Professional Documents

Culture Documents

Burnishing Machine Type 70

Burnishing Machine Type 70

Uploaded by

JayakrishnaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Burnishing Machine Type 70

Burnishing Machine Type 70

Uploaded by

JayakrishnaCopyright:

Available Formats

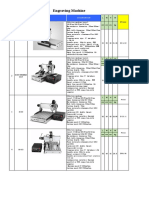

BURNISHING MACHINE TYPE 70

This machine is a more rigid build development of the well proven type 119, built for burnishing larger workpieces, while

still suitable for very small workpieces too.

All functions are controlled by a PLC control SIEMENS. The feed of the burnishing spindles is hydraulically-mechanically

controlled and is equipped with micrometer screws for the burnishing dimensions.

The machine has an electronic speed control for the burnishing spindles. With the AB-system , developed by

STRAUSAK the workpiece drive is effected by different speeds of the two burnishing spindles. While one side is

burnishing, the other side is driven. In some cases, the double friction wheel drive may be used as an auxiliary drive.

Various automatic loading devices can be attached. (at the picture of the type 70 burnishing machine, there is an auto-

matic loader type W 25). For the setting up operations the loading devices can be swung out.

Technical data : Pivot diameter 0,1 - 8 mm

Pivot length max. 11 mm

Shoulder distance max. 60 mm

Length of the part max. 80 mm

Diameter of the burnishing disc (60) 70 mm

R.P.M. of the burnishing disc 200 - 2’500 R.P.M.

R.P.M of the workpiece 50 - 500 R.P.M.

Net weight 350 kg

Space requirement 900 x 1’250 mm

Automatic loaders :

Loader Loader

type 28 type W 20

You might also like

- Upvc Window MachineDocument6 pagesUpvc Window MachineSathish JayaprakashNo ratings yet

- Chapter 2 Machine IntroductionDocument4 pagesChapter 2 Machine IntroductionTech CIMNo ratings yet

- VMC & HMC PDFDocument103 pagesVMC & HMC PDFNARENDER SINGHNo ratings yet

- f573 Okuma Ma 600 HB Space Center Technical DetailsDocument4 pagesf573 Okuma Ma 600 HB Space Center Technical DetailsJordan Martinez LizNo ratings yet

- 1116-002007 Emco Emcoturn 365 PDFDocument2 pages1116-002007 Emco Emcoturn 365 PDFRandesNo ratings yet

- Cutting Machine of DemonstrationDocument27 pagesCutting Machine of Demonstrationartsycraftsy2310No ratings yet

- Catalogue 0501Document8 pagesCatalogue 0501Neeraj VohraNo ratings yet

- UntitledDocument12 pagesUntitledAngel Rodriguez PizarroNo ratings yet

- AL800G - ALN800G English FranceDocument2 pagesAL800G - ALN800G English FrancePhu MrNo ratings yet

- Finish Machine Presentation - July12-1Document28 pagesFinish Machine Presentation - July12-1MehtaMilanNo ratings yet

- Leonardo: A Genius in Pallet WrappingDocument2 pagesLeonardo: A Genius in Pallet WrappingAmirmasoudNo ratings yet

- Flour Siever / Flour Sifter: SpecificationDocument9 pagesFlour Siever / Flour Sifter: SpecificationJustine AbanadorNo ratings yet

- Web SML500e EngDocument3 pagesWeb SML500e EngHassan AhmedNo ratings yet

- Press Brake Machine WC67K-80T-3200Document4 pagesPress Brake Machine WC67K-80T-3200Jonathan GomezNo ratings yet

- SBM 1250 Double Twist Bunching LineDocument12 pagesSBM 1250 Double Twist Bunching LineEMRE KAAN USTANo ratings yet

- Referensi Mesin LaserDB Laser DB-FM3015ADocument3 pagesReferensi Mesin LaserDB Laser DB-FM3015Asarjono.pws03No ratings yet

- Cutting EquipmentsDocument23 pagesCutting EquipmentsManoj SahuNo ratings yet

- InternshipDocument41 pagesInternshipMin Kyaw HtetNo ratings yet

- Proposal HMG-350JM SXKH Die Spotting PressDocument9 pagesProposal HMG-350JM SXKH Die Spotting Press846213No ratings yet

- ZOOMLION 40T QY40V Tech Specs PDFDocument30 pagesZOOMLION 40T QY40V Tech Specs PDFvikrantathavaleNo ratings yet

- Especificaciones de Rectificadora de CigueñalDocument10 pagesEspecificaciones de Rectificadora de CigueñalCR OtinianoNo ratings yet

- PCI Meteor3000 ENDocument2 pagesPCI Meteor3000 ENHX WEINo ratings yet

- ALLROUNDER 720 H-AnexoDocument2 pagesALLROUNDER 720 H-AnexoLuis Enrique Rosales UrquizaNo ratings yet

