Professional Documents

Culture Documents

NDD010 MCS Type B Foam Chambers PDF

NDD010 MCS Type B Foam Chambers PDF

Uploaded by

Iskandar Zulkarnain HasibuanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NDD010 MCS Type B Foam Chambers PDF

NDD010 MCS Type B Foam Chambers PDF

Uploaded by

Iskandar Zulkarnain HasibuanCopyright:

Available Formats

MCS TYPE B

FOAM MAKER & FOAM CHAMBER

NDD010

Approvals: UL, ULC

Superior Foam Quality

Operates At 30 PSI (2.1 bar) Minimum

Tool Free Maintenance

Corrosion Resistant Polyester Finish

Double Aeration Foam Maker

Description Features The aerated foam solution then

passes through a series of precisely

The MCS Type B Foam Maker and Foam • Four Sizes

designed mechanical agitation devices

Chamber is designed to introduce • Superior Foam Quality

which maximize foam expansion, and

expanded foam directly onto the • Operates at 30 PSI (2.1 bar) minimum

enhance drainage time. The expanded

surface of a flammable or combustible • Tool Free Maintenance

foam then passes into the foam

liquid for fire extinguishment and/or • Corrosion Resistant Polyester Finish

chamber body which is designed to

vapor suppression. Classified as a Type

Operation further enhance expansion, and reduce

II discharge device in accordance with

the velocity of the foam stream prior to

NFPA Standard 11, foam chambers MCS Type B Foam Chambers produce

discharge onto the product surface.

deliver low expansion foam directly foam by introducing air into the foam

onto the fuel surface with a minimum of solution stream. Foam solution can The foam chamber is fitted with a

foam submergence and fuel agitation. be delivered to the foam chamber in frangible vapor seal located at the inlet

Minimizing submergence and agitation a variety of ways as previously noted. to the discharge pipe connected to the

increases the effectiveness of the foam The inlet of the foam maker is fitted storage tank. The vapor seal prevents

blanket, resulting in more efficient with a factory installed high efficiency the escape of product vapors into

operation, and superior extinguishing venturi jet which is designed to draw air the atmosphere and/or foam system

capabilities. Foam chambers have the into the foam solution stream. The high piping. The exclusive location of the

added advantage of directing all their efficiency jet produces superior quality vapor seal in the discharge piping, also

flow directly onto the product surface foam, and results in operating pressures prevents the escape of product into the

regardless of weather conditions, for 25% lower than previously possible, foam chamber in the event of an overfill

the most effective utilization of foam now as low as 30 PSI (2.1 bar). situation.

resources. Foam chambers have a long

Air is drawn into the foam maker The flow of expanded foam ruptures the

history of timely and safe control of

through a series of annular holes vapor seal at a predetermined pressure,

numerous incidents.

located around the integral foam allowing the foam to enter the tank.

Foam chambers are compatible with maker. To prevent obstruction, the air As the foam exits the foam chamber, it

all types of foam concentrate; protein, inlet holes are protected by a stainless impacts the deflector which is designed

fluoroprotein, AFFF, and AR-AFFF. They steel screen selected with a perforation to direct the flow against the wall of the

are generally installed on the side wall size designed to exclude most known tank to reduce the amount of foam

of vertical storage tanks above the nesting birds and insects. The open submergence into the product, as well

maximum product level. Piping coupled area of the screen is designed to be as dispersing it to each side for more

to the unit can be linked to a fixed foam no less than the total area of the foam complete coverage.

proportioning system, or terminated maker air inlet holes.

Approvals and Listings

a safe distance from the tank, where

foam solution can be delivered via UL Listed

mobile fire apparatus or portable foam ULC Listed

proportioning equipment.

