Professional Documents

Culture Documents

Aumech Rame 408 PDF

Aumech Rame 408 PDF

Uploaded by

Venkat MacharlaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aumech Rame 408 PDF

Aumech Rame 408 PDF

Uploaded by

Venkat MacharlaCopyright:

Available Formats

SSRG International Journal of Mechanical Engineering (SSRG-IJME) – volume X Issue Y–Month 2017

Effect of Cryogenic treatment on Compression

Strength of Al-Cu alloys

G Ramanjaneya Yadav *1, N Harsha#2, V Durga Prasada Rao#3 , S Rajesh#4

M.Tech-Student, Department of Mechanical Engineering, S R K R Engineering College, Bhimavaram, India.

*

#

Department of Mechanical Engineering, S R K R Engineering College, Bhimavaram, India.

namburi.harsha1987@gmail.com

1

Abstract — It is well known that the cryogenic or more compatible materials, different in

treatment enhances metallurgical properties of most composition, characteristics and sometimes also in

of the metals, which in turn improve various strengths different phases. Kelly [2] very clearly stresses that

of the treated parts. It creates denser molecular the alloy composites should not be regarded simple as

structure of the metals and alloys resulting in a larger a combination of two materials. In the broader

contact surface area that reduces friction, heat and significance; the combination has its own distinctive

wear. Now a day’s mostly the Mechanical properties properties. In terms of strength or resistance to heat or

of the Materials are significantly varied by changing some other desirable quality, it is better than either of

percentage composition of Alloy materials present in the components alone or radically different from either

it. In this work, the effect of Cryogenic treatment on of them.

Compression Strength of Aluminium-Copper Alloy is By the work of Panchakshari H.V [3], he reveals

studied by varying the percentage of copper for that the microstructure of alloys changes due to the

different durations of Cryogenic Treatment. The cryogenic treatment which influences of different

specimens were fabricated by varying the copper process parameters on micro-hardness of Al alloy

percentage in the Al-Cu Alloy for 1.5%, 3.0%, and were compared and the results showed that cryogenic

4.5% by metal casting process and then turning them treatment could improve hardness of Al/Al2O3

to obtain an l/d ratio of 3:2. Then these fabricated composites. Experimental investigations showed that

Metal Alloy specimens are cryogenically treated by as the percentage of reinforcement increases corrosion

using liquid nitrogen for different durations of Six, resistance has further improved by cryogenic

Eight and Ten hours for all specimens for which the treatment [4]. Pavan K M [5] by probing in the field of

copper percentage has been varied. Both untreated cryogenics stated that cryogenics improves the

and Cryogenic treated specimens are tested for the resistance to stress corrosion which is plays a vital role

Compression Strengths on Universal Testing Machine. in designing the aerospace components.

The experimental results show that as the duration of

cryogenic treatment increases the Compression K.K.Padmanabhan [6] investigation revealed that

Strengths also increases, but as the percentage of aluminium 6063 properties will be enhanced by

Copper increases in the Alloy the Compression cryogenic treatment but the trend of enhancement is

Strength increases to some extent and then decreases. not revealed. Hence an available base material chosen

in this work is aluminium 6063 alloy and pure copper

Keywords — cryogenic treatment, compression to from different Aluminium-copper alloys. The alloy

Strength, metal casting, Al-Cu Alloy. composition of aluminium 6063 alloy is as shown in

the Table 1

I. INTRODUCTION TABLE I

A typical Metal Alloy is a system of materials The alloy composition of Al 6063

composing of two or more materials (mixed and Element %Weight

bonded) on a macroscopic scale. An alloy may be a Si 0.2-0.6

solid solution of metal elements (a single phase) or a Fe 0-0.35

mixture of metallic phases (two or more solutions). Cu 0-0.10

Mechanical properties of alloys will often be quite Mn 0-0.10

different from those of its individual base components. Me 0.45-0.9

When designed properly a prefect ratio of mixed Zn 0-0.1

components yields optimal nature of the mechanical Other’s 0.05-0.25

property at that particular percentage of composition. Al 97.5-99.3

The main controllable process parameters affecting

J. Hashim [1] narrated that the multifunctional the strengths of the alloys are the percentage variation

material systems that provide key characteristics are of alloying material and the cryogenic treatment time.

not obtainable from any discrete material. They are Hence these parameters are chosen as primary and

cohesive structures made by physically combining two

ISSN: 2348 – 8360 www.internationaljournalssrg.org Page 1

SSRG International Journal of Mechanical Engineering (SSRG-IJME) – volume X Issue Y–Month 2017

secondary parameters respectively. In the current the specimen followed by turning the surface of the

context, traditional casting is performed for specimen to achieve exact dimensions.

manufacturing the Aluminium-Copper alloy and then

they are subjected for the cryogenic treatment for

different ageing durations. The levels of the both

primary and secondary parameters are as shown in the

Table 2.