- RSM 500 A - RSM 800: Cylindrical Grinding MachinesDocument2 pagesRSM 500 A - RSM 800: Cylindrical Grinding MachinesSerbanNo ratings yet

- CNC-engraving Machine - Unit PriceDocument2 pagesCNC-engraving Machine - Unit PriceШеф ОтрисовкаNo ratings yet

- MR - Samaksh Jhalani-7-Ply-150-1800mm Automatic Corrugated Cardboard Production LineDocument43 pagesMR - Samaksh Jhalani-7-Ply-150-1800mm Automatic Corrugated Cardboard Production LineSamaksh JhalaniNo ratings yet

- BOMAG - Datasheet - BF200C - PRE89007010 - SA02Document4 pagesBOMAG - Datasheet - BF200C - PRE89007010 - SA02Jason TanNo ratings yet

- PCI MeteorTS900V ENDocument2 pagesPCI MeteorTS900V ENHX WEINo ratings yet

- Especificaciones RM 90go!Document2 pagesEspecificaciones RM 90go!Harol MendozaNo ratings yet

- 1250mm Aluminum and Steel Coil Coating LineDocument33 pages1250mm Aluminum and Steel Coil Coating LineValmik SoniNo ratings yet

- Ficha Técnica Grúa QY70V53227YA - 1CDocument23 pagesFicha Técnica Grúa QY70V53227YA - 1CLipe CeaNo ratings yet

- Mazak Make Turning Center: MODEL: - Quick Turn 6T, YOM: - 2006Document1 pageMazak Make Turning Center: MODEL: - Quick Turn 6T, YOM: - 2006voho nhattanNo ratings yet

- Multifunctional Lathe Machine CQ6232GZDocument4 pagesMultifunctional Lathe Machine CQ6232GZAbdelbasset ZaraiNo ratings yet

- WMTCNC CNC Lathe Machines (Slant Bed & Flat Bed Lathe)Document118 pagesWMTCNC CNC Lathe Machines (Slant Bed & Flat Bed Lathe)walid ben khedherNo ratings yet

- Quot. 070g Mos-23 Al Areen Projects Spacifications.Document22 pagesQuot. 070g Mos-23 Al Areen Projects Spacifications.Abuelgassim GarelnabiNo ratings yet

- SM401Document8 pagesSM401sistemavictorsinaisNo ratings yet

- TCF 160 / TCF 200 / TCF 224 / TCF 250 TCF 275 / TCF 300: Heavy Centre LathesDocument8 pagesTCF 160 / TCF 200 / TCF 224 / TCF 250 TCF 275 / TCF 300: Heavy Centre LathesRajiv GandhiNo ratings yet

- Devis Presse À Présenter SXKH PDFDocument10 pagesDevis Presse À Présenter SXKH PDFArmandNo ratings yet

- PC200 200LC-8 Cen00049-09 PDFDocument14 pagesPC200 200LC-8 Cen00049-09 PDFRyan Abubakar Obili PakayaNo ratings yet

- PC200 200LC-8 Cen00049-09Document14 pagesPC200 200LC-8 Cen00049-09LU YONo ratings yet

- Specification of Machine Tools.Document16 pagesSpecification of Machine Tools.PriyaNo ratings yet

- Technical Specifications: Heavy Duty Lathe TOS Mod. SUS-80Document4 pagesTechnical Specifications: Heavy Duty Lathe TOS Mod. SUS-80kazemiNo ratings yet

- Semi Atuomatic CATLOGUES 2-6-155Document4 pagesSemi Atuomatic CATLOGUES 2-6-155Fayas RasheedNo ratings yet

- BC Doosan DB130 Lot 1Document3 pagesBC Doosan DB130 Lot 1Welly CholilNo ratings yet

- Catalogue - BalerDocument3 pagesCatalogue - Balerpushpajeet2905No ratings yet

- Io - 471156282 - Fom71mp Lab - enDocument84 pagesIo - 471156282 - Fom71mp Lab - enebola.depoNo ratings yet

- Kopex Famago Technical PotentialDocument23 pagesKopex Famago Technical Potentialgarves007No ratings yet

- TAJMAC-ZPS ProductionProgram enDocument68 pagesTAJMAC-ZPS ProductionProgram endarkojevNo ratings yet

- B GravographDocument12 pagesB GravographWahyu PcNo ratings yet

- Official Quotation: Boring Machine TX68Document4 pagesOfficial Quotation: Boring Machine TX68Abdulaziz RakhmatullayevNo ratings yet

- Quotation of Hka-1100Document11 pagesQuotation of Hka-1100api-724687963No ratings yet

- Main Technical SpecificationsDocument10 pagesMain Technical Specificationsmarsh2002No ratings yet

- TRUMPF CNC-Sheet Metal Machining Centre: Punching, Nibbling and Forming With Rotation of All ToolsDocument9 pagesTRUMPF CNC-Sheet Metal Machining Centre: Punching, Nibbling and Forming With Rotation of All ToolsGreyphen GreyNo ratings yet

