Professional Documents

Culture Documents

United States Patent: (75) Inventors: Jeffrey H. Wood, Eureka, MO (US)

United States Patent: (75) Inventors: Jeffrey H. Wood, Eureka, MO (US)

Uploaded by

Clóvis Ferreira0 ratings0% found this document useful (0 votes)

14 views14 pagesThe patent document describes a floor beam assembly, system, and associated method for installing floor beams within an aircraft structure. The floor beam assembly includes at least one floor beam, at least one floor beam bracket attached to the floor beam, at least one pivot arm pivotally attached to the aircraft structure, and a pad attached to the pivot arm. The pivot arm is configured to pivot the pad into position proximate to the floor beam bracket to attach thereto. The assembly allows for efficient installation of floor beams within an aircraft fuselage.

Original Description:

Patent

Original Title

Us 7775478

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe patent document describes a floor beam assembly, system, and associated method for installing floor beams within an aircraft structure. The floor beam assembly includes at least one floor beam, at least one floor beam bracket attached to the floor beam, at least one pivot arm pivotally attached to the aircraft structure, and a pad attached to the pivot arm. The pivot arm is configured to pivot the pad into position proximate to the floor beam bracket to attach thereto. The assembly allows for efficient installation of floor beams within an aircraft fuselage.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

14 views14 pagesUnited States Patent: (75) Inventors: Jeffrey H. Wood, Eureka, MO (US)

United States Patent: (75) Inventors: Jeffrey H. Wood, Eureka, MO (US)

Uploaded by

Clóvis FerreiraThe patent document describes a floor beam assembly, system, and associated method for installing floor beams within an aircraft structure. The floor beam assembly includes at least one floor beam, at least one floor beam bracket attached to the floor beam, at least one pivot arm pivotally attached to the aircraft structure, and a pad attached to the pivot arm. The pivot arm is configured to pivot the pad into position proximate to the floor beam bracket to attach thereto. The assembly allows for efficient installation of floor beams within an aircraft fuselage.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 14

USOO7775478B2

(12) United States Patent (10) Patent No.: US 7.775.478 B2

Wood et al. (45) Date of Patent: Aug. 17, 2010

(54) FLOOR BEAM ASSEMBLY, SYSTEM, AND 4,185,799 A 1/1980 Richards, Jr.

ASSOCATED METHOD 4,261,155 A * 4, 1981 Gilb ............................ 52.7O2

4,409,765 A * 10/1983 Pall ........................... 52,167.1

(75) Inventors: Jeffrey H. Wood, Eureka, MO (US); 4,479,621 A 10/1984 Bergholz

John H. Fogarty, Lake St. Louis,MO 4,531,334 A * 7/1985 Nylander et al. .............. 52/109

(US) 4,926,590 A 5/1990 Harris ............................. 52/8

4,964,775 A * 10/1990 Youmans ..................... 414/12

(73) Assignee: The Boeing Company, Chicago, IL 4,989,809 A 2f1991 Arnold

(US) 5,016,403 A * 5/1991 Fujita .............................. 52/7

(*) Notice: Subject to any disclaimer, the term of this 5,240,342 A * 8/1993 Kresa, Jr. .... ... 403,232.1

patent is extended or adjusted under 35 RE34,468 E * 12/1993 Rau et al. ... ... 296,26.02

U.S.C. 154(b) by 463 days. 5,711,504 A 1/1998 Cusimano ................ 248,354.3

5,778,604. A 7/1998 Snow ............................ 52.66

(21) Appl. No.: 11/537,145

(22) Filed: Sep. 29, 2006

(Continued)

(65) Prior Publication Data

FOREIGN PATENT DOCUMENTS

US 2008/OO78129 A1 Apr. 3, 2008

JP O6158875 A * 6, 1994

(51) Int. Cl.

E04B I/32 (2006.01)

B64C I/00 (2006.01)

(52) U.S. Cl. ........................ 244/119:52/582.2:52/289; Primary Examiner Robert J Canfield

52/702:52/246; 52/745.05 Assistant Examiner Brent W Herring

(58) Field of Classification Search ................. 244/119: (74) Attorney, Agent, or Firm—Alston & Bird LLP

52/245, 246, 261,263, 650.3, 69, 70, 71, (57) ABSTRACT

52/289, 702, 655.1, 127.8, 167. 1, 167.3,

52/167.4, 167.8, 651.1, 282.5, 582.1, 582.2,

52/745.05

See application file for complete search history. A floor beam assembly, system, and method for installing

floor beams within a structure are provided. According to one

(56) References Cited embodiment, a floor beam assembly for installing a floor

U.S. PATENT DOCUMENTS beam within a structure is provided. The assembly includes at

least one floor beam and at least one floor beam bracket

436,767 A 9, 1890 Baker .......................... 52.289 attached to a respective floor beam. The assembly also

1,282,090 A * 10/1918 Lemme ... ... 52/592.4 includes at least one pivot arm pivotally attached to the struc

1,900,274 A * 3/1933 Brockie ...................... 135,147 ture. In addition, the assembly includes a pad attached to the

2,167,557 A 7, 1939 Stout ............................. 52?69 at least one pivot arm, wherein the at least one pivot arm is

2,849.205 A * 8/1958 Chapin, Jr. ...... ... 248,282.1 configured to pivot the pad to a position proximate to a respec

3,103,025 A 9, 1963 Gassner et al. ................... 14.6 tive floor beam bracket to be attached thereto.

