Professional Documents

Culture Documents

Estabilidad de Pilares

Estabilidad de Pilares

Uploaded by

JhonMarriagaCopyright:

Available Formats

You might also like

- SWMS 2 Fixing CarpenterDocument3 pagesSWMS 2 Fixing CarpenterJonasNo ratings yet

- 2011 Esterhuizen Dolinar Ellenberger Pillar Strength in Undergorund Stone Mines in The USDocument9 pages2011 Esterhuizen Dolinar Ellenberger Pillar Strength in Undergorund Stone Mines in The USJesus Alberto Castillo GomezNo ratings yet

- Uation of The Strength of Slender Pillars: G.S. EsterhuizenDocument8 pagesUation of The Strength of Slender Pillars: G.S. EsterhuizenRichard Mijail ChaconNo ratings yet

- cdc_9813_DS1Document7 pagescdc_9813_DS1Martin GriffinNo ratings yet

- Empirical Approaches For Weak Rock MassesDocument10 pagesEmpirical Approaches For Weak Rock MassesmiltonNo ratings yet

- Pillar Design in Hard Brittle RocksDocument4 pagesPillar Design in Hard Brittle Rocksfrank berriosNo ratings yet

- International Journal of Rock Mechanics & Mining Sciences: Shrey Arora, Brijes MishraDocument15 pagesInternational Journal of Rock Mechanics & Mining Sciences: Shrey Arora, Brijes MishraPablo Cesar TrejoNo ratings yet

- Stability of Compacted Rockfill SlopesDocument10 pagesStability of Compacted Rockfill Slopesakhila s100% (1)

- Safety Science: E. Ghasemi, K. ShahriarDocument7 pagesSafety Science: E. Ghasemi, K. ShahriarAnand sharmaNo ratings yet

- 1 s2.0 S1365160900000381 MainDocument14 pages1 s2.0 S1365160900000381 Mainehoh_212989465No ratings yet

- Effect of Lateral Soil Movement of Unstable Slope On Socketed PilesDocument4 pagesEffect of Lateral Soil Movement of Unstable Slope On Socketed PileserpublicationNo ratings yet

- Yielding Pillar Concept and Its DesignDocument8 pagesYielding Pillar Concept and Its Designkatta_sridharNo ratings yet

- Deep Cover Pillar Extraction in The U.S. CoalfieldsDocument13 pagesDeep Cover Pillar Extraction in The U.S. CoalfieldsAnand sharmaNo ratings yet

- Structural Analysis of Highly Fractured, Heterogeneous Basement, Say ...Document5 pagesStructural Analysis of Highly Fractured, Heterogeneous Basement, Say ...Abdullah OmerNo ratings yet

- Ground Support in Mining and Underground ConstructDocument9 pagesGround Support in Mining and Underground Constructrowa.fangNo ratings yet

- An Evaluation of The Strength of Slender PillarsDocument7 pagesAn Evaluation of The Strength of Slender PillarsAnonymous cMBxGANo ratings yet

- Geotechnical Sedimentology-Its Use in Underground Coal MiningDocument7 pagesGeotechnical Sedimentology-Its Use in Underground Coal Miningpradhith kattaNo ratings yet

- Diseñode Pilaresen Roca Dura, VillaescusaDocument12 pagesDiseñode Pilaresen Roca Dura, VillaescusaluzmsanchezNo ratings yet

- 1numerical and Theoretical Study of Bi-Planar Failure in Footwall SlopesDocument13 pages1numerical and Theoretical Study of Bi-Planar Failure in Footwall Slopesyuanjiahao20No ratings yet

- Geosciences 08 00124Document23 pagesGeosciences 08 00124admplant cppNo ratings yet

- SCC Met SyllabusDocument9 pagesSCC Met SyllabusBoago KeofetlhileNo ratings yet

- Wiley Duncan Wright FlyerDocument1 pageWiley Duncan Wright FlyerRAJIT KUMAR YADAVNo ratings yet

- SmlfuDocument7 pagesSmlfuLEKWAPE DENNISNo ratings yet

- RCK - Effect of Weathering On The Strength and Modulus of Basalt and Siltstone (Gu Et Al, 2008)Document8 pagesRCK - Effect of Weathering On The Strength and Modulus of Basalt and Siltstone (Gu Et Al, 2008)sandycastleNo ratings yet

- Epoxy-Grouted Rock Alaska: For Skyline Logging in SoutheastDocument20 pagesEpoxy-Grouted Rock Alaska: For Skyline Logging in SoutheastWang JingzhouNo ratings yet

- ITASCA ECU 669 002 3D Open Pit Stability Analysis RB @mining EngDocument6 pagesITASCA ECU 669 002 3D Open Pit Stability Analysis RB @mining EngTchouleko tanekeuNo ratings yet

- Diseno de PilaresDocument15 pagesDiseno de PilaresIsmaelNo ratings yet

- 2001 - Estimating The Geotechnical Properties of The Heterogeneous Rock Masses Such As FlyschDocument8 pages2001 - Estimating The Geotechnical Properties of The Heterogeneous Rock Masses Such As Flyschsilvioco88No ratings yet

- Appendix D - Geotech Report PDFDocument16 pagesAppendix D - Geotech Report PDFbufaloteNo ratings yet

- Adeline T 2013Document12 pagesAdeline T 2013Ghassen LaouiniNo ratings yet

- Bearing CapacityDocument7 pagesBearing CapacityFranco04No ratings yet

- Wang 2005Document14 pagesWang 2005Nipa BiswasNo ratings yet

- TheStability of A Laminated Voussoir Beam PDFDocument17 pagesTheStability of A Laminated Voussoir Beam PDFDaniel SantanaNo ratings yet

- Stacey Et Al (2003) - New Slope Stability Considerations For Deep Open Pit MinesDocument19 pagesStacey Et Al (2003) - New Slope Stability Considerations For Deep Open Pit MinesOnie SaintNo ratings yet

- Gartrell 2004 Marine BDocument15 pagesGartrell 2004 Marine Bnoted2No ratings yet

- Membrane Analysis of Flat Plate Slabs: Aci Structural Journal Technical PaperDocument10 pagesMembrane Analysis of Flat Plate Slabs: Aci Structural Journal Technical PaperpicottNo ratings yet

- The Effect of Foundation Damage On The PillarsDocument7 pagesThe Effect of Foundation Damage On The Pillarsalvaroaac4No ratings yet

