Professional Documents

Culture Documents

Passion For An Airless Future

Passion For An Airless Future

Uploaded by

afshinCopyright:

Available Formats

You might also like

- Transmision Automatica 4l60 Chevrolet Blazer 95-03Document109 pagesTransmision Automatica 4l60 Chevrolet Blazer 95-03angelo marra100% (2)

- Still NGT4Document6 pagesStill NGT4Ali Biomy100% (1)

- Airless TyresDocument10 pagesAirless TyresPranith KumarNo ratings yet

- Airless TyresDocument10 pagesAirless Tyresacharyasandeep100% (1)

- Airless Tyre 9044 MwiEBemDocument10 pagesAirless Tyre 9044 MwiEBemSachinhonnatti SachinhonnattiNo ratings yet

- Airless Tyre 9044 mwiEBemDocument10 pagesAirless Tyre 9044 mwiEBemVamsi BandiNo ratings yet

- Airless Tyre 9044 MwiEBemDocument10 pagesAirless Tyre 9044 MwiEBemprasanna hamsikaNo ratings yet

- Airless Tyre 9044 MwiEBemDocument10 pagesAirless Tyre 9044 MwiEBemSachinhonnatti SachinhonnattiNo ratings yet

- New Microsoft Word DocumentDocument1 pageNew Microsoft Word DocumentSrikhar KondisettyNo ratings yet

- Problem in Conventoinal Tyre: Portmanteau Tyre French Michelin Polyurethane SpokesDocument12 pagesProblem in Conventoinal Tyre: Portmanteau Tyre French Michelin Polyurethane SpokesBaneeIshaqueKNo ratings yet

- Tweel by MichelinDocument7 pagesTweel by MichelinAbhilash K PillaiNo ratings yet

- Airless Tyres: Sandeepa Chikkalli (2GP16ME038)Document13 pagesAirless Tyres: Sandeepa Chikkalli (2GP16ME038)Anilkumar m rNo ratings yet

- What Is The Uptis Prototype and What Advantages Does It Offer?Document3 pagesWhat Is The Uptis Prototype and What Advantages Does It Offer?Magdiel SchmitzNo ratings yet

- Airless Tyres Seminar ReportsDocument29 pagesAirless Tyres Seminar ReportsHarsha GowdaNo ratings yet

- On TweelDocument21 pagesOn TweelRaju UpparapellyNo ratings yet

- Airless Tyres Seminar ReportsDocument29 pagesAirless Tyres Seminar ReportsPranay Gaddam50% (2)

- Technical Seminar: BY: Praveen S Boodagoli 1SI15ME122 B.E (Mechanical Engineering)Document17 pagesTechnical Seminar: BY: Praveen S Boodagoli 1SI15ME122 B.E (Mechanical Engineering)PRAVEEN BOODAGOLINo ratings yet

- Presentation On TweelsDocument15 pagesPresentation On TweelsRahul100% (4)

- Non Pneumatic TyreDocument13 pagesNon Pneumatic TyreDevender NaikNo ratings yet

- Static Analysis On Custom Polyurethane SDocument4 pagesStatic Analysis On Custom Polyurethane SafshinNo ratings yet

- NPT Report PDFDocument18 pagesNPT Report PDFShridhar KoriNo ratings yet

- AirlessNon Pneumatic TyresDocument14 pagesAirlessNon Pneumatic TyresElaine RodriguezNo ratings yet

- Recent Trends in Tyre TechnologyDocument22 pagesRecent Trends in Tyre TechnologyRahul100% (1)

- Seminar Topic: Tyres: By-N.B.R Kaushik Mechanical 4 Year Roll No:711633Document47 pagesSeminar Topic: Tyres: By-N.B.R Kaushik Mechanical 4 Year Roll No:711633kaushikNo ratings yet

- TPCS Airless Tyres Report VARSHADocument21 pagesTPCS Airless Tyres Report VARSHASumit PatilNo ratings yet

- Airless Tire SeminarDocument15 pagesAirless Tire SeminarTushar JamaleNo ratings yet

- Airless Tires - Satya.Document22 pagesAirless Tires - Satya.noaninbubble100% (2)