3,843,154 A * 10/1974 Thompson ............... 280,766.1

4,045,926 A * 9/1977 Gibbs ............................ 52/66

4,084,789 A * 4, 1978 Francis ....................... 254/418 34 Claims, 7 Drawing Sheets

US 7,775.478 B2

Page 2

U.S. PATENT DOCUMENTS 7,107,734 B2 * 9/2006 Jines et al. ................. 52?655.1

7,191,982 B2* 3/2007 Vetillard et al. . ... 244f119

6,018,920 A 2/2000 Fancher ..................... 52/582.2 7,475,850 B2 * 1/2009 Vetillard et al. ......... 244/117 R

6,086,018 A 7/2000 Gobeil et al. 2003/0221379 A1* 12/2003 Oliver et al. ............... 52,167.1

6,142,488 A * 1 1/2000 Orr ......................... 280/6.153 2004O163355 A1* 8, 2004 Collie 52.7O2

6,164,017 A 12/2000 Burton ............................ 52/7 2005, 0108959 A1* 5, 2005 Powell et al. .............. 52,167.1

6,247.286 B1 - 6 2001 Heyns... 52/589.1 2005, 0115170 A1* 6/2005 Mualla ...................... 52,167.1

6,381,907 B1 * 5/2002 MacKarvich ... 52/126.6 2006/0006283 A1 1/2006 Vetillard et al.

6,438,905 B2 * 8/2002 Constantinou . 52,167.3 2006,0006284 A1 1/2006 Vetillard et al.

6,729,075 B2 * 5/2004 Jines et al. ....................... 52/7 2006/0049600 A1* 3/2006 Dudding et al. ........ 280,124.11

6,735,917 B1 * 5/2004 Notermann .... ... 52,656.9 2009, 0236472 A1* 9, 2009 Wood ......................... 244,119

6,837,010 B2 * 1/2005 Powell et al. ... 52,167.3

6,840,016 B1* 1/2005 Mualla ....... ... 52,167.1 * cited by examiner

U.S. Patent Aug. 17, 2010 Sheet 1 of 7 US 7.775.478 B2

U.S. Patent Aug. 17, 2010 Sheet 2 of 7

U.S. Patent Aug. 17, 2010 Sheet 3 of 7 US 7.775.478 B2

U.S. Patent Aug. 17, 2010 Sheet 4 of 7 US 7.775.478 B2

U.S. Patent Aug. 17, 2010 Sheet 5 Of 7 US 7.775.478 B2

U.S. Patent Aug. 17, 2010 Sheet 6 of 7 US 7.775.478 B2

US 7,775,478 B2

1. 2

FLOOR BEAMASSEMBLY, SYSTEM, AND According to aspects of the assembly, each pad is pivotally

ASSOCATED METHOD attached to the at least one pivot arm such that each pad is

capable of pivoting relative to the pivot arm to align with a

BACKGROUND OF THE INVENTION respective floor beam bracket. In addition, the assembly may

include an adhesive applied to each pad and/or a mating

1) Field of the Invention surface of each floor beam bracket. The adhesive could be a

Embodiments of the present invention relate to floor beams two-part paste adhesive. Each pad may be attached to a pair of

and, more particularly, to apparatus, Systems, and methods pivot arms. The floor beams may be a composite material.

for installing floor beams within a structure. Furthermore, a mating Surface area of each floor beam

2) Description of Related Art 10

bracket may be larger than a mating Surface area of a respec

The floor of an aircraft is typically built up from a series of tive pad. The assembly could further include at least one

spaced apart transverse floor beams that span across oval Support bracket attached to the structure and configured to

hoop frames to form the structural framework for the aircraft Support at least a portion of the at least one floor beam

fuselage. The floor beams are usually aluminum and are indi

vidually attached with fasteners at each end to the hoop 15 thereon. Each floor beam may be supported by at least one

frames via a lap joint. The joint formed between the floor Support bracket without being attached to the Support bracket.

beam and the hoop frame bears the transverse and shear loads An additional aspect of the present invention includes a

applied to the floor beam. Loads applied in the fore and aft system for installing a floor beam assembly within a structure.

direction are bore by longitudinal shear trusses between the The system includes a structure (e.g., aircraft structure) com

floor and the fuselage floor. prising a plurality of Support members (e.g., hoop frames),

Current techniques for joining the floor beams and hoop and a plurality of floor beams positioned proximate to at least

frames require precise installation of mate-drilled holes one of the Support members. The system also includes at least

between the floorbeams and the hoop frames to ensure proper one floor beam bracket attached to a respective floor beam.

hole alignment for the fasteners. Once the floor beams are Moreover, the system includes at least one pivot arm pivotally

installed, the individual components comprising the floor 25

attached to at least one of the Support members, and a pad

assembly (e.g., seat tracks, floor panels, etc.) are Subse attached to the pivot arm, wherein the pivot arm is configured

quently attached to the floor beams. Future aircraft are mov to pivot the pad to a position proximate to a respective floor

ing away from aluminum to lightweight materials, such as beam bracket to be attached thereto.

composite materials. The use of composite material creates

unique design, integration, and assembly issues that would 30 According to various modifications of the system, each

normally not be problematic with respect to metallic materi pivot arm is directly attached to at least one of the Support

als. members. At least a portion of each support member may

It would therefore be advantageous to provide an assembly, define an aperture, wherein each pad is configured to be

a system, and a method for installing floor beams within a pivoted through the aperture and align with a respective floor

structure. In addition, it would be advantageous to provide an 35 beam bracket. The system may include at least one pivot arm

improved assembly, a system, and a method for installing bracket attached to a respective Support member, and a pair of

floor beams within a structure that provide adequate Support pivot arms may be attached to a respective pivot arm bracket.

from loads applied to the floor beams. Moreover, it would be Each pad may be pivotally attached to the at least one pivot

further advantageous to provide an assembly, a system, and a arm Such that the pad may pivot relative to the pivot arm. In

method for more efficiently and effectively installing floor 40

addition, the system may further include an adhesive (e.g., a

beams within a structure. two-part paste adhesive) applied to each pad and/or a mating

BRIEF SUMMARY OF THE INVENTION surface of each floor beam bracket. The system could also

include a floor panel positioned adjacent to a plurality of the

Embodiments of the invention may address at least some of 45

floor beams, and a plurality of shear trusses attached to the

the above needs and achieve other advantages by providing an floor panel and the structure. Moreover, the system could

assembly, a system, and a method for installing floor beams include at least one Support bracket coupled to at least one of

within a structure. Generally, embodiments of the present the Support members and configured to Support at least a

invention include floor beams supported by brackets secured portion of the at least one floor beam thereon.