- Analysis of Alternatives For Using Cable Bolts As Primary Support at Two Low-Seam Coal MinesDocument9 pagesAnalysis of Alternatives For Using Cable Bolts As Primary Support at Two Low-Seam Coal Minesbmm13609913No ratings yet

- Behavior of Single Pile and Pile Groups Subjected To Abrupt Collapse of A Retaining WallDocument6 pagesBehavior of Single Pile and Pile Groups Subjected To Abrupt Collapse of A Retaining WallRaja RajanNo ratings yet

- Shaking Table Tests and Stability Analysis of Steep Nailed SlopesDocument16 pagesShaking Table Tests and Stability Analysis of Steep Nailed Slopesjacs127No ratings yet

- Dilution-Based Stability Graph For Open Stope Design: January 2015Document9 pagesDilution-Based Stability Graph For Open Stope Design: January 2015Jean Alexander Vega PratiNo ratings yet

- SPE 142022 The Role of Geomechanics in Diagnosing Drilling Hazards and Providing Solutions To The Northern Iraq FieldsDocument11 pagesSPE 142022 The Role of Geomechanics in Diagnosing Drilling Hazards and Providing Solutions To The Northern Iraq FieldsAnkit SharmaNo ratings yet

- Index Properties and Observations For Design of Chambers in RockDocument30 pagesIndex Properties and Observations For Design of Chambers in RockOlivinNo ratings yet

- Stability of Slopes Characterised by Colluvium: Investigation, Analysis and StabilisationDocument8 pagesStability of Slopes Characterised by Colluvium: Investigation, Analysis and StabilisationimamtaNo ratings yet

- Using Point Load Test To Determine Uniaxial STR of Coal Meassure RockDocument10 pagesUsing Point Load Test To Determine Uniaxial STR of Coal Meassure RockScott Downs0% (1)

- Structural and Fracture Analysis Usingemi and Fmi Image Log in The Carbonate Asmari Reservoir (Oligo-Miocene), SW IranDocument17 pagesStructural and Fracture Analysis Usingemi and Fmi Image Log in The Carbonate Asmari Reservoir (Oligo-Miocene), SW IranwandaNo ratings yet

- Cali Brac I On StressDocument10 pagesCali Brac I On StressJorge Cortez CampañaNo ratings yet

- Seismic Inversion in The Barnett Shale Successfully Pinpoints Sweet Spots To Optimize Well Bore Placement and Reduce Drilling RisksDocument28 pagesSeismic Inversion in The Barnett Shale Successfully Pinpoints Sweet Spots To Optimize Well Bore Placement and Reduce Drilling RisksfhosniNo ratings yet

- Lee Et Al 2010 - Colour - Stresses in The Australian Tectonic Plate - Va...Document16 pagesLee Et Al 2010 - Colour - Stresses in The Australian Tectonic Plate - Va...Boris Leal MartinezNo ratings yet

- Support For Very Weal RockDocument20 pagesSupport For Very Weal RockBalaji Rao ChNo ratings yet

- FinalPaper ENGEOVol67Document11 pagesFinalPaper ENGEOVol67limaNo ratings yet

- 11-A New Approach To Surface Crown Pillar DesignDocument9 pages11-A New Approach To Surface Crown Pillar DesignSANTIAGO NAVIA VÁSQUEZNo ratings yet

- Tensile Strength of Geological Discontinuities Including Incipient Bedding, Rock Joints and Mineral VeinsDocument13 pagesTensile Strength of Geological Discontinuities Including Incipient Bedding, Rock Joints and Mineral Veins101 Laksmita Chitrayuna SyahiraNo ratings yet

- Lateral Earth Pressures For Seismic Design of Cantilever Retaining WallsDocument8 pagesLateral Earth Pressures For Seismic Design of Cantilever Retaining Wallsredpol100% (2)

- Fault Zone Dynamic Processes: Evolution of Fault Properties During Seismic RuptureFrom EverandFault Zone Dynamic Processes: Evolution of Fault Properties During Seismic RuptureMarion Y. ThomasNo ratings yet

- Lithospheric DiscontinuitiesFrom EverandLithospheric DiscontinuitiesHuaiyu YuanNo ratings yet

- Atlas of Typical Seismic and Geological Sections for Major Petroliferous Basins in ChinaFrom EverandAtlas of Typical Seismic and Geological Sections for Major Petroliferous Basins in ChinaNo ratings yet

- Shallow Foundations: Discussions and Problem SolvingFrom EverandShallow Foundations: Discussions and Problem SolvingRating: 5 out of 5 stars5/5 (1)

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- Plate Boundaries and Natural HazardsFrom EverandPlate Boundaries and Natural HazardsJoao C. DuarteNo ratings yet

- Atlas of Structural Geological Interpretation from Seismic ImagesFrom EverandAtlas of Structural Geological Interpretation from Seismic ImagesAchyuta Ayan MisraNo ratings yet

- PM Passing PlanDocument17 pagesPM Passing Planbarryallen240473No ratings yet

- Community Digital Product Value Stream Management Architecture BlueprintDocument57 pagesCommunity Digital Product Value Stream Management Architecture Blueprintofd86174No ratings yet

- PR 1515Document36 pagesPR 1515REGUIEGNo ratings yet

- Trade Bridge ConsultantsDocument12 pagesTrade Bridge ConsultantsCharlie0862No ratings yet

- 70 Bertram Owners Manual FGDocument443 pages70 Bertram Owners Manual FGHassanMashiniNo ratings yet

- Polyscope Manual: Original Instructions (En) Us VersionDocument121 pagesPolyscope Manual: Original Instructions (En) Us VersionJorge ResendeNo ratings yet

- Curriculum Map: Learn Earn Achieve Productivity Series Technology and Livelihood Education Second EditionDocument38 pagesCurriculum Map: Learn Earn Achieve Productivity Series Technology and Livelihood Education Second EditionRochelle AlmodalNo ratings yet

- IMAS-07-40-Ed2 Enero 2016 Monitoreo A Las ODHDocument43 pagesIMAS-07-40-Ed2 Enero 2016 Monitoreo A Las ODHAlvaroNo ratings yet

- Project Risk Management: An: Andrew WestdorpDocument32 pagesProject Risk Management: An: Andrew WestdorpAtif KhanNo ratings yet

- Digit BGRPolicy WordingDocument4 pagesDigit BGRPolicy Wordingvaibhav_kaushikNo ratings yet

- The Impact of Geopolitical Risks On TourismDocument16 pagesThe Impact of Geopolitical Risks On TourismCristina AftodeNo ratings yet

