Professional Documents

Culture Documents

Biodiesel Production From Allanblackia Floribunda Seed Oil PDF

Biodiesel Production From Allanblackia Floribunda Seed Oil PDF

Uploaded by

Fortune JournalsCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Official History of 86th DivisionDocument344 pagesOfficial History of 86th DivisionFilipNo ratings yet

- Baldur's Gate - MapsDocument58 pagesBaldur's Gate - MapsLaurent GorseNo ratings yet

- Generac Kovai PriceList US 0801 2019Document9 pagesGenerac Kovai PriceList US 0801 2019RONALDNo ratings yet

- A Randomized Controlled Trial of Intravenous Paracetamol and Intravenous Tramadol For Labour AnalgesiaDocument11 pagesA Randomized Controlled Trial of Intravenous Paracetamol and Intravenous Tramadol For Labour AnalgesiaFortune JournalsNo ratings yet

- Avsm 004Document7 pagesAvsm 004Fortune JournalsNo ratings yet

- Chemical Contaminants and Pollutants in The Measurable Life of Dhaka City PDFDocument17 pagesChemical Contaminants and Pollutants in The Measurable Life of Dhaka City PDFFortune JournalsNo ratings yet

- Cerebral Infarction in Risk Factor of Adenoma and Symptomatic Aortic Stenosis Case Report and Literature Reviewp PDFDocument8 pagesCerebral Infarction in Risk Factor of Adenoma and Symptomatic Aortic Stenosis Case Report and Literature Reviewp PDFFortune JournalsNo ratings yet

- Capsicum Protects Against Rotenoneinduced Toxicity in Mice Brain Via Reduced Oxidative Stress and 5lipoxygenase Activationp PDFDocument18 pagesCapsicum Protects Against Rotenoneinduced Toxicity in Mice Brain Via Reduced Oxidative Stress and 5lipoxygenase Activationp PDFFortune JournalsNo ratings yet

- Biomineralogy of Angiogenesis PDFDocument7 pagesBiomineralogy of Angiogenesis PDFFortune JournalsNo ratings yet

- Cancer Therapyinduced Cardiotoxicity Where Are We Now PDFDocument8 pagesCancer Therapyinduced Cardiotoxicity Where Are We Now PDFFortune JournalsNo ratings yet

- Biochemistry and Pathophysiology of Glycation of Dna Implications in Diabetes PDFDocument16 pagesBiochemistry and Pathophysiology of Glycation of Dna Implications in Diabetes PDFFortune JournalsNo ratings yet

- MAC Layer Protocols For Sensor Networks: Leonardo Leiria FernandesDocument29 pagesMAC Layer Protocols For Sensor Networks: Leonardo Leiria FernandesSrinivas GopisettiNo ratings yet

- SEWING TOOLS AND EQUIPMENT AND THEIR USES (Teacher's Copy)Document4 pagesSEWING TOOLS AND EQUIPMENT AND THEIR USES (Teacher's Copy)Pilar Villanueva86% (7)

- Exponents, Radicals and LogarithmsDocument32 pagesExponents, Radicals and LogarithmsandrikaNo ratings yet

- Colours Show MoodDocument2 pagesColours Show MoodSuraya NordinNo ratings yet

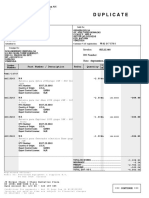

- Duplicate: Invoice: DO NumberDocument2 pagesDuplicate: Invoice: DO NumberLiau Zhan HongNo ratings yet

- MIl-C-70508 Municion Cal. 9 MMDocument17 pagesMIl-C-70508 Municion Cal. 9 MMDavid BasanteNo ratings yet

- Design of 200m3 TankDocument4 pagesDesign of 200m3 TankMiko AbiNo ratings yet

- Parameter& Relation TutorialDocument24 pagesParameter& Relation TutorialPrasad GoNo ratings yet

- Water Level Controller Using 8051 Circuit PrincipleDocument4 pagesWater Level Controller Using 8051 Circuit PrincipleLappi SchematicsNo ratings yet

- Proposal Rev 02Document30 pagesProposal Rev 02suronocaturatmojo100% (1)

- Letter of DiscrepancyDocument1 pageLetter of DiscrepancyImam MekarNo ratings yet

