Professional Documents

Culture Documents

Amada Saw Blades Speed and Feed Calculation

Amada Saw Blades Speed and Feed Calculation

Uploaded by

Aaron NadarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Amada Saw Blades Speed and Feed Calculation

Amada Saw Blades Speed and Feed Calculation

Uploaded by

Aaron NadarCopyright:

Available Formats

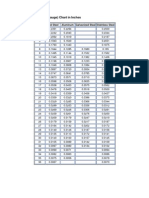

Cutting conditions setting guide

Cutting conditions setting chart

Fundamentals of cutting conditions setting

Setting of cutting rate 1. Select a blade that meets the cutting requirements from ”Blade type selection guide".

Cutting rate means the sectional area (cm2) that is cut per minute, and is expressed with the unit of [cm2/min]. 2. Select a tooth pitch that meets the dimensions of the material to be cut from ”Blade pitch selection guide”.

To obtain the target cutting rate, calculate the cutting time that is expressed by the following expression and adjust the 3. Set the blade speed referring to the chart below.

cutting speed. 4. Referring to the cutting rate given in the chart below, adjust the cutting speed so that the cutting time calculated

Cutting time(minute) = Sectional area of material2 to be cut (cm ) as described in the page on the left can be obtained

2

Cutting rate (cm /min) Note: lf the blade is a new one, perform break-in cutting. (See separate sheet for break-in cutting.)

A simple method for calculation of sectional area is as follows:

H-Beam Tube Solid material

Sectional area of rectangular material = Width (cm) x Height (cm) Material size

Sectional area of round material = Diameter (cm) x Diameter (cm) x 0.8 (mm)

9-bundled 9-bundled

* In case of cluster cutting, multiply the sectional area of one piece by the number of clustered pieces

Sectional area

(cm2)

Grade of the material to be cut

Blade speed

(m/min)

Cutting rate

(cm2/min)

Cutting time

(m/min)

Blade speed

(m/min)

Cutting rate

(cm2/min)

Cutting time

(m/min)

Blade speed

(m/min)

Cutting rate

(cm2/min)

Cutting time

(m/min)

Blade speed

(m/min)

Cutting rate

(cm2/min)

Cutting time

(m/min)

Blade speed

(m/min)

Cutting rate

(cm2/min)

Cutting time

(m/min)

Blade speed

(m/min)

Cutting rate

(cm2/min)

Cutting time

(m/min)

Note 1: The above chart shows average data in the general market collected at random without consideration of blade type or band saw machine type.

Note 2: Cutting conditions vary greatly depending on the blade type, band saw machine type, shape and heat treatment of the material to be cut and required cutting specification (crooked cut, cut face roughness, blade life, etc.).

Note 3: Material grade codes included in the above chart are from standards of three countries. However, this chart does not constitute a standard cross-referancechart.

You might also like

- 2 - SC2000 CNC System Software User's ManualDocument64 pages2 - SC2000 CNC System Software User's ManualJeff BanaganNo ratings yet

- Metal Forming PractiseDocument18 pagesMetal Forming PractisejoaopedrosousaNo ratings yet

- Multiview and Sectional View DrawingsDocument55 pagesMultiview and Sectional View DrawingsTuba KhanNo ratings yet

- High Speed Machining PresentationDocument36 pagesHigh Speed Machining Presentationsav33No ratings yet

- Design of A Hydraulic Shearing MachineDocument12 pagesDesign of A Hydraulic Shearing Machinenitin chaudharyNo ratings yet

- Gcode GRBL ProcedureDocument4 pagesGcode GRBL Proceduremahesh babuNo ratings yet

- SINUMERIKDocument39 pagesSINUMERIKRavi KumarNo ratings yet

- Manufacturing Process of Steam Turbine BladesDocument34 pagesManufacturing Process of Steam Turbine BladesThinesh Rau KrishnamurtyNo ratings yet

- The Wood-Mizer Way: Issue 89Document32 pagesThe Wood-Mizer Way: Issue 89jmooney3381100% (2)

