Professional Documents

Culture Documents

Quality Assurance Plan Fastners

Quality Assurance Plan Fastners

Uploaded by

SuKHjiT SiNGhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality Assurance Plan Fastners

Quality Assurance Plan Fastners

Uploaded by

SuKHjiT SiNGhCopyright:

Available Formats

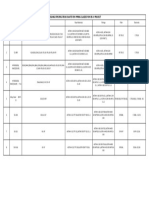

QUALITY ASSURANCE PLAN FASTNERS

PROJECT: MILAN LAB CONNECTIVITY ITEM DETAIL: F/T STUD WITH 2 HEAVY HEX NUTS & 2 WASHER

CLIENT: YASH EPC PROJECTS PVT. LTD. QAP NO.:PNB/YASH/01

CONSULTANT : PRACTBBBL ENGINEERS REV NO. 1 & DATE:: 27.03.2019

MANUFACTURER NAME: PIONEER NUTS & BOLTS PVT. LTD REF DOC.: ASTM A320 GR. L7/A 194 GR7/GR4

TPIA/INSPECTION: BVIL PO NO.:19/GSPL/ML/10-AMD 02 DATED: 26.03.2019

SR. NO. COMPONENT&OPERATTIONS TYPES OF CHECK QUANTAM OF REFERENCE DOCUMENTS ACCEPTANCE NORMS FORMET OF RECORD INSPECTION

CHECK VENDOR TPIA

1 RAW MATERIAL

1.MANUFACTURING PROCESS OF ASTM A320 L7/A 194 GR7 ASTM A320 L7/A 194 GR 7 MTC/LAB TEST REPORT 3.1

100%

RAW MATERIAL STEEL R R

2.CHEMICAL COMPOSITION ASTM A320 L7/A 194 GR7 ASTM A320 L7/A 194 GR7 MTC/LAB TEST REPORT 3.1

PER HEAT

R R

3.PMI CHECK 100% ASTM A320 L7/A 194 GR7 ASTM A320 L7/A 194 GR7 INSPECTION REPORT 3.2 R W

4.VISUAL 100% ASTM A320 L7/A 194 GR7 ASTM A320 L7/A 194 GR7 INSPECTION REPORT 3.2 P W

2 INPROCESS INSPECTION

1.MFG. BOLT & NUT 1.CUTTING,GRINDING,FORGING, 100% VENDOR DRG./ASTM A 320 L7 / A 194 VENDOR DRG./ASTM A 320 L7 / A 194 DIMENSION REPORT 3.1 P R

THREADING, ETC GR7/ASME B18.2.1&2.2/ ASTM F436 GR7/ASME B18.2.1&2.2/ ASTM F436

2.PRODUCT DIMENSONS 100% VENDOR DRG./ASTM A 320 L7 / A 194 VENDOR DRG./ASTM A 320 L7 / A 194 DIMENSION REPORT 3.1 P R

GR7/ASME B18.2.1&2.2/ ASTM F436 GR7/ASME B18.2.1&2.2/ ASTM F436

2. HEAT TREATMENT 1.HEAT TREATMENT 100% ASTM A 370 /A 320 L7/A 194 GR7/ASTM ASTM A 370 /A 320 L7/A 194 GR7/ASTM F436 HT GRAPH/INSPECTION P R

CYCLE(TEMP./TIME CHART) F436 TENDER SPEC. TENDER SPEC. REPORT 3.1

3.STAMPING OF SAMPLE FOR 1.STAMPING OF TEST SAMPLE 100% ASTM A 370 /A 320 L7/A 194 GR7/ASTM ASTM A 370 /A 320 L7/A 194 GR7/ASTM F436 INSPECTION REPORT 3.2 P W

TESTING F436 TENDER SPEC. TENDER SPEC.

4.MECHANICAL TESTING 1.TENSILE TESTING(TS,YS,EL%, %RA) ONE/HEAT/LOT ASTM A 370 /A 320 L7 / A 194 GR7/TENDER ASTM A 370 /A 320 L7 / A 194 GR7/TENDER INSPECTION REPORT 3.2 P W

SPEC. SPEC.

2.PROOF LOAD TEST ONE/HEAT/LOT ASTM A 370 /A 320 L7 / A 194 GR7/TENDER ASTM A 370 /A 320 L7 / A 194 GR7/TENDER INSPECTION REPORT 3.2 P W

SPEC. SPEC.