to a structure, such as an aircraft structure. Pads that are 50 A further aspect of the present invention provides a method

coupled to the aircraft structure may be pivoted to attach to for installing a floor beam assembly within a structure. The

respective floor beams once the floor beams are positioned on method includes positioning at least one floor beam proxi

the brackets. Fasteners need not necessarily be used to attach mate to the structure. The method also includes pivoting a pad

the pads to the floor beams, which may reduce the incidence coupled to the structure to align with a respective floor beam

of misalignment and the installation time. The floor beams 55 bracket attached to at least one of the floor beams, and attach

may be pre-assembled with the floor panel such that the floor ing each pad to a respective floor beam bracket. The pivoting

assembly may be quickly secured to the aircraft structure. step could include pivoting the pad about a pivot arm attached

In one embodiment of the present invention, a floor beam to the structure or pivoting the pad about a pair of pivot arms

assembly for installing a floor beam within a structure is coupled to the structure. The pivoting step could also include

provided. The assembly includes at least one floor beam and 60 pivoting the pad about a plurality of axes to align the pad with

at least one floor beam bracket attached to a respective floor a respective floor beam bracket. In addition, the pivoting step

beam. The assembly also includes at least one pivot arm may include pivoting each of the pads through a respective

pivotally attached to the structure. In addition, the assembly aperture defined in the structure to align with a respective

includes a pad attached to the at least one pivot arm, wherein floor beam bracket. The method could further include apply

the at least one pivot arm is configured to pivot the pad to a 65 ing an adhesive to the pad and/or a mating Surface of the floor

position proximate to a respective floor beam bracket to be beam bracket prior to attaching each pad to a respective floor

attached thereto. beam bracket. Furthermore, the positioning step could

US 7,775,478 B2

3 4

include positioning at least one floor beam on at least one of may be various configurations, such as hat-shaped as shown

a plurality of Support brackets attached to the structure. in FIG. 2, and secured to the aircraft skin using techniques

known to those of ordinary skill in the art. Moreover, vertical

BRIEF DESCRIPTION OF THE SEVERAL stanchions 21 may be employed for adding structural Support

VIEWS OF THE DRAWING(S) from shear loading on the floor beam assembly.

The floor panel 14 is positioned adjacent to at least one

Having thus described the invention in general terms, ref floor beam 12, but is typically positioned over a plurality of

erence will now be made to the accompanying drawings, floor beams. The floor panel 14 is generally planar and of

which are not necessarily drawn to scale, and wherein: sufficient thickness and durability to provide support for

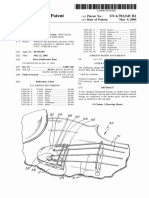

FIG. 1 is a perspective view of a structural system accord 10 objects positioned thereon. The floor panel 14 may also be

ing to one embodiment of the present invention; various materials and configurations depending on the par

FIG. 2 is an enlarged perspective view of a floor beam ticular application desired, such as for Supporting aircraft

assembly according to one embodiment of the present inven passengers and a seat track assembly.

tion; Each floor beam 12 extends transversely to a longitudinal

FIGS. 3-6 illustrate elevation views of the installation of a 15 axis (i.e., in a fore-aft direction) of the aircraft structure. In

floor beam to an aircraft structure according to an embodi particular, each floor beam 12 is paired with a respective hoop

ment of the present invention; frame 16. The floorbeams 12 are of sufficient length to extend

FIGS. 7 and 8 are perspective views of a floor beam assem proximate to opposite sides of a respective hoop frame 16.

bly according to another embodiment of the present inven The floor beams 12 are slightly longer than the floor panel 14

tion; and (see FIG. 6) and are generally positioned below a medial

FIG. 9 is a perspective view of a portion of a structural plane intersecting each hoop frame 16. Typically, the floor

system according to one embodiment of the present inven beams 12 are configured in an I-beam cross section and are

tion. made from a composite material.

It is understood that the illustrated floor beams 12 are not

DETAILED DESCRIPTION OF THE INVENTION 25 meant to be limiting, as the floor beams could be various sizes

and cross sections (e.g., C-shaped) in additional aspects of the

The present invention now will be described more fully present invention. Thus, the floor beams 12 may be various

hereinafter with reference to the accompanying drawings, in sizes depending on the amount of support desired. Moreover,

which some, but not all embodiments of the invention are there may be any number of floor beams 12, such as a floor

shown. Indeed, the invention may be embodied in many dif 30 beam attached to every other hoop frame 16, or more than one

ferent forms and should not be construed as limited to the floor beam per hoop frame. And, the floor beams 12 may be

embodiments set forth herein; rather, these embodiments are positioned at various locations with respect to each hoop

provided so that this disclosure will satisfy applicable legal frame 16 (e.g., above or below a median plane) and orienta

requirements. Like numbers refer to like elements through tions with respect to the longitudinal axis of the aircraft struc

Out. 35 ture (e.g., obliquely or parallel). The floor beams 12 could

Referring now to the drawings and, in particular to FIG. 1, also be various materials, such as a metallic or composite

there is shown a system 10 for installing a floor beam assem material, or a combination thereof.

bly within an aircraft structure. In particular, the floor beam As depicted in FIG. 2, a floor beam bracket 22 is attached

assembly includes a plurality of floor beams 12 and a floor to opposite ends of each floor beam 12. Each floor beam

panel 14 that is attached to a structure. Such as a plurality of 40 bracket 22 is attached to one side of the floor beam 12 and

hoop frames 16. The floorbeams 12 and floorpanel 14 may be proximate to an upper edge 28 of the floorbeam. For example,

preassembled and secured to the hoop frames 16, as will be in instances in which the floor beam 12 is I-shaped, the floor

explained in further detail below. Although the system 10 is beam bracket 22 may be attached proximate to the upper

discussed in conjunction with an aircraft structure, it is under flange of the floor beam for additionally supporting the floor

stood that the system may be used in a variety of industries. 45 beam bracket. The floor beam bracket 22 includes an attach