12/18 NDD010 (Rev Q) Page 1 of 6

MCS TYPE B

FOAM MAKER & FOAM CHAMBER

NDD010

Specifications installed, and without damaging the and pressure have been determined,

seal. During testing the vapor seal shall they can be plugged into the formula

The entire assembly shall consist of the

prevent test solution from entering shown on page 3 to determine the

foam chamber body with integral foam

the storage tank. No external sealing actual orifice size required. Once the

maker, factory installed integral venturi

devices shall be necessary to accomplish orifice size is determined, confirm that

style jet, deflector, deflector mounting

testing. A drain shall be provided in the it falls within the orifice range shown

hardware, and gaskets. A lifting lug

bottom of the foam chamber to allow for the selected size of foam maker. The

designed to support the weight of the

for draining of the test solution. The required flow rate and inlet pressure

assembly shall be provided. The foam

drain shall be operable without tools. must be specified when ordering.

deflector shall be available in split or

shallow configurations, and shall be Deflectors are available in split,

Interchangeability

suitable for bolting. The foam chamber shallow or split shallow configurations.

body shall contain a frangible vapor seal MCS Type B Foam Makers and Foam The split deflector is designed to

positioned to prevent condensation Chambers are dimensionally equivalent accommodate most installations,

and product vapors from entering the to prior Model MCS and MCS Type A and can be installed from outside the

foam chamber body. The vapor seal Foam Makers and Foam Chambers. tank. Shallow deflectors are intended

shall be designed to rupture with a All customer connection points are for use when the tank is fitted with

minimum inlet pressure of 30 PSI (2.1 identical, eliminating the need for a floating roof which may pass over

bar) at the inlet to the foam chamber piping modifications when replacing the deflector, minimizing possible

and shall withstand a maximum back earlier versions. Orifice plates and vapor damage to the roof seals. Shallow

pressure of 1.0 PSI (0.07 bar), or equal seals from previous models are not deflectors must be installed from inside

to 27 in. (686 mm) of water, as specified compatible with MCS Type B. the tank. The split shallow deflector

by API for welded storage tanks. The is designed to accommodate most

Selection internal floating roof applications and

vapor seal is fabricated of graphite with

a Teflon seal and is compatible with a MCS Type B Foam Makers and Foam can be installed from the outside of the

wide range of corrosive chemicals. The Chambers are available in four sizes to tank. All Deflector mounting hardware

vapor seal shall be a fully self-contained suit most requirements. Refer to the is included.

disc and shall not require adhesives, National Foam Engineering Manual,

sealants, or loose gaskets to accomplish and the applicable design standards Materials of Construction

sealing. The vapor seal shall be held in and local codes to determine the Body ..........................................Carbon Steel

place by a brass holder. required flow rate for the application. Jet/Receiver ........................................... Brass

Access to the frangible vapor seal shall The foam maker can be sized to provide Deflector ..................................Carbon Steel

be accomplished through a removable any flow and pressure that falls within Drain Assembly .................................... Brass

top cover, without the need to remove the operational limits of the foam Flange Gaskets .....High Temp. Synthetic

retaining nuts. All nuts shall be designed maker. To select the correct size of Fiber w/ Nitrile or

to be captive to prevent loss. foam maker, see the flow range charts EPDM Binders

All cover and vapor seal retaining on page 4, which show the operational Vapor Seal Disk ...Teflon Coated Graphite

hardware shall consist of stainless steel limits of each foam maker. If the flow Vapor Seal Holder................................ Brass

studs with brass nuts to resist galling, rate falls within the range of more than Vapor Seal Gasket.............................. Teflon

seizing, and corrosion. All carbon steel one unit, either size may be utilized. To Wing Nuts.................... Brass w/SS Washer

parts shall be abrasive blasted and determine the correct orifice, you must Internal Studs and Nuts......... Zinc Plated

coated with a fused polyester powder determine the design flow required Air Strainer ...........................Stainless Steel

finish. and the available pressure at the foam Finish:

maker inlet. Generally, the higher the • Foam Chamber Body and Deflector:

The foam maker and foam chamber

operating pressure, the better the Abrasive blast to SSPC-SP6

shall be UL Listed for operation as low

quality of the foam produced. The better Chemical wash, rinse and seal.