- 11th Floor Accomplishment As of 8/9/21 Units 1st Coat 2nd Coat Flood Test Remarks Unit ADocument27 pages11th Floor Accomplishment As of 8/9/21 Units 1st Coat 2nd Coat Flood Test Remarks Unit Afrancis baldonadoNo ratings yet

- Laserjet Professional M1130/M1210: MFP SeriesDocument16 pagesLaserjet Professional M1130/M1210: MFP SeriesDhanesh RamachandramNo ratings yet

- MMS Manual Contents Ver 1Document42 pagesMMS Manual Contents Ver 1Kardi SolehNo ratings yet

- Mud Max Mud Max Compact: Centrifugal Pump Series 250Document32 pagesMud Max Mud Max Compact: Centrifugal Pump Series 250Hussein MohamedNo ratings yet

- Butter Chicken Ingredients (Serves 4)Document2 pagesButter Chicken Ingredients (Serves 4)barbaraNo ratings yet

- BM SA ROPE ATTACHMENTS HRDocument4 pagesBM SA ROPE ATTACHMENTS HRTheo van der BergNo ratings yet

- Risk Involved in Construction Works.Document10 pagesRisk Involved in Construction Works.Shaibal AhmedNo ratings yet

- AMAC Brochures PC12 Revision 19.08.2019 1Document8 pagesAMAC Brochures PC12 Revision 19.08.2019 1Maria Luisa CucunubaNo ratings yet

- BLEPT 09-2016 Room Assignment Rosales-SecDocument114 pagesBLEPT 09-2016 Room Assignment Rosales-SecPRC Baguio50% (2)

- The Church's Mission and Post-Modern Humanism by M. M. ThomasDocument5 pagesThe Church's Mission and Post-Modern Humanism by M. M. ThomasPaul PeterNo ratings yet

- Law of SupplyDocument26 pagesLaw of SupplyamitNo ratings yet

- ALFOplus User ManualDocument110 pagesALFOplus User ManualAntonio Bezerra0% (2)

- VolcanoesDocument14 pagesVolcanoesSHANNEL ANN VILLUGANo ratings yet

- Geological Chance of SuccessDocument11 pagesGeological Chance of SuccesssarapkanNo ratings yet

- Full Download Test Bank For Essentials of Anatomy and Physiology 7th Edition by Martini PDF Full ChapterDocument21 pagesFull Download Test Bank For Essentials of Anatomy and Physiology 7th Edition by Martini PDF Full Chapterkimgarciajbpoqktdfy100% (19)

- Handling of Synthetic Silica and Silicate: Technical Bulletin Fine Particles 28Document32 pagesHandling of Synthetic Silica and Silicate: Technical Bulletin Fine Particles 28devang asherNo ratings yet

Biodiesel Production From Allanblackia Floribunda Seed Oil PDF

Biodiesel Production From Allanblackia Floribunda Seed Oil PDF

Uploaded by

Fortune JournalsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Biodiesel Production From Allanblackia Floribunda Seed Oil PDF

Biodiesel Production From Allanblackia Floribunda Seed Oil PDF

Uploaded by

Fortune JournalsCopyright:

Available Formats

Journal of Environmental Science and Public Health

doi: 10.26502/jesph.96120051

Volume 3, Issue 1 Research Proposal

Biodiesel Production from Allanblackia floribunda Seed oil

Sylvia Adipah*

Department of Environmental Engineering and Science, Chongqing University, Chongqing, China

*

Corresponding Author: Sylvia Adipah, Department of Environmental Engineering and Science, Chongqing

University, Chongqing, China, E-mail: fransil351@yahoo.com

Received: 12 December 2018; Accepted: 03 January 2019; Published: 08 February 2019

1. Introduction

At present, one of the ongoing challenges facing human society is to continue to provide energy in usable forms

such as electricity while there is a growth in population and global warming are increasing. Under these

circumstances, the utilization of renewable energy resources has become a global strategy for sustainable energy

use, which is of particular importance for coping with increasing stress from the energy crises and global warming.

Biogas has been developed rapidly and globally as an effective method to generated renewable energy, energy

production and sustains environmental production.

1.1 Biodiesel

Biodiesel is defined as an oxygenated, sulfur-free, biodegradable, non-toxic, and eco-friendly alternative diesel oil.