- 1325 Portable CNC Cutting MachineDocument9 pages1325 Portable CNC Cutting MachineJorge Ligeti LandersNo ratings yet

- Turning Tools - General InformationDocument22 pagesTurning Tools - General Informationenamicul50No ratings yet

- Cimatron Mold Handout 2P en Letter WEBDocument2 pagesCimatron Mold Handout 2P en Letter WEBPaul VeramendiNo ratings yet

- Wilson Tool - Amada Thick Turret Catalogue 2011 - SM TECHDocument37 pagesWilson Tool - Amada Thick Turret Catalogue 2011 - SM TECHSM TECH SRLNo ratings yet

- Metrology & Mech. Measurement Ch. 02 System of Limits, Fits, Tolerance and GaugingDocument20 pagesMetrology & Mech. Measurement Ch. 02 System of Limits, Fits, Tolerance and GaugingAjij MujawarNo ratings yet

- PAS3 Instruction ManualDocument19 pagesPAS3 Instruction ManualMaitry ShahNo ratings yet

- SANDVIK FRP TOOL SUMMARY c-2920-30Document63 pagesSANDVIK FRP TOOL SUMMARY c-2920-30yanuar_adhiNo ratings yet

- Specification Arburg Allrounder 570c Golden EditionDocument6 pagesSpecification Arburg Allrounder 570c Golden EditionsygabrielaNo ratings yet

- Sheet Metal Thickness ChartDocument1 pageSheet Metal Thickness Chartmatthewwalls4386No ratings yet

- CNC Programmer ResumeDocument3 pagesCNC Programmer Resumenaunit3666No ratings yet

- Fiber Laser Cutting MachineDocument48 pagesFiber Laser Cutting Machinedanaytesfu27No ratings yet

- Iso 6722 2006Document13 pagesIso 6722 2006andiagressNo ratings yet

- ME364 Forming SheetDocument11 pagesME364 Forming SheetVed Prakash ChoudharyNo ratings yet

- Branson Ultrasonic IntroductionDocument10 pagesBranson Ultrasonic Introductionharnav5No ratings yet

- Tool Shop OptimizationDocument98 pagesTool Shop OptimizationRodolfo GarciaNo ratings yet

- ZW3D Mold Design: Professional and PracticalDocument24 pagesZW3D Mold Design: Professional and PracticalTrung Đức100% (1)

- Tool Room Machine ListDocument12 pagesTool Room Machine ListsachinNo ratings yet

- Recent Trends in ManufacturingDocument13 pagesRecent Trends in ManufacturingAmbarish100% (2)

- 3D Virtual Operations Manual 2009Document343 pages3D Virtual Operations Manual 2009Moises PaniaguaNo ratings yet

- Sick 4000 StandardDocument116 pagesSick 4000 StandardBogdan CarpenNo ratings yet

- Metric Tap Drill ChartDocument6 pagesMetric Tap Drill ChartBv RaoNo ratings yet

- Tolerance FinderDocument6 pagesTolerance FinderJyoti KaleNo ratings yet

- Burrs SnippetDocument3 pagesBurrs SnippetNurul HudaNo ratings yet

- Countersink Tool Downward - WZ19enDocument10 pagesCountersink Tool Downward - WZ19enBebe Ionuț AnițaNo ratings yet

- 5cuttingconditions 170204214737Document93 pages5cuttingconditions 170204214737ramadanNo ratings yet

- Desma Corporate Catalogue 2014Document20 pagesDesma Corporate Catalogue 2014Jigar M. Upadhyay100% (2)

- BCS100 Height Controller User Manual V3.12Document44 pagesBCS100 Height Controller User Manual V3.12morteza hamishegiNo ratings yet

- Reaction Injection MoldingDocument8 pagesReaction Injection MoldingAmeer_Takashim_9385No ratings yet

- AMADA Katalog 2011 PDFDocument93 pagesAMADA Katalog 2011 PDFdejavu_45No ratings yet

