is greater than 4.5 volts, repair the wire between pin 2 of the harness side of

the camshaft position sensor and pin 45 of the MCM 120-pin connector.

8. Has the engine had any gear train, camshaft, or flywheel repairs made?

[a] Yes, verify proper gear train timing and proper flywheel installation.

[b] No, go to next step.

9. Remove the camshaft position sensor and inspect for damage. Is there damage to the sensor?

[a] Yes, inspect the tone wheel on the intake cam for damage. Check gear train for excessive

lash or damage. If damage is found, repair as necessary, and replace the camshaft position

sensor. Verify repairs.

[b] No, replace the camshaft position sensor. Verify repairs.

723/FMI 31

1. Use DDDL to insure that cranking speed is over 150 RPM. Is cranking speed over 150 RPM?

[a] Yes, go to next step.

[b] No, refer to section 3.3 "Defective Starter" to determine the cause of low crank speed.

2. Disconnect the camshaft position sensor harness connector.

3. Turn on the ignition (key ON, engine OFF).

4. Inspect the sensor harness for bent, spread, or corroded pins.

[a] If the pins are bent, spread, or corroded, repair as necessary.

[b] If connector shows no signs of damage, go to next step.

5. Measure the voltage between pin 1 and pin 3 on the harness side of the camshaft position sensor.

[a] If the voltage is greater than 4.5 volts, go to next step.

[b] If the voltage is less than 4.5 volts, go to step 7.

6. Measure the voltage between pin 2 and pin 3 on the harness side of the camshaft position sensor.

[a] If the voltage is less than 11.5 volts, repair the wire between pin 2 of the harness side of the

camshaft position sensor and pin 45 of the MCM 120-pin connector.

[b] If the voltage is greater than 11.5 volts, go to step 8.

7. Measure the voltage between pin 1 on the harness side of the camshaft position sensor and

engine ground.

[a] If the voltage is less than 4.5 volts, repair the wire between pin 1 of the harness side of the

camshaft position sensor and pin 82 of the MCM 120-pin connector.

[b] If the voltage is greater than 4.5 volts, repair the wire between pin 2 of the harness side of

the camshaft position sensor and pin 45 of the MCM 120-pin connector.

8. Has the engine had any gear train, camshaft, or flywheel repairs made?

[a] Yes, verify proper gear train timing and proper flywheel installation.

[b] No, go to next step.

9. Remove the camshaft position sensor and inspect for damage. Is there damage to the sensor?

[a] Yes, inspect the tone wheel on the intake cam for damage. Check gear train for excessive

lash or damage. If damage is found, repair as necessary, and replace the camshaft position

sensor. Verify repairs.

[b] No, replace the camshaft position sensor. Verify repairs.

ADDITIONAL SERVICE INFORMATION

Additional service information is available in Power Service Literature.

Detroit Diesel®, DDC®, Series 60® and the spinning arrows design are registered trademarks of Detroit Diesel Corporation.

© Copyright 2009 Detroit Diesel Corporation. All rights reserved. Printed in U.S.A.

You might also like

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- 120k Active Code 668-2Document4 pages120k Active Code 668-2selviantobilmon78No ratings yet

- J1587 Fault Codes PDFDocument13 pagesJ1587 Fault Codes PDFCuong DinhNo ratings yet

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- SyllabusDocument12 pagesSyllabuslostmyheartNo ratings yet

- Book 1 - Section C - Steel Framed Wall SystemsDocument57 pagesBook 1 - Section C - Steel Framed Wall SystemsManasi SatbhaiNo ratings yet

- 60.1 Removal of The 2V2-2HH Soot SensorDocument2 pages60.1 Removal of The 2V2-2HH Soot SensorCuong DinhNo ratings yet

- FAULT CODE 455 - Electronic Fuel Injection Control Valve Circuit - Voltage Above Normal or Shorted To High SourceDocument6 pagesFAULT CODE 455 - Electronic Fuel Injection Control Valve Circuit - Voltage Above Normal or Shorted To High Sourcemohammed abbasNo ratings yet