- U Turn The Rise and Demise of The AutomoDocument13 pagesU Turn The Rise and Demise of The AutomogaayuraamuNo ratings yet

- The Future of Tires Innovations in Tire TechnologyDocument5 pagesThe Future of Tires Innovations in Tire Technologybrian.kweonaecomNo ratings yet

- Airless Tyres: Presenter: Prasad Govind KumbharDocument19 pagesAirless Tyres: Presenter: Prasad Govind KumbharPrasad Govind KumbharNo ratings yet

- Continental Car Tyres - Best in BrakingDocument9 pagesContinental Car Tyres - Best in BrakingContinentalTyresNo ratings yet

- Brochure Eng (Dynamec)Document14 pagesBrochure Eng (Dynamec)선철규No ratings yet

- Modeling Liquids and Gases Just Got EasierDocument55 pagesModeling Liquids and Gases Just Got Easiergonzalo limachiNo ratings yet

- Estancia PresentaciónDocument5 pagesEstancia Presentaciónislasgonzalezisraelelienai207No ratings yet

- Mwfly Business Magazine EN - CompressedDocument25 pagesMwfly Business Magazine EN - CompressedinfoNo ratings yet

- 2015 Cate Level-1Document27 pages2015 Cate Level-1FlavioRodolfoSevero0% (1)

- Non Pneumatic TyreDocument17 pagesNon Pneumatic Tyrereghurahul88No ratings yet

- Raw Materials of Tyre Industry - Overview (FY 2010-11) : Cord, Polyester Tyre Cord Insufficient To Meet Domestic DemandDocument9 pagesRaw Materials of Tyre Industry - Overview (FY 2010-11) : Cord, Polyester Tyre Cord Insufficient To Meet Domestic DemandGupta GuptaNo ratings yet

- Reddy PDFDocument18 pagesReddy PDF20wj1a0339No ratings yet

- Department of Mechanical Engineering: Seminar Presentation (RME-851) OnDocument22 pagesDepartment of Mechanical Engineering: Seminar Presentation (RME-851) OnshivamNo ratings yet

- 6) Conclusions & Future Scope of Work 308Document1 page6) Conclusions & Future Scope of Work 308Mani SankarNo ratings yet

- Materials in Automotive Application, State of The Art and ProspectsDocument31 pagesMaterials in Automotive Application, State of The Art and ProspectsPaoloMaccaronioNo ratings yet

- 20-20 Vision - Retos de Desarrollo MciDocument5 pages20-20 Vision - Retos de Desarrollo MciDanny RodriguezNo ratings yet

- MICHELIN+CROSSCLIMATEDOSSIER DE PRESSE UK LightDocument12 pagesMICHELIN+CROSSCLIMATEDOSSIER DE PRESSE UK Lightlui lopezNo ratings yet

- Artificial IntelligenceDocument57 pagesArtificial IntelligenceTestNo ratings yet

- Schaeffler de enDocument36 pagesSchaeffler de enzoeNo ratings yet

- Futuro CombustiblesDocument6 pagesFuturo CombustiblesIsamar LópezNo ratings yet

- Tire Technology 032022Document104 pagesTire Technology 032022HYUNSOOK SHINNo ratings yet

- Design of A CFRP Composite Monocoque Simulation ApproachDocument8 pagesDesign of A CFRP Composite Monocoque Simulation ApproachGregory Aguilera LopesNo ratings yet

- Airless TyresDocument20 pagesAirless TyresKingsly Jasper100% (1)

- BCG - The Great Mobility Tech RaceDocument20 pagesBCG - The Great Mobility Tech Raceditokrista100% (1)

- Airless TyreDocument19 pagesAirless TyreSonu KumarNo ratings yet

- BorgWarner - Delphi Technologies Aftermarket - Fuel Brochure - 2020Document12 pagesBorgWarner - Delphi Technologies Aftermarket - Fuel Brochure - 2020Wai MinNo ratings yet

- Michelin Tire Care PDFDocument27 pagesMichelin Tire Care PDFkpil0% (1)