as 30 PSI (2.1 bar).

the foam quality, the more efficient the Oven baked fusion coated

It shall be possible to test the foam operation, therefore, it is beneficial to polyester, 3 mils DFT.

maker and foam chamber assembly utilize the highest operating pressure

by removing the lid. Testing shall be • All Other Components:

economically feasible. After the flow

accomplished with the vapor seal Natural Finish

Page 2 of 6 12/18 NDD010 (Rev Q)

MCS TYPE B

FOAM MAKER & FOAM CHAMBER

NDD010

Split Deflector Shallow Deflector Split Shallow Deflector

FOAM CHAMBER ORDERING INFORMATION

SIZE WITH SPLIT DEFLECTOR WITH SHALLOW DEFLECTOR SPLIT SHALLOW DEFLECTOR ONLY

MCS-9 1253-1651-2 1253-1651-3 1253-1763-1

MCS-17 1253-2651-2 1253-2651-3 1253-1765-1

MCS-33 1253-3651-2 1253-3651-3 1253-1767-1

MCS-55 1253-4651-2 1253-4651-3 1253-1769-1

When ordering please supply the following information: tank identification, tank size and type, product being stored, flow and inlet

pressure at each foam chamber, deflector type, foam concentrate type, and percentage of concentration.

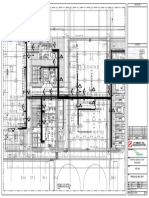

REMOVABLE LID

DEFLECTOR

FOAM CHAMBER

LABEL TANK

AIR STRAINER SHELL

COMPANION

FLANGES

FOAM SOLUTION

RISER

COMPANION

FLANGES

COMPANION

FLANGES

SWING JOINT

PLUG

SLOPE FOR DRAINAGE

FOAM CHAMBER INSTALLATION

12/18 NDD010 (Rev Q) Page 3 of 6

MCS TYPE B

FOAM MAKER & FOAM CHAMBER

NDD010

Orifice Jet Sizing - MCS Type B Foam Makers

All foam makers shall be sized using the following formula: Legend:

Q - Flow in GPM (LPM)

English Metric D - Diameter of Jet in Inches (MM)

C - Coefficient of Discharge for the

Q Q

D= D= Jet (See Orifice Jet Sizing Chart)

29.8 x C x P 0.6659 x C x P P - Pressure in PSI (BAR)

The following are the maximum and minimum jet sizes for each foam maker size and the C factor for each jet:

MCS-9 (C = 0.920) English Metric

Smallest Jet------ 0.504” (12.8016 mm) Dia ............................38.1 GPM .......@....... 30 PSI 144.4 LPM .......@....... 2.068 BAR

49.1 GPM .......@....... 50 PSI 185.9 LPM .......@....... 3.447 BAR

62.2 GPM .......@....... 80 PSI 235.5 LPM .......@....... 5.516 BAR

69.6 GPM .......@....... 100 PSI 263.6 LPM .......@....... 6.895 BAR

Largest Jet ------- 0.760” (19.3040 mm) Dia ............................86.7 GPM .......@....... 30 PSI 328.3 LPM .......@....... 2.068 BAR

111.8 GPM .......@....... 50 PSI 423.2 LPM .......@....... 3.447 BAR

141.6 GPM .......@....... 80 PSI 536.0 LPM .......@....... 5.516 BAR

158.4 GPM .......@....... 100 PSI 599.4 LPM .......@....... 6.895 BAR

MCS-17 (C = 0.870)

Smallest Jet------ 0.721” (18.3134 mm) Dia ............................73.8 GPM .......@....... 30 PSI 279.4 LPM .......@....... 2.068 BAR

95.2 GPM .......@....... 50 PSI 360.4 LPM .......@....... 3.447 BAR

120.5 GPM .......@....... 80 PSI 456.1 LPM .......@....... 5.516 BAR

134.8 GPM .......@....... 100 PSI 510.2 LPM .......@....... 6.895 BAR

Largest Jet ------- 1.051” (26.6954 mm) Dia. .........................156.9 GPM .......@....... 30 PSI 593.8 LPM .......@....... 2.068 BAR

