Professional Documents

Culture Documents

Liste Code G Fanuc

Liste Code G Fanuc

Uploaded by

Frô Le Mage BlancOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Liste Code G Fanuc

Liste Code G Fanuc

Uploaded by

Frô Le Mage BlancCopyright:

Available Formats

http://www.helmancnc.

com/fanuc-g71-turning-cycle/

G

Description

code

G00 Rapid traverse

G01 Linear interpolation

G02 Circular interpolation CW

G03 Circular interpolation CCW

G04 Dwell

G09 Exact stop

G10 Programmable data input

G20 Input in inch

G21 Input in mm

G22 Stored stroke check function on

G23 Stored stroke check function of

G27 Reference position return check

G28 Return to reference position

G32 Thread cutting

G40 Tool nose radius compensation cancel

G41 Tool nose radius compensation left

G42 Tool nose radius compensation right

G70 Finish machining cycle

G71 Turning cycle

G72 Facing cycle

G73 Pattern repeating cycle

G74 Peck drilling cycle

G75 Grooving cycle

G76 Threading cycle

G92 Coordinate system setting or max. spindle speed setting

G94 Feed Per Minute

G95 Feed Per Revolution

G96 Constant surface speed control

G97 Constant surface speed control cancel

• Fanuc G71 Turning Cycle

• Programming

• Parameters

• G71 Turning Cycle Overview

• G71 Turning Cycle Working

• Fanuc G71 Example

• G70 Finishing Cycle

• Why Use G70 Finishing Cycle

• Fanuc G70 Example

• G70 G71 Example

Fanuc G71 Turning Cycle

G71 turning cycle is used for rough-material removal from a cnc lathe

component. G71 turning cycle makes large diameter cutting easy. Cutting can be

done in simple straight line or a complex contour can also be machined very

easily.

Through G71 turning cycle parameters cnc machinists can control

• Depth of cut.

• Retract height.

• Finishing allowance in x-axis and z-axis.

• Cycle cutting-feed, spindle speed.

Programming

G71 U... R...

G71 P... Q... U... W... F... S...

Parameters

First block

Paramet

Description

er

U Depth of cut.

R Retract height.

Second block

Paramet

Description

er

P Contour start block number.

Q Contour end block number.

U Finishing allowance in x-axis.

W Finishing allowance in z-axis.

F Feedrate during G71 cycle.

S Spindle speed during G71 cycle.

G71 Turning Cycle Overview

• G71 turning cycle cuts the whole contour repeatedly which is given in P Q

blocks.

• Depth of every cut can be controlled by first-block U value.

• Second-block U W are the finishing allowances which can be given if you

want to make a finish cut with G70 finishing cycle.

• F is cutting feed and S is spindle speed (given in second-block) which are

used during G71 turning cycle.

Note – The F and S given inside P Q block will not be used during G71 turning

cycle, they are used with G70 finishing cycle if later called.

G71 Turning Cycle Working

N60 G71 U10 R10

N70 G71 P80 Q90 U3 W0 F0.25

N80 G00 X60

N90 G01 Z-75

When G71 turning cycle is run the whole operation will be done in following

sequence,

First-cut

1 – Tool will move in x-axis U (depth of cut) deep with programmed feed from

starting-point.

2 – Tool will travel with feed in z-axis (destination point in z-axis is given in P Q

blocks )

3 – Tool rapidly retracts R amount in both x-axis and z-axis (at 45 degrees).

4 – Tool rapidly travel in z-axis to start-point

5 – Tool rapidly moves to last cut depth.

6 – Tool moves with feed in x-axis U deep (first-block U depth of cut).

7 – Tool with feed moves in z-axis (destination point given in P Q blocks).

8 – Tool rapidly retracts in x-axis and z-axis R amount (45 degrees).

9 – Tool rapidly moves to start-point only in z-axis.

This whole sequence of operation keep on going, until the destination point in x-axis is met.

If finishing allowance is given tool will not make the exact diameter and length given in P Q blocks but

will leave that much allowance, This finishing allowance can be later machined by calling G70

finishing cycle.

Fanuc G71 Turning Cycle

Fanuc G71 Example

Here is a cnc part-program which shows how G71 turning cycle can be used, this is the program for the

drawing given above

N50 G00 X106 Z5 M3 S800

N60 G71 U10 R10

N70 G71 P80 Q90 U3 W0 F0.25

N80 G00 X60

N90 G01 Z-75

In this program G71 turning cycle will keep repeating the contour given inside P Q blocks shown

below

N80 G00 X60

N90 G01 Z-75

These two cnc program blocks tell us that we want to remove material till X60 deep and in Z-75 in

length.

The depth of cut is given in first-block U10 retract amount is also given R10.

Finishing allowance in x-axis is U3 but there is no finishing allowance given in z-axis W0.