- Airless Tyres: DEPT OF MECHANICAL, AIT, Bangalore - Page 1Document20 pagesAirless Tyres: DEPT OF MECHANICAL, AIT, Bangalore - Page 1Bharath BharmaNo ratings yet

- TSR 051Document3 pagesTSR 051Gokul RajNo ratings yet

- Briefing No.23 Nanotechnology in Automotive TyresDocument4 pagesBriefing No.23 Nanotechnology in Automotive TyresHarilaos VasiliadisNo ratings yet

- Report On Airless TyreDocument22 pagesReport On Airless Tyre7B38 Pratik ShendeNo ratings yet

- The Design and Development of New Hyundai Kappa 1.2L Dual CVVT EngineDocument11 pagesThe Design and Development of New Hyundai Kappa 1.2L Dual CVVT EngineSubbu Kannappan SrinivasanNo ratings yet

- Alfa Sud Four Engine - SAEDocument14 pagesAlfa Sud Four Engine - SAEJulio OrtizNo ratings yet

- Covax D EngineDocument2 pagesCovax D EngineSAJID IBRAHIMNo ratings yet

- Analysis and Simulation of Contact Stress Model For Elastic Wheels On Road SurfaceDocument8 pagesAnalysis and Simulation of Contact Stress Model For Elastic Wheels On Road SurfaceafshinNo ratings yet

- Ottawa UDocument19 pagesOttawa UafshinNo ratings yet

- Static Analysis On Custom Polyurethane SDocument4 pagesStatic Analysis On Custom Polyurethane SafshinNo ratings yet

- Design and Analysis of Air Less Tires: ISSN: 2454-132X Impact Factor: 4.295Document16 pagesDesign and Analysis of Air Less Tires: ISSN: 2454-132X Impact Factor: 4.295afshinNo ratings yet

- Requirements For Tire Models of The Lightweight Wheeled Mobile RobotsDocument19 pagesRequirements For Tire Models of The Lightweight Wheeled Mobile RobotsafshinNo ratings yet

- Surface & Coatings TechnologyDocument8 pagesSurface & Coatings TechnologyafshinNo ratings yet

- Mack Numeros de Funciones PDFDocument2 pagesMack Numeros de Funciones PDFDarío Ache EmeNo ratings yet

- Electronic Stability ProgramDocument23 pagesElectronic Stability ProgramdwiudNo ratings yet

- Dynapac Vibro CA250Document2 pagesDynapac Vibro CA250Rachmat ArifNo ratings yet

- Catalog FilterDocument89 pagesCatalog FilterAnangtri Wahyudi50% (2)

- Programa TU 19 Junio T3Document1 pagePrograma TU 19 Junio T3cumbiambero lopezNo ratings yet

- Goldwing InstructionsDocument5 pagesGoldwing InstructionsVanadia NohanNo ratings yet

- Mercedes Benz's Motorsport HistoryDocument108 pagesMercedes Benz's Motorsport HistoryCsiki GáborNo ratings yet

- Luhar AerodynamicsDocument39 pagesLuhar AerodynamicsJorge EstradaNo ratings yet

- Hyundai Motor IndiaDocument33 pagesHyundai Motor IndiaarnoteamanNo ratings yet

- 01 AC Compressor2022 Hi-1Document2 pages01 AC Compressor2022 Hi-1فريزون يمن-verlzon YemenNo ratings yet

- Scion XD Fault Codes DTCDocument9 pagesScion XD Fault Codes DTCCesar AguirreNo ratings yet

- 2 Poles LiftDocument5 pages2 Poles LiftQirat KhanNo ratings yet

- Affidavit Claim AuthoDocument4 pagesAffidavit Claim AuthoRanie RgmrgmNo ratings yet

- Elite-I20 Hatchback Brochure PDFDocument14 pagesElite-I20 Hatchback Brochure PDFrajsinhbchauhanNo ratings yet

- Veloster Radio Update TSBDocument9 pagesVeloster Radio Update TSBWassim Ben H'midaNo ratings yet

- 1992 300SE 400SE 500SEL Owner's Manual PDFDocument145 pages1992 300SE 400SE 500SEL Owner's Manual PDFفاديابوزور100% (1)