202.4 GPM .......@....... 50 PSI 766.1 LPM .......@....... 3.447 BAR

256.2 GPM .......@....... 80 PSI 969.8 LPM .......@....... 5.516 BAR

286.4 GPM .......@....... 100 PSI 1084.1 LPM .......@....... 6.895 BAR

MCS-33 (C = 0.973)

Smallest Jet------ 0.980” (24.8920 mm) Dia ..........................152.5 GPM .......@....... 30 PSI 577.4 LPM .......@....... 2.068 BAR

196.8 GPM .......@....... 50 PSI 745.0 LPM .......@....... 3.447 BAR

249.0 GPM .......@....... 80 PSI 942.6 LPM .......@....... 5.516 BAR

278.5 GPM .......@....... 100 PSI 1054.1 LPM .......@....... 6.895 BAR

Largest Jet ------- 1.530” (39.8620 mm) Dia ..........................371.8 GPM .......@....... 30 PSI 1407.3 LPM .......@....... 2.068 BAR

479.6 GPM .......@....... 50 PSI 1815.5 LPM .......@....... 3.447 BAR

607.0 GPM .......@....... 80 PSI 2297.7 LPM .......@....... 5.516 BAR

678.8 GPM .......@....... 100 PSI 2569.4 LPM .......@....... 6.895 BAR

MCS-55 (C = 0.880)

Smallest Jet------ 1.457” (37.0078 mm) Dia ..........................304.9 GPM .......@....... 30 PSI 1154.2 LPM .......@....... 2.068 BAR

393.6 GPM .......@....... 50 PSI 1489.9 LPM .......@....... 3.447 BAR

497.9 GPM .......@....... 80 PSI 1884.7 LPM .......@....... 5.516 BAR

556.7 GPM .......@....... 100 PSI 2107.4 LPM .......@....... 6.895 BAR

Largest Jet ------- 1.987” (50.4698 mm) Dia ..........................567.1 GPM .......@....... 30 PSI 2146.7 LPM .......@....... 2.068 BAR

731.6 GPM .......@....... 50 PSI 2769.4 LPM .......@....... 3.447 BAR

926.0 GPM .......@....... 80 PSI 3505.2 LPM .......@....... 5.516 BAR

1035.4 GPM .......@....... 100 PSI 3919.4 LPM .......@....... 6.895 BAR

Page 4 of 6 12/18 NDD010 (Rev Q)

MCS TYPE B

FOAM MAKER & FOAM CHAMBER

NDD010

Vapor Seal Ordering Information Foam chambers shipped prior to with holder. Future replacements only

October 2003 have a vapor seal require the replacement of the vapor

Vapor Seal Disks are available with or

cartridge (graphite vapor seal, Viton seal after installation of the brass holder.

without the holder. Foam chambers

seal & stainless steel holder) which See pages 5 and 6 for Vapor Seal and

shipped after October 2003 are

is no longer available. Replacement Holder Mounting.

provided with the brass vapor seal

vapor seals for these chambers require

holder and require the purchase of only

the purchase of the vapor seal kit

the vapor seal.

MOUNTING JACKSCREW

(IN COMPRESSION)