It can be derived from renewable sources, such as vegetable oil, animal fat, and used cooking oil that meets the

requirements of ASTM and European standards. These renewable sources are composed of mono-alkyl esters of

long chain fatty acids. Biofuel must meet the stringent quality standards to be considered as viable transportation

fuel. One of the methods of producing biodiesel is transesterification. As a result of high viscosity, there is the need

of injection and atomization characteristics of vegetable oil compared to those obtained petroleum diesel fuels. To

improve the performance of most modern diesel engines those have fuel injection system sensitive to viscosity

change, one way to avoid this problem is to reduce fuel viscosity of vegetable oil. Another effective way is by

converting vegetable oil into biodiesel such as dilution, micro emulsification, pyrolysis, and transesterification are

the four techniques used to solve the problems encountered with the high fuel viscosity.

J Environ Sci Public Health 2019; 3 [1]: 104-112 104

The most common methods use is tranesterification leading to mono alkyl esters of vegetable oils and fats, now

called biodiesel when used for fuel purposes. The methyl ester produced by transesterification of vegetable oil has a

high cetane number, low viscosity and improved heating value compared to those of pure vegetable oil which results

in shorter ignition delay and longer combustion duration and hence low particulate emissions.

2. Research Questions

How will the technology help to generate sustainable energy?

Is biogas production from Allanblackia floribunda Seed oil environmentally friendly?

How do we improve the efficiency of the biogas production from Allanblackia floribunda Seed oil?

Is biogas production from Allanblackia floribunda Seed oil cost-effective compared to other technologies?

3. Aim/Objective of the Research

The main objective of this study is to investigate the feasibility of using Allanblackia floribunda Seed oil as a new

potential non-edible feedstock for biodiesel production. The specific objectives of the study include;

i. To synthesize four novel dicationic functional ionic liquids with an imidazolium structure for biodiesel

production

ii. To investigate the catalytic performance of transesterification of Allanblackia floribunda Seed oil with

methanol to biodiesel

iii. To determine the effect of the optimization of reaction conditions on the transesterification using the

response surface methodology (RSM)

iv. To evaluate the properties and application feasibility of the biodiesel obtained from Allanblackia

floribunda Seed oil

v. To use biogas production from Allanblackia floribunda Seed oil as an effective method to generate

renewable energy.

4. Significant of the Research

With the shortening and increasing scarcity of known petroleum reserves which has made renewable energy sources

more attractive and significant, the outcome of this study is to sell out Allanblackia floribunda Seed oil and promote

it cultivation. The study will also draw focus to other non-edible oil for biodiesel production. The study is also

believed to bring enhancement and reduction of greenhouse gas emissions, regional development and social

structure, especially to developing countries. The study is also fore saw to bring a balance between agriculture,

economic development, and the environment. It is also expected that the methyl esters will help improve the

lubrication properties of diesel fuel blend which will subsequently help reduce long term engine wear in diesel

engines since biodiesel is said to be a good lubricant (about 66% better than petrodiesel).

J Environ Sci Public Health 2019; 3 [1]: 104-112 105

5. Outcome of the Research

Is to use Allanblackia floribunda Seed oil to produce biogas energy with increasing stress from the energy crises.

6. Expected Results

The study is expected to cover the process of Allanblackia floribunda Seed oil biodiesel production including

synthesis of the catalyst, monitoring of the biodiesel production, the most enhanced method for the production of

biodiesel and the efficient method for the biodiesel purification using. It is expected that the result of these studies

will create the awareness and consequently enhance the cultivation and comprehensive use of Allanblackia

floribunda Seed oil. The study is expected to contribute knowledge to the scientific world. It is also expected that at

least two or more publications will be obtained from the studies.

7. Materials

Crude Allanblackia floribunda Seed oil, Methanol, acetone, dichloromethane, N-methyl imidazole, acetonitrile,

ethyl acetate, NaOH, 1, 2-dibromoethane, 1, 3-dibromopropane, 1, 4-dibromobutane, 1, 5-dibromopentane, and 1, 6-

dibromohexane will be used (grade of analytical reagent). Preparation of dicationic ionic liquids.