- Código de Falla DD15 SPN677Document6 pagesCódigo de Falla DD15 SPN677sofiayniko100% (4)

- Manual For N14Document16 pagesManual For N14Jechkong78% (9)

- Engine Speed Timing Sensor - CalibrateDocument9 pagesEngine Speed Timing Sensor - Calibratewagner_guimarães_150% (2)

- FRAMO Rbp250 Anti Heeling Pump ManualDocument13 pagesFRAMO Rbp250 Anti Heeling Pump ManualFatma KosovaliNo ratings yet

- 15.2 Removal of The DD13 Exhaust Gas Recirculation Valve ActuatorDocument1 page15.2 Removal of The DD13 Exhaust Gas Recirculation Valve ActuatorCuong DinhNo ratings yet

- 16.1 Description and Operation of The DD15 and DD16 Exhaust Gas Recirculation Valve ActuatorDocument2 pages16.1 Description and Operation of The DD15 and DD16 Exhaust Gas Recirculation Valve ActuatorCuong DinhNo ratings yet

- J1939 Fault Codes PDFDocument11 pagesJ1939 Fault Codes PDFCuong Dinh100% (1)

- Troubleshooting Vijeo Designer WebGate ProblemsDocument4 pagesTroubleshooting Vijeo Designer WebGate ProblemsRichard LambNo ratings yet

- 2014 Nissan Juke 47748 PDFDocument349 pages2014 Nissan Juke 47748 PDFhidraulic100% (1)

- NUMBER: 10 1-09 S.M. REF.: Listed in Table Engine: Ddec Vi DATE: October 2009Document4 pagesNUMBER: 10 1-09 S.M. REF.: Listed in Table Engine: Ddec Vi DATE: October 2009Hamilton mirandaNo ratings yet

- 08DDECVI17Document6 pages08DDECVI17Horacio IbarraNo ratings yet

- NUMBER: 10 6-09 S.M. REF.: Listed in Table ENGINE: DD Platform DATE: October 2009Document6 pagesNUMBER: 10 6-09 S.M. REF.: Listed in Table ENGINE: DD Platform DATE: October 2009Hamilton mirandaNo ratings yet

- 3226 Fmi 13Document6 pages3226 Fmi 13Hamilton miranda100% (2)

- 5 Ddecvi 07Document12 pages5 Ddecvi 07octavio hernandez100% (1)

- Mb900 Trouble Guide - Part4Document106 pagesMb900 Trouble Guide - Part4Eckard GuendelNo ratings yet

- Engine Speed Senzor TestDocument7 pagesEngine Speed Senzor TestHusi NihaNo ratings yet

- 08DDECVI46Document4 pages08DDECVI46Hamilton mirandaNo ratings yet

- NUMBER: 8 16-10 S.M. REF.: Listed in Table ENGINE: EPA10 DD Platform DATE: AugustDocument6 pagesNUMBER: 8 16-10 S.M. REF.: Listed in Table ENGINE: EPA10 DD Platform DATE: AugustHamilton mirandaNo ratings yet

- 1-SECM-04a Check For Shorted Data LinkDocument6 pages1-SECM-04a Check For Shorted Data LinkMarco Antonio Rubiano Gómez100% (1)

- A 240Document89 pagesA 240Mario Diaz Lopez100% (1)

- 08DDECVI47REVDocument4 pages08DDECVI47REVHamilton mirandaNo ratings yet

- Service Bulletin Trucks: Climate Unit Stepper Motor TestingDocument5 pagesService Bulletin Trucks: Climate Unit Stepper Motor TestingWilson BuenoNo ratings yet

- NUMBER: 2 8-09 S.M. REF.: Listed in Table Engine: Epa07 Dd15 DATE: February 2009Document4 pagesNUMBER: 2 8-09 S.M. REF.: Listed in Table Engine: Epa07 Dd15 DATE: February 2009Hamilton mirandaNo ratings yet