Thus, the floor beam assembly could be utilized in a variety of ment portion 24 that is attached to a respective floor beam 12

industries where a floor beam assembly may be installed to a using fasteners, cross pins, adhesive, or the like. Moreover,

structure, such as in the aircraft, automotive, marine, or con the floor beam bracket 22 includes a mating portion 26 that

struction industries. extends transversely from the attachment portion 24. The

The system 10 may include a variety of components that 50 floor beam bracket 22 can be manufactured from a metallic

comprise a structure. In general, an aircraft structure may material. Such as aluminum or titanium, or composite mate

include a plurality of structural Supports, such as the hoop rials. The floor beam bracket 22 may be various configura

frames 16 illustrated in FIG.1. The hoop frames 16, as known tions to facilitate engagement with a pad 38, which is

to those of ordinary skill in the art, are formed in a circular or explained in further detail below. For example, the floor beam

other looped configuration to define the framework of the 55 bracket 22 could be configured as shown in FIGS. 7 and 8. In

aircraft fuselage. The hoop frames 16 may be various cross FIGS. 7 and 8, themating portion 26 of the floorbeam bracket

sections, such as a C-shaped cross section, as shown in FIG. 22 extends on opposite sides of a respective floor beam 12,

2. The hoop frames 16 are typically a metallic material, such and an attachment portion 24 is positioned on opposite sides

as aluminum, but could be a composite or combination of of the floor beam 12 for attachment thereto.

metallic and composite materials. Attached to the exterior of 60 A support bracket 30 may be attached to each hoop frame

the hoop frames 16 is aircraft skin 18. The skin 18 may be 16 for supporting each endofa respective floorbeam 12. Each

attached to the hoop frames 16 using shear ties 19, as known support bracket 30 includes a support surface 32 and an

to those of ordinary skill in the art. The skin 18 may be various attachment Surface 34 extending generally perpendicular

materials, such as a composite (e.g., composite tape plies) therefrom. A lower edge 37 of the floor beam 12 is supported

and/or metallic material. The skin 18, as also known to those 65 on the support surface 32. In particular, each floor beam 12 is

of ordinary skill in the art, may include stringers 20 (see FIG. positioned adjacent to the Support Surface 32, generally with

2) for adding structural support to the skin. The stringers 20 out using any attachment mechanism, Such as fasteners. The

US 7,775,478 B2

5 6

attachment Surface 34 is positioned adjacent to a respective the pads 38 with the mating surfaces 26 of the floor beam

hoop frame 16 and could be attached thereto using various brackets 24 is capable of securing the floor beams 12 adjacent

techniques, such as fasteners. The Support bracket 30 is typi to the support brackets 30.

cally a metallic material. Such as aluminum or titanium. The An adhesive is typically used to attach the pads 38 to

configuration of the Support bracket 30 may vary, as long as respective mating surfaces 26 of the floor beam brackets 22.

the attachment surface 34 facilitates attachment to the hoop The surface of the pads 38 and the mating surfaces 26 of the

frame 16, and the Support Surface 32 facilitates Supporting of floor beam brackets 22 may be pre-doped with a two-part

the floor beam 12. adhesive, with one part on the pad and one part on the mating

A plurality of pivot arms 36 are attached to respective hoop Surface. Alternatively, a one-part paste adhesive may be

10 applied to the pad 38 and/or the mating surface 26 before

frames 16. Each pivot arm 36 is configured to pivot about bringing the Surfaces into engagement with one another. For

point A. Attached at the opposite end of the pivot arm 36 is a example, the adhesive could be a two-part structural paste

pad 38 such that pivoting of the pivot arm about point A also adhesive (e.g., Hysol R. EA-9394 manufactured by Henkel

pivots the pad. Each pad 38 is also capable of independently Corp.).

pivoting about point B. Pins or the like may be used to secure 15 To further secure the floor beam assembly to the aircraft

the pivot arm 36 to the hoop frame 16 and the pad 38 to the structure, shear trusses 46 are secured to the floorpanel 14 and

pivot arm to facilitate pivoting thereabout. The hoop frames aircraft structure, as shown in FIGS. 6 and 9. In particular,

16 may be reinforced in the areas of attachment to the pivot FIGS. 2 and 9 illustrate that the aircraft structure includes a

arms 36. Such as by thickening the hoop frame material. In plurality of shelves 44 having a base 45 positioned adjacent to

addition, the hoop frames 16 may define an aperture 42 in the aircraft skin 18 and between a pair of stringers 20. Each

order to allow each pad 38 to pivot through the aperture so as shelf 44 extends outwardly towards a respective hoop frame

to operably contact a respective floor beam bracket 22. Thus, 16 such that the shear truss 46 is capable of being positioned

a portion of the hoop frame 16 may be removed, or otherwise adjacent to the shelf 44 and the floor panel 14. The shear

never formed, in order to define the aperture 42. The pivot trusses 46 may be a composite material that is attached to the

arms 36 and pads 38 are typically a metallic material, such as 25 floor panel 14 and shelf 44 with an adhesive, although the

titanium or aluminum. shear trusses could be a metallic material and secured with

fasteners and the like.

It is understood that the pivot arms 36 may be various Thus, embodiments of the present invention may provide

configurations in order to allow pivoting about the hoop several advantages. For example, the floor beams 12, floor

frames 16. For example, FIGS. 7 and 8 illustrate an alternative 30 panel 14, and/or floor beam brackets 22 may be preassembled

embodiment of the present invention, where a pair of pivot and attached to an aircraft structure. Thus, the floor beam

arms 36 are attached to a pivot bracket 40. The pivot bracket assembly may be readily positioned and secured to the air

40 is attached to one side (or opposite sides) of a respective craft structure. Moreover, the pivot arms 36 and pads 38 may

hoop frame 16 and is configured such that the pivot arms 36 attach the floor beams 12 to the structure without using fas

are spaced inwardly and away from the hoop frame 16. Thus, 35 teners, which may provide for more efficient installation.

