Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

6 views----

----

Uploaded by

Akbarlollo

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- United States Patent: MG, Christopher Lbecke, (58) Field of Classification SearchDocument11 pagesUnited States Patent: MG, Christopher Lbecke, (58) Field of Classification SearchAkbarNo ratings yet

- Figil: %nen 2NES 3Document3 pagesFigil: %nen 2NES 3AkbarNo ratings yet

- US1957244ADocument2 pagesUS1957244AAkbarNo ratings yet

- Daftar Pustaka KorosiDocument1 pageDaftar Pustaka KorosiAkbarNo ratings yet

- Azas Teknik Kimia 1 122111Document2 pagesAzas Teknik Kimia 1 122111Akbar100% (1)

----

----

Uploaded by

Akbar0 ratings0% found this document useful (0 votes)

6 views7 pageslollo

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentlollo

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

6 views7 pages----

----

Uploaded by

Akbarlollo

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 7

United States Patent 1)

Petrosky

[54] MANUFACTURE OF METHYL CHLORIDE

BY HYDROCHLORINATING METHANOL,

USING A SPLIT METHANOL FEED

[75] Inventor: Jimmy T, Petrosky, Wichita, Kans.

73] Assignee: Vulcan Materials Company,

Birmingham, Als.

[21] Appl. No. 279,093

[22] Filed: Dee. 2, 1988

[51] Int, CLs .. COTE 17/16

52] US.Cl. . 510/258

[58] Field of Search ..

(56) ‘References Cited

U.S. PATENT DOCUMENTS

026,131 12/1935. Klein eta

2091,986 9/1937 Holt etal.

2A2L441 6/1987 Thronson et al.

2.887.484 8/1958 Kolker

3,981,938 9/1976 Steele etal.

FOREIGN PATENT DOCUMENTS

2447551 4/1975 Fed. Rep. of Germany

1560892 2/1980 United Kingdom

OTHER PUBLICATIONS

“Kirk-Othmer Encyclopedia of Chemical Technol-

ogy”, vol. 3, p. 741, (1948).

‘570/258, 259

4,922,043

May 1, 1990

(11) Patent Number:

[45] Date of Patent:

Vulcan Materials Company, “Manufacture of Chlo-

romethanes from Methyl Alcohol and Chlorine”.

Sconce, “Chlorine, Its Manufacture, Properties and

Uses”, ACS Monograph No. 154, pp. 363-364, and

FIG. 12-6 on p. 365.

Encyclopedia of Chemical Processing and Design, vol.

8, pp. 256-259 (1979).

Vulcan Materials Company In-House literature

searches dated Jun. 17, 1982; Jan. 7, 1987; and Jul. 23,

1987.

Primary Examiner—Howard T. Mars

57] ABSTRACT

Ina process for making methyl chloride by the catalytic,

hydrochlorination of methanol in the liquid phase, the

common formation of unwanted dimethyl ether by-pro-

duct is reduced by conducting the process in at least

two reactors operating in series and by introducing all

or substantially all of the required hydrogen chloride

feed into the first reactor while splitting the introdue-

tion of methanol feed, preferably as a vapor, between oF

among the reactors.

The overall feed ratio of methanol to hydrogen chloride

is in the range between about 0.65 to about 1.0 mol

methanol per mol hydrogen chloride. Aqueous zine

chloride is the preferred catalyst.

5 Claims, 1 Drawing Sheet

US. Patent May 1, 1990 4,922,043

4,922,043

1

MANUFACTURE OF METHYL CHLORIDE BY

HYDROCHLORINATING METHANOL, USING A

‘SPLIT METHANOL FEED

BACKGROUND OF THE INVENTION

|. Field of the Invention

This invention relates to an improved process for

making methyl chloride by reacting methanol with

hydrogen chloride in the presence of a metal chloride

catalyst, eg. zinc chloride. As such a process normally

results in the formation of substantial amounts of di-

methyl ether (DME) as an unwanted by-product, the

improvement is particularly concerned with a method

of reducing such ether formation. 2. Description of the

Prior Art

Methyl chloride has many uses in industry and sci-

ence. For instance, it not only finds wide use as a sol-

vent, extractant, propellant or refrigerant, itis also used

‘as a methylating agent in organic synthesis and, impor-

tantly, as a starting material in the production of dichlo-

romethane, trichloromethane and carbon tetrachloride

by reaction with chloride. Another important use of

‘methyl chloride is as an intermediate in the production

of silicones.

‘A common and economical process for providing

methyl chloride involves the hydrochlorination of

methanol according to the reaction MeOH-+HCl-

—-MeCl+HLO. As it is described, for instance, in the

Encyclopedia of Chemical Processing and Design, Vol.

8, pp 256-9 (1975), this reaction can be carried out using

either a liquid or a solid catalyst. However, the object of

this invention is concerned only withthe reaction when

it is conducted in the liquid phase.