- NUMBER: 10 10-09 REV S.M. REF.: Listed in Table ENGINE: EPA07 DD Platform DateDocument6 pagesNUMBER: 10 10-09 REV S.M. REF.: Listed in Table ENGINE: EPA07 DD Platform DateHamilton mirandaNo ratings yet

- Nissan 2012 Boletin Tecnico - AbsDocument7 pagesNissan 2012 Boletin Tecnico - AbsMarcos PalavecinoNo ratings yet

- QSG12 C CheckDocument5 pagesQSG12 C CheckNikkikumar MaisuriyaNo ratings yet

- Engine Speed&Timing Sensor - Calibrate (RENR9319)Document8 pagesEngine Speed&Timing Sensor - Calibrate (RENR9319)Cesar Arturo Pajuelo Espinoza83% (6)

- A New SPN and Troubleshooting Procedures Have Been Added To The DD15 Troubleshooting Guide (DDC-SVC-MAN-0029)Document4 pagesA New SPN and Troubleshooting Procedures Have Been Added To The DD15 Troubleshooting Guide (DDC-SVC-MAN-0029)Hamilton mirandaNo ratings yet

- Pruebas y Adjustes - Troubleshooting 3512G PDFDocument32 pagesPruebas y Adjustes - Troubleshooting 3512G PDFPLANTAS ELECTRICAS H&BNo ratings yet

- Blackmer Power Pumps: Models: Xl2B, Xl3B, Xl4CDocument12 pagesBlackmer Power Pumps: Models: Xl2B, Xl3B, Xl4CKhoh Kai ShengNo ratings yet

- Webco ABS Sensor TestsDocument4 pagesWebco ABS Sensor TestsДмитрий Пупкин0% (1)

- CB150 Operating Manual T2 (258126)Document13 pagesCB150 Operating Manual T2 (258126)Cesar VellorinNo ratings yet

- 641 - 2051B ManualDocument10 pages641 - 2051B ManualPirv Maria AncaNo ratings yet

- 626 Es V6-2.5L Dohc (1997)Document539 pages626 Es V6-2.5L Dohc (1997)Jesus Campos LunaNo ratings yet

- Service Letter: Single EngineDocument8 pagesService Letter: Single EngineElmer VillegasNo ratings yet

- NUMBER: 6 01-10 S.M. REF.: Listed in Table ENGINE: DD Platform DATE: June 2010Document6 pagesNUMBER: 6 01-10 S.M. REF.: Listed in Table ENGINE: DD Platform DATE: June 2010Cuong DinhNo ratings yet

- Number: 08 Ddec Vi-48 S.M. REF.: 72.5 Engine: Dd15 DATE: September 2008Document2 pagesNumber: 08 Ddec Vi-48 S.M. REF.: 72.5 Engine: Dd15 DATE: September 2008Hamilton mirandaNo ratings yet

- 301 12 PDFDocument13 pages301 12 PDFEduardo VillatoroNo ratings yet

- 2012 Chevrolet K2500 HD Pickup Silverado: DTC C0710Document5 pages2012 Chevrolet K2500 HD Pickup Silverado: DTC C0710alberto navasNo ratings yet

- Enine Timing Clibration Engine Speed Timing Sensor Calibrate RENR9319Document8 pagesEnine Timing Clibration Engine Speed Timing Sensor Calibrate RENR9319Khaled Kamel100% (2)

- 4 TNV 84 TZDocument6 pages4 TNV 84 TZCarlos Rivera MontesNo ratings yet

- 10 Intermittentfault10Document94 pages10 Intermittentfault10libertyplusNo ratings yet

- Volkswagen - New Beetle - Wiring Diagram - 2007 - 2008Document13,861 pagesVolkswagen - New Beetle - Wiring Diagram - 2007 - 2008Harshad NaringrekarNo ratings yet

- K3-Ve Cooling Cooling Fan System Cooling Fan CircuitDocument6 pagesK3-Ve Cooling Cooling Fan System Cooling Fan Circuitbcmailist0% (1)