3.HARDNESS TESTING 5%/HEAT/LOT ASTM A 370 /A 320 L7/A 194 GR7/ASTM ASTM A 370 /A 320 L7/A 194 GR7/ASTM F436 INSPECTION REPORT 3.2 P W

F436 TENDER SPEC. TENDER SPEC.

4.IMPACT TEST AT -101 C ONE/HEAT/LOT ASTM A 370 /A 320 L7 / A 194 GR7/TENDER AVG 27J & IND 20J / TENDER SPEC. INSPECTION REPORT 3.2 P W

SPEC.

5.PRODUCT CHEMICAL CHECK 1. CHEMICAL ANALYSIS ONE/HEAT/LOT ASTM A 370 /A 320 L7 / A 194 A 320 L7/ A 194 GR4/GR7/TENDER SPEC INSPECTION REPORT 3.2 P R

GR4/GR7/TENDER SPEC.

5%/HEAT/LOT ASTM A 370 /A 320 L7 / A 194 GR7/TENDER A 320 L7/ A 194 GR4/GR7/TENDER SPEC INSPECTION REPORT 3.2

ANALYSIS 2.PMI TEST SPEC. P W

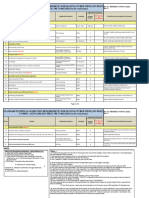

QUALITY ASSURANCE PLAN FASTNERS

PROJECT: MILAN LAB CONNECTIVITY ITEM DETAIL: F/T STUD WITH 2 HEAVY HEX NUTS & 2 WASHER

CLIENT: YASH EPC PROJECTS PVT. LTD. QAP NO.:PNB/YASH/01

CONSULTANT : REV NO. 1 & DATE:: 27.03.2019

MANUFACTURER NAME: PIONEER NUTS & BOLTS PVT. LTD REF DOC.: ASTM A320 GR. L7/A 194 GR7/GR4

TPIA/INSPECTION: BVIL PO NO.:19/GSPL/ML/10-AMD 02 DATED: 26.03.2019

SR. NO. COMPONENT&OPERATTIONS TYPES OF CHECK QUANTAM OF REFERENCE DOCUMENTS ACCEPTANCE NORMS FORMET OF RECORD INSPECTION

CHECK VENDOR TPIA

3 FINAL INSPECTION

ASTM A 370 /A 320 L7/A 194 GR7/ASTM ASTM A 370 /A 320 L7/A 194 GR7/ASTM F436 INSPECTION REPORT 3.2

1.FINALINSPECTION 1.VISUAL/STAMPING/MARKING 100% F436 TENDER SPEC. TENDER SPEC. P 100% W

ASTM A 370 /A 320 L7/A 194 GR7/ASTM ASTM A 370 /A 320 L7/A 194 GR7/ASTM F436 INSPECTION REPORT 3.2

2.DIMENSIONS 100% F436 TENDER SPEC. TENDER SPEC. P 10% W

4 FINAL DOCUMENTS

1.QAP/PO/MTC/IR/COMPLIANCE AS PER TENDER SPEC / AS PER APPR. DRG. & AS PER TENDER SPEC / AS PER APPR. DRG. &

1.FINAL DOCUMENTS CERTIFICATES 100% QAP QAP COMPLIANCE CERTIFICATE P R

AS PER TENDER SPEC / AS PER APPR. DRG. & AS PER TENDER SPEC / AS PER APPR. DRG. &

2.INSPECTION RELEASE NOTE 100% QAP QAP COMPLIANCE CERTIFICATE H P

Legend: P-Perform, W-Witness, H-Hold, TPIA-Third Party Inspection Agency

NOTE: 1.TPIA SHALL ISSUE 3.2 CERTIFICATE AS PER BS EN 10204.

2.MATERIAL & TYPE SHALL BE AS PER TENDER SPEC/DATA SHEET.

3.START & STOP TEMP. CHART SAHLL BE SIGNED BY TPIA, ALSO POWER FAILURE LOG SHALL BE MAINTAINED.

4.SAMPLE FROM ANY ONE LOT/HEAT SHALL BE TESTED BY CLIENT (GSPL) UNDER THEIR WITNESS THIRD PARTY LAB AT DICRETION.