TABLE II

Process parameters

Process Levels

S.No

parameters 1 2 3

% Copper

1 1.5% 3.0% 4.5%

Variation

Cryogenic

2 6hrs 8hrs 10hrs

Time

II. EXPERIMENTAL WORK Fig 2: CNC Lathe

To get homogenous deformation, the specifications

In the present work Aluminium-Copper alloys are of the specimens are taken so that the L/D=1.5, Where

prepared by using aluminium 6063 and by varying ‘L’ is Length of the Specimen and ‘D’ is the effective

copper (Cu) in three different percentages (1.5%, 3%, Diameter of the Cross Section of the Specimen. In the

4.5%). For preparing 1.5% copper alloy, 800 grams of present experimentation work we have adapted the

aluminium 6063 is taken in one crucible and heated specimen specifications as D =20 mm and L=30 mm.

till the aluminium in the crucible is liquefied. In other Now fabricated specimens are cryogenically treated

crucible 12 grams of copper (for 1.5%) is taken and for different time duration levels. The time for which

heated separately until it gets liquefied. Now both are the specimens are subjected to cryogenic treatment is

mixed by manual stirring so that a uniform called soaking period in a cryogenic container as

aluminium-copper solution is attained in one crucible. shown in Fig 3.

Fig 1 shows the furnace used in preparing the

composite.

Fig 1: Furnace

Then the molten metal alloy is ready to pour into Fig 3: cryogenic container

the mould and allowed it to solidify for a definite The alloy samples obtained by varying the

period and the required casting is obtained by percentage of copper are subjected to different soaking

breaking the sand mould. The above procedure is periods i.e., Three samples each from 1.5%, 3%, 4.5%

repeated for the remaining two percentages of copper of Cu were stored in the liquid nitrogen container for 6

i.e., 3% and 4.5% and corresponding alloys are hours, 8 hours and 10 hours. After storing for the

obtained. The castings that are prepared from the required time period samples are taken out and kept

above procedure are machined on the CNC lathe (Fig. separately. The experimental plan is as shown in the

2) to the required dimensions by facing the edges of table 3.

ISSN: 2348 – 8360 www.internationaljournalssrg.org Page 2

SSRG International Journal of Mechanical Engineering (SSRG-IJME) – volume X Issue Y–Month 2017

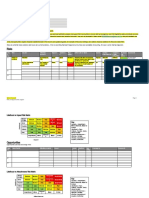

TABLE III percentage composition of copper is shown in

Experimental plan Fig 6 (a,b,c). The plots show that, the compressive

Expt. No. % Copper Cryogenic Time strength of Al-Cu alloy increases with increase in

cryogenic time.

1 1.5% 0hrs

2 3.0% 0hrs

3 4.5% 0hrs

4 1.5% 6hrs

5 3.0% 6hrs

6 4.5% 6hrs

7 1.5% 8hrs

8 3.0% 8hrs

9 4.5% 8hrs

10 1.5% 10hrs

11 3.0% 10hrs

12 4.5% 10hrs

Fig 6(a):CompressiveStress vs Cryogenic time for

1.5%Cu specimens

Hence finally the fabricated test specimens were

subjected for compression tests. The Load vs

Elongation curves for all specimens are shown in the

Fig 4.

III. RESULTS AND DISCUSSIONS

From the results it is observed that as the cryogenic

treatment time increases, the load bearing capacity i.e.,

the strength of the Aluminium-Copper Alloy

increases. Hence the result is in coincidence with [3]

and [4]. The measured compressive load is plotted

against the Cryogenic treatment time and as shown in

the Fig 5.