an aperture 42 is not required in this particular embodiment to Thus, embodiments of the present invention eliminate the

allow for pivoting of the pivot arm. The pivot bracket 40 may need for mate-drilled holes and reduce the probability of

be attached to the hoop frame 16 using fasteners, cross pins, introducing foreign object debris in the form of fasteners or

adhesives, or the like. FIGS. 7 and 8 also demonstrate that the other debris resulting from removal of material to accommo

floor beam 12 may be modified to allow the pivot arms 36 to 40 date the fasteners. In addition, the pivot arms 36 and pads 38

be spaced outwardly from the hoop frame 16 and effectively may be configured to accommodate radial and fore/aft mis

between an end of a floor beam and the corresponding hoop alignment of the pads and floor beam brackets 22.

frame. In particular, FIG. 8 illustrates an S-shaped profile at Many modifications and other embodiments of the inven

the end of the floor beam 12, although other profiles could be tion set forth herein will come to mind to one skilled in the art

employed to allow for free rotation of the pivot arms 36. 45 to which the invention pertains having the benefit of the

FIGS. 3-6 depict the operations used to install a floor beam teachings presented in the foregoing descriptions and the

assembly to an aircraft structure according to one embodi associated drawings. Therefore, it is to be understood that the

ment of the present invention. Namely, FIG. 3 shows that the invention is not to be limited to the specific embodiments

floor beam 12 and the floor beam bracket 22 are typically disclosed and that modifications and other embodiments are

preassembled, and then the floor beam is positioned adjacent, 50 intended to be included within the scope of the appended

and in a weight-bearing relationship, to a Supporting Surface claims. Although specific terms are employed herein, they are

32 of the support bracket 30, as depicted in FIG. 4. FIG. 5 used in a generic and descriptive sense only and not for

demonstrates that the pivot arms 36 may then be pivoted purposes of limitation.

about pivot A towards themating surface 26 of the floor beam That which is claimed:

bracket 22. Moreover, the pad 38 may be pivoted about pivot 55 1. A floor beam assembly comprising:

B to ensure proper radial alignment with the mating Surface at least one floor beam;

26 of the floor beam bracket 22. In this regard, the pivot arms at least one floorbeam bracket attached to a respective floor

36 and the pads 38 are generally pivoted such that the pads are beam;

flush and in uniform contact with a respective mating Surface at least one pivot arm having a longitudinal axis and

26 of the floor beam bracket 22. In addition, the mating 60 attached to, and configured to pivot about, a structure

surface 26 of the floor beam bracket 22 could be oversized to along a first axis; and

further facilitate proper alignment with the pad 38. Thus, the a pad attached to, and configured to pivot about, the at least

preassembled floor beams 12 and floor beam brackets 22 may one pivot arm along a second axis, wherein the longitu

be readily positioned on the support brackets 30 and the pads dinal axis extends between the first axis and the second

38 rotated to engage respective mating Surfaces 26, while also 65 axis, and wherein the at least one pivot arm is configured

accommodating for any fore or aft misalignment of the floor to pivot the pad into engagement with a respective floor

beams to the hoop frames 16. Moreover, the engagement of beam bracket to be attached thereto.

US 7,775,478 B2

7 8

2. The assembly according to claim 1, wherein each pad is wherein each pad is configured to be pivoted through the

pivotally attached to the at least one pivot arm, and wherein aperture and align with a respective floor beam bracket.

each pad is capable of pivoting relative to the at least one pivot 17. The system according to claim 14, further comprising

arm to align with a respective floor beam bracket. at least one pivot armbracket attached to a respective Support

3. The assembly according to claim 1, further comprising member.

an adhesive applied to at least one of each pad and a mating 18. The system according to claim 17, wherein a pair of

surface of each floor beam bracket. pivot arms are attached to a respective pivot arm bracket.

4. The assembly according to claim3, wherein the adhesive 19. The system according to claim 14, wherein each pad is

comprises a two-part paste adhesive. pivotally attached to the at least one pivot arm, and wherein

5. The assembly according to claim 1, wherein each pad is 10 eachpad is capable of pivoting relative to the at least one pivot

attached to a pair of pivot arms. arm to align with a respective floor beam bracket.

6. The assembly according to claim 1, wherein each floor 20. The system according to claim 14, further comprising

beam comprises a composite material. an adhesive applied to at least one of each pad and a mating

7. The assembly according to claim 1, further comprising at surface of each floor beam bracket.

least one Support bracket attached to the structure and con 15 21. The system according to claim 20, wherein the adhe

figured to support at least a portion of the at least one floor sive comprises a two-part paste adhesive.

beam thereon. 22. The system according to claim 14, further comprising a

8. The assembly according to claim 7, wherein each floor floor panel positioned adjacent to a plurality of the floor

beam is configured to rest on the at least one Support bracket beams.

in a weight-bearing relationship. 23. The system according to claim 22, further comprising a

9. The assembly according to claim 1, wherein a mating plurality of shear trusses attached to the floor panel and the

Surface area of each floorbeam bracket is larger than amating Structure.

Surface area of a respective pad. 24. The system according to claim 14, wherein the struc

10. The assembly according to claim 1, wherein the at least ture comprises an aircraft structure, and wherein the Support

one bracket comprises a planar mating Surface, and wherein 25 members comprise a plurality of hoop frames.

the pad comprises a planar Surface configured to be posi 25. The system according to claim 14, further comprising

tioned in flush and uniform contact with the planar mating at least one Support bracket coupled to at least one of the

surface of the floor beam bracket for attachment thereto. Support members and configured to Support at least a portion

11. The assembly according to claim 1, further comprising of the at least one floor beam thereon.

a plurality of floor beam brackets, pivot arms, and pads, 30 26. A method for installing a floor beam assembly within a

wherein the at least one floorbeam comprises first and second structure comprising:

opposing ends, wherein one of the floor beam brackets is positioning at least one floor beam proximate to the struc

attached to the first opposing end and another floor beam ture;

bracket is attached to the second opposing end, and wherein pivoting a pad coupled to the structure into engagement

one of the pads is configured to pivot about a first pivot arm 35 with a respective floor beam bracket attached to at least

and attach to the floor beam bracket at the first opposing end one of the floor beams such that the floor beam bracket

and another pad is configured to pivot about second pivot arm opposes further pivoting of the pad, wherein pivoting

and attach to the floor beam bracket at the second opposing comprises pivoting the pad about a plurality of axes to

end. align with a respective floor beam bracket, and wherein

12. The assembly according to claim 1, wherein the first 40 the axes do not intersect one another; and

and second axes do not intersect one another. attaching each pad to a respective floor beam bracket while