- Research Project Report: On (A Study of Customer Satisfaction Towards Honda in Two-Wheeler in Lucknow)Document79 pagesResearch Project Report: On (A Study of Customer Satisfaction Towards Honda in Two-Wheeler in Lucknow)Piyush SinghNo ratings yet

- Volvo A35C Fuse and Relay BoxDocument5 pagesVolvo A35C Fuse and Relay BoxIisakki100% (1)

- 2014 JP GrandCherokee SPDocument9 pages2014 JP GrandCherokee SPSteve Ruge100% (1)

- Hey Everyone I Am A New and Used Car Salesperson Here To Help Reddit! AMA - IAmADocument58 pagesHey Everyone I Am A New and Used Car Salesperson Here To Help Reddit! AMA - IAmAUserNo ratings yet

- AuDi Kamera Instalacija - De.enDocument22 pagesAuDi Kamera Instalacija - De.enRivle potNo ratings yet

- JLG 800AJ Rough Terrain Knuckle BoomDocument2 pagesJLG 800AJ Rough Terrain Knuckle Boomseii.chenNo ratings yet

- Citroen Dispatch HandbookDocument324 pagesCitroen Dispatch HandbookControl TechNo ratings yet

- Cashless Garages Pan India List-NewDocument17 pagesCashless Garages Pan India List-NewkkskkssNo ratings yet

- The All-New ToyotaDocument10 pagesThe All-New ToyotaBINNo ratings yet

- Business Proposal New VentureDocument18 pagesBusiness Proposal New VentureBramhananda ReddyNo ratings yet

- Revoflash 3 r19 Vag Ecu List v08 05Document6 pagesRevoflash 3 r19 Vag Ecu List v08 05Gasper Ceballos100% (1)

Passion For An Airless Future

Passion For An Airless Future

Uploaded by

afshinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Passion For An Airless Future

Passion For An Airless Future

Uploaded by

afshinCopyright:

Available Formats

Today for Tomorrow

Future look

In celebration of SAE’s Centennial in 2005,

industry executives discuss the future of

mobility technology.

Passion for an

airless future

A

friend once told me, “Show me Still, Michelin continues to look to-

your checkbook and your calen- wards the future to seek better mobility.

dar and I’ll tell you what you’re Last fall at the Paris Auto Show, Michelin

passionate about.” It’s true. Passion re- introduced two examples of new tech-

quires commitment of both time and re- nologies that are non-pneumatic—tires

source. without air—the Michelin Airless and

Michelin is passionate about technol- Michelin Tweel. The fusion of tire and

by Terry Gettys, President, ogy and innovation, which have been wheel into a single component, Michelin

Michelin Americas Research bred into the company’s culture since its Tweel technology was developed in North

Corporation founding more than 100 years ago. America at the company’s technology

Michelin sustains its dedication to tech- center in Greenville, SC.

nology and innovation with R&D spend- Tweel is one of the most exciting ad-

ing that is second to none in the industry, vances in tire technology in my lifetime:

both in total dollars and as a percentage tires operating without air—on purpose.

of gross sales. Without the need to retain air, there is no

Nearly 60 years ago, Michelin in- longer a need for a rigid wheel. A flexible

vented the radial tire, which is now the wheel using new polyurethane and glass-

recognized standard for most tire seg- reinforced plastics can start to provide

ments. Some companies might have been suspension-like functions to the new

tempted to hold that ground, focusing Tweel design.

simply on manufacturing and distribut- And by fusing the tire and wheel to-

ing that one range of technology. But gether, some complex systems can be

Michelin continues working to improve eliminated. The traditional tire, wheel,

the performance of the radial because valve, and tire pressure-monitoring sys-

there is still more ground to be gained in tem is replaced with a single Tweel as-

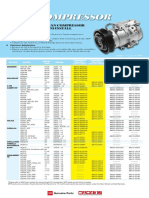

Michelin’s Tweel automotive application on fuel economy, rolling resistance, traction, sembly. This innovation eliminates the

an Audi A4 wear life, and other properties. That drive need for mounting and dismounting and

comes from a passion for continuous simplifies the logistics. A flexible wheel

improvement. also eliminates the possibility of pinch

Over the last several years, Michelin’s shock, sidewall damage, and wheel strike-

commitment to innovation has centered on through, all hazards of conventional tire-

continued-mobility options, where Michelin wheel assembly.