REVIEWED & ACCEPTED

PREPARED BY: APPROVED BY: CONSULTANT: CLIENT:GUJRAT STATE PETRONET LIMITED

You might also like

- D&D 5E Tomb of Annihilation PDFDocument260 pagesD&D 5E Tomb of Annihilation PDFRodolfo Arango93% (97)

- 2 High Pressure Compressor PDFDocument132 pages2 High Pressure Compressor PDFHarry Wart Wart100% (3)

- Steel Rivets and Bars For Rivets, Pressure VesselsDocument4 pagesSteel Rivets and Bars For Rivets, Pressure VesselsxaviereduardoNo ratings yet

- Sample FET To ISO 15848-1 PDFDocument4 pagesSample FET To ISO 15848-1 PDFVivi Oktavianti100% (1)

- Lone Wolves Pitch Bible PDFDocument15 pagesLone Wolves Pitch Bible PDFSupernova DesignNo ratings yet

- Tubacex-Prakash 10650T1 QapDocument3 pagesTubacex-Prakash 10650T1 Qaprabiprasad.iispl.comletedNo ratings yet

- Masdar Technical Supplies: Inspection and Test PlanDocument1 pageMasdar Technical Supplies: Inspection and Test PlanmaqboolNo ratings yet

- WM65AJN200Document4 pagesWM65AJN200Shasin SolankiNo ratings yet

- QAP NovelDocument2 pagesQAP NovelSamanth KumarNo ratings yet

- 302522HE0078 Rev 0 Sep 14Document7 pages302522HE0078 Rev 0 Sep 14lou32contrerasNo ratings yet

- QCP STD (Format)Document4 pagesQCP STD (Format)Kene Aguilar ZanabriaNo ratings yet

- Tech SpecDocument16 pagesTech SpecKingston RivingtonNo ratings yet

- Inspection Checklist: S.No Components Class Type of Check Quantum of CheckDocument8 pagesInspection Checklist: S.No Components Class Type of Check Quantum of CheckCheeragNo ratings yet

- Steel PipesDocument16 pagesSteel PipesAdam GordonNo ratings yet

- QAP For MS Pipes RevisedDocument3 pagesQAP For MS Pipes RevisedAnuj PandeyNo ratings yet

- Qap B7M - 2HMDocument4 pagesQap B7M - 2HMJJ VAPINo ratings yet

- Itp TTRK PDFDocument5 pagesItp TTRK PDFrahmath nawazNo ratings yet

- Inspection and Test Plan For Cement Mortar Lining of Steel Pipes, Fittings, Bends and Welded JointsDocument5 pagesInspection and Test Plan For Cement Mortar Lining of Steel Pipes, Fittings, Bends and Welded Jointsrahmath nawazNo ratings yet

- Scan Report of Analysis - Pt. Bumi Lestari Wisesa - 1 Kode Sample OrsaDocument2 pagesScan Report of Analysis - Pt. Bumi Lestari Wisesa - 1 Kode Sample Orsasunda.empire1989No ratings yet

- Steam Trap & Piston Valve Qap PDFDocument1 pageSteam Trap & Piston Valve Qap PDFajmainNo ratings yet

- Catálogo de Válvulas de Segurança ApolloDocument1 pageCatálogo de Válvulas de Segurança Apolloarhon berdichNo ratings yet

- Series Asme Safety Valve: DescriptionDocument1 pageSeries Asme Safety Valve: DescriptionADAN CESSANo ratings yet

- MRS Qap-SkidDocument3 pagesMRS Qap-Skidrahul.adityaNo ratings yet

- Qap B7 - 2HDocument4 pagesQap B7 - 2HJJ VAPINo ratings yet

- FT Valvula Compuerta Clase 800 SWDocument1 pageFT Valvula Compuerta Clase 800 SWFernando CarreñoNo ratings yet

- 74-008 SS PipeSS PIPES - ASTM A312:2015Document2 pages74-008 SS PipeSS PIPES - ASTM A312:2015salesoman3No ratings yet

- Chromium-Vanadium Alloy Steel Valve Spring Quality Wire: Standard Specification ForDocument4 pagesChromium-Vanadium Alloy Steel Valve Spring Quality Wire: Standard Specification ForErick ERICKNo ratings yet

- QAP (WO No. 58 & 59) PDFDocument3 pagesQAP (WO No. 58 & 59) PDFKailasNo ratings yet

- Steel Rivets and Bars For Rivets, Pressure VesselsDocument4 pagesSteel Rivets and Bars For Rivets, Pressure VesselsAdán Cogley CantoNo ratings yet

- Public Health and Municipal Engineering Department - NelloreDocument3 pagesPublic Health and Municipal Engineering Department - Nellorejuliyet strucNo ratings yet