13. The assembly according to claim 1, wherein the at least the floor beam bracket and pad are in engagement with

one pivot arm comprises a first end and a second opposite end one another.

and the longitudinal axis extends between the first and second 27. The method according to claim 26, wherein pivoting

ends, and wherein the pivot arm is attached to the structure 45 comprises pivoting the pad about a pivot arm attached to the

proximate to the first end and the at least one pad is attached Structure.

to the pivot arm proximate to the second end. 28. The method according to claim 26, wherein pivoting

14. A system for installing a floor beam assembly compris comprises pivoting the pad about a pair of pivot arms coupled

ing: to the structure.

a structure comprising a plurality of Support members; 50 29. The method according to claim 26, wherein pivoting

a plurality of floor beams positioned proximate to at least comprises pivoting the pad about a plurality of axes to align

one of the Support members; with a respective floor beam bracket, and wherein the axes

at least one floorbeam bracket attached to a respective floor extend parallel to one another.

beam; 30. The method according to claim 26, further comprising

at least one pivot arm having a longitudinal axis and 55 applying an adhesive to at least one of the pad and a mating

attached to, and configured to pivot about, at least one of Surface of the floor beam bracket prior to attaching each pad

the Support members along a first axis; and to a respective floor beam bracket.

a pad attached to, and configured to pivot about, the at least 31. The method according to claim 26, wherein pivoting

one pivot arm along a second axis, wherein the longitu comprises pivoting each of the pads through a respective

dinal axis extends between the first axis and the second 60 aperture defined in the structure to align with a respective

axis, and wherein the at least one pivot arm is configured floor beam bracket.

to pivot the pad into engagement with a respective floor 32. The method according to claim 26, wherein positioning

beam bracket to be attached thereto. comprises positioning the at least one floor beam on at least

15. The system according to claim 14, wherein each pivot one of a plurality of support brackets attached to the structure.

arm is directly attached to at least one of the Support members. 65 33. A system for installing a floor beam assembly compris

16. The system according to claim 15, wherein at least a 1ng:

portion of each Support member defines an aperture, and an aircraft structure comprising a plurality of hoop frames;

US 7,775,478 B2

10

a plurality of floor beams positioned proximate to at least positioning at least one floor beam proximate to the struc

one of the hoop frames; ture;

at least one floorbeam bracket attached to a respective floor pivoting a pad coupled to the structure into engagement

beam; with a respective floor beam bracket attached to at least

5 one of the floor beams such that the floor beam bracket

at least one pivot arm pivotally attached to at least one of opposes further pivoting of the pad, wherein pivoting

the hoop frames; and comprises pivoting each of the pads through a respective

a pad attached to the at least one pivot arm, wherein the at aperture defined in the structure to align with a respec

least one pivot arm is configured to pivot the pad to a tive floor beam bracket; and

position proximate to a respective floor beam bracket to 10 attaching each pad to a respective floor beam bracket while

be attached thereto. the floor beam bracket and pad are in engagement with

one another.

34. A method for installing a floor beam assembly within a

structure comprising:

You might also like

- US6699426Document16 pagesUS6699426Muhammed BALIKÇINo ratings yet

- United States Patent (10) Patent No.: US 7,909,748 B2Document50 pagesUnited States Patent (10) Patent No.: US 7,909,748 B2Alex MungaiNo ratings yet

- United States Patent: (12) (10) Patent No.: US 7.225,900 B2Document8 pagesUnited States Patent: (12) (10) Patent No.: US 7.225,900 B2flavioNo ratings yet

- Sai Gó: (5) (5) (5) (Sics211Document33 pagesSai Gó: (5) (5) (5) (Sics211Dhrubajyoti BoraNo ratings yet

- United States Patent (10) Patent No.: US 9,080,720 B2Document16 pagesUnited States Patent (10) Patent No.: US 9,080,720 B2sfjhsakjfhNo ratings yet

- US8749333Document19 pagesUS8749333Anonymous GIIncAfLRNo ratings yet

- United States Patent (10) Patent No.: US 7.562,614 B2: Polston (45) Date of Patent: Jul. 21, 2009Document22 pagesUnited States Patent (10) Patent No.: US 7.562,614 B2: Polston (45) Date of Patent: Jul. 21, 2009Слэйтер Строительная компанияNo ratings yet

- US6662930Document13 pagesUS6662930channakeshava pandurangaNo ratings yet

- Google Patent IIDocument8 pagesGoogle Patent IIRezky PrasetyajiNo ratings yet

- United States Patent (10) Patent No.: US 8,794,651 B2Document29 pagesUnited States Patent (10) Patent No.: US 8,794,651 B2swapnil kaleNo ratings yet

- United States Patent (10) Patent No.: US 7,037,958 B1Document13 pagesUnited States Patent (10) Patent No.: US 7,037,958 B1Alexander Franco CastrillonNo ratings yet

- Method For Parachute Reefing ControlDocument9 pagesMethod For Parachute Reefing ControlgabrielmolloNo ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument21 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentPato Patiño MuñozNo ratings yet

- United States Patent (10) Patent No.: US 8,102,071 B2Document52 pagesUnited States Patent (10) Patent No.: US 8,102,071 B2Marlon MataNo ratings yet

- United States Patent (10) Patent No.: US 7,252,264 B2: Nattinger (45) Date of Patent: Aug. 7, 2007Document11 pagesUnited States Patent (10) Patent No.: US 7,252,264 B2: Nattinger (45) Date of Patent: Aug. 7, 200712348No ratings yet

- United States Patent (10) Patent No.: US 8,151,529 B2: Weidmann Et Al. (45) Date of Patent: Apr. 10, 2012Document9 pagesUnited States Patent (10) Patent No.: US 8,151,529 B2: Weidmann Et Al. (45) Date of Patent: Apr. 10, 2012Akshay GamreNo ratings yet