- The Art of Bending - Press Brake Tooling Solutions For Every Challenge - by Jeff Paulson - Marketing Manager - Wilson Tool InternationalDocument1 pageThe Art of Bending - Press Brake Tooling Solutions For Every Challenge - by Jeff Paulson - Marketing Manager - Wilson Tool InternationalSM TECH SRLNo ratings yet

- TM-0026M-F (Property Requirements of Externally-Threaded Fasteners, Steel)Document5 pagesTM-0026M-F (Property Requirements of Externally-Threaded Fasteners, Steel)方綵樺100% (1)

- Amada ARIES 222 224 Programming Manual NC Turret Punch PressDocument103 pagesAmada ARIES 222 224 Programming Manual NC Turret Punch PressJorge BarceloNo ratings yet

- AMO Absolute Encoder CatalogDocument36 pagesAMO Absolute Encoder CatalogElectromateNo ratings yet

- Roll FormingDocument2 pagesRoll FormingMujjo SahbNo ratings yet

- Technical Specifications of MOTI-30-3NC Busbar MachineDocument26 pagesTechnical Specifications of MOTI-30-3NC Busbar MachineycemalNo ratings yet

- Gear and Screw MeasurementDocument47 pagesGear and Screw MeasurementProf Afaqahmed JamadarNo ratings yet

- 2361Document103 pages2361Alen AnušićNo ratings yet

- Quick Guide To Bysoft 7: Installation Installation Designer DesignerDocument1 pageQuick Guide To Bysoft 7: Installation Installation Designer DesignerGunnie PandherNo ratings yet

- 12 Different Types of CNC Machine (Complete Guide) & PDFDocument16 pages12 Different Types of CNC Machine (Complete Guide) & PDFAK KHANNo ratings yet

- Sandvik - Technical Guide - Materials ISODocument41 pagesSandvik - Technical Guide - Materials ISOznovak77100% (1)

- BodorThinker3.0 4 SM enDocument122 pagesBodorThinker3.0 4 SM enMarian ArsuNo ratings yet

- Mechanics Modeling of Sheet Metal Forming-Tang, Sing C. - Pan, Jwo-Society of Automotive Engineers, Inc. (2007)Document300 pagesMechanics Modeling of Sheet Metal Forming-Tang, Sing C. - Pan, Jwo-Society of Automotive Engineers, Inc. (2007)cerverus13No ratings yet

- Dieffenbacher Product Catalog 052019 EN-minDocument73 pagesDieffenbacher Product Catalog 052019 EN-minЕвгений ТокаревNo ratings yet

- Upform Burring: Two Operation Type M2.6 M6 For Forming Taps & Cutting TapsDocument2 pagesUpform Burring: Two Operation Type M2.6 M6 For Forming Taps & Cutting TapsAleksandar JerinicNo ratings yet

- Metric Thread - NovoDocument20 pagesMetric Thread - NovoNel FredsonNo ratings yet

- Pattern CastingDocument17 pagesPattern CastingKishor kumar Bhatia100% (1)

- Dokumen - Tips Amada Astro II 100 NT Maschinen Press Brake Hds 1030 NT Press CapacityDocument7 pagesDokumen - Tips Amada Astro II 100 NT Maschinen Press Brake Hds 1030 NT Press CapacityAnton WilliamsNo ratings yet

- Spot Laser Welding MachineDocument2 pagesSpot Laser Welding Machinetapanvnahar musicNo ratings yet

- Handbook ScrewDocument24 pagesHandbook ScrewomidmmsNo ratings yet

- Thermal Friction Drilling: Parameters For Metric Thread ToolsDocument2 pagesThermal Friction Drilling: Parameters For Metric Thread Tools69x4No ratings yet

- Bodor Laser Product CatalogDocument26 pagesBodor Laser Product CatalogMaarif MaarifNo ratings yet

- Milling Formulas and DefinitionsDocument10 pagesMilling Formulas and DefinitionsCherish QiuNo ratings yet

- AGLCO ProfileDocument23 pagesAGLCO ProfileAaron NadarNo ratings yet

- 07 High Speed Steel Drills Metric 2018Document35 pages07 High Speed Steel Drills Metric 2018Aaron NadarNo ratings yet