- Carbon and Alloy Steel Forgings For Magnetic Retaining Rings For Turbine GeneratorsDocument2 pagesCarbon and Alloy Steel Forgings For Magnetic Retaining Rings For Turbine GeneratorsfaroukNo ratings yet

- Product Guide 7903 PDFDocument8 pagesProduct Guide 7903 PDFCHIRAG PATELNo ratings yet

- A 488 - A 488M - 99 Qtq4oc05oq - PDFDocument15 pagesA 488 - A 488M - 99 Qtq4oc05oq - PDFMarceloNo ratings yet

- Batch Test CertificateDocument3 pagesBatch Test Certificatekarthikeyan1003No ratings yet

- A488 13208-2Document18 pagesA488 13208-2DeepakRajurkarNo ratings yet

- 02 I Test PlanDocument1 page02 I Test Planrahmath nawazNo ratings yet

- Qap B16Document4 pagesQap B16JJ VAPINo ratings yet

- Stainless Steel Forgings, Ferritic/Austenitic (Duplex), For Pressure Vessels and Related ComponentsDocument4 pagesStainless Steel Forgings, Ferritic/Austenitic (Duplex), For Pressure Vessels and Related ComponentsСергей ЩучевNo ratings yet

- Air Filter Regulator CA Gas 94539Document2 pagesAir Filter Regulator CA Gas 94539mishtinilNo ratings yet

- Batch Test CertificateDocument3 pagesBatch Test Certificatekarthikeyan1003No ratings yet

- Quality Assurance Plan (Qap) For L.T.C.S. FittingsDocument2 pagesQuality Assurance Plan (Qap) For L.T.C.S. FittingsVIVEK TIWARINo ratings yet

- Popular Standard Specification of MaterialsDocument2 pagesPopular Standard Specification of MaterialsBijay MuduliNo ratings yet

- Gtes LT HSRP QapDocument5 pagesGtes LT HSRP Qapshashank shahNo ratings yet

- Qap Sa420Document3 pagesQap Sa420Abhishek NagNo ratings yet

- Astm A765 PDFDocument4 pagesAstm A765 PDFCristian OtivoNo ratings yet

- Welding Specifications ChartDocument1 pageWelding Specifications ChartAbhinit KumarNo ratings yet

- Reliable Pipes and TubesDocument4 pagesReliable Pipes and TubesretrogradesNo ratings yet

- A 266 - A 266M - 03 Qti2ni0wmw - PDFDocument4 pagesA 266 - A 266M - 03 Qti2ni0wmw - PDFCristian CanavidesNo ratings yet

- Bharat Oman QAPDocument6 pagesBharat Oman QAPJJ VAPINo ratings yet

- Astm A31 1995Document4 pagesAstm A31 1995Jesse ChenNo ratings yet

- Spec 6a E21 en Add3Document16 pagesSpec 6a E21 en Add3LiLiNo ratings yet

- Raw Material ReportsDocument24 pagesRaw Material ReportsSufyan SafiNo ratings yet

- QAP For ACSR Conductor PDFDocument10 pagesQAP For ACSR Conductor PDFprithvirajd20100% (1)

- Tdi 50000 Tpy, GNFCDocument6 pagesTdi 50000 Tpy, GNFCkrunal panchalNo ratings yet

- Is 432 Part 2 Product ManualDocument5 pagesIs 432 Part 2 Product ManualManikanta Sai KumarNo ratings yet

- IS 432 Part 2 Product ManualDocument5 pagesIS 432 Part 2 Product ManualtadilakshmikiranNo ratings yet

- 74-002CS Pipes - Astm A106Document2 pages74-002CS Pipes - Astm A106salesoman3No ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Naq 5250Document2 pagesNaq 5250SuKHjiT SiNGhNo ratings yet

- Licensed To TUFF®: (Reaffirmed 2010)Document5 pagesLicensed To TUFF®: (Reaffirmed 2010)SuKHjiT SiNGhNo ratings yet

- 4iti I: Al4 9FdDocument2 pages4iti I: Al4 9FdSuKHjiT SiNGhNo ratings yet

- Quality Assurance Plan FastnersDocument1 pageQuality Assurance Plan FastnersSuKHjiT SiNGhNo ratings yet