7.1 Preparation of intermediates of [mIm]2CnBr2

Mixture of 1, 2-dibromoethane (0.02 mol, 3.75 g) and dehydrated N-methyl-imidazole (0.04 mol, 3.284 g) will be

stirred with 50 mL acetonitrile solution in a three-neck flask at 70°C for 24 hrs. The mixture will be cooled to room

temperature and filtered to give a crude solid. The crude solid will then be washed a number of times (3) with

acetone and then vacuum-dried. By the same method, bis-(3-methyl-1-imidazole) -propylene dibromo-salt, bis-(3-

methyl-1-imidazole)-butylene dibromo-salt, bis-(3-methyl-1-imidazole)-pentylene dibromosalt, and bis-(3-methyl-1-

imidazole)-hexylene dibromic salt will be synthesized.

7.2 Preparation of dicationic functional ionic liquids

Bis-(3-methyl-1-imidazole)-ethylene dibromosalt (0.01 mol, 3.52 g) and NaOH (0.02 mol, 0.8 g) will be dissolved

with 50 mL acetone solvent in a single-neck flask and stirred at room temperature for a day. The resulting

precipitate of sodium bromide will be removed through filtration with the solvent allowed to evaporate under

vacuum. The mixture will be washed repeatedly with dichloromethane, then evaporated under reduced pressure to

yield the product (pale yellow powder bis-(3-methyl-1-imidazole)-ethylene dihydroxide,) expressed as IMC2OH.

Via the same procedure, bis-(3-methyl-1-imidazole)-propylene dihydroxide, bis-(3-methyl-1-imidazole)-butylene

dihydroxide, bis-(3-methyl-1-imidazole)-pentylene dihydroxide, and bis-(3-methyl-1-imidazole)-hexylene

dihydroxide will be prepared (IMC3OH, IMC4OH, IMC5OH, and IMC6OH, respectively).

7.3 Transesterification of Crude Allanblackia floribunda Seed Oil

The crude Allanblackia floribunda Seed oil will be dehydrated at 140°C under vacuum in the rotary evaporator for

2 hrs. The dehydrated crude Allanblackia floribunda Seed oil with a specified amount of dicationic functional ionic

J Environ Sci Public Health 2019; 3 [1]: 104-112 106

liquid catalyst will be mixed with excess methanol to form a homogenous reaction system in 100 mL three-neck

flask and refluxed for some time at a recommended temperature under stirring with a constant speed. The ionic

liquid catalyst will be available in the lower liquid phase. Mixture of methanol and glycerol will then be separated

from the lower oily liquid phase by decantation. After draining off the glycerol, the upper mixture will be washed

twice or more with 1:1 volume of water to remove excess methanol to achieve the target product.

7.4 Alkali-catalyzed transesterification

Methyl esters of Allanblackia floribunda Seed oil will be prepared by refluxing the oil at a preset temperature with a

certain volume of methanol containing the catalyst for 2 hrs in a 250 mL three-neck reaction flask equipped with a

condenser. After the reaction, the product will be purified by neutralizing with 10% of sulphuric acid. The product

will then be washed and dried under reduced pressure at a temperature of about 70°C with a rotary evaporator.

8. Product Analyses and Yield Determination

The methyl esters will be determined with GC-MS. This will be carried out on an Agilent HP-6890 gas

chromatograph (Agilent Technologies, Palo Alto, CA, USA) with a HP-5MS 5% phenylmethylsiloxane capillary

column (30 m × 0.25 mm i.d., film thickness 0.25 μm; Restek, Bellefonte, PA). The identification of fatty acids will

be performed by comparing the obtained mass spectra with NIST05.LIB and NIST05s. LIB (National Institute of

Standards and Technology) libraries data provided by the software (AMDIS-Chromatogram) of GC-MS system.

Biodiesel yields will be determined with 7890 A gas chromatograph (Agilent Technology Inc. USA) equipped with

flame-ionization detector (FID) and HP-5 capillary column (30 m × 0.32 mm × 0.25 μm). Biodiesel yield will be

quantified using tetradecane as the internal standard. The analysis of biodiesel for each sample will carried out by

dissolving 1 mL of the sample into 5 mL of n-hexane and injecting 0.5 μL into GC. The yield of the biodiesel will

be determined using the following equation:

wtetradecane AB ftetradecane

Biodiesel yield 100%

Atetradecane ws (1)

Where wtetradecane is the weight of the internal standard, AB is the peak area of methyl esters, ftetradecane is the response

factor, Atetradecane is the peak area of the internal standard, and ws is the weight of the sample.

