Professional Documents

Culture Documents

C and C Certified Denim Manufacturing

C and C Certified Denim Manufacturing

Uploaded by

MADRAS COTTONOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

C and C Certified Denim Manufacturing

C and C Certified Denim Manufacturing

Uploaded by

MADRAS COTTONCopyright:

Available Formats

INTRODUCTION

3. C2C CERTIFIED DENIM: ORCHESTRATING A NETWORK OF PARTNERS

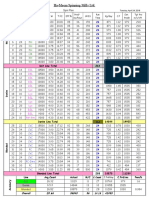

The key challenge in creating Cradle to Cradle Certified™ denim jeans is the complexity of the network

of partners involved. Table 1 below lists the knowledge partners contributing to this project. Table 2 below

highlights the supplier group who made the GOLD Certified denim jeans possible.

Table 1: Overview of knowledge partners on the C2C Certified™ denim jeans project

Partner Role

McDonough Innovation Advice on design and production requirements

McDonough Braungart Design Served as assessor for the C2C CertifiedTM Products Program

Chemistry

Eco Intelligent Growth Served as assessor for the C2C CertifiedTM Products Program

Table 2: Overview of material suppliers involved in the C2C Certified™ denim jeans project

Supplier Part / Process Product provided

Fabric 99% cotton, 1% elastane

98% cotton, 2% elastane

Sewing Thread Cotton (Gold level) and polyester

(Bronze level) sewing thread

Fabric dyes DyStar® Indigo Vat 40% Solu-

tion

Interlining Cotton interlining for waistband

Patch Laser cut jacron patch

Cut-make-trim Product manufacturing

Laundry

Premium Stretch Fiber Environmentally compatible

Stretch Fiber (Roica® V550)

Metal trims Metal buttons

Metal rivets

Pocket lining Organic cotton pocket lining

Various Auxiliaries, printing and laundry Washing chemicals

chemicals Printing chemicals

You might also like

- Levi Strauss and Co Purchasing PresentationDocument18 pagesLevi Strauss and Co Purchasing PresentationCezara GhebosuNo ratings yet

- Dressing Is Easy Archizoom's Sartorial RevolutionDocument18 pagesDressing Is Easy Archizoom's Sartorial RevolutionArnaud JammetNo ratings yet

- Case1 4 TrueReligionDocument15 pagesCase1 4 TrueReligionAhmad100% (4)

- BCI Conversion Factors Multipliers Oct 2020 1Document24 pagesBCI Conversion Factors Multipliers Oct 2020 1Prashant PatilNo ratings yet

- Pid#527241 & 527245 Fabric Test ReportDocument3 pagesPid#527241 & 527245 Fabric Test ReportAll In OneNo ratings yet

- Gini N JonyDocument5 pagesGini N JonyHarshada Sambare50% (2)

- Levis Strauss & CompanyDocument19 pagesLevis Strauss & CompanyNeetika Chauhan100% (5)

- Nomanterrytowelpresentation 191112170502Document38 pagesNomanterrytowelpresentation 191112170502Mehzabeen ShahidyNo ratings yet

- Trims, Closures & AccessoriesDocument4 pagesTrims, Closures & AccessoriessupriyadhageNo ratings yet

- Technical Services - Digital PVHDocument70 pagesTechnical Services - Digital PVHChandan MajhiNo ratings yet

- Assignment 1 APPAREL MANUFACTURING INDUSTRYDocument3 pagesAssignment 1 APPAREL MANUFACTURING INDUSTRYdimuthu jayawardeneNo ratings yet

- Product Overview: Product ID 00261115, COS RTW IRIS TUNICDocument10 pagesProduct Overview: Product ID 00261115, COS RTW IRIS TUNICApoorv SadhNo ratings yet

- Textile Finishing - 1Document15 pagesTextile Finishing - 1fetufekci3525No ratings yet

- Industrial Attachment of ItramexDocument102 pagesIndustrial Attachment of ItramexMir MD. Musa Ali RezaNo ratings yet

- Item Manamgent - Data SheetDocument24 pagesItem Manamgent - Data Sheetanowar hossainNo ratings yet

- Complex Plant For Denim Yarn Spinning, Fabric Weaving, Finishing and Garment ProductionDocument1 pageComplex Plant For Denim Yarn Spinning, Fabric Weaving, Finishing and Garment ProductionMansoor KhanaliNo ratings yet

- Prepared By: GETU MESFIN Academic Advisor : Textile Engineering 4 Year Internship ReportDocument26 pagesPrepared By: GETU MESFIN Academic Advisor : Textile Engineering 4 Year Internship ReportAbel KirubNo ratings yet

- Men's Formal Trouser: Presentation On Export MerchandisingDocument33 pagesMen's Formal Trouser: Presentation On Export Merchandisinggoel_anshipu87No ratings yet

- Process Flow Chart of Carded Yarn Manufacturing Process - Textile LearnerDocument3 pagesProcess Flow Chart of Carded Yarn Manufacturing Process - Textile LearnerНурбек КасимовNo ratings yet