- In MetallographyDocument1 pageIn MetallographySuKHjiT SiNGhNo ratings yet

- S.NO. Size IS 6623 Gr.8S: Proof Load For Nuts & HardnessDocument3 pagesS.NO. Size IS 6623 Gr.8S: Proof Load For Nuts & HardnessSuKHjiT SiNGhNo ratings yet

- Sample - Result - 2019 04 23 - 18 25 59Document1 pageSample - Result - 2019 04 23 - 18 25 59SuKHjiT SiNGhNo ratings yet

- Sample Qap For NpcilDocument2 pagesSample Qap For NpcilSuKHjiT SiNGhNo ratings yet

- Manufacturer Party Name Purchase Order No Internal Work Order Item & Lot No Size & Item Code Quantity Bag No. For Customer SupportDocument3 pagesManufacturer Party Name Purchase Order No Internal Work Order Item & Lot No Size & Item Code Quantity Bag No. For Customer SupportSuKHjiT SiNGhNo ratings yet

- Packing List - RitesDocument1 pagePacking List - RitesSuKHjiT SiNGhNo ratings yet

- MSI X370 SpecsDocument3 pagesMSI X370 SpecsPeeGee MendozaNo ratings yet

- IndexDocument8 pagesIndexTamanna TabassumNo ratings yet

- La Cumparsita Classical GuitarDocument6 pagesLa Cumparsita Classical GuitarwolfhipiNo ratings yet

- SMB3 All Forts Wrong Warp Detailed ExplanationDocument4 pagesSMB3 All Forts Wrong Warp Detailed ExplanationKieran BlythNo ratings yet

- Final Test 1Document4 pagesFinal Test 1Настя СтеповичNo ratings yet

- Roland Xv-5080Document40 pagesRoland Xv-5080Sal CarolloNo ratings yet

- Remittance BusinessDocument14 pagesRemittance BusinessPalash SahaNo ratings yet

- Ball ScrewDocument4 pagesBall ScrewJohn BlackburnNo ratings yet

- MAF in A NutshellDocument1 pageMAF in A NutshelltrallalaNo ratings yet

- Test B: UnitsDocument4 pagesTest B: UnitsEduardo Rodrigues Ferreira80% (5)

- Khans of BollywoodDocument9 pagesKhans of BollywoodLeo da LeonNo ratings yet

- Jowar Roti RecipeDocument2 pagesJowar Roti RecipearunagirinatharNo ratings yet

- 4th Grade Summer Reading List 2013Document2 pages4th Grade Summer Reading List 2013Mary Ann Placzek Scheuer0% (1)

- PDF El Libro de La Psicologia (Grandes Ideas, Explicaciones Sencillas / Big Ideas Simply Explained)Document2 pagesPDF El Libro de La Psicologia (Grandes Ideas, Explicaciones Sencillas / Big Ideas Simply Explained)CRISTIAN ARAUJONo ratings yet

- Warhammer - 40.000 - Space - Marine Art - BookDocument56 pagesWarhammer - 40.000 - Space - Marine Art - BookGabJr100% (1)

- From Atob: Sample PagesDocument10 pagesFrom Atob: Sample PagesFaqət MaqsudovaNo ratings yet

- Plane Table SurveyDocument82 pagesPlane Table SurveyMahesh PalNo ratings yet

- Deep Down UnderDocument13 pagesDeep Down Underapi-690977678No ratings yet

- Reactivating Tally - Erp 9Document2 pagesReactivating Tally - Erp 9Vijay SrivastavNo ratings yet

- Barcode ReaderDocument6 pagesBarcode ReaderVladik SumanNo ratings yet

- 2 Ton Hurricane Hook MountDocument1 page2 Ton Hurricane Hook MountVitor OlivettiNo ratings yet

- 11 - Sony Ps Vita PCH 1000Document2 pages11 - Sony Ps Vita PCH 1000cesarbridesNo ratings yet

- Maghinay SelaginellaPlanaDocument13 pagesMaghinay SelaginellaPlanaHelen Bernadette Cabahug MaghinayNo ratings yet

- Life 5A Unit 5 A4Document4 pagesLife 5A Unit 5 A4Aldo GrenatNo ratings yet

- Huddersfield Jazz Guitar Society: Celebrating The Art and Craft of Jazz GuitarDocument28 pagesHuddersfield Jazz Guitar Society: Celebrating The Art and Craft of Jazz GuitardarrendbNo ratings yet

- Sports Quota Admission ListDocument3 pagesSports Quota Admission ListAkulBansalNo ratings yet