9. Experimental Design and Statistical Analysis

A three-variable and five-level central composite design (CCD) will be adopted and used in this study.

9.1 Characterization of the biodiesel

The major properties of the biodiesel will be evaluated using recommended standard methods. The properties

include; cetane number, flash point, water content, acid value oxidative stability, copper corrosion, kinematic

J Environ Sci Public Health 2019; 3 [1]: 104-112 107

viscosity and sulfur content will be determined. Other properties including pour point, cloud point, cold filter

plugging point, density at 20°C, ash content and glycerin content will be determined.

10. The Research Work and Progress of the Overall Arrangements/Research Plan

The research will take a year to acquire reagents; to synthesize four novel dicationic functional ionic liquids with an

imidazolium structure for biodiesel production; to investigate the catalytic performance of transesterification of

Allanblackia floribunda Seed oil with methanol to biodiesel to determine the effect of the optimization of reaction

conditions on the transesterification using the response surface methodology (RSM) to evaluate the properties and

application feasibility of the biodiesel obtained from Allanblackia floribunda Seed oil; and submission of report.

11. Feasibility Analysis

This study is unique of its kind and is intended to bring/ establish that Allanblackia floribunda Seed oil as one of the

potential non-edible oils for biodiesel production

12. Limitations

Availability of high water usage concerning biogas production. High maintenance requirements will reduce the

environmental benefits and increase carbon emissions and costs. Land use for Allanblackia floribunda tree will often

compete with food crops, forest and urbanization. Food competition is ultimately the key social issue as energy

crops will compete with food crops for valuable agricultural land. Taking waste wood from poor communities may

remove self-sufficiency in areas where wood fuel is their only source of heat.

13. Research Plan

Chapter One: Introduction

i. Overview of Bio-energy

ii. Suitability vegetable for use as biodiesel.

Chapter Two: Biodiesel production from new-edible Allanblackia floribunda Seed oil.

Chapter Three: Acid treated attapulgite functionalized with Na compounds as novel bi-functional heterogenous

solid catalysts for biodiesel production.

Chapter Four: Biodiesel production from waste non edible feedstock and Kinetics of the transesterification.

Chapter Five: Conclusion and Recommendation.

14. Monitoring Procedures

Performance figures, performance criteria and assessment aspects; biogas production biogas utilization

environmental impacts socio-economic efficiency

J Environ Sci Public Health 2019; 3 [1]: 104-112 108

15. Description of Biogas Production System

Figure 1: Biogas production system.

Figure 2: Sources of Biomass.

Figure 3: Flow chart for the extraction of oil from Allanblackia floribunda.

16. Conclusion

Biogas is yet to make significant impact in the energy sector in Ghana despite its potential for electricity, lighting

(biogas lamps) and cooking in institutions, abattoirs and households. Biogas is a holistic approach to tackling energy

crises in the twenty-first century. Professionals have proposed various ideas, plans, policies, and strategies and have

implemented them in cities to achieve bioenergy goals. Government should play a role in promulgating supporting

policies and strengthening the supervision and control of biogas projects. Emerging analysis is an appropriate

method to evaluate the sustainability of alternative energy production, because it accounts for all inputs to the

system. However, the generation of electricity does produce a product with higher energy quality and increased

utility. Whether or not the conversion to electricity and the subsequent loss of sustainability is justified is a decision

that needs to be made by the beneficiaries of the production system.

J Environ Sci Public Health 2019; 3 [1]: 104-112 109

Benefits from the Research Findings

Communities, People, local governments and Researchers.

Resources Required

Fund, Human resources, Research equipment, and Research facilities.

Duration of the Research

The research is made up of an experimental work and it will take four years for data collection and analyses to

achieve a good work.

References

1. Singh SP, Singh D. Biodiesel production through the use of different sources and characterization of oils

and their esters as the substitute of diesel: A review. Renew Sust Energ Rev 14 (2010): 200-216.

2. Bi Y, Ding D, Wang D. Low-melting-point biodiesel derived from corn oil via urea complexation.

Bioresource Technol 101 (2010): 1220-1226.

3. Zabeti M, Daud WMAW, Aroua MK. Biodiesel production using alumina-supported calcium oxide: An

optimization study. Fuel Process Technol 91 (2010): 243-248.