- United States Patent (10) Patent No.: US 8,147,768 B2Document12 pagesUnited States Patent (10) Patent No.: US 8,147,768 B2habbibrachmanNo ratings yet

- US7418738-Vertical Adjustment Flip-Up PDFDocument15 pagesUS7418738-Vertical Adjustment Flip-Up PDFja2ja1No ratings yet

- United States Patent (10) Patent No.: US 7,759,419 B2: Stoffer Et Al. (45) Date of Patent: Jul. 20, 2010Document24 pagesUnited States Patent (10) Patent No.: US 7,759,419 B2: Stoffer Et Al. (45) Date of Patent: Jul. 20, 2010Alexander Franco CastrillonNo ratings yet

- United States Patent (10) Patent No.: US 7,311,236 B2: Smith Et Al. (45) Date of Patent: Dec. 25, 2007Document14 pagesUnited States Patent (10) Patent No.: US 7,311,236 B2: Smith Et Al. (45) Date of Patent: Dec. 25, 2007chicken curryNo ratings yet

- United States Patent (10) Patent No.: US 7,207,268 B2: Brunst (45) Date of Patent: Apr. 24, 2007Document8 pagesUnited States Patent (10) Patent No.: US 7,207,268 B2: Brunst (45) Date of Patent: Apr. 24, 2007Quý Đình Mai MaiNo ratings yet

- US7827620Document9 pagesUS7827620Devansh ChhajlaniNo ratings yet

- US7946356Document53 pagesUS7946356Ahmad Reza FarokhiNo ratings yet

- Us 9050873Document24 pagesUs 9050873Julius RojoNo ratings yet

- United States Patent (10) Patent No.: US 7489,225 B2: Dadafshar (45) Date of Patent: Feb. 10, 2009Document24 pagesUnited States Patent (10) Patent No.: US 7489,225 B2: Dadafshar (45) Date of Patent: Feb. 10, 2009Jie99No ratings yet

- United States Patent (10) Patent No.: US 6,921,304 B2: Hewitt (45) Date of Patent: Jul. 26, 2005Document17 pagesUnited States Patent (10) Patent No.: US 6,921,304 B2: Hewitt (45) Date of Patent: Jul. 26, 2005shruti kapseNo ratings yet

- United States Patent (10) Patent No.: US 7.624,666 B1: O'Neill Et Al. (45) Date of Patent: Dec. 1, 2009Document9 pagesUnited States Patent (10) Patent No.: US 7.624,666 B1: O'Neill Et Al. (45) Date of Patent: Dec. 1, 2009Turk SoloNo ratings yet

- United States Patent (10) Patent No.: US 7,490,539 B2: Ma (45) Date of Patent: Feb. 17, 2009Document18 pagesUnited States Patent (10) Patent No.: US 7,490,539 B2: Ma (45) Date of Patent: Feb. 17, 2009Mary HullNo ratings yet

- US7617715Document13 pagesUS7617715Saeed Aba ateNo ratings yet

- United States Patent (10) Patent No.: US 7.467,604 B1: Werner Et Al. (45) Date of Patent: Dec. 23, 2008Document22 pagesUnited States Patent (10) Patent No.: US 7.467,604 B1: Werner Et Al. (45) Date of Patent: Dec. 23, 2008BobNo ratings yet

- United States Patent: Hughes Et Al. (45) Date of Patent: Aug. 2, 2011Document14 pagesUnited States Patent: Hughes Et Al. (45) Date of Patent: Aug. 2, 2011Daniel ChudNo ratings yet

- Dome Hubs - Us9328502Document13 pagesDome Hubs - Us9328502ca.lalamaNo ratings yet

- US9005048Document20 pagesUS9005048Pardeep SharmaNo ratings yet

- US7059434Document18 pagesUS7059434Baiuliang BaiuliangNo ratings yet

- Sanitary Mixing AssemblyDocument9 pagesSanitary Mixing AssemblyatolosaNo ratings yet

- US8069593Document9 pagesUS8069593PUVAN TSTNo ratings yet

- United States Patent: (12) (10) Patent No.: US 8,075,651 B2Document11 pagesUnited States Patent: (12) (10) Patent No.: US 8,075,651 B2maaathanNo ratings yet

- United States Patent (10) Patent No.: US 8,733,508 B2Document12 pagesUnited States Patent (10) Patent No.: US 8,733,508 B2lalit PatilNo ratings yet

- United States Patent (10) Patent No.: US 7,681,342 B2: Choi (45) Date of Patent: Mar. 23, 2010Document20 pagesUnited States Patent (10) Patent No.: US 7,681,342 B2: Choi (45) Date of Patent: Mar. 23, 2010Ronan RojasNo ratings yet

- Us 6703545Document7 pagesUs 6703545Rubens Francisco MoreteNo ratings yet

- US8690637Document13 pagesUS8690637Sandeep SNo ratings yet

- US7596959Document48 pagesUS7596959Yu An ShihNo ratings yet

- Wolf - 2013 - Gasoline Deposit Control Additive CompositionDocument9 pagesWolf - 2013 - Gasoline Deposit Control Additive CompositionCitlali MoraNo ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument6 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentPriyankaNo ratings yet

- Us6547055 Patente UsaDocument12 pagesUs6547055 Patente UsaLuis Peralta GuzmanNo ratings yet

- Us 7908972Document23 pagesUs 7908972Abas NjarkhatirNo ratings yet

- US7094341Document31 pagesUS7094341Diego RossoNo ratings yet

- United States Patent (10) Patent No.: US 7,229,132 B2: Meeker Et Al. (45) Date of Patent: Jun. 12, 2007Document21 pagesUnited States Patent (10) Patent No.: US 7,229,132 B2: Meeker Et Al. (45) Date of Patent: Jun. 12, 2007dylan tikoyNo ratings yet

- United States Patent (10) Patent No.: US 7.587,842 B2: Tajiri Et Al. (45) Date of Patent: Sep. 15, 2009Document11 pagesUnited States Patent (10) Patent No.: US 7.587,842 B2: Tajiri Et Al. (45) Date of Patent: Sep. 15, 2009emre yıldırımNo ratings yet