- OSH Chapter 6-Hazard Identification, Risk Assessment and Risk Contol (HIRARC)Document33 pagesOSH Chapter 6-Hazard Identification, Risk Assessment and Risk Contol (HIRARC)Eida Hidayah100% (3)

- 2 Gray Cook Assessing Movement Part Two TranscriptDocument4 pages2 Gray Cook Assessing Movement Part Two TranscriptSeba Millón CampañaNo ratings yet

- Imr504 - Information Systems Project ManagementDocument16 pagesImr504 - Information Systems Project ManagementAmirull AdlanNo ratings yet

- Risk Assessment - Rebar Shifting Using BHDocument4 pagesRisk Assessment - Rebar Shifting Using BHLeoniv Arviz LiboroNo ratings yet

- Analyzing Forex Exposure of Infosys: CIA-1 OF International Financial ManagementDocument12 pagesAnalyzing Forex Exposure of Infosys: CIA-1 OF International Financial ManagementNehal SharmaNo ratings yet

- CP FloodDocument42 pagesCP FloodRayban100% (4)

- Exam QuestionsDocument55 pagesExam QuestionsCharlie Maurer67% (3)

- SerumDocument5 pagesSerumganangNo ratings yet

- Case Study - The Success and Failure of Disney's RemakesDocument17 pagesCase Study - The Success and Failure of Disney's RemakesWenqi GuNo ratings yet

- Deputy CISO - Biogen PDFDocument5 pagesDeputy CISO - Biogen PDFNamasivayam SarojaNo ratings yet

- Banking Ass - KPMG Study - Bank MarginsDocument58 pagesBanking Ass - KPMG Study - Bank MarginscommercestudentNo ratings yet

- Pillars of Financial Inclusion Remittances - Micro Insurance and Micro SavingsDocument27 pagesPillars of Financial Inclusion Remittances - Micro Insurance and Micro SavingsDhara PatelNo ratings yet

- CONSIDERATIONS OF ENTITY'S INTERNAL CONTROL Red Sirug Lecture NoteDocument7 pagesCONSIDERATIONS OF ENTITY'S INTERNAL CONTROL Red Sirug Lecture NoteMikaNo ratings yet

- UCM TLE 7 CaregivingDocument4 pagesUCM TLE 7 Caregivingven bonaNo ratings yet

- QRADocument10 pagesQRApgupta71100% (1)

- A Glass Half Full - Rhb-Report-My - Budget-2022-Equity-Impact - 20211030Document19 pagesA Glass Half Full - Rhb-Report-My - Budget-2022-Equity-Impact - 20211030Shaun WooNo ratings yet

- Project Plan: Group Case Study 4 OctoberDocument15 pagesProject Plan: Group Case Study 4 OctobernileshvpNo ratings yet

- Sociología de La CuraDocument5 pagesSociología de La CuraAna Carolina Cáceres MolanoNo ratings yet

Estabilidad de Pilares

Estabilidad de Pilares

Uploaded by

JhonMarriagaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Estabilidad de Pilares

Estabilidad de Pilares

Uploaded by

JhonMarriagaCopyright:

Available Formats

TechnicaLPa p e r s

Assessment of stable and failed pillars in

underground limestone mines

Introduction g.s. esterhuizen, d.r. dolinar and pillar conditions (Bauer et al., 2005).

Underground limestone mines in j.l. ellenberger Newly designed or current pillar lay-

the United States make use of the outs can be compared to the current

room-and-pillar method of mining to G.S. Esterhuizen, D.R. Dolinar and J.L. Ellenberger, experience by plotting them on the

extract the relatively flat-lying members SME are senior research engineer, lead research engineer chart. An example is given in which a

limestone deposits in the Eastern and and lead research scientist, respectively, with the National Institute for typical pillar layout is assessed us-ing

Midwestern regions of the Unit-ed Occupational Safety and Health (NIOSH), Pittsburgh, PA. Paper

the chart data.

number TP-08-004. Original manuscript submitted February 2008.

States. Limestone pillars are re-quired

to support the overburden and to Revised manuscript accepted for publication April 2008. Discussion of Observations of pillar stability

this peer-reviewed and approved paper is invited and must

provide a safe, stable working Pillars were assessed at under-

environment for mining personnel and be submitted to SME Publications Dept. prior to Feb. 28, 2009. ground limestone mines located in

equipment. Unstable pillars can Illinois, Indiana, Iowa, Kentucky,

result in rock falls from the pillar ribs and can lead to the Maryland, Missouri, Ohio, Pennsyl-

collapse of the roof if one or more pillars should fail. Fall- vania, Tennessee and West Virginia. The pillar stability was

of-ground injuries from the roof and pillar ribs accounted evaluated at more than one location at each mine to capture

for about 15 percent of lost workdays in underground the variety of geological and mining conditions. Two criteria

limestone mines from 1997 to 2006 (Mine Safety and were used to assess the success of the pillars. The first

Health Administration, 2007) . Limestone pillars of vari-ous criterion is the requirement for regional stability, which is

sizes and shapes are used to support the overburden rocks in defined as the need for a pillar system to success-fully

U.S. limestone mines with varying degrees of suc-cess support the overburden. If a pillar system fails in providing

(Iannacchione, 1999; Esterhuizen et al., 2006). regional support, a wide area collapse is likely to occur with

This paper provides an assessment of the performance associated surface subsidence. The second criterion is the

of these pillars as observed at 98 different locations in 34 requirement for local pillar stability, de-fined as stable pillar

mines in the Eastern and Midwestern regions of the Unit-ed ribs. Rib conditions were assessed by noting the presence of

States. The results are presented in a stability chart that rib spalling, stress fractures or open cracks.

indicates the failed and stable pillars observed as well as the

modes of observed instability. Data from one nonproducing The presence of geological features such as joints, slips,

mine in Ohio was added to the database, owing to its great faults and weak bedding planes was also recorded. Where

depth of workings and reported stable unstable conditions or failed pillars were ob-served, the

likely factors contributing to pillar instability were noted. In

Abstract addition, pillar and room dimensions were measured and

information on the depth of cover, extent of floor benching

Pillars in underground limestone mines are required to and other mining parameters collected. Mine maps were

support the overburden and provide a safe, stable working

obtained so that the pillar loads could be calculated using the

environment for mining personnel and equipment. Pillar

tributary area method or numeri-cal models.