- Tech Pack FinallllDocument23 pagesTech Pack FinallllAbhinav AshishNo ratings yet

- Nisha Chandani PGFA2034Document5 pagesNisha Chandani PGFA2034NISHA CHANDANI Jaipuria JaipurNo ratings yet

- 2020 Class C Components Brochure WebDocument15 pages2020 Class C Components Brochure WebMaulik BrahmaneNo ratings yet

- Technical Director (TD) : Department: Spinning HierarchyDocument14 pagesTechnical Director (TD) : Department: Spinning HierarchyWaqas AkramNo ratings yet

- Technical Specifications Shimmer PDFDocument1 pageTechnical Specifications Shimmer PDFFarah NamiNo ratings yet

- Suite ddf12809c14 CASIMIRODocument2 pagesSuite ddf12809c14 CASIMIROMartinez UlisesNo ratings yet

- Global Standard: Annex To Policy For Scope Certificates V 2.0 September 2019Document2 pagesGlobal Standard: Annex To Policy For Scope Certificates V 2.0 September 2019Lamia ould amerNo ratings yet

- Clothing Sheet 1.diploma Book1Document19 pagesClothing Sheet 1.diploma Book1utsashkumar10116No ratings yet

- Proj Profile For Cement With TL600KGDocument6 pagesProj Profile For Cement With TL600KGVISHALAG10No ratings yet

- Digital Textile PrintingDocument4 pagesDigital Textile Printingharoon76No ratings yet

- About Company: LocationsDocument17 pagesAbout Company: LocationsPrakhar SharmaNo ratings yet

- Cotton SorterDocument23 pagesCotton Sorterapi-19978170No ratings yet

- TMFactoryIntroduction PDFDocument64 pagesTMFactoryIntroduction PDFcbs9wyyrtyNo ratings yet

- Textile Spinning To Finishing Process: Business English ProgramDocument41 pagesTextile Spinning To Finishing Process: Business English ProgramM.TauqeerNo ratings yet

- South Textile IndustryDocument3 pagesSouth Textile IndustryJayanti SinghNo ratings yet

- Job SheetDocument1 pageJob Sheetsejal gandhiNo ratings yet

- Resource Efficient and Cleaner Production in Textile SectorDocument16 pagesResource Efficient and Cleaner Production in Textile SectorshiyakNo ratings yet

- Brochure May 2024Document10 pagesBrochure May 2024zidrufilmaNo ratings yet

- Gohar Textile Mill (GTM) Internship ReportDocument50 pagesGohar Textile Mill (GTM) Internship ReportAdii ChatthaNo ratings yet

- Quality Wise Sort Analysis To Optimize Fabric Defect Detection in Terry WeavingDocument3 pagesQuality Wise Sort Analysis To Optimize Fabric Defect Detection in Terry WeavingMễro ĢANo ratings yet

- 2 Developments in Fibers For Technical Non 2016 Advances in Technical NonwDocument78 pages2 Developments in Fibers For Technical Non 2016 Advances in Technical Nonwneuzainamine48No ratings yet

- RNF 15Document1 pageRNF 15Georgina TiNo ratings yet

- Catalogue of Nitra PublicationDocument14 pagesCatalogue of Nitra PublicationaymanNo ratings yet

- GTW Supporting Documents v1.3Document49 pagesGTW Supporting Documents v1.3Yassine BfruNo ratings yet

- Technical Textiles EBookletDocument73 pagesTechnical Textiles EBookletjennygraceshaliniNo ratings yet

- MoistTech Full Product CatalogDocument5 pagesMoistTech Full Product CatalogAnonymous kr9TDDmWfJNo ratings yet

- Textile Preparatory Processing GemedaDocument79 pagesTextile Preparatory Processing GemedaGemeda GebinoNo ratings yet

- About NITRADocument53 pagesAbout NITRANitraNtcNo ratings yet

- Development of Eco-Friendly Herbal Finished Sanitary NapkinDocument7 pagesDevelopment of Eco-Friendly Herbal Finished Sanitary NapkinIJIRSTNo ratings yet

- En Valento 2022Document396 pagesEn Valento 2022G JNo ratings yet

- The Textile and Apparel Industry in IndiaDocument12 pagesThe Textile and Apparel Industry in IndiaAmbika sharmaNo ratings yet

- Product Catalogue - Shijiazhuang Huanyang Textile Co.,Ltd.Document1 pageProduct Catalogue - Shijiazhuang Huanyang Textile Co.,Ltd.a27gabrNo ratings yet

- (Download PDF) Pollution Control in Textile Industry Bhatia Online Ebook All Chapter PDFDocument42 pages(Download PDF) Pollution Control in Textile Industry Bhatia Online Ebook All Chapter PDFmark.marra419100% (13)

- U2S2-4 - Processes of Textile ManufacturingDocument13 pagesU2S2-4 - Processes of Textile ManufacturingHieu100% (6)