- Alternator DiagnosticDocument19 pagesAlternator Diagnosticvickers100% (1)

- Q and A Part1Document56 pagesQ and A Part1Subramanian VenkatNo ratings yet

- MC 10147003 9999Document3 pagesMC 10147003 9999Juliaman NapituNo ratings yet

- Charging System - TestDocument5 pagesCharging System - TestPromesa De IsraelNo ratings yet

- GR00004300C 13aDocument260 pagesGR00004300C 13aEduardo Enrique Rojas ValenzuelaNo ratings yet

- Mb900 Trouble Guide - Part3Document106 pagesMb900 Trouble Guide - Part3Eckard GuendelNo ratings yet

- C9 IAPCV Circuit TestDocument7 pagesC9 IAPCV Circuit Testharikrishnanpd3327No ratings yet

- SPN 157 Has Been Added To The Manual.: Number: 08 Fstg-7 S.M. REF.: 24 Engine: Dd15 DATE: September 2008Document2 pagesSPN 157 Has Been Added To The Manual.: Number: 08 Fstg-7 S.M. REF.: 24 Engine: Dd15 DATE: September 2008abdelrhmangbr86No ratings yet

- Motorcycle Service Bulletin 2023 04 BS VI E Carb Cleaning SOPDocument7 pagesMotorcycle Service Bulletin 2023 04 BS VI E Carb Cleaning SOPAkshay KumkarNo ratings yet

- DTC P0011Document9 pagesDTC P0011Ronald MoonNo ratings yet

- Engine Pressure Sensor Open or Short Circuit - TestDocument10 pagesEngine Pressure Sensor Open or Short Circuit - TestGustavo GarzaNo ratings yet

- 2GR-FE Engine MechanicalDocument156 pages2GR-FE Engine MechanicalLuks Fernandez100% (8)

- Boletin de Servicio Nissan ABS Well Sensor PDFDocument7 pagesBoletin de Servicio Nissan ABS Well Sensor PDFmaryNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- 19.3 Installation of The GHG14 DD15 at Exhaust Gas Recirculation Valve-Hot PipeDocument1 page19.3 Installation of The GHG14 DD15 at Exhaust Gas Recirculation Valve-Hot PipeCuong DinhNo ratings yet

- 2.1 Description and Operation of The Exhaust Manifold and Related PartsDocument4 pages2.1 Description and Operation of The Exhaust Manifold and Related PartsCuong DinhNo ratings yet

- 18.1 Removal of The Exhaust Gas Recirculation Actuator LeverDocument2 pages18.1 Removal of The Exhaust Gas Recirculation Actuator LeverCuong DinhNo ratings yet

- 17.2 Removal of The GHG14 DD15 AT Exhaust Gas Recirculation Valve ActuatorDocument1 page17.2 Removal of The GHG14 DD15 AT Exhaust Gas Recirculation Valve ActuatorCuong DinhNo ratings yet

- 17.1 Description and Operation of The GHG14 DD15 AT Exhaust Gas Recirculation Valve Actuator PDFDocument1 page17.1 Description and Operation of The GHG14 DD15 AT Exhaust Gas Recirculation Valve Actuator PDFCuong DinhNo ratings yet

- 19.1 Description and Operation of The GHG14 DD15 AT Exhaust Gas Recirculation Valve-Hot Pipe PDFDocument1 page19.1 Description and Operation of The GHG14 DD15 AT Exhaust Gas Recirculation Valve-Hot Pipe PDFCuong DinhNo ratings yet

- 16.3 Installation of The DD15 and DD16 Exhaust Gas Recirculation Valve ActuatorDocument2 pages16.3 Installation of The DD15 and DD16 Exhaust Gas Recirculation Valve ActuatorCuong DinhNo ratings yet

- 19.3 Installation of The GHG14 DD15 at Exhaust Gas Recirculation Valve-Hot PipeDocument1 page19.3 Installation of The GHG14 DD15 at Exhaust Gas Recirculation Valve-Hot PipeCuong DinhNo ratings yet