4. Lin L, Zhou CS, Saritporn V, et al. Opportunities and challenges for biodiesel fuel. Appl Energ 88 (2011):

1020-1031.

5. Mustafa B. Potential alternatives to edible oils for biodiesel production-A review of current work. Energ

Convers Manage 52 (2011): 1479-1492.

6. Wu X, Leung DYC. Optimization of biodiesel production from camelina oil using orthogonal experiment.

Appl Energ 88 (2011): 3615-3624.

7. Corro G, Tellez N, Ayala E, et al. Two-step biodiesel production from Jatropha curcas crude oil using

SiO2·HF solid catalyst for FFA esterification step. Fuel 89 (2010): 2815-2821.

8. Nakpong P, Wootthikanokkhan S. Roselle (Hibiscus sabdariffa L.) oil as an alternative feedstock for

biodiesel production in Thailand. Fuel 89 (2010): 1806-1811.

9. Kafuku G, Mbarawa M. Alkaline catalyzed biodiesel production from moringa oleifera oil with optimized

production parameters. Appl Energ 87 (2010): 2561-2565.

10. Anwar F, Rashid U, Ashraf M, et al. Okra (Hibiscus esculentus) seed oil for biodiesel production. Appl

Energ 87 (2010): 779-785.

11. Sharma YC, Singh B. An ideal feedstock, kusum (Schleichera triguga) for preparation of biodiesel:

Optimization of parameters. Fuel 89 (2010): 1470-1474.

12. Wu JW, Lin LC, Tsai TH. Drug-drug interactions of silymarin on the perspective of pharmacokinetics. J

Ethnopharmacol 121 (2009): 185-193.

J Environ Sci Public Health 2019; 3 [1]: 104-112 110

13. Doehmer J, Weiss G, McGregor GP, et al. Assessment of a dry extract from milk thistle (Silybum

marianum) for interference with human liver cytochrome-P450 activities. Toxicol in Vitro 25 (2011): 21-

27.

14. Morazzoni P, Bombardelli E. Silybum marianum (Carduus marianus). Fitoterapia 46 (1995): 3-42.

15. Ghavami N, Ramin AA. Grain yield and active substances of milk thistle as affected by soil salinity. Soil

Sci Plant Anal 39 (2008): 2608-2618.

16. Li F, Yang L, Zhao T, et al. Optimization of enzymatic pretreatment for n-hexane extraction of oil from

Silybum marianum seeds using response surface methodology. Food Bioprod Process 90 (2012): 87-94.

17. Zhang J, Chen S, Yang R, et al. Biodiesel production from vegetable oil using heterogenous acid and alkali

catalyst. Fuel 89 (2010): 2939-2944.

18. Suppalakpanya K, Ratanawilai SB, Tongurai C. Production of ethyl ester from crude palm oil by two-step

reaction with a microwave system. Fuel 89 (2010): 2140-2144.

19. Ayhan D. Biodiesel from waste cooking oil via base-catalytic and supercritical methanol transesterification.

Energ Convers Manage 50 (2009): 923-927.

20. Hayyan A, Alam MZ, Mirghani MES, et al. Reduction of high content of free fatty acid in sludge palm oil

via acid catalyst for biodiesel production. Fuel Process Technol 92 (2011): 920-924.

21. Wang R, Zhou WW, Hanna MA, et al. Biodiesel preparation, optimization, and fuel properties from non-

edible feedstock, Datura stramonium L. Fuel 91 (2012): 182-186.

22. Eevera T, Rajendran K, Saradha S. Biodiesel production process optimization and characterization to

assess the suitability of the product for varied environmental conditions. Renew Energ 34 (2009): 762-765.

23. Rashid U, Anwar F. Production of biodiesel through optimized alkaline-catalyzed transesterification of

rapeseed oil. Fuel 87 (2008): 265-273.

24. Martin RS, de la Cerda T, Uribe A, et al. Evaluation of guindilla oil (Guindilia trinervis Gillies ex Hook. et

Arn.) for biodiesel production. Fuel 89 (2010): 3785-3790.

25. Agarwal AK, Rajamanoharan K. Experimental investigations of performance and emissions of Karanja oil

and its blends in a single cylinder agricultural diesel engine. Appl Energ 86 (2009): 106-112.