G70 Finishing Cycle

If you programmed G71 turning cycle with finishing allowances then that finish allowances can be

removed with G70 finishing cycle.

G70 finishing cycle repeats the whole contour the G71 way, but in just one-cut removing the finishing

allowances.

Why Use G70 Finishing Cycle

As material can be removed with G71 turning cycle, but if you want a different cutting-feed and

spindle speed for the last cut, then it is recommended that you use G70 finishing cycle.

G70 finishing cycle use F and S values which are given inside P Q programmed blocks. (G71 use F S

values which are given inside G71 second block.)

Fanuc G70 Example

N50 G00 X106 Z5 M3 S800

N60 G71 U10 R10

N70 G71 P80 Q90 U3 W0 F0.25

N80 G00 X60

N90 G01 Z-75 F0.15

N100 G00 X200 Z100

N110 G92 S1200

N120 T3 G96 S150 M03

N130 G00 X106 Z5

N140 G70 P80 Q90

N150 G00 X200 Z100

N160 M30

G70 G71 Example

G71 Rough Turning Cycle Example

O0004

G00 X200 Z10 M3 S800

G71 U2 R1 F200

G71 P80 Q120 U0.5 W0.2

N80 G00 X40 S1200

G01 Z-30 F100

X60 W-30

W-20

N120 X100 W-10

G70 P80 Q120

M30

You might also like

- VLTD Fitment Certificate (Generated Online in VAHAN)Document1 pageVLTD Fitment Certificate (Generated Online in VAHAN)Siddhant BhandarkarNo ratings yet

- Complete G Code ListDocument7 pagesComplete G Code ListRevolusiSoekarno100% (3)

- EAP Grammar in Context: Reading & WritingDocument27 pagesEAP Grammar in Context: Reading & WritingMónica Coirolo50% (2)

- VEX LiftsDocument24 pagesVEX LiftsivstinivsNo ratings yet

- Curricula Simplificada UPDATED Oct 2019Document3 pagesCurricula Simplificada UPDATED Oct 2019BJ JOs100% (1)

- Production of Chess PiecesDocument19 pagesProduction of Chess PieceshoanghuanNo ratings yet

- SFM PlasticsDocument1 pageSFM PlasticsWalter RichardNo ratings yet

- GNG 1105 Final Exam 2000Document3 pagesGNG 1105 Final Exam 2000Stefano MazzaNo ratings yet

- CNC ProgramsDocument5 pagesCNC ProgramsBravo VermaNo ratings yet

- G - Code M - CodeDocument3 pagesG - Code M - CodeblashkogNo ratings yet

- CNC ProgrammingDocument60 pagesCNC ProgrammingRohan Dutta100% (2)

- G Code:-: CNC Lathe G & M CodesDocument3 pagesG Code:-: CNC Lathe G & M CodesCIPETNo ratings yet

- Lathe ProgramDocument6 pagesLathe ProgramAwoke TesfaNo ratings yet

- The Text Used On A Typical Detail Sheet Should Be - Placed HorizontallyDocument30 pagesThe Text Used On A Typical Detail Sheet Should Be - Placed HorizontallyShalom HaileNo ratings yet

- BengkelDocument7 pagesBengkelMohamad HarithNo ratings yet

- ALL CNC Printouts PROGRAMS PRINTOUTDocument26 pagesALL CNC Printouts PROGRAMS PRINTOUTGajananNo ratings yet

- IAAF Track and Field Facilities Manual 2008 Edition - Marking Plan 200m Indoor TrackDocument1 pageIAAF Track and Field Facilities Manual 2008 Edition - Marking Plan 200m Indoor Trackfifix123No ratings yet

- VMC Slot ProgramingDocument5 pagesVMC Slot ProgramingMechanical FactsNo ratings yet

- TAPER TURNING and Thread CuttingDocument3 pagesTAPER TURNING and Thread CuttingErin BarryNo ratings yet

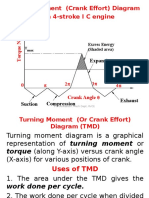

- Turning Moment Diagram & FlywheelDocument88 pagesTurning Moment Diagram & FlywheelAshishAgarwal100% (1)

- CNC Mill ProgrammingDocument24 pagesCNC Mill ProgrammingZahidah AmaninaNo ratings yet

- Haas G72 Type I Rough and G70 Finish Facing Program ExampleDocument3 pagesHaas G72 Type I Rough and G70 Finish Facing Program ExampleCnc Page100% (1)

- JJ102 Electrical Technology CHAPTER - 5 TansfomersDocument17 pagesJJ102 Electrical Technology CHAPTER - 5 TansfomersAh TiangNo ratings yet

- CNC Turning (Bridgeport)Document63 pagesCNC Turning (Bridgeport)Siti Idah Tawhid100% (1)