- 15.3 Installation of The DD13 Exhaust Gas Recirculation Valve ActuatorDocument1 page15.3 Installation of The DD13 Exhaust Gas Recirculation Valve ActuatorCuong DinhNo ratings yet

- 15.3 Installation of The DD13 Exhaust Gas Recirculation Valve ActuatorDocument1 page15.3 Installation of The DD13 Exhaust Gas Recirculation Valve ActuatorCuong DinhNo ratings yet

- 16.5 Installation of The DD15 and DD16 Sonceboz® Exhaust Gas Recirculation Valve ActuatorDocument2 pages16.5 Installation of The DD15 and DD16 Sonceboz® Exhaust Gas Recirculation Valve ActuatorCuong DinhNo ratings yet

- 7.1 Removal of The Exhaust Gas Recirculation Crossover TubeDocument3 pages7.1 Removal of The Exhaust Gas Recirculation Crossover TubeCuong DinhNo ratings yet

- 56.1 Removal of The GHG14 Two-Box Option (2V2) From The VehicleDocument1 page56.1 Removal of The GHG14 Two-Box Option (2V2) From The VehicleCuong DinhNo ratings yet

- 14.1 Removal of The GHG14 DD15 AT Exhaust Gas Recirculation Valve Actuator Pull RodDocument1 page14.1 Removal of The GHG14 DD15 AT Exhaust Gas Recirculation Valve Actuator Pull RodCuong DinhNo ratings yet

- 56.2 Installation of The GHG14 Two-Box Option (2V2) To The VehicleDocument2 pages56.2 Installation of The GHG14 Two-Box Option (2V2) To The VehicleCuong DinhNo ratings yet

- 23.2 Removal of The Mixer PipeDocument1 page23.2 Removal of The Mixer PipeCuong DinhNo ratings yet

- 60.2 Installation of The 2V2-2HH Soot SensorDocument2 pages60.2 Installation of The 2V2-2HH Soot SensorCuong Dinh100% (1)

- 15.1 Description and Operation of The DD13 Exhaust Gas Recirculation Valve ActuatorDocument2 pages15.1 Description and Operation of The DD13 Exhaust Gas Recirculation Valve ActuatorCuong DinhNo ratings yet

- 8.1 Removal of The Exhaust Gas Recirculation VenturiDocument1 page8.1 Removal of The Exhaust Gas Recirculation VenturiCuong DinhNo ratings yet

- 11.2 Removal of The DD15 and DD16 Exhaust Gas Recirculation CoolerDocument1 page11.2 Removal of The DD15 and DD16 Exhaust Gas Recirculation CoolerCuong DinhNo ratings yet

- 11.4 Installation of The DD15 and DD16 Exhaust Gas Recirculation CoolerDocument1 page11.4 Installation of The DD15 and DD16 Exhaust Gas Recirculation CoolerCuong DinhNo ratings yet

- 11.1 Description and Operation of The DD15 and DD16 Exhaust Gas Recirculation CoolerDocument3 pages11.1 Description and Operation of The DD15 and DD16 Exhaust Gas Recirculation CoolerCuong DinhNo ratings yet

- 13.1 Removal of The Exhaust Gas Recirculation Valve Actuator Pull Rod PDFDocument1 page13.1 Removal of The Exhaust Gas Recirculation Valve Actuator Pull Rod PDFCuong DinhNo ratings yet

- 11.3 Testing and Inspection of The DD15 and DD16 Exhaust Gas Recirculation CoolerDocument1 page11.3 Testing and Inspection of The DD15 and DD16 Exhaust Gas Recirculation CoolerCuong DinhNo ratings yet

- Audio SystemDocument12 pagesAudio SystemCuong DinhNo ratings yet

- Gravel Bed Filters: Learner GuideDocument31 pagesGravel Bed Filters: Learner GuideRobson DE Freitas WerlingNo ratings yet