stability was assessed by the National Institute for Occupa-

tional Safety and Health in underground limestone mines in Rock samples were collected to determine the uni-axial

the Eastern and Midwestern United States. It was found that compressive strength (UCS) of the rocks. The UCS results

current mine layouts have been successful in providing were grouped into three categories based on the average

support to the overburden, while a small number of isolated strength obtained at the individual mine sites and are shown

pillar failures were observed. The stable pillar layouts and in Table 1. It can be seen that there is a considerable

failed pillars were plotted on a chart that demonstrates the variation in the strength of the limestone being mined. This

relationship between pillar width-to-height ratio and pil-lar variation in strength was accounted for in the assessment of

stress. The results show that pillar failures occurred at the

pillar stability. Table 2 summarizes the dimensions and

lower range of width-to-height ratios and can occur at

cover depth of the pillar layouts that were investigated.

relatively low stress levels. Zones indicating the potential

risk of pillar instability are shown on the chart, based on The results of the survey showed that all the mine sites

hazards associated with the onset of rib spalling, large visited were successful in terms of the criterion for regional

angular discontinuities and unconfined pillars. The chart stability. No case of wide area collapse or signs of large

can assist limestone mine planners to evaluate potential areas of overloaded pillars were observed. Howev-er, a

instability in current or new pillar layouts that are similar number of isolated failed pillars in otherwise stable layouts

to those included on the stability chart. were observed. These isolated failed pillars are

Mining Engineering november 2008 43

Figure 1 Figure 2

Remaining stump of a collapsed pillar in an abandoned Pillar that has an original width-to-height ratio

area. Thin weak beds in the pillar and moist conditions of 1.7 failed by progressive spalling. Thin

are thought to have contributed to the failure. The width- weak beds are thought to have contributed to

to-height ratio was 0.82, and the average pillar stress the failure. The average pillar stress was

was about 11 percent of the UCS. about 11 percent of the UCS prior to failure.

likely to be the lowest strength members of the pillars in a ments. However, in the case of the failed pillars, it was not

layout, and do not represent the average strength of the always possible to measure the original pillar dimensions

pillars. It was further observed that most of the failed pillars and these were obtained from mine maps showing the

had been stable on initial mining but became un-stable when original dimensions. The chart shows both stable pillar

the height was increased by floor benching. layouts and the individual failed pillars. The diameter of

The key parameters describing the unstable pillars are each stable layout data point is related to the number of

summarized in Table 3, and examples of the failed pillars pillars in the layout, and varies from tens of pillars to more

are shown in Figs. 1 through 4. It can be seen that stress than 1,000 pillars in some of the cases. The failed pillar data

related rib slabbing and spalling is a feature in three of the points, on the other hand, each represent only a single pillar.

four failed pillars shown. In addition, the weaken-ing effects

of angular discontinuities or thin weak bands within the A number of lines have been added to the chart to high-

pillars are clearly demonstrated. light potential failure mechanisms, while the background

The criterion for local stability was assessed by con- shading indicates the relative risk of pillar instability. Each

sidering all cases where rib spalling or slabbing was of these lines and shaded zones are discussed below:

observed. Figure 5 shows an example of rib spalling at

approximately 900 ft of cover. It was found that rib spal-ling • Limit of experience: A curve that bounds the

can initiate when the average pillar stress exceeds about 11 case histories was drawn to indicate the limit of

percent to 12 percent of the UCS. In some cases, it becomes current limestone pillar experience. It can be seen

necessary to install rib support, such as screen and bolts, to that the lower bound width-to-height ratio is about

secure the rib walls. However, not all of the pillars that 0.25 at a low stress-to-strength ratio. The upper limit

exceeded the 11 percent to 12 percent stress ratio showed of stress is about 25 percent of the UCS. This curve

signs of rib spalling. Therefore, 11 percent to 12 percent simply bounds the current experience and does not

stress level should be interpreted as the lower limit for the represent a pillar strength equation.

onset of rib spalling. An assessment of the results further • Unconfined pillar core: Studies of stress distribu-

showed that instability caused by jointing or geological tions within pillars (Lunder and Pakalnis, 1997;

structures was not directly related to the pillar stress but was Esterhuizen, 2006) show that when the width-to-

simply a function of the presence or absence of unfavorable height ratio decreases below a value of about 0.8, the

geology. core of the pillar becomes unconfined. Because much

of the strength of a pillar is derived from the confined

Development of pillar stability chart core, the lack of confinement can result in reduced

All data collected on pillar performance were collated in pillar strength. Notably, about 75 percent of the

a spreadsheet, and a pillar stability chart was devel-oped in observed failed pillars had width-to-height ratios of

which the pillar stress, normalized by the UCS, was plotted less than 0.8. A review of failed pillar data in hard

against the width-to -height ratio of the pil-lars, as shown in rock mines (Lunder and Pakalnis, 1997; Mar-tin and

Fig. 6. The pillar dimensions used in this chart are the Maybee, 2000; Esterhuizen, 2006) showed that pillar

minimum pillar width and maximum pillar height. This strength is highly variable at these low width-to-

means that the smaller width of a rectangu-lar pillar and the height ratios. Factors that can contribute to the

maximum height of partially benched pillars were used in variable strength include the sensitivity of slender

creating the chart. Where possible, dimensions are based on pillars to the presence of unfavorable geological

actual underground measure- structures and the phenomenon of rock

44 November 2008 Mining Engineering

Figure 3 Figure 4

Partially benched pillar failing under elevated stresses Partially benched pillar that failed along two

at the edge of bench mining. Typical hourglass angular discontinuities. Width-to-height ratio is

formation indicating overloaded pillar. Width-to-height 0.58 based on full benching height and average

ratio was 0.44 based on full benching height and pillar stress is about 4 percent of the UCS.

average pillar stress was about 12 percent of the UCS.

splitting parallel to the applied load in low confine- When designing pillars in this zone, the potential

ment (Diederichs, 2002). Splitting and slabbing of for encountering unfavorable angular discontinui-

limestone was observed at stress levels that are only ties should be considered.

less than 12 percent of the UCS of the rock (Ian-

nacchione, 1999), which indicates that pillar strength The shaded zones in Fig. 6 indicate the relative risk

might be significantly reduced in the absence of of instability based on a qualitative assessment of the

confinement. likelihood and consequences of pillar instability. Darker

• The onset of spalling: As discussed earlier, spalling shading indicates a relatively higher risk. The following

and slabbing of pillar ribs was observed to start four risk zones are indicated:

when the average pillar stress was around 11 per-

cent to 12 percent of the UCS. Spalling represents an • Very low risk: No failed pillars or stress related rib

additional rock-fall hazard that must be addressed instability was found in this zone. Pillar layouts that

when mining. Limited spalling can typically be ad- plot within this zone can, therefore, be expected to

dressed by repeated scaling of pillar ribs. In cases have a very low risk of failure.