26. Gerhard K. Biodiesel and renewable diesel: A comparison. Prog Energ Combust 36 (2010): 364-373.

27. Robert OD. Effect of antioxidants on the oxidative stability of methyl soyate (biodiesel). Fuel Process

Technol 86 (2005): 1071-1085.

28. Sarin A, Singh NP, Sarin R, et al. Natural and synthetic antioxidants: Influence on the oxidative stability of

biodiesel synthesized from non-edible oil. Energy 35 (2010): 4645-4648.

29. Rashid U, Anwar F, Knothe G. Biodiesel from Milo (Thespesia populnea L.) seed oil. Biomass Bioenerg

35 (2011): 4034-4039.

30. Bryan RM. Preparation of fatty acid methyl esters from hazelnut, high-oleic peanut and walnut oils and

evaluation as biodiesel. Fuel 92 (2012): 231-238.

31. Ramos MJ, Fernandez CM, Casas A, et al. Influence of fatty acid composition of raw materials on biodiesel

properties. Bioresource Technol 100 (2009): 261-268.

J Environ Sci Public Health 2019; 3 [1]: 104-112 111

32. Perez A, Casas A, Fernandez CM, et al. Winterization of peanut biodiesel to improve the cold flow

properties. Bioresource Technol 101 (2010): 7375-7381.

33. Bhale PV, Deshpande NV, Thombre SB. Improving the low temperature properties of biodiesel fuel.

Renew Energ 34 (2009): 794-800.

34. Thomas QC. Improving cold flow properties of canola-based biodiesel. Biomass Bioenerg 35 (2011): 600-

607.

Citation: Sylvia Adipah. Biodiesel Production from Allanblackia floribunda Seed oil. Journal of

Environmental Science and Public Health 3 (2018): 104-112.

This article is an open access article distributed under the terms and conditions of the

Creative Commons Attribution (CC-BY) license 4.0

J Environ Sci Public Health 2019; 3 [1]: 104-112 112

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Official History of 86th DivisionDocument344 pagesOfficial History of 86th DivisionFilipNo ratings yet

- Baldur's Gate - MapsDocument58 pagesBaldur's Gate - MapsLaurent GorseNo ratings yet

- Generac Kovai PriceList US 0801 2019Document9 pagesGenerac Kovai PriceList US 0801 2019RONALDNo ratings yet

- A Randomized Controlled Trial of Intravenous Paracetamol and Intravenous Tramadol For Labour AnalgesiaDocument11 pagesA Randomized Controlled Trial of Intravenous Paracetamol and Intravenous Tramadol For Labour AnalgesiaFortune JournalsNo ratings yet

- Avsm 004Document7 pagesAvsm 004Fortune JournalsNo ratings yet

- Chemical Contaminants and Pollutants in The Measurable Life of Dhaka City PDFDocument17 pagesChemical Contaminants and Pollutants in The Measurable Life of Dhaka City PDFFortune JournalsNo ratings yet

- Cerebral Infarction in Risk Factor of Adenoma and Symptomatic Aortic Stenosis Case Report and Literature Reviewp PDFDocument8 pagesCerebral Infarction in Risk Factor of Adenoma and Symptomatic Aortic Stenosis Case Report and Literature Reviewp PDFFortune JournalsNo ratings yet

- Capsicum Protects Against Rotenoneinduced Toxicity in Mice Brain Via Reduced Oxidative Stress and 5lipoxygenase Activationp PDFDocument18 pagesCapsicum Protects Against Rotenoneinduced Toxicity in Mice Brain Via Reduced Oxidative Stress and 5lipoxygenase Activationp PDFFortune JournalsNo ratings yet

- Biomineralogy of Angiogenesis PDFDocument7 pagesBiomineralogy of Angiogenesis PDFFortune JournalsNo ratings yet

- Cancer Therapyinduced Cardiotoxicity Where Are We Now PDFDocument8 pagesCancer Therapyinduced Cardiotoxicity Where Are We Now PDFFortune JournalsNo ratings yet

- Biochemistry and Pathophysiology of Glycation of Dna Implications in Diabetes PDFDocument16 pagesBiochemistry and Pathophysiology of Glycation of Dna Implications in Diabetes PDFFortune JournalsNo ratings yet