- LazyCam PostProcessor VariablesDocument2 pagesLazyCam PostProcessor Variablescastellano_rNo ratings yet

- Turning Exercies - Ip710 - Dr.V.RameshDocument8 pagesTurning Exercies - Ip710 - Dr.V.Rameshvajram1100% (2)

- Soalan Quality ControlDocument5 pagesSoalan Quality ControlIskandar Ibrahim100% (1)

- Introduction To Introduction To Computer Numerical Control: Computer Aided Manufacturing TECH 4/53350 1Document11 pagesIntroduction To Introduction To Computer Numerical Control: Computer Aided Manufacturing TECH 4/53350 1BabuRaoThellaNo ratings yet

- Kinematics of Machinery ManualDocument29 pagesKinematics of Machinery ManualShubham NaikNo ratings yet

- Unit - 8: CNC ProgrammingDocument21 pagesUnit - 8: CNC ProgrammingVarshaNo ratings yet

- A Letter Engraving Custom MacroDocument15 pagesA Letter Engraving Custom Macrofirepower117No ratings yet

- NC ProgrammingDocument54 pagesNC ProgrammingVed Vrat NuclearNo ratings yet

- Part Manufacturing On CNC Milling: Manufacturing Process Lab Lab Report Experiment # 04Document7 pagesPart Manufacturing On CNC Milling: Manufacturing Process Lab Lab Report Experiment # 04yushi100% (2)

- Processing Long&Cross Section Using CDSDocument5 pagesProcessing Long&Cross Section Using CDSKãrthîk RãjãhNo ratings yet

- WinCNC - V1.12 - V8 Operating Manual PDFDocument48 pagesWinCNC - V1.12 - V8 Operating Manual PDFMilko Migneco100% (1)

- Parametric Design of A Spiral Gear ProcessDocument5 pagesParametric Design of A Spiral Gear ProcessGoutam AcharjeeNo ratings yet

- CNC TRAINDocument124 pagesCNC TRAINakshat naiduNo ratings yet

- Tutorial 1 PDFDocument9 pagesTutorial 1 PDFMuaz Mohd ZahidinNo ratings yet

- Jm201 - CNC MillingDocument24 pagesJm201 - CNC MillingMuhd Zulhusni Ag Jaludin100% (1)

- Mitsubishi Motors Service & Maintenance Schedule: Xpander RNDocument1 pageMitsubishi Motors Service & Maintenance Schedule: Xpander RNTuan MottaNo ratings yet

- U W CNC Lathe CNC Program ExamplesDocument30 pagesU W CNC Lathe CNC Program ExamplesTrần Xuân Thanh100% (1)

- Lecture 5 - Canned Cycle-TurningDocument11 pagesLecture 5 - Canned Cycle-TurningAditya RatleyNo ratings yet

- CAM Lab Manual - 2014Document146 pagesCAM Lab Manual - 2014Nithish Kumar K MNo ratings yet

- Cannedcycle 180102172200Document27 pagesCannedcycle 180102172200WernerNo ratings yet

- 8 Fixed Canned Cycles (CNC Course CD) PDFDocument24 pages8 Fixed Canned Cycles (CNC Course CD) PDFVeerasamy SureshbabuNo ratings yet

- Programe FanucDocument47 pagesPrograme Fanucbranet_adrianaNo ratings yet

- CNC Programming "Milling": Module ObjectivesDocument37 pagesCNC Programming "Milling": Module Objectiveshasan alsarrafNo ratings yet

- Turning Part ProgramDocument21 pagesTurning Part Programtayalpunit196524No ratings yet

- Mill Fanuc: Fanuc G68 Coordinate Rotation - Subprogram ExampleDocument73 pagesMill Fanuc: Fanuc G68 Coordinate Rotation - Subprogram Exampleسليمان مصريNo ratings yet

- Presentation 4Document34 pagesPresentation 4Amaterasu Susanoo TsukuyomiNo ratings yet

- CNC Programs ExamplesDocument5 pagesCNC Programs ExamplesNemikumar Gandhi100% (2)

- Module 2 SolutionDocument3 pagesModule 2 SolutionYogesh SainiNo ratings yet

- Phases of A CNC Program1Document5 pagesPhases of A CNC Program1jebishaNo ratings yet

- FANUC G Code of LatheDocument25 pagesFANUC G Code of LatheHùng LêNo ratings yet

- CNC Part ProgrammingDocument61 pagesCNC Part ProgrammingrajaNo ratings yet

- Description For M Codes3Document19 pagesDescription For M Codes3balabooksNo ratings yet

- FanucDocument10 pagesFanucgigofive66No ratings yet

- CNC Programming and OperationDocument80 pagesCNC Programming and OperationMohammed Habeeb100% (1)