of severe spalling or slabbing of a pillar ribs, it has • Low risk: A few isolated cases of pillar instability

been necessary to support the ribs with screen and were observed within this zone. Pillars should be

rock bolts where long-term access is required. designed with due consideration of the potential

• Angular discontinuity hazard: Angular disconti- for rib spalling and pillar weakening by large dis-

nuities that are exposed on both sides of a pillar continuities.

can cause a significant reduction in the strength of • Moderate risk: Two moderate-risk zones are indicated.

a pillar. Figure 7 shows a pillar that was severely Pillars that plot near the upper part of the experience

compromised by an angular discontinuity. It was curve are subject to increasing stress and there is lim-

necessary to install long rock bolts right through the ited experience with pillar performance at those stress

pillar to prevent it from failing. During the survey magnitudes. Slender pillars with width-to-height ratios

of pillar conditions, large angular discontinuities of less than 0.8 are vulnerable to the effects of large

were observed in several mines, but did not appear angular discontinuities and the lack of confinement.

to be wide -

spread within Table 1

the limestone

Uniaxial compressive strength of limestone rocks collected at mine sites.

formations

currently being Average, Range, Samples Representative

Group psi psi tested limestone formations

mined. When

the width-to-

height ratio of Lower strength 12,800 6,400-20,800 50 Burlington, Salem,

a pillar is less Galena-Plattesville

than 1.5, a dis-

continuity with Medium strength 19,600 11,900-30,000 100 Camp Nelson, Monteagle,

a dip of 30° can Plattin, Vanport,

be exposed Upper Newman, Chickamauga

on both sides

High strength 31,800 22,000-43,700 32 Loyalhanna, Tyrone

of the pillar.

Mining Engineering november 2008 45

Figure 5 Table 2

Example of rib slabbing when the average pillar Summary of mining dimensions and cover depth of

stress exceeds about 11 percent of the UCS. mines included in study.

Dimension Average Minimum Maximum

Pillar width (ft) 43.0 15.0 70.5

Pillar height (ft) 36.5 15.8 124.6

Width-to-height ratio 1.41 0.29 3.52

Cover depth (ft) 385 75 2,200

Example of applying the stability chart to

assess a pillar layout

Consider a new limestone mine in the Midwestern

United States that will use 40-ft-wide square pillars on 80-ft

centers with 40-ft wide headings and crosscuts. The pillar

height on development will be 28 ft. Benching of an

additional 28 ft of floor stone is planned, which will result

in an ultimate pillar height of 56 ft. The initial width-to-

height ratio will, therefore, be 1.43, reducing to 0.71 after

Several failed pillars were observed within this zone.

floor benching. The UCS of the rock is 140 MPa (20,000

• High risk: Pillars within the high-risk zone are

psi). If the maximum depth of cover is 300 ft, the average

potentially exposed to a combination of increasing

pillar stress in square pillars can be estimated using the

stresses, rib spalling, large discontinuity hazards and

tributary area method

the lack of confinement. In addition, pillars that fall

(1)

outside the limit of current experience are consid-

ered to represent an elevated risk. Several of the

single failed pillars fall within the high-risk zone.

where

It can be seen that many of the stable pillar layouts σp is the average pillar stress in pounds per square

inch,

shown in the chart fall within one or more of the shaded

h is the depth of cover,

zones. These zones do not imply that the pillar layouts are w is the pillar width and

necessarily unstable, but rather indicate the types of stability b is the room width in feet.

hazards that might be encountered and that would need to be The average pillar stress for the example is calculated to

accounted for in the design and during the course of mining. be 9.10 MPa (1,320 psi), which is 6.6 percent of the

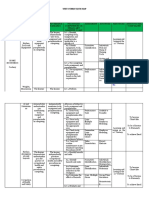

Table 3

Summary of observed failed pillars.

Width- Average

Pillar Pillar to- pillar Rock

width, height, height, stress, strength,

Case ft ft ratio psi psi Factors contributing to pillar failure

1 35 60 0.58 1,305 31,175 Partially benched pillar, contains angular discontinuities

2 35 60 0.58 1,363 31,175 Partially benched pillar, contains angular discontinuities

3 35 60 0.58 1,494 31,175 Partially benched pillar, contains angular discontinuities

4 50 90 0.56 1,827 22,185 Pillar fully benched to 90-ft height reduced width-to-height ratio

5 35 60 0.58 1,856 31,175 Benched pillar, contains angular discontinuities

6 40 90 0.44 2,494 21,750 Partly benched pillar

7 28 52 0.54 2,494 21,750 Large steep dipping discontinuity and elevated stress ahead of benching

8 40 90 0.44 2,509 21,750 Partly benched pillar

9 26 32 0.81 2,755 23,200 Thin weak beds in limestone, pillar undersized causing elevated stress

10 42 24 1.73 2,525 23,200 Thin weak beds in pillar causing progressive spalling

11 41 50 0.82 2,583 23,200 Thin weak beds in pillar and moist conditions, pillar collapsed

12 20 40 0.49 2,755 23,200 Benched pillar is undersized causing elevated stresses

13 22 40 0.54 2,900 23,200 Benched pillar is undersized causing elevated stresses

14 12 28 0.43 3,495 31,175 Undersized pillar

15 27 30 0.90 3,625 23,200 Thin weak beds in pillar caused progressive slabbing

16 18 24 0.75 3,915 23,200 Undersized pillar subject to elevated stress

17 40 52 0.77 1,220 23,900 Partially benched pillar, contains angular discontinuities

18 40 52 0.77 1,100 23,900 Partially benched pillar, contains angular discontinuities

46 November 2008 Mining Engineering

Figure 6

Limestone pillar stability chart showing stable pillar layouts and single failed pillars. Potential failure

mechanisms and relative risk of pillar instability are indicated.