FOR MCS-17, MCS-33 & MCS-55 VAPOR SEAL HOLDER VAPOR SEAL HOLDER

DISK DISK

JACKSCREWS

MOUNTING STUD MOUNTING STUD

WITH WITH

BRASS WINGNUT BRASS WINGNUT

(IN TENSION) HOLDER (IN TENSION) HOLDER

MCS-17, MCS-33 & MCS-55 MCS-9

VAPOR SEAL & HOLDER MOUNTING VAPOR SEAL & HOLDER MOUNTING

VAPOR SEAL ORDERING INFORMATION

COMPATIBLE VAPOR SEAL KIT

SIZE JET ORIFICE SIZE VAPOR SEAL DISK WITH HOLDER

MCS-9 Low Flow .504 - .620 1253-1840-7 1253-1840-5

MCS-9 Hi Flow .621 - .760 1253-1840-8 1253-1840-6

MCS-17 ALL SIZES 1253-2840-7 1253-2840-6

MCS-33 ALL SIZES 1253-3840-7 1253-3840-6

MCS-55 ALL SIZES 1253-4840-7 1253-4840-6

Foam Chamber Accessory - Screen

Guard

The Foam Chamber Screen Guard is SCREEN GUARD

designed to prevent birds and animals ORDERING INFORMATION

SCREEN

from entering the foam chamber GUARD SCREEN GUARD

ASSEMBLY

through the chamber discharge flange FOAM CHAMBER PART NUMBER

opening. NOTE: The Screen Guard is THUMB MCS-9 1253-1920-3

used on floating roof applications SCREW

where the Vapor Seal is not used. The MCS-17 1253-2920-3

FOAM

Screen Guard is ordered separately CHAMBER MCS-33 1253-3920-3

DISCHARGE

from the foam chamber. FLANGE MCS-55 1253-4920-3

12/18 NDD010 (Rev Q) Page 5 of 6

MCS TYPE B

FOAM MAKER & FOAM CHAMBER

NDD010

D J P

TANK SHELL

E

STUD FLANGE ½"

D

(SPLIT DEFLECTOR MODELS)

REMOVABLE LID JACKSCREW

INTERNAL FOAM TUBE

(QTY. - 2)

LID CABLE TOP ANGLE

OF TANK

H

K

A K

M

LIFTING

A LUG N

SPLIT A

DEFLECTOR

CHAMBER

BODY DRAIN SHALLOW

L DEFLECTOR

B JET/RECEIVER

LABEL

TANK VAPOR SEAL

AIR SHELL & HOLDER

STRAINER ASSEMBLY

G - 150# FF FLANGE 3/8 [10 MM] MCS-9 F

F

SOLUTION INLET 1/2 [13 MM] MCS-17, 33, 55

(BOLT HOLES TO

Note:

STRADDLE CENTERLINE) All dimensions are in inches (MM)

FOAM CHAMBER SECTION

FOAM CHAMBER WITH SPLIT DEFLECTOR WITH SHALLOW DEFLECTOR

TOP ANGLE TOP ANGLE

OUTLINE OF DEFLECTOR SPLIT DEFLECTOR

OUTLINE OF DEFLECTOR

MOUNTING TABS MOUNTING TAB

MOUNTING TABS

Rø Rø SHALLOW

B.C. DEFLECTOR

S ø B.C.

MOUNTING

Tø

Tø TAB

FLANGE FLANGE

OUTLINE OUTLINE S ø B.C.

DETAIL A DETAIL B

TANK CUT FOR MCS-9, MCS-17 & MCS-33 FOAM CHAMBERS TANK CUT FOR MCS-55 FOAM CHAMBER

ONLY ONLY

SHALLOW AND SPLIT DEFLECTOR MOUNTING SHALLOW AND SPLIT DEFLECTOR MOUNTING

TYPE A B C D E F G H J K L M N P R S T WEIGHT

MCS-9 29-1/2 15-1/4 5-1/2 11 6-1/2 7 2-1/2 4 12 8 1-11/16 5-3/4 14-1/4 8-1/2 4-1/2 7-1/2 3/4 83

Type B (479) (387) (140) (279) (165) (178) (64) (102) (305) (203) (43) (146) (362) (216) (114) (191) (19) (37.6)

MCS-17 35-13/16 19-9/16 6-1/2 13 7-1/2 9 3 4-1/2 18 9-1/2 1-11/16 6-1/2 16 12 6-5/8 9-1/2 7/8 125

Type B (910) (497) (165) (330) (191) (229) (76) (114) (457) (241) (43) (165) (406) (305) (168) (241) (22) (56.7)