Fig 6 (b): Compressive Stress vs Cryogenic time for

3.0%Cu specimens

Fig 5: Load vs Elongation curves for all the specimens

S Takamori [7] in his investigation stated that

Fig 6 (c): Compressive Stress vs Cryogenic time for

mould temperature also plays a key role in enhancing

4.5%Cu specimens

the material properties. Thus the Compressive strength

of the Aluminium-Copper Alloy upon cryogenic

treatment should enhance because the cryogenic

temperature can effectively strain harden with higher

dislocation density of samples. The variation of

compressive stress for cryogenically treated Al-Cu

Alloys with respect to cryogenic time for different

ISSN: 2348 – 8360 www.internationaljournalssrg.org Page 3

SSRG International Journal of Mechanical Engineering (SSRG-IJME) – volume X Issue Y–Month 2017

1.5% Cu-6hrs-Specimen-1 1.5% Cu-6hrs-Specimen-2

1.5% Cu-8hrs-Specimen-1 1.5% Cu-8hrs-Specimen-2

1.5% Cu-10hrs-Specimen-1 1.5% Cu-10hrs-Specimen-2

3.0% Cu-6hrs-Specimen-1 3.0% Cu-6hrs-Specimen-2

3.0% Cu-8hrs-Specimen-1 3.0% Cu-8hrs- Specimen-2

ISSN: 2348 – 8360 www.internationaljournalssrg.org Page 4

SSRG International Journal of Mechanical Engineering (SSRG-IJME) – volume X Issue Y–Month 2017

3.0% Cu-10hrs-Specimen-1 3.0% Cu-10hrs-Specimen-2

4.5% Cu-6hrs-Specimen-1 4.5% Cu-6hrs-Specimen-2

4.5% Cu-8hrs-Specimen-1 4.5% Cu-8hrs-Specimen-2

4.5% Cu-10hrs-Specimen-1 4.5% Cu-10hrs-Specimen-2

ISSN: 2348 – 8360 www.internationaljournalssrg.org Page 5

SSRG International Journal of Mechanical Engineering (SSRG-IJME) – volume X Issue Y–Month 2017

1.5% Cu-0hrs-Specimen-1 1.5% Cu-0hrs-Specimen-2

3% Cu-0hrs-Specimen-1 3% Cu-0hrs-Specimen-2

4.5% Cu-0hrs-Specimen-1 4.5% Cu-0hrs-Specimen-2

Fig 4: Load vs Elongation curves for all the specimens

ISSN: 2348 – 8360 www.internationaljournalssrg.org Page 6

SSRG International Journal of Mechanical Engineering (SSRG-IJME) – volume X Issue Y–Month 2017

It is also clear from the results that, as percentage of accurate implementation of cryogenic treatment of

copper increases in the Aluminium, the strength of the alloys will help to save production time and hence

Aluminium-Copper Alloy increases to an extent and production cost.

then decreases. This is evident by Compressive load

vs. % Cu plot as shown in Fig 7.

REFERENCES

[1] J Hashim, L Looney, M.S.J Hashmi, Metal matrix

composites: production by the stir casting method, Journal of

Materials Processing Technology. 1999:Vol 92-93 pp:1-7.

[2] Kelly,T.chou and A. Okura, Fibre-reinforced metal-

matrix composites, Composites, 1985, 16 (3), pp.187-206,

[3] Panchakshari H.V, Girish D.P, Effect of cryogenic

treatment on microstructure and micro hardness of AL6061-

AL2O3 metal matrix composites 2012 JERS/Vol. III/ Issue

I/January-March pp:105-107.

[4] Arun C Dixit U , Effect of cryogenic treatment on

corrosion resistance of hybrid Aluminium-7075 metal matrix

composites, 2016,IJERGS Volume 4, Issue 3,pp:678-684.

[5] Pavan K.M, Sachin L.S Effect of cryogenic treatment on

the mechanical and microsructural properties of aluminium

alloys, 2014, proceedings of IRF International Conference

ISBN :9789382702696, pp: 73-77

[6] K.K.Padmanabhan, G.Prabhu, Experimental

Investigation by Cryogenic Treatment of Aluminium 6063

and 8011 and NiCoW Coating to Improve Hardness and

Fig 7: Compressive Load vs %Cu in the alloy Wear, International Journal of Engineering (IJE) 2016,

Vol. 29,No:6.