UCS. This point plots within the “Low Risk” zone in Fig. uniaxial compressive strength of the rock; and

6. The pillars should be free of stress related rib spalling • a small number of isolated failed pillars were ob-

during initial mining but unfavorable angular disconti- served in otherwise stable layouts.

nuities can compromise their strength. A geotechnical

investigation might be warranted to confirm or refute the Factors contributing to the isolated pillar failures in-

presence of such structures. The chart further shows that cluded unfavorably oriented geological structures and

after bench mining to a height of 56 ft, the pillars will plot elevated stress levels in undersized pillars. Stress related

within the “Moderate Risk” zone because the pillar cores pillar failures were associated with progressive slabbing and

will become unconfined in addition to being vulnerable to spalling of pillar ribs. Unfavorable geology, such as angular

large angular discontinuities. It might be prudent to reduce discontinuities in the pillars and thin weak beds in the

the bench height to 20 ft for example, which will increase limestone formation, contributed to failure in some cases.

the benched pillar width-to-height ratio to 0.83. This will Notably, about 75 percent of the observed failed pillars have

width-to-height ratios of less than 0.8.

reduce the potential for instability of the benched pillars.

A pillar stability chart developed from the data shows

that a limiting curve can be drawn that encloses the ob-

served cases. The limiting curve does not represent a pillar

Conclusions strength equation, but simply bounds the current pillar

The assessment of pillar conditions in U.S. limestone experience. The potential failure mechanisms and relative

mines has shown that: risk of pillar instability have been indicated on the chart,

based on observations and analysis of pillar performance.

• pillars in current mining operations have been The chart and the indicated stability zones can assist mine

suc-cessful in providing support to the overburden designers in anticipating stability issues in their pillar

and preventing wide area pillar collapse and layouts and implementing appropriate risk mitigation

associated surface subsidence; measures.

• pillar rib instability in the form of spalling or As a cautionary note, the stability chart is based on

stress related slabbing appears to initiate when the observations of limestone mine pillars in the Mid-western

aver-age pillar stress exceeds about 11 percent of the and Eastern United States and should not be

Mining Engineering november 2008 47

used to assess pillar stability in cases outside of this Figure 7

geographic area. In addition, the validity of the chart is

limited to pillar cases that have similar dimensions, rock Example of a pillar that is bisected by a large

strength and depth of cover as those used to develop the angular discontinuity.

chart. n

References

Mine Safety & Health Administration, 2007, Webpage: www.msha.

gov/stats.

Esterhuizen G.S., Iannacchione, A.T., Ellenberger, J.L., and Dolinar,

D.R., 2006, “Pillar stability issues based on a survey of pillar perfor-mance

in underground limestone mines,” 25th International Conference on

Ground Control in Mining, Morgantown, WV, pp. 354-361.

Iannacchione, A.T., 1999, “Analysis of pillar design practices and

techniques for U.S. limestone mines,” Trans. Inst. Min. Metall., Sect. A:

Min. Industry, Vol. 108, September-December, pp. A152-A160.

Bauer, S.J., Munson, D.E., Hardy, M.P., Barrix, J., and McGunegle,

B., 2005, “In situ stress measurements and their implications in a deep

Ohio mine,” 40th U.S. Rock Mechanics Symposium, Anchorage, Alaska,

June 25-29, Paper 05-804.

Lunder, P.J., and Pakalnis, R., 1997, “Determining the strength of hard

rock mine pillars,” Bull. Can. Inst. Min. Metall., Vol. 90, pp. 51-55. pillars,” Int. Jnl. Rock Mechanics & Min. Sci., Vol. 37, pp. 1239-1246.

Esterhuizen, G.S., 2006, “Evaluation of the strength of slender pil- Diederichs, M.S., 2002, “Stress induced damage accumulation and

lars,” Trans. Soc. Min. Metal. Explor., Vol. 320, pp. 69-76. implications for hard rock engineering,” NARMS-TAC 2002, Hammah et

Martin, C.D., and Maybee, W.G., 2000, “The strength of hard rock al., eds., University of Toronto, pp. 3-12.

48 November 2008 Mining Engineering

You might also like

- SWMS 2 Fixing CarpenterDocument3 pagesSWMS 2 Fixing CarpenterJonasNo ratings yet

- 2011 Esterhuizen Dolinar Ellenberger Pillar Strength in Undergorund Stone Mines in The USDocument9 pages2011 Esterhuizen Dolinar Ellenberger Pillar Strength in Undergorund Stone Mines in The USJesus Alberto Castillo GomezNo ratings yet

- Uation of The Strength of Slender Pillars: G.S. EsterhuizenDocument8 pagesUation of The Strength of Slender Pillars: G.S. EsterhuizenRichard Mijail ChaconNo ratings yet

- cdc_9813_DS1Document7 pagescdc_9813_DS1Martin GriffinNo ratings yet

- Empirical Approaches For Weak Rock MassesDocument10 pagesEmpirical Approaches For Weak Rock MassesmiltonNo ratings yet

- Pillar Design in Hard Brittle RocksDocument4 pagesPillar Design in Hard Brittle Rocksfrank berriosNo ratings yet

- International Journal of Rock Mechanics & Mining Sciences: Shrey Arora, Brijes MishraDocument15 pagesInternational Journal of Rock Mechanics & Mining Sciences: Shrey Arora, Brijes MishraPablo Cesar TrejoNo ratings yet

- Stability of Compacted Rockfill SlopesDocument10 pagesStability of Compacted Rockfill Slopesakhila s100% (1)

- Safety Science: E. Ghasemi, K. ShahriarDocument7 pagesSafety Science: E. Ghasemi, K. ShahriarAnand sharmaNo ratings yet

- 1 s2.0 S1365160900000381 MainDocument14 pages1 s2.0 S1365160900000381 Mainehoh_212989465No ratings yet

- Effect of Lateral Soil Movement of Unstable Slope On Socketed PilesDocument4 pagesEffect of Lateral Soil Movement of Unstable Slope On Socketed PileserpublicationNo ratings yet

- Yielding Pillar Concept and Its DesignDocument8 pagesYielding Pillar Concept and Its Designkatta_sridharNo ratings yet

- Deep Cover Pillar Extraction in The U.S. CoalfieldsDocument13 pagesDeep Cover Pillar Extraction in The U.S. CoalfieldsAnand sharmaNo ratings yet

- Structural Analysis of Highly Fractured, Heterogeneous Basement, Say ...Document5 pagesStructural Analysis of Highly Fractured, Heterogeneous Basement, Say ...Abdullah OmerNo ratings yet

- Ground Support in Mining and Underground ConstructDocument9 pagesGround Support in Mining and Underground Constructrowa.fangNo ratings yet

- An Evaluation of The Strength of Slender PillarsDocument7 pagesAn Evaluation of The Strength of Slender PillarsAnonymous cMBxGANo ratings yet