- 1.2 DC StandardsDocument21 pages1.2 DC StandardsCarlos Buznego Niochet100% (1)

- C Program Is A Low Pass Filter DesignDocument5 pagesC Program Is A Low Pass Filter DesignPushan Kumar DattaNo ratings yet

- CPG FMCG Food Benchmark StudyDocument94 pagesCPG FMCG Food Benchmark StudySuhailNo ratings yet

- How Do Blind People Learn LanguageDocument2 pagesHow Do Blind People Learn LanguageSara SaderNo ratings yet

- Optex Vibro DatasheetDocument2 pagesOptex Vibro DatasheetGabriel ChiriacNo ratings yet

- Traduccion Guia de InglesDocument6 pagesTraduccion Guia de Inglessamuel lopezNo ratings yet

- E-10 Code (141/CA141) Oil Press. Sensor Low Error (LH Bank Only)Document150 pagesE-10 Code (141/CA141) Oil Press. Sensor Low Error (LH Bank Only)ЕгорNo ratings yet

- SOI Asia Workshop 2008 Pre-Workshop Unix Basic AssignmentDocument11 pagesSOI Asia Workshop 2008 Pre-Workshop Unix Basic AssignmentParamjeet RanaNo ratings yet

- V 01Document2 pagesV 01mdhfrancis50% (2)

- Om 05145 01Document40 pagesOm 05145 01Franco bucciarelliNo ratings yet

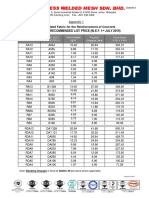

- Steel Welded Fabric List Price (SG) - V2.00Document2 pagesSteel Welded Fabric List Price (SG) - V2.00biik0076153No ratings yet

- Maersk Line Container Equipment Guide PDFDocument4 pagesMaersk Line Container Equipment Guide PDFfahrie_manNo ratings yet

- IIT Bombay Spoken Tutorials For ICT Training in Schools: Value To The SchoolDocument2 pagesIIT Bombay Spoken Tutorials For ICT Training in Schools: Value To The SchoolmanaliNo ratings yet

- Ipms4gtp ReportDocument15 pagesIpms4gtp ReportgebriyeNo ratings yet

- Perkembangan Teori Manajemen Dari Pemikiran Scientific Management Hingga Era Modern Suatu Tinjauan PustakaDocument20 pagesPerkembangan Teori Manajemen Dari Pemikiran Scientific Management Hingga Era Modern Suatu Tinjauan PustakaDian Sukmasari RahmahNo ratings yet

- Innovation Boot CampDocument15 pagesInnovation Boot CampGokul Ranganathan50% (2)

- Provisional Inst List Engg 2022Document16 pagesProvisional Inst List Engg 2022arp2781No ratings yet

- Material Safety Data Sheet: Section I: Identification of ProductDocument4 pagesMaterial Safety Data Sheet: Section I: Identification of ProductBarryNo ratings yet

- Chemical Resistance of Polyurea CoatingsASTM-D-1308-3912 PDFDocument3 pagesChemical Resistance of Polyurea CoatingsASTM-D-1308-3912 PDFA MahmoodNo ratings yet

- T1080 - Mechanical Drawing and Design N5 QP Apr 2018Document6 pagesT1080 - Mechanical Drawing and Design N5 QP Apr 2018pearlmayongoNo ratings yet

- Catalogo App Parts.Document14 pagesCatalogo App Parts.Fc Agricola AgricolaNo ratings yet

- BUS-VANET: A BUS Vehicular Network Integrated With Traffic InfrastructureDocument5 pagesBUS-VANET: A BUS Vehicular Network Integrated With Traffic InfrastructureshaliniNo ratings yet

- Vjti Academic DiaryDocument121 pagesVjti Academic DiaryDIPAK VINAYAK SHIRBHATENo ratings yet

- Current LimitingDocument3 pagesCurrent Limitingmessage4guruNo ratings yet

- Outline All Courses CCNDocument3 pagesOutline All Courses CCNAmir SohailNo ratings yet