[7] Susumu takamori, Casting surface of AL9I alloy and its

From the Fig 8 which is the variation plot between reaction with sand mould, 2008 Materials Transactions, Vol.

the % elongation vs cryogenic time it is obvious that, 49, No. 5 pp:1089 to 1092

the ductile nature of the Al-Cu Alloy also increases

with respect to the duration of the cryogenic treatment.

Fig8: % Elongation vs Cryogenic time alloy specimens

IV. CONCLUSIONS

The alloys produced by varying the percentage

composition of different alloying materials will

enhance the mechanical properties of the base

materials up to some extent. But in order to improve

the material characteristics every time varying the

percentage composition of the alloy increases the

production cost which as a consequence decrease the

domestic applicability of the product. In present

investigation, one such trail is successfully carried-out

on Aluminium-Copper alloy which is a most

significant domestic alloy. This study showed that, the

cryogenic treatment, instead of varying the percentage

composition to the base material, enhanced the

material properties of Aluminium-Copper alloy. This

ISSN: 2348 – 8360 www.internationaljournalssrg.org Page 7

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Strategic Human Resource Development I SlidesDocument26 pagesStrategic Human Resource Development I SlidesAbhiman Behera50% (2)

- LorelDocument23 pagesLorelRabindra KarkiNo ratings yet

- Court Cases - Type of Court Cases and CasesDocument24 pagesCourt Cases - Type of Court Cases and CasesVenkat MacharlaNo ratings yet

- Delegation Powers: Directorate of Town and Country Planning Department Andhra PradeshDocument36 pagesDelegation Powers: Directorate of Town and Country Planning Department Andhra PradeshVenkat MacharlaNo ratings yet

- Andhra Pradesh Agricultural Land (Conversion For Non-Agricultural Purposes) ACT, 2006Document22 pagesAndhra Pradesh Agricultural Land (Conversion For Non-Agricultural Purposes) ACT, 2006Venkat Macharla100% (2)

- Welcome TO Training Programme For Planning & Regulation SecretariesDocument20 pagesWelcome TO Training Programme For Planning & Regulation SecretariesVenkat MacharlaNo ratings yet

- Presentation On Induction Training To Ward Secretaries: Town and Country Planning DepartmentDocument9 pagesPresentation On Induction Training To Ward Secretaries: Town and Country Planning DepartmentVenkat MacharlaNo ratings yet

- Presentasion ON Fee/ChargesDocument28 pagesPresentasion ON Fee/ChargesVenkat MacharlaNo ratings yet

- Presentation On Induction Training To Ward Secretaries: Town and Country Planning DepartmentDocument12 pagesPresentation On Induction Training To Ward Secretaries: Town and Country Planning DepartmentVenkat MacharlaNo ratings yet

- Act Provisions On Enforcement of UCsDocument7 pagesAct Provisions On Enforcement of UCsVenkat MacharlaNo ratings yet

- NFL PDFDocument10 pagesNFL PDFVenkat MacharlaNo ratings yet

- Quality of Water: Prepared by Macherla Venkateswara RaoDocument11 pagesQuality of Water: Prepared by Macherla Venkateswara RaoVenkat MacharlaNo ratings yet

- Repalle MAUD MS298Document6 pagesRepalle MAUD MS298Venkat MacharlaNo ratings yet

- 5 Regression 150330040604 Conversion Gate01Document5 pages5 Regression 150330040604 Conversion Gate01Venkat Macharla100% (1)

- Certificate: Name of RecipientDocument1 pageCertificate: Name of RecipientVenkat MacharlaNo ratings yet

- Hardness PDFDocument1 pageHardness PDFVenkat MacharlaNo ratings yet

- Fci PDFDocument1 pageFci PDFVenkat MacharlaNo ratings yet

- Differentiation by TrockersDocument47 pagesDifferentiation by TrockersRodney Takundanashe Mandizvidza100% (1)

- Mill Behaviour of Rubber On Two Roll Mill With Temperature: Nippon Gomu Kyokaishi, 88, No. 4, 2015, Pp. 130-135Document6 pagesMill Behaviour of Rubber On Two Roll Mill With Temperature: Nippon Gomu Kyokaishi, 88, No. 4, 2015, Pp. 130-135Prashantha NandavarNo ratings yet