- Geotechnical Sedimentology-Its Use in Underground Coal MiningDocument7 pagesGeotechnical Sedimentology-Its Use in Underground Coal Miningpradhith kattaNo ratings yet

- Diseñode Pilaresen Roca Dura, VillaescusaDocument12 pagesDiseñode Pilaresen Roca Dura, VillaescusaluzmsanchezNo ratings yet

- 1numerical and Theoretical Study of Bi-Planar Failure in Footwall SlopesDocument13 pages1numerical and Theoretical Study of Bi-Planar Failure in Footwall Slopesyuanjiahao20No ratings yet

- Geosciences 08 00124Document23 pagesGeosciences 08 00124admplant cppNo ratings yet

- SCC Met SyllabusDocument9 pagesSCC Met SyllabusBoago KeofetlhileNo ratings yet

- Wiley Duncan Wright FlyerDocument1 pageWiley Duncan Wright FlyerRAJIT KUMAR YADAVNo ratings yet

- SmlfuDocument7 pagesSmlfuLEKWAPE DENNISNo ratings yet

- RCK - Effect of Weathering On The Strength and Modulus of Basalt and Siltstone (Gu Et Al, 2008)Document8 pagesRCK - Effect of Weathering On The Strength and Modulus of Basalt and Siltstone (Gu Et Al, 2008)sandycastleNo ratings yet

- Epoxy-Grouted Rock Alaska: For Skyline Logging in SoutheastDocument20 pagesEpoxy-Grouted Rock Alaska: For Skyline Logging in SoutheastWang JingzhouNo ratings yet

- ITASCA ECU 669 002 3D Open Pit Stability Analysis RB @mining EngDocument6 pagesITASCA ECU 669 002 3D Open Pit Stability Analysis RB @mining EngTchouleko tanekeuNo ratings yet

- Diseno de PilaresDocument15 pagesDiseno de PilaresIsmaelNo ratings yet

- 2001 - Estimating The Geotechnical Properties of The Heterogeneous Rock Masses Such As FlyschDocument8 pages2001 - Estimating The Geotechnical Properties of The Heterogeneous Rock Masses Such As Flyschsilvioco88No ratings yet

- Appendix D - Geotech Report PDFDocument16 pagesAppendix D - Geotech Report PDFbufaloteNo ratings yet

- Adeline T 2013Document12 pagesAdeline T 2013Ghassen LaouiniNo ratings yet

- Bearing CapacityDocument7 pagesBearing CapacityFranco04No ratings yet

- Wang 2005Document14 pagesWang 2005Nipa BiswasNo ratings yet

- TheStability of A Laminated Voussoir Beam PDFDocument17 pagesTheStability of A Laminated Voussoir Beam PDFDaniel SantanaNo ratings yet

- Stacey Et Al (2003) - New Slope Stability Considerations For Deep Open Pit MinesDocument19 pagesStacey Et Al (2003) - New Slope Stability Considerations For Deep Open Pit MinesOnie SaintNo ratings yet

- Gartrell 2004 Marine BDocument15 pagesGartrell 2004 Marine Bnoted2No ratings yet

- Membrane Analysis of Flat Plate Slabs: Aci Structural Journal Technical PaperDocument10 pagesMembrane Analysis of Flat Plate Slabs: Aci Structural Journal Technical PaperpicottNo ratings yet

- The Effect of Foundation Damage On The PillarsDocument7 pagesThe Effect of Foundation Damage On The Pillarsalvaroaac4No ratings yet

- Analysis of Alternatives For Using Cable Bolts As Primary Support at Two Low-Seam Coal MinesDocument9 pagesAnalysis of Alternatives For Using Cable Bolts As Primary Support at Two Low-Seam Coal Minesbmm13609913No ratings yet

- Behavior of Single Pile and Pile Groups Subjected To Abrupt Collapse of A Retaining WallDocument6 pagesBehavior of Single Pile and Pile Groups Subjected To Abrupt Collapse of A Retaining WallRaja RajanNo ratings yet

- Shaking Table Tests and Stability Analysis of Steep Nailed SlopesDocument16 pagesShaking Table Tests and Stability Analysis of Steep Nailed Slopesjacs127No ratings yet

- Dilution-Based Stability Graph For Open Stope Design: January 2015Document9 pagesDilution-Based Stability Graph For Open Stope Design: January 2015Jean Alexander Vega PratiNo ratings yet

- SPE 142022 The Role of Geomechanics in Diagnosing Drilling Hazards and Providing Solutions To The Northern Iraq FieldsDocument11 pagesSPE 142022 The Role of Geomechanics in Diagnosing Drilling Hazards and Providing Solutions To The Northern Iraq FieldsAnkit SharmaNo ratings yet

- Index Properties and Observations For Design of Chambers in RockDocument30 pagesIndex Properties and Observations For Design of Chambers in RockOlivinNo ratings yet

- Stability of Slopes Characterised by Colluvium: Investigation, Analysis and StabilisationDocument8 pagesStability of Slopes Characterised by Colluvium: Investigation, Analysis and StabilisationimamtaNo ratings yet

- Using Point Load Test To Determine Uniaxial STR of Coal Meassure RockDocument10 pagesUsing Point Load Test To Determine Uniaxial STR of Coal Meassure RockScott Downs0% (1)

- Structural and Fracture Analysis Usingemi and Fmi Image Log in The Carbonate Asmari Reservoir (Oligo-Miocene), SW IranDocument17 pagesStructural and Fracture Analysis Usingemi and Fmi Image Log in The Carbonate Asmari Reservoir (Oligo-Miocene), SW IranwandaNo ratings yet

- Cali Brac I On StressDocument10 pagesCali Brac I On StressJorge Cortez CampañaNo ratings yet

- Seismic Inversion in The Barnett Shale Successfully Pinpoints Sweet Spots To Optimize Well Bore Placement and Reduce Drilling RisksDocument28 pagesSeismic Inversion in The Barnett Shale Successfully Pinpoints Sweet Spots To Optimize Well Bore Placement and Reduce Drilling RisksfhosniNo ratings yet

- Lee Et Al 2010 - Colour - Stresses in The Australian Tectonic Plate - Va...Document16 pagesLee Et Al 2010 - Colour - Stresses in The Australian Tectonic Plate - Va...Boris Leal MartinezNo ratings yet

- Support For Very Weal RockDocument20 pagesSupport For Very Weal RockBalaji Rao ChNo ratings yet