- MAC Layer Protocols For Sensor Networks: Leonardo Leiria FernandesDocument29 pagesMAC Layer Protocols For Sensor Networks: Leonardo Leiria FernandesSrinivas GopisettiNo ratings yet

- SEWING TOOLS AND EQUIPMENT AND THEIR USES (Teacher's Copy)Document4 pagesSEWING TOOLS AND EQUIPMENT AND THEIR USES (Teacher's Copy)Pilar Villanueva86% (7)

- Exponents, Radicals and LogarithmsDocument32 pagesExponents, Radicals and LogarithmsandrikaNo ratings yet

- Colours Show MoodDocument2 pagesColours Show MoodSuraya NordinNo ratings yet

- Duplicate: Invoice: DO NumberDocument2 pagesDuplicate: Invoice: DO NumberLiau Zhan HongNo ratings yet

- MIl-C-70508 Municion Cal. 9 MMDocument17 pagesMIl-C-70508 Municion Cal. 9 MMDavid BasanteNo ratings yet

- Design of 200m3 TankDocument4 pagesDesign of 200m3 TankMiko AbiNo ratings yet

- Parameter& Relation TutorialDocument24 pagesParameter& Relation TutorialPrasad GoNo ratings yet

- Water Level Controller Using 8051 Circuit PrincipleDocument4 pagesWater Level Controller Using 8051 Circuit PrincipleLappi SchematicsNo ratings yet

- Proposal Rev 02Document30 pagesProposal Rev 02suronocaturatmojo100% (1)

- Letter of DiscrepancyDocument1 pageLetter of DiscrepancyImam MekarNo ratings yet

- 11th Floor Accomplishment As of 8/9/21 Units 1st Coat 2nd Coat Flood Test Remarks Unit ADocument27 pages11th Floor Accomplishment As of 8/9/21 Units 1st Coat 2nd Coat Flood Test Remarks Unit Afrancis baldonadoNo ratings yet

- Laserjet Professional M1130/M1210: MFP SeriesDocument16 pagesLaserjet Professional M1130/M1210: MFP SeriesDhanesh RamachandramNo ratings yet

- MMS Manual Contents Ver 1Document42 pagesMMS Manual Contents Ver 1Kardi SolehNo ratings yet

- Mud Max Mud Max Compact: Centrifugal Pump Series 250Document32 pagesMud Max Mud Max Compact: Centrifugal Pump Series 250Hussein MohamedNo ratings yet

- Butter Chicken Ingredients (Serves 4)Document2 pagesButter Chicken Ingredients (Serves 4)barbaraNo ratings yet

- BM SA ROPE ATTACHMENTS HRDocument4 pagesBM SA ROPE ATTACHMENTS HRTheo van der BergNo ratings yet

- Risk Involved in Construction Works.Document10 pagesRisk Involved in Construction Works.Shaibal AhmedNo ratings yet

- AMAC Brochures PC12 Revision 19.08.2019 1Document8 pagesAMAC Brochures PC12 Revision 19.08.2019 1Maria Luisa CucunubaNo ratings yet

- BLEPT 09-2016 Room Assignment Rosales-SecDocument114 pagesBLEPT 09-2016 Room Assignment Rosales-SecPRC Baguio50% (2)

- The Church's Mission and Post-Modern Humanism by M. M. ThomasDocument5 pagesThe Church's Mission and Post-Modern Humanism by M. M. ThomasPaul PeterNo ratings yet

- Law of SupplyDocument26 pagesLaw of SupplyamitNo ratings yet

- ALFOplus User ManualDocument110 pagesALFOplus User ManualAntonio Bezerra0% (2)

- VolcanoesDocument14 pagesVolcanoesSHANNEL ANN VILLUGANo ratings yet

- Geological Chance of SuccessDocument11 pagesGeological Chance of SuccesssarapkanNo ratings yet

- Full Download Test Bank For Essentials of Anatomy and Physiology 7th Edition by Martini PDF Full ChapterDocument21 pagesFull Download Test Bank For Essentials of Anatomy and Physiology 7th Edition by Martini PDF Full Chapterkimgarciajbpoqktdfy100% (19)

- Handling of Synthetic Silica and Silicate: Technical Bulletin Fine Particles 28Document32 pagesHandling of Synthetic Silica and Silicate: Technical Bulletin Fine Particles 28devang asherNo ratings yet