MCS-33 39-5/16 20-13/16 7-1/2 15 8-1/2 10 4 6 24 11 1-11/16 8 24-1/2 16 8-5/8 11-3/4 7/8 188

Type B (999) (529) (191) (381) (216) (254) (102) (152) (610) (279) (43) (203) (622) (406) (219) (298) (22) (85.3)

MCS-55 46-5/16 25-7/16 8-1/2 17 8-1/2 12 6 6-3/4 30 12 3-1/2 9 23-1/4 20 10-3/4 14-1/4 1 285

Type B (1176) (646) (216) (432) (216) (305) (152) (171) (762) (305) (89) (229) (591) (508) (273) (362) (25) (129.3)

Page 6 of 6 12/18 NDD010 (Rev Q)

National Foam National Foam operates a continuous program of product development. The

350 East Union Street, West Chester, PA 19382, USA right is therefore reserved to modify any specification without prior notice

and National Foam should be contacted to ensure that the current issues of all

24hr RED ALERT® : 610-363-1400 • Fax: 610-431-7084 technical data sheets are used.

www.nationalfoam.com © National Foam

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- C1 1 PDFDocument114 pagesC1 1 PDFVidaurri100% (1)

- Urs For Purified Water SystemsDocument3 pagesUrs For Purified Water SystemsIskandar Zulkarnain Hasibuan0% (1)

- 2052 9001 040 - Osd2 02Document180 pages2052 9001 040 - Osd2 02babubhaiyya4211No ratings yet

- 2020B CNC Machine ManualDocument33 pages2020B CNC Machine ManualFelipeAndrésLondoñoGrandaNo ratings yet

- Test Report: CERT.1909041043Document4 pagesTest Report: CERT.1909041043Iskandar Zulkarnain HasibuanNo ratings yet

- Technical Data: 1. DescriptionDocument5 pagesTechnical Data: 1. DescriptionIskandar Zulkarnain HasibuanNo ratings yet

- Quantitative Risk Assessment Final Report: NW Innovation WorksDocument63 pagesQuantitative Risk Assessment Final Report: NW Innovation WorksIskandar Zulkarnain HasibuanNo ratings yet

- Guard For ALLDocument9 pagesGuard For ALLIskandar Zulkarnain HasibuanNo ratings yet

- Different Between Nm3Document11 pagesDifferent Between Nm3Iskandar Zulkarnain HasibuanNo ratings yet

- Air Receiver SizingDocument3 pagesAir Receiver SizingIskandar Zulkarnain HasibuanNo ratings yet

- Bill QuantityDocument29 pagesBill QuantityIskandar Zulkarnain HasibuanNo ratings yet

- Specification: Category: Pump Trap Model: PT-104Document2 pagesSpecification: Category: Pump Trap Model: PT-104Iskandar Zulkarnain HasibuanNo ratings yet

- Keyplan: Issued For Tender Ygm Izh 0 12.06.2015Document1 pageKeyplan: Issued For Tender Ygm Izh 0 12.06.2015Iskandar Zulkarnain HasibuanNo ratings yet

- Bayer Healthcare: Issued For Tender QC Lab Renovation ProjectDocument1 pageBayer Healthcare: Issued For Tender QC Lab Renovation ProjectIskandar Zulkarnain HasibuanNo ratings yet

- Price List FKK 2013Document1 pagePrice List FKK 2013Iskandar Zulkarnain HasibuanNo ratings yet

- Price Lis Pipa Besi 240615Document6 pagesPrice Lis Pipa Besi 240615Iskandar Zulkarnain HasibuanNo ratings yet

- Psa Gaseous Nitrogen892 21857Document6 pagesPsa Gaseous Nitrogen892 21857Iskandar Zulkarnain HasibuanNo ratings yet

- Ga 37-75 PDFDocument9 pagesGa 37-75 PDFIskandar Zulkarnain HasibuanNo ratings yet