- FinalPaper ENGEOVol67Document11 pagesFinalPaper ENGEOVol67limaNo ratings yet

- 11-A New Approach To Surface Crown Pillar DesignDocument9 pages11-A New Approach To Surface Crown Pillar DesignSANTIAGO NAVIA VÁSQUEZNo ratings yet

- Tensile Strength of Geological Discontinuities Including Incipient Bedding, Rock Joints and Mineral VeinsDocument13 pagesTensile Strength of Geological Discontinuities Including Incipient Bedding, Rock Joints and Mineral Veins101 Laksmita Chitrayuna SyahiraNo ratings yet

- Lateral Earth Pressures For Seismic Design of Cantilever Retaining WallsDocument8 pagesLateral Earth Pressures For Seismic Design of Cantilever Retaining Wallsredpol100% (2)

- Fault Zone Dynamic Processes: Evolution of Fault Properties During Seismic RuptureFrom EverandFault Zone Dynamic Processes: Evolution of Fault Properties During Seismic RuptureMarion Y. ThomasNo ratings yet

- Lithospheric DiscontinuitiesFrom EverandLithospheric DiscontinuitiesHuaiyu YuanNo ratings yet

- Atlas of Typical Seismic and Geological Sections for Major Petroliferous Basins in ChinaFrom EverandAtlas of Typical Seismic and Geological Sections for Major Petroliferous Basins in ChinaNo ratings yet

- Shallow Foundations: Discussions and Problem SolvingFrom EverandShallow Foundations: Discussions and Problem SolvingRating: 5 out of 5 stars5/5 (1)

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- Plate Boundaries and Natural HazardsFrom EverandPlate Boundaries and Natural HazardsJoao C. DuarteNo ratings yet

- Atlas of Structural Geological Interpretation from Seismic ImagesFrom EverandAtlas of Structural Geological Interpretation from Seismic ImagesAchyuta Ayan MisraNo ratings yet

- PM Passing PlanDocument17 pagesPM Passing Planbarryallen240473No ratings yet

- Community Digital Product Value Stream Management Architecture BlueprintDocument57 pagesCommunity Digital Product Value Stream Management Architecture Blueprintofd86174No ratings yet

- PR 1515Document36 pagesPR 1515REGUIEGNo ratings yet

- Trade Bridge ConsultantsDocument12 pagesTrade Bridge ConsultantsCharlie0862No ratings yet

- 70 Bertram Owners Manual FGDocument443 pages70 Bertram Owners Manual FGHassanMashiniNo ratings yet

- Polyscope Manual: Original Instructions (En) Us VersionDocument121 pagesPolyscope Manual: Original Instructions (En) Us VersionJorge ResendeNo ratings yet

- Curriculum Map: Learn Earn Achieve Productivity Series Technology and Livelihood Education Second EditionDocument38 pagesCurriculum Map: Learn Earn Achieve Productivity Series Technology and Livelihood Education Second EditionRochelle AlmodalNo ratings yet

- IMAS-07-40-Ed2 Enero 2016 Monitoreo A Las ODHDocument43 pagesIMAS-07-40-Ed2 Enero 2016 Monitoreo A Las ODHAlvaroNo ratings yet

- Project Risk Management: An: Andrew WestdorpDocument32 pagesProject Risk Management: An: Andrew WestdorpAtif KhanNo ratings yet

- Digit BGRPolicy WordingDocument4 pagesDigit BGRPolicy Wordingvaibhav_kaushikNo ratings yet

- The Impact of Geopolitical Risks On TourismDocument16 pagesThe Impact of Geopolitical Risks On TourismCristina AftodeNo ratings yet

- OSH Chapter 6-Hazard Identification, Risk Assessment and Risk Contol (HIRARC)Document33 pagesOSH Chapter 6-Hazard Identification, Risk Assessment and Risk Contol (HIRARC)Eida Hidayah100% (3)

- 2 Gray Cook Assessing Movement Part Two TranscriptDocument4 pages2 Gray Cook Assessing Movement Part Two TranscriptSeba Millón CampañaNo ratings yet

- Imr504 - Information Systems Project ManagementDocument16 pagesImr504 - Information Systems Project ManagementAmirull AdlanNo ratings yet

- Risk Assessment - Rebar Shifting Using BHDocument4 pagesRisk Assessment - Rebar Shifting Using BHLeoniv Arviz LiboroNo ratings yet

- Analyzing Forex Exposure of Infosys: CIA-1 OF International Financial ManagementDocument12 pagesAnalyzing Forex Exposure of Infosys: CIA-1 OF International Financial ManagementNehal SharmaNo ratings yet

- CP FloodDocument42 pagesCP FloodRayban100% (4)

- Exam QuestionsDocument55 pagesExam QuestionsCharlie Maurer67% (3)

- SerumDocument5 pagesSerumganangNo ratings yet

- Case Study - The Success and Failure of Disney's RemakesDocument17 pagesCase Study - The Success and Failure of Disney's RemakesWenqi GuNo ratings yet

- Deputy CISO - Biogen PDFDocument5 pagesDeputy CISO - Biogen PDFNamasivayam SarojaNo ratings yet

- Banking Ass - KPMG Study - Bank MarginsDocument58 pagesBanking Ass - KPMG Study - Bank MarginscommercestudentNo ratings yet

- Pillars of Financial Inclusion Remittances - Micro Insurance and Micro SavingsDocument27 pagesPillars of Financial Inclusion Remittances - Micro Insurance and Micro SavingsDhara PatelNo ratings yet

- CONSIDERATIONS OF ENTITY'S INTERNAL CONTROL Red Sirug Lecture NoteDocument7 pagesCONSIDERATIONS OF ENTITY'S INTERNAL CONTROL Red Sirug Lecture NoteMikaNo ratings yet

- UCM TLE 7 CaregivingDocument4 pagesUCM TLE 7 Caregivingven bonaNo ratings yet

- QRADocument10 pagesQRApgupta71100% (1)

- A Glass Half Full - Rhb-Report-My - Budget-2022-Equity-Impact - 20211030Document19 pagesA Glass Half Full - Rhb-Report-My - Budget-2022-Equity-Impact - 20211030Shaun WooNo ratings yet

- Project Plan: Group Case Study 4 OctoberDocument15 pagesProject Plan: Group Case Study 4 OctobernileshvpNo ratings yet

- Sociología de La CuraDocument5 pagesSociología de La CuraAna Carolina Cáceres MolanoNo ratings yet