- CNC CodeDocument9 pagesCNC CodeMochammad Karim Al AminNo ratings yet

- G M Codes For Turning and MillingDocument10 pagesG M Codes For Turning and MillingParanthaman RamanNo ratings yet

- FME CNC Unit 5Document78 pagesFME CNC Unit 5B30parvej arif shahNo ratings yet

- HC700 SDK SpecificationDocument680 pagesHC700 SDK SpecificationTzahiKupfer0% (1)

- Mete AggiesDocument16 pagesMete AggiesJohn Renzel RiveraNo ratings yet

- Ready To Go Lessons For Maths Stage 4 AnswersDocument9 pagesReady To Go Lessons For Maths Stage 4 AnswersNangNo ratings yet

- Batuigas Et. Al - Researh ProposalDocument28 pagesBatuigas Et. Al - Researh ProposalYzel SeniningNo ratings yet

- EX - NO 3 (A) Applications Using TCP Sockets Like Echo Client and Echo Server AimDocument4 pagesEX - NO 3 (A) Applications Using TCP Sockets Like Echo Client and Echo Server AimHaru HarshuNo ratings yet

- A Time When I Felt Extremely Proud of MyselfDocument2 pagesA Time When I Felt Extremely Proud of Myselfsaadhana elangovanNo ratings yet

- Orientation On The Manual For The Evaluation (Autosaved)Document31 pagesOrientation On The Manual For The Evaluation (Autosaved)Em Boquiren CarreonNo ratings yet

- Algorithm and Validation of Tower of HanoiDocument2 pagesAlgorithm and Validation of Tower of HanoiKyaan MosqNo ratings yet

- Franco Mastrandrea - What Makes A Sound Quantum AnalystDocument18 pagesFranco Mastrandrea - What Makes A Sound Quantum AnalystNebojsa PavlovicNo ratings yet

- The Story of An Hour LitChartDocument10 pagesThe Story of An Hour LitChartNoelle AgaibyNo ratings yet

- Flexible Transportand DRTReportDocument64 pagesFlexible Transportand DRTReportDualDuelNo ratings yet

- 09 - Chapter5 Determinents of FDI PDFDocument13 pages09 - Chapter5 Determinents of FDI PDFdeepakadhanaNo ratings yet

- Assignment4 Solutions Chap6Document7 pagesAssignment4 Solutions Chap6Mohit soniNo ratings yet

- EAP 11 - 12 - UNIT 4 - LESSON 2 - Techniques in Paraphrasing TextsDocument55 pagesEAP 11 - 12 - UNIT 4 - LESSON 2 - Techniques in Paraphrasing TextsMaricelNo ratings yet

- Uniform Rotary MotionDocument26 pagesUniform Rotary MotionMark RamosNo ratings yet

- The Contemporary World ModuleDocument131 pagesThe Contemporary World ModuleJay Vincent AmoloNo ratings yet

- The Nature of Probability and StatisticsDocument16 pagesThe Nature of Probability and StatisticsCynthia Plaza100% (1)

- Week 3 Ila RPL FLT Weekly Home Learning Plan Als PandemicDocument3 pagesWeek 3 Ila RPL FLT Weekly Home Learning Plan Als Pandemicelvis ibera100% (1)

- Trine Natasja Sindahl PSYKphd MAR2019 B5Document169 pagesTrine Natasja Sindahl PSYKphd MAR2019 B5Maira Espinoza LabraNo ratings yet

- BatStateU FO TAO 08 Grades Form 1 Regular Admission Rev. 02 1Document1 pageBatStateU FO TAO 08 Grades Form 1 Regular Admission Rev. 02 1asdfghNo ratings yet

- Psixologiya 2 Son 2023Document265 pagesPsixologiya 2 Son 2023Otabek ShamsiddinovNo ratings yet

- Access Specifier FinalDocument6 pagesAccess Specifier FinalManojChowdaryNo ratings yet

- 2021 Ford® Ranger Midsize Pickup Truck - BrochuresDocument5 pages2021 Ford® Ranger Midsize Pickup Truck - BrochuresRizal Mohamad Al-AyyubiNo ratings yet

- The Evolution of The International Human Rights ReDocument36 pagesThe Evolution of The International Human Rights ReAsha YadavNo ratings yet

- Decision AnalysisDocument28 pagesDecision AnalysisAshley MorrisNo ratings yet

- Skoog Química Analítica cCh8 InglésDocument6 pagesSkoog Química Analítica cCh8 InglésDavid DualNo ratings yet

- Solar Cells Theory Full VersionDocument139 pagesSolar Cells Theory Full Versionnoorev100% (1)

- Money Laundering: Risks You Cannot IgnoreDocument4 pagesMoney Laundering: Risks You Cannot IgnoreKunwarbir Singh lohatNo ratings yet

- 3.1descriptin of The Study AreaDocument4 pages3.1descriptin of The Study Areaadamu shumetNo ratings yet