- United States Patent (10) Patent No.: US 8,083,653 B2Document18 pagesUnited States Patent (10) Patent No.: US 8,083,653 B2Alex MungaiNo ratings yet

- United States Patent (10) Patent No.: Us 7,517,506 B2: Poh (45) Date of Patent: Apr. 14, 2009Document7 pagesUnited States Patent (10) Patent No.: Us 7,517,506 B2: Poh (45) Date of Patent: Apr. 14, 2009Mary Grace VelitarioNo ratings yet

- Brevet 2 Filetare VartejDocument11 pagesBrevet 2 Filetare VartejirinaNo ratings yet

- United States Patent: Anderson Et Al. (45) Date of Patent: Feb. 22, 2005Document19 pagesUnited States Patent: Anderson Et Al. (45) Date of Patent: Feb. 22, 2005santosh mhetreNo ratings yet

- United States Patent: Jan. 17, 2006 Phillips Et AlDocument10 pagesUnited States Patent: Jan. 17, 2006 Phillips Et AlFajar BarkahNo ratings yet

- US7178757Document18 pagesUS7178757wen longNo ratings yet

- United States Patent: (10) Patent No.: US 6,226,947 B1Document15 pagesUnited States Patent: (10) Patent No.: US 6,226,947 B1Mary HullNo ratings yet

- US8413764 - Ladder Mechanism PatentDocument15 pagesUS8413764 - Ladder Mechanism PatentEzgi DemirtaşNo ratings yet

- Sizii: (12) United States PatentDocument10 pagesSizii: (12) United States PatentrakkaNo ratings yet

- Mold CastingDocument22 pagesMold CastingDicky MadikatamaNo ratings yet

- Aviation Weather Handbook (2024): FAA-H-8083-28From EverandAviation Weather Handbook (2024): FAA-H-8083-28No ratings yet

- 02 Chapter 2Document48 pages02 Chapter 2Pranay PandeyNo ratings yet

- Educ 109 Ulo 8-9Document32 pagesEduc 109 Ulo 8-9Rhealyn RobledoNo ratings yet

- Lab 12Document16 pagesLab 12Miguel MikeNo ratings yet

- User Manual For TOTP System: Submitted byDocument9 pagesUser Manual For TOTP System: Submitted byNidhal AmanNo ratings yet

- 5) Freshmen Sem 2 - Skills Employability (Sas)Document5 pages5) Freshmen Sem 2 - Skills Employability (Sas)Crislyn Jilou Bugas AdlawanNo ratings yet

- EPACII PCP Operational ManualDocument118 pagesEPACII PCP Operational ManualSergey ZaytsevNo ratings yet

- FactoryTalk Historian SE - PI Web Services vs. PI Web APIDocument5 pagesFactoryTalk Historian SE - PI Web Services vs. PI Web APIDiegoFonsecaNo ratings yet

- Recal 2019.Document27 pagesRecal 2019.mussab100% (2)

- Qanda 2023 CommDocument451 pagesQanda 2023 CommJoe Soliman100% (2)

- 7.7.1 PROFIBUS FMS With SIMATIC NET Software 05/2000 + SP2Document56 pages7.7.1 PROFIBUS FMS With SIMATIC NET Software 05/2000 + SP2SaasiNo ratings yet

- Rega Planet 2000 ManualDocument4 pagesRega Planet 2000 ManualjamocasNo ratings yet

- NSDL Conso File FVU Error Code ListDocument22 pagesNSDL Conso File FVU Error Code Listlekireddy33% (9)

- Arslan 20 Bba 11Document11 pagesArslan 20 Bba 11Arslan Ahmed SoomroNo ratings yet

- Disjuntor SF1 - Dados ElétricosDocument1 pageDisjuntor SF1 - Dados ElétricosotavioalcaldeNo ratings yet

- SDP-Circular Kannada UpdatedDocument1 pageSDP-Circular Kannada UpdatedmathibettuNo ratings yet

- Forest Fire Prevention Management PDFDocument234 pagesForest Fire Prevention Management PDFSanjiv KubalNo ratings yet

- APSC Mains GS5 Syllabus Topic ListDocument11 pagesAPSC Mains GS5 Syllabus Topic ListAdhish Bipul BarmanNo ratings yet

- Diesel Power Plant PresentationDocument30 pagesDiesel Power Plant Presentationjlaguilar67% (3)

- SCB N KingfiherDocument7 pagesSCB N KingfiherSergel Capsule100% (1)

- GHMC taxGHMC TAXDocument12 pagesGHMC taxGHMC TAXpoornima_npNo ratings yet

- Gasket Constants For The LaymanDocument4 pagesGasket Constants For The LaymanBruno AguilarNo ratings yet

- Roa, Jr. vs. Court of AppealsDocument1 pageRoa, Jr. vs. Court of AppealsPio Guieb AguilarNo ratings yet

- Merchant Banking (In The Light of SEBI (Merchat Bankers) Regulations, 1992)Document38 pagesMerchant Banking (In The Light of SEBI (Merchat Bankers) Regulations, 1992)Parul PrasadNo ratings yet

- JWT Spring Boot ExampleDocument9 pagesJWT Spring Boot Exampleaaaa100% (1)

- LCE Decline To Issue Preventive SuspensionDocument4 pagesLCE Decline To Issue Preventive SuspensionJem YuloNo ratings yet

- Hybrid GrandglowDocument5 pagesHybrid Grandglowmohsan bilalNo ratings yet

- CH. 1 SignalsDocument29 pagesCH. 1 SignalsSohini ChakrabortyNo ratings yet

- Operations Management 10Th Edition Nigel Slack Full ChapterDocument67 pagesOperations Management 10Th Edition Nigel Slack Full Chapterrose.rios155100% (7)

- Biodiversity Management PlanDocument55 pagesBiodiversity Management Planshamroz khanNo ratings yet

- Data Communication Concepts: Dr. Shuchita Upadhyaya Bhasin Professor Department of Computer Science & ApplicationsDocument14 pagesData Communication Concepts: Dr. Shuchita Upadhyaya Bhasin Professor Department of Computer Science & ApplicationsRaj VermaNo ratings yet