- Material Requisition FormatDocument1 pageMaterial Requisition FormatAaron NadarNo ratings yet

- Daily Score Card ReportDocument10 pagesDaily Score Card ReportAaron NadarNo ratings yet

- Sam MalofDocument5 pagesSam MalofMarcos SalazarNo ratings yet

- Wood Products GlossaryDocument72 pagesWood Products GlossaryKane51No ratings yet

- 50 Best Tools.1Document35 pages50 Best Tools.1Ian Foreman100% (20)

- Bandsaw Tune UpDocument6 pagesBandsaw Tune UpAndrea Novella100% (1)

- Electro Motion Machine Tools Stock ListDocument13 pagesElectro Motion Machine Tools Stock ListElectro Motion UK (Export) LtdNo ratings yet

- Manual Sierra BandaDocument62 pagesManual Sierra BandaElvis Luis Rivera Dueñas100% (1)

- Sawing ProcessingDocument22 pagesSawing ProcessingGilang RestuNo ratings yet

- Horizontal Band SawDocument17 pagesHorizontal Band SawOscar AdrianNo ratings yet

- Skil 3385Document56 pagesSkil 3385gdiliogNo ratings yet

- Portable Bandsaw Variable Speed: Assembly and Operating InstructionsDocument11 pagesPortable Bandsaw Variable Speed: Assembly and Operating Instructionsjimmyboy111No ratings yet

- Catalogue Hakansson 2014Document28 pagesCatalogue Hakansson 2014Edylasmana PitekNo ratings yet

- Wood Machining Tech in JapanDocument20 pagesWood Machining Tech in JapanMayur12345dtNo ratings yet

- Kugel Medical GMBH & Co. KGDocument26 pagesKugel Medical GMBH & Co. KGEdgar OrtizNo ratings yet

- WRSDocument31 pagesWRSKyle CarrollNo ratings yet

- Woodworking Plans - Router JigsDocument6 pagesWoodworking Plans - Router Jigsjumapamo75% (4)

- Preventive Maintenance Checklist: Tool Room & Production SawsDocument2 pagesPreventive Maintenance Checklist: Tool Room & Production SawsValerio Ambrocio IsmaelNo ratings yet

- D&L SB180 8-2022.ai - DL-SB180-82022Document2 pagesD&L SB180 8-2022.ai - DL-SB180-82022brian.obaraNo ratings yet

- Wilton Operators Manual 14-Inch Vertical Band Saws Model 8201Document32 pagesWilton Operators Manual 14-Inch Vertical Band Saws Model 8201ullwnNo ratings yet

- Kinkelder StandardDocument24 pagesKinkelder StandardJason StephensNo ratings yet

- Woodworking - Basics-Shopjigs PDFDocument4 pagesWoodworking - Basics-Shopjigs PDFv00d00blues100% (1)

- Design and Fabrication of Automatic Pneumatic Ground Clearance Adjustment SystemDocument41 pagesDesign and Fabrication of Automatic Pneumatic Ground Clearance Adjustment SystemGAME தமிழ்No ratings yet

- Module 5-2-1Document27 pagesModule 5-2-1Zawadi BetuelNo ratings yet

- PuneDocument1,314 pagesPuneSATISH WORDBOXNo ratings yet

- Beer Tasting PaddlesDocument12 pagesBeer Tasting PaddlesAdriano KytNo ratings yet

- Fabrication GuideDocument22 pagesFabrication GuideasiapolyNo ratings yet

- Metalband SawDocument7 pagesMetalband SawRichard JongNo ratings yet

- Baxter 115c-Min Compressed-1Document17 pagesBaxter 115c-Min Compressed-1pc100xohmNo ratings yet

- Bandsaw BS 350 SHI Semiautomatic - Hydraulic Instructions For UseDocument60 pagesBandsaw BS 350 SHI Semiautomatic - Hydraulic Instructions For UseMilenko KraišnikNo ratings yet