- Weight of M.S. PipeDocument14 pagesWeight of M.S. PipeRajat BaghelNo ratings yet

- Supplementary Learning Materials For Junior High School LearnersDocument10 pagesSupplementary Learning Materials For Junior High School LearnersLloyd CajuiganNo ratings yet

- Master Unit Manual PDFDocument170 pagesMaster Unit Manual PDFfar333100% (1)

- Pressure Distribution of TAM Grouting Under A Deep Excavation in Silty SoilDocument11 pagesPressure Distribution of TAM Grouting Under A Deep Excavation in Silty SoilVetriselvan ArumugamNo ratings yet

- Objective: Performance Analysis of RL High Pass FilterDocument2 pagesObjective: Performance Analysis of RL High Pass FilterMuhammed FahdNo ratings yet

- Trickling FiltersDocument16 pagesTrickling FiltersGunnar AgarwalNo ratings yet

- Design For Lifting Pad EyeDocument4 pagesDesign For Lifting Pad EyeAsaru Deen0% (1)

- Open TutorialDocument2 pagesOpen Tutorialeph86% (7)

- WM RF User Parameter SetupDocument4 pagesWM RF User Parameter SetupAbhijit_batNo ratings yet

- Introduction of Validation and QualificationDocument24 pagesIntroduction of Validation and QualificationMuhamad Bima Muria50% (2)

- ACCC Conductor Installation Guidelines 20181Document89 pagesACCC Conductor Installation Guidelines 20181EDGARDO DIAZGRANADOSNo ratings yet

- Answer The Following Problems by Choosing The Letter That Corresponds To Your AnswerDocument3 pagesAnswer The Following Problems by Choosing The Letter That Corresponds To Your AnswerRixer PrietoNo ratings yet

- Single Replacement Reactions LabDocument3 pagesSingle Replacement Reactions Labapi-241225667No ratings yet

- Autoranging Digital Multimeter: Owner'S ManualDocument19 pagesAutoranging Digital Multimeter: Owner'S ManualtarakhovskyNo ratings yet

- IuPS Over ATM Integration SoPDocument10 pagesIuPS Over ATM Integration SoPkwidyaNo ratings yet

- Ce 8403 Applied Hydraulic Engineering Question Bank: S. No Questions Year Unit IV - Turbines Part ADocument9 pagesCe 8403 Applied Hydraulic Engineering Question Bank: S. No Questions Year Unit IV - Turbines Part Asuriya saravananNo ratings yet

- 3PAR Compatibility CheklistDocument2 pages3PAR Compatibility CheklistS Radhakrishna BhandaryNo ratings yet

- Power SystemDocument52 pagesPower Systemtebelayhabitamu12No ratings yet

- Civil QuantitiesDocument9 pagesCivil QuantitiesJonas Kañombi MukwatuNo ratings yet

- Safety at Workplace: Safety Start With YouDocument27 pagesSafety at Workplace: Safety Start With YouRosel SariegoNo ratings yet

- PG GovernorsDocument4 pagesPG GovernorsPj EastonNo ratings yet

- Ramakrishna Myaka: Profile SummaryDocument2 pagesRamakrishna Myaka: Profile SummaryRamakrishna MyakaNo ratings yet

- Bajaj Luminaires - Price - List PDFDocument70 pagesBajaj Luminaires - Price - List PDFArjun M Kumar80% (5)

- Assessment of Air Preheater Effects On Power Plant EfficiencyDocument38 pagesAssessment of Air Preheater Effects On Power Plant Efficiencysugianto barusNo ratings yet

- Part2 Maxwell Ultracapacitors TechnologyAtGlanceDocument80 pagesPart2 Maxwell Ultracapacitors TechnologyAtGlanceruhulNo ratings yet

- KLH - Component Catalogue For Cross Laminated Timber StructuresDocument28 pagesKLH - Component Catalogue For Cross Laminated Timber StructuresIuliaNo ratings yet

- Formulas FinalDocument2 pagesFormulas FinalTam AdıNo ratings yet