- U2S3-4 - Environmental Impact of Textile IndustriesDocument9 pagesU2S3-4 - Environmental Impact of Textile IndustriesHieu100% (7)

- 1 150903121804 Lva1 App6891Document149 pages1 150903121804 Lva1 App6891veselieNo ratings yet

- Revestimentos CORREIASDocument2 pagesRevestimentos CORREIASValNo ratings yet

- 10 5923 J Materials 20150503 01Document9 pages10 5923 J Materials 20150503 01Martin Eduardo Prieto BenitesNo ratings yet

- Fabric Processing PDFDocument2 pagesFabric Processing PDFMarniNo ratings yet

- World 5 Most Sustainable Textile Fibers - Textile DetailsDocument29 pagesWorld 5 Most Sustainable Textile Fibers - Textile DetailsNadeem AhmedNo ratings yet

- The Dyeing of Cotton Fabrics: A Practical Handbook for the Dyer and StudentFrom EverandThe Dyeing of Cotton Fabrics: A Practical Handbook for the Dyer and StudentNo ratings yet

- Carr and Latham's Technology of Clothing ManufactureFrom EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerRating: 4 out of 5 stars4/5 (1)

- Sustainable Innovations in Textile Chemical ProcessesFrom EverandSustainable Innovations in Textile Chemical ProcessesNo ratings yet

- Handbook of Renewable Materials for Coloration and FinishingFrom EverandHandbook of Renewable Materials for Coloration and FinishingMohd YusufNo ratings yet

- MR Final Report - Group 2, C1Document85 pagesMR Final Report - Group 2, C1Areeba AmjadNo ratings yet

- English - 2019 - Test 1Document19 pagesEnglish - 2019 - Test 1Luiza KhachatryanNo ratings yet

- A 1Document7 pagesA 1Lia AmmuNo ratings yet

- Resume ImranDocument2 pagesResume ImranImran LakhaniNo ratings yet

- Women's Knitwear AnalysisDocument42 pagesWomen's Knitwear AnalysisnidhisanjeetNo ratings yet

- Judge Irrelevant EvidencesDocument3 pagesJudge Irrelevant Evidencesbodiongan jestoniNo ratings yet

- Production Management in Cottonking PVT - LTD: A Project OnDocument51 pagesProduction Management in Cottonking PVT - LTD: A Project OnUnique ComputersNo ratings yet

- De Thi Giua Ki 1 Lop 9 Mon Tieng Anh Co File NgheDocument13 pagesDe Thi Giua Ki 1 Lop 9 Mon Tieng Anh Co File NgheMỹ NươngNo ratings yet

- Sustainable Processing in Garment IndustryDocument12 pagesSustainable Processing in Garment IndustryAmrita MitraNo ratings yet

- ĐỀ KIỂM TRA GIỮA KÌ - GRADE 9Document90 pagesĐỀ KIỂM TRA GIỮA KÌ - GRADE 9MyDuyen PhanNo ratings yet

- Levis AssgnDocument4 pagesLevis Assgninstantshikhar222No ratings yet

- I. Chọn từ có cách phát âm khác với các từ còn lại ở phần gạch chân. (1m)Document6 pagesI. Chọn từ có cách phát âm khác với các từ còn lại ở phần gạch chân. (1m)Phương ThảoNo ratings yet

- Spin PlanDocument2 pagesSpin PlanMazumder Apu100% (1)

- Denim Jeans: Part Number Part Name Description Supplier Country of OriginDocument1 pageDenim Jeans: Part Number Part Name Description Supplier Country of OriginRafiul HasanNo ratings yet

- FHM Singapore - September 2015Document117 pagesFHM Singapore - September 2015UncircleDecoder50% (6)

- Brand Management Case Study 1 Levi'sDocument4 pagesBrand Management Case Study 1 Levi'sKhurram HamidNo ratings yet

- ĐỀ số 8Document4 pagesĐỀ số 8Thanh Thư TrầnNo ratings yet

- Marketing Management: "Fresh Look Fresh Feel Fresh Attitude"Document49 pagesMarketing Management: "Fresh Look Fresh Feel Fresh Attitude"Taqdees Shaikh PawaskarNo ratings yet

- Diaz v. PeopleDocument2 pagesDiaz v. PeopleMirellaNo ratings yet

- Libro Decimo PG 11-25 PDFDocument14 pagesLibro Decimo PG 11-25 PDFcarlosmojicaNo ratings yet

- Men's GarmentsDocument19 pagesMen's GarmentsMrs.Arthy SaravananNo ratings yet

- Aarvee Denim & Export LTD.: CertificateDocument46 pagesAarvee Denim & Export LTD.: CertificateVinita AgrawalNo ratings yet

- Levi S Personal Pair Jeans ADocument6 pagesLevi S Personal Pair Jeans AGP0% (1)

- Reading Module 8Document11 pagesReading Module 8lawrencekailNo ratings yet

- OFFL3T1Document18 pagesOFFL3T1MariiaNo ratings yet