- Raw Mill P9: Eqpt No. 9MNE020A 9MNE030A 9MNE040A 9MNE050A Type Material DataDocument3 pagesRaw Mill P9: Eqpt No. 9MNE020A 9MNE030A 9MNE040A 9MNE050A Type Material Datamuziibu alfisyahNo ratings yet

- CABEÇOTES - HTT - Stanki - Glubokogo - SverleniyaDocument12 pagesCABEÇOTES - HTT - Stanki - Glubokogo - Sverleniyacarolina lopesNo ratings yet

- HCN-5000 50 BrochureDocument3 pagesHCN-5000 50 Brochurevictor saenz100% (1)

- One Wave Soldering Machine-Interbras PDFDocument4 pagesOne Wave Soldering Machine-Interbras PDFUserSMTNo ratings yet

- Manufacturing LabDocument3 pagesManufacturing LabWaqas HassanNo ratings yet

- CNC MachineDocument3 pagesCNC Machineg1763970No ratings yet

- A Life of Victory BookletDocument12 pagesA Life of Victory BookletJayakrishnaNo ratings yet

- Healing ConfessionsDocument4 pagesHealing ConfessionsJayakrishnaNo ratings yet

- Baptism of The Holy Spirit BookletDocument12 pagesBaptism of The Holy Spirit BookletJayakrishna100% (1)

- History of TIGDocument13 pagesHistory of TIGJayakrishna100% (1)

- Cutting Data - Greenwood Tools LTDDocument3 pagesCutting Data - Greenwood Tools LTDJayakrishnaNo ratings yet

- TIG Welding Electrodes - Purchase Online & Usage GuideDocument4 pagesTIG Welding Electrodes - Purchase Online & Usage GuideJayakrishnaNo ratings yet

- The History of Welding - MillerWeldsDocument7 pagesThe History of Welding - MillerWeldsJayakrishnaNo ratings yet

- Agteks DirecTwistDocument27 pagesAgteks DirecTwistJayakrishnaNo ratings yet

- User Manual 4793536Document24 pagesUser Manual 4793536JayakrishnaNo ratings yet

- Beef Rendang Roti Wraps - Curry Recipes - SBS FoodDocument3 pagesBeef Rendang Roti Wraps - Curry Recipes - SBS FoodJayakrishnaNo ratings yet

- High Speed Spindle Design and Construction - Modern Machine ShopDocument24 pagesHigh Speed Spindle Design and Construction - Modern Machine ShopJayakrishnaNo ratings yet

- DIY Garage Malaga - Catering For The Curious!Document1 pageDIY Garage Malaga - Catering For The Curious!JayakrishnaNo ratings yet

- E71t Gs vs. E71t 11 - The Skilled WelderDocument10 pagesE71t Gs vs. E71t 11 - The Skilled WelderJayakrishnaNo ratings yet

- STRAUSAK U-Grind 5 Axis CNC Tool GrinderDocument7 pagesSTRAUSAK U-Grind 5 Axis CNC Tool GrinderJayakrishnaNo ratings yet

- ISO15 Spindle PDFDocument9 pagesISO15 Spindle PDFJayakrishna0% (1)

- CT65 Parts ListDocument26 pagesCT65 Parts ListJayakrishnaNo ratings yet

- CNC Metal Working Machinery: Main Catalogue 2019Document180 pagesCNC Metal Working Machinery: Main Catalogue 2019JayakrishnaNo ratings yet

- XYZ Compact Turn: CNC Turning Center Parts ManualDocument23 pagesXYZ Compact Turn: CNC Turning Center Parts ManualJayakrishnaNo ratings yet

- Hardinge Spindle Bearing Replacement PDFDocument4 pagesHardinge Spindle Bearing Replacement PDFJayakrishnaNo ratings yet

- Microcut Mcu-5x Milling MachineDocument6 pagesMicrocut Mcu-5x Milling MachineJayakrishnaNo ratings yet

- RONDA Mecano 100: Caliber R150 - 11 '''Document3 pagesRONDA Mecano 100: Caliber R150 - 11 '''JayakrishnaNo ratings yet

- How To Set Up Simulator Ard MMDocument12 pagesHow To Set Up Simulator Ard MMJayakrishnaNo ratings yet

- TL4076 ManualmainDocument15 pagesTL4076 ManualmainJayakrishnaNo ratings yet

- Burnishing Machine ST 119 CNC: WWW - Strausak-Mikro - CHDocument7 pagesBurnishing Machine ST 119 CNC: WWW - Strausak-Mikro - CHJayakrishnaNo ratings yet

- La The Struck by BarDocument21 pagesLa The Struck by BarJayakrishnaNo ratings yet

- HS 30 eDocument9 pagesHS 30 eJayakrishnaNo ratings yet

- Affolter Af90+af45 enDocument2 pagesAffolter Af90+af45 enJayakrishnaNo ratings yet