‘The liquid-phase reaction system is usually con-

ducted in an aqueous medium, at or near atmospheric

pressure and at a reaction temperature of from about

100" to about 200° C. Catalysts for the liquid-phase

reaction are water solutions of metal chlorides, such as

ferric chloride or bismuth oxychloride or most prefera-

bly zinc chloride. The reaction has been most com-

monly carried out by bubbling HCI and methanol as a

gaseous mixture through a single reactor or several

reactors operating in parallel, although sometimes the

reactors have been operated in series. In all such con-

ventional cases, however, substantially all ofthe metha-

nol and all of the HCI is fed through a single-feed sys-

tem into the first and in some cases the only reaction

stage. As shown in U.S. Patent 2,847,484, when more

than one reactor is used, the effluent vapors are passed

from the first reactor through a subsequent reactor or

reactors operating in series. The temperature of the

solution and the concentration of catalyst are so main

tained that the water of reaction is continuously vapor-

ized from the reaction mixture along with the methyl

chloride, thereby providing continuous operation. By-

product hydrogen chloride, such as that avsilable from

the chlorination of methane or ethane, can be used.

is generally accompanied by a side reaction wherein

dimethyl ether (DME) is formed from methanol ac-

cording to the equation 2MeOH--DME+H20, the

crude methyl chloride obtained by the hydrochlorina-

tion of methanol contains not only water, unreacted

methanol, and hydrochloric acid but also a substantial

proportion of DME as an impurity. The methanol and

hydrochloric acid are usually removed by scrubbing the

crude methyl chloride vapor with cold water and then

25

30

38

0

4s

”

6

2

with cold dilute sodium hydroxide solution, and the

water and DME are removed by scrubbing with cold

concentrated sulfuric acid. The resulting pure methyl

chloride vapor is compressed, condensed with cold

water, and placed in storage tanks.

‘While removal of DME from the methyl chloride is

readily accomplished by scrubbing with sulfuric acid,

not only isits formation wasteful in terms of greater raw

material costs, but the disposal of unwanted sulfuric

acid-containing DME presents a problem in view of

increasing ecological concerns and resulting restriction

on the disposal of industrial waste streams.

SUMMARY AND OBJECTS OF THE

INVENTION

According to the present invention, when the hydro-

chlorination reaction is carried out in two or more reac-

tors in series, an improvement in performance is ob-

tained by splitting the methanol feed such that only part

of the methanol feed is introduced into the first reactor

together with the gaseous hydrogen chloride feed while

the effluent from the first reactor is fed into the subse-

‘quent reactor or reactors together with the balance of

the methanol and with no or only a small amount of

additional hydrogen chloride.

‘While this novel split-feed arrangement was initially

‘tied in the expectation that it would increase the con-

version of methanol to methyl chloride, surprisingly, no

such increase was found to occur. On the contrary, the

conversion of methanol to methyl chloride remained

substantially unchanged and the total methanol conver-

sion decreased. However, this seeming disadvantage

‘was more than offset by ‘an entirely unexpected and

highly desirable decrease in the conversion of methanol

to DME, resulting in a litle more unreacted methanol

in the reactor effluent but significantly less DME. Of

course, unreacted methanol can easily be recovered

from the effluent and recycled to the reactors.

‘Accordingly, it is an object of this invention to re-

duce raw material costs in the manufacture of methyl

chloride by hydrochlorination of methanol.

It is another object to reduce the production of eco-

logically objectionable by-products, notably DME, in

the manufacture of methyl chloride from methanol.

It is further object to provide an improved process

for making methyl chloride from methanol in a series of

at least two reaction stages, such that the production of

DME is reduced and the amount of sulfuric acid re-

quired as a scrubbing liquid in the process is thereby

also reduced.

These and other objects, as well as the nature and

scope of the invention, and of the manner and process of

using it, including the best mode thereof, are more fully

described in and will become apparent from the follow-

ing specification and claims.

tis to be understood that all parts, concentrations,

percentages, and proportions of materials are expressed

‘throughout ‘on a weight basis unless otherwise indi-

cated.

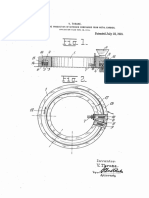

DESCRIPTION OF THE DRAWINGS

‘The drawing is a schematic flow diagram for a pro-

ccess of the invention, comprising two hydrochlorina-

tion reactors in series followed by a plurality of scrub-

bing towers wherein the crude methyl chloride vapor

produced in the reactors is purified prior to recovery.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- United States Patent: MG, Christopher Lbecke, (58) Field of Classification SearchDocument11 pagesUnited States Patent: MG, Christopher Lbecke, (58) Field of Classification SearchAkbarNo ratings yet

- Figil: %nen 2NES 3Document3 pagesFigil: %nen 2NES 3AkbarNo ratings yet

- US1957244ADocument2 pagesUS1957244AAkbarNo ratings yet

- Daftar Pustaka KorosiDocument1 pageDaftar Pustaka KorosiAkbarNo ratings yet

- Azas Teknik Kimia 1 122111Document2 pagesAzas Teknik Kimia 1 122111Akbar100% (1)