- STRAMAN - Workbookfinal2 (1) JESSA MAY R, CABATINGADocument38 pagesSTRAMAN - Workbookfinal2 (1) JESSA MAY R, CABATINGAWazzup BatangeñioNo ratings yet

- TF418 Termostato Digital Orquidea O3 Manual InstalacionDocument6 pagesTF418 Termostato Digital Orquidea O3 Manual Instalaciondadivan1100% (1)

- Adorama ProPhotoLab Umum Pricelist Feb2011 FinalDocument1 pageAdorama ProPhotoLab Umum Pricelist Feb2011 FinalDidi IDNo ratings yet

- Is 2798 (1998) - Methods of Test For Plastics ContainersDocument4 pagesIs 2798 (1998) - Methods of Test For Plastics Containersclintdara100% (1)

- Advanced PDS Skills: Presented by Muhammad Ali HaiderDocument15 pagesAdvanced PDS Skills: Presented by Muhammad Ali Haiderali534No ratings yet

- Mitsubishi / 304: Oem Number Oem NumberDocument71 pagesMitsubishi / 304: Oem Number Oem NumberBobCavNo ratings yet

- Unidrive M400: Fast Set-Up and Diagnostics With Real-Text Display, Integrated PLC and Safety InputsDocument16 pagesUnidrive M400: Fast Set-Up and Diagnostics With Real-Text Display, Integrated PLC and Safety InputsJunior enriquez cabezudoNo ratings yet

- Energain FlyerDocument4 pagesEnergain FlyerStamatis BabalisNo ratings yet

- AI in Healthcare - Theory To PracticeDocument6 pagesAI in Healthcare - Theory To PracticensahniNo ratings yet

- Scientific Method BeriberiDocument4 pagesScientific Method BeriberiadelavazNo ratings yet

- Course Title: Transportation Engineering II Lab Course Code: CE 452Document4 pagesCourse Title: Transportation Engineering II Lab Course Code: CE 452Md. Murshedul Islam 173-47-091No ratings yet

- 08 - 02 - 2020 - Student - Letter SCIENCE - 28.012020 PDFDocument440 pages08 - 02 - 2020 - Student - Letter SCIENCE - 28.012020 PDFPankaj KaleNo ratings yet

- Amnex Corporate Presentation PDFDocument28 pagesAmnex Corporate Presentation PDFShweta SharmaNo ratings yet

- How To Digitally Sign A PDF Document in DelphiDocument2 pagesHow To Digitally Sign A PDF Document in DelphiangdrakeNo ratings yet

- Tissues 1.Document2 pagesTissues 1.Adeaga ElizabethNo ratings yet

- Steel Final Project: Prepared By: Siva Soran Supervised By: Mr. Shuaaib A. MohammedDocument25 pagesSteel Final Project: Prepared By: Siva Soran Supervised By: Mr. Shuaaib A. Mohammedsiva soranNo ratings yet

- Solera TitanDocument64 pagesSolera TitanAndrea MejiaNo ratings yet

- MF8470-8480 каталог PDFDocument641 pagesMF8470-8480 каталог PDFСергій Xрестик100% (1)

- AP at RHHS 2016Document13 pagesAP at RHHS 2016Ryan YuNo ratings yet

- Philips Medical Systems - HeartStart MRX M3536A - User - ID10664 PDFDocument186 pagesPhilips Medical Systems - HeartStart MRX M3536A - User - ID10664 PDFFelipe100% (1)

- Mixed Model Assembly Sequencing at Toyota: Project Update: by Bo Liu, Yudhisthir PaudelDocument6 pagesMixed Model Assembly Sequencing at Toyota: Project Update: by Bo Liu, Yudhisthir PaudelyudhidelNo ratings yet

- Name and Logo of Council: RisksDocument2 pagesName and Logo of Council: RisksAbdur Rauf KhanNo ratings yet

- DOJ Directory As of 17 June 2020 PDFDocument64 pagesDOJ Directory As of 17 June 2020 PDFKatrina Janine Cabanos-ArceloNo ratings yet

- Pyqt 5Document21 pagesPyqt 5MaikOlliverNo ratings yet

- RES 6101 The Reading Guide 211Document95 pagesRES 6101 The Reading Guide 211Hà ThuNo ratings yet