Zero Pressure tires and the Michelin PAX One of the most amazing aspects of

System continue to gain acceptance in the Tweel unit is that it performs like a

Europe and North America. Last year, the pneumatic tire. Tweel architecture sup-

Honda Odyssey Touring Edition became ports the load mechanically, yet it de-

the first mainstream vehicle in North forms to absorb bumps and road hazards

America to use the PAX System. for ride comfort, and generates a contact

The non-pneumatic Tweel unit replaces

the traditional tire/wheel/valve/pressure

monitoring assembly

86 JUNE 2005 aei

Today for Tomorrow

patch. In fact, the contact patch on the which reduces driver fatigue.

prototype passenger-car application is The U.S. military’s interest in Tweel

almost twice as large as the contact patch technology centers on its unique contin-

of the original OE fitment. ued mobility, even after multiple hits from

As the Tweel unit began to take shape, land mines and incoming artillery. The

fitment opportunities quickly became ap- Tweel assembly does not have a single

parent. Michelin has a long history of point of failure. It also has high blast re- Michelin’s approach to the market

collaboration with Segway, which led to sistance, directing the explosive energy of

the first real-world fitments for the new land mines and other direct hits outward,

Segway Concept Centaur and iBOT wheel- rather than up through traditional tires

chair from Independence Technology. and into the vehicle itself.

The Tweel non-pneumatic solution for First applications for Tweel—iBOT,

the iBOT wheelchair provides consistent Centaur, skid steer, and multiple military

performance and maintenance-free op- uses—are reality for this new airless tech-

eration. Additionally, the use of small nology. In the realm of long-term future

Tweel assemblies on the front casters applications, Michelin is experimenting

allowed designers to eliminate the need with Tweel fitments on passenger cars.

for a complicated suspension device. The Engineers have found that some proper-

adaptation of non-pneumatic Tweel units ties can be tuned independently of each

complements the Centaur’s off-highway other, which is a significant change from

capability. conventional tires. Vertical stiffness—

Both iBOT and Centaur are on the which primarily affects ride comfort—and

lower end of the vehicle maturity curve lateral stiffness—which affects handling

in terms of speed and weight. The next and cornering—can be optimized inde-

steps up the vehicle curve are low-speed pendently.

applications on much heavier industrial The Tweel prototype offers responsive

and military vehicles. handling while staying within 5% of the

The Tweel assembly has completed a rolling resistance and mass levels of to-

second round of field testing on skid day’s tires. That translates to being

steer machines at working locations in within 1% of the fuel economy of a com- Non-pneumatic Tweel assemblies

t h e U . S . , I t a l y, F r a n c e , a n d t h e parable OE fitment of the test application. complement Segway Centaur’s off-

Netherlands. The elimination of air pres- Additionally, lateral stiffness is increased highway capability

sure has drastically reduced down- by a factor of five in this application.

time—a critical issue for the construction The radial tire will continue to be the

industry. The Tweel fitment is more sta- undisputed standard for some time to

ble than traditional skid steer tire solu- come. Tweel is a stretch application for

tions, and enables the equipment to work the future. aei

faster with more comfort for the operator,

aei JUNE 2005 87

You might also like

- Transmision Automatica 4l60 Chevrolet Blazer 95-03Document109 pagesTransmision Automatica 4l60 Chevrolet Blazer 95-03angelo marra100% (2)

- Still NGT4Document6 pagesStill NGT4Ali Biomy100% (1)

- Airless TyresDocument10 pagesAirless TyresPranith KumarNo ratings yet

- Airless TyresDocument10 pagesAirless Tyresacharyasandeep100% (1)

- Airless Tyre 9044 MwiEBemDocument10 pagesAirless Tyre 9044 MwiEBemSachinhonnatti SachinhonnattiNo ratings yet

- Airless Tyre 9044 mwiEBemDocument10 pagesAirless Tyre 9044 mwiEBemVamsi BandiNo ratings yet

- Airless Tyre 9044 MwiEBemDocument10 pagesAirless Tyre 9044 MwiEBemprasanna hamsikaNo ratings yet

- Airless Tyre 9044 MwiEBemDocument10 pagesAirless Tyre 9044 MwiEBemSachinhonnatti SachinhonnattiNo ratings yet

- New Microsoft Word DocumentDocument1 pageNew Microsoft Word DocumentSrikhar KondisettyNo ratings yet

- Problem in Conventoinal Tyre: Portmanteau Tyre French Michelin Polyurethane SpokesDocument12 pagesProblem in Conventoinal Tyre: Portmanteau Tyre French Michelin Polyurethane SpokesBaneeIshaqueKNo ratings yet

- Tweel by MichelinDocument7 pagesTweel by MichelinAbhilash K PillaiNo ratings yet

- Airless Tyres: Sandeepa Chikkalli (2GP16ME038)Document13 pagesAirless Tyres: Sandeepa Chikkalli (2GP16ME038)Anilkumar m rNo ratings yet

- What Is The Uptis Prototype and What Advantages Does It Offer?Document3 pagesWhat Is The Uptis Prototype and What Advantages Does It Offer?Magdiel SchmitzNo ratings yet

- Airless Tyres Seminar ReportsDocument29 pagesAirless Tyres Seminar ReportsHarsha GowdaNo ratings yet

- On TweelDocument21 pagesOn TweelRaju UpparapellyNo ratings yet

- Airless Tyres Seminar ReportsDocument29 pagesAirless Tyres Seminar ReportsPranay Gaddam50% (2)

- Technical Seminar: BY: Praveen S Boodagoli 1SI15ME122 B.E (Mechanical Engineering)Document17 pagesTechnical Seminar: BY: Praveen S Boodagoli 1SI15ME122 B.E (Mechanical Engineering)PRAVEEN BOODAGOLINo ratings yet

- Presentation On TweelsDocument15 pagesPresentation On TweelsRahul100% (4)

- Non Pneumatic TyreDocument13 pagesNon Pneumatic TyreDevender NaikNo ratings yet

- Static Analysis On Custom Polyurethane SDocument4 pagesStatic Analysis On Custom Polyurethane SafshinNo ratings yet

- NPT Report PDFDocument18 pagesNPT Report PDFShridhar KoriNo ratings yet

- AirlessNon Pneumatic TyresDocument14 pagesAirlessNon Pneumatic TyresElaine RodriguezNo ratings yet

- Recent Trends in Tyre TechnologyDocument22 pagesRecent Trends in Tyre TechnologyRahul100% (1)

- Seminar Topic: Tyres: By-N.B.R Kaushik Mechanical 4 Year Roll No:711633Document47 pagesSeminar Topic: Tyres: By-N.B.R Kaushik Mechanical 4 Year Roll No:711633kaushikNo ratings yet

- TPCS Airless Tyres Report VARSHADocument21 pagesTPCS Airless Tyres Report VARSHASumit PatilNo ratings yet

- Airless Tire SeminarDocument15 pagesAirless Tire SeminarTushar JamaleNo ratings yet

- Airless Tires - Satya.Document22 pagesAirless Tires - Satya.noaninbubble100% (2)

- U Turn The Rise and Demise of The AutomoDocument13 pagesU Turn The Rise and Demise of The AutomogaayuraamuNo ratings yet

- The Future of Tires Innovations in Tire TechnologyDocument5 pagesThe Future of Tires Innovations in Tire Technologybrian.kweonaecomNo ratings yet

- Airless Tyres: Presenter: Prasad Govind KumbharDocument19 pagesAirless Tyres: Presenter: Prasad Govind KumbharPrasad Govind KumbharNo ratings yet

- Continental Car Tyres - Best in BrakingDocument9 pagesContinental Car Tyres - Best in BrakingContinentalTyresNo ratings yet

- Brochure Eng (Dynamec)Document14 pagesBrochure Eng (Dynamec)선철규No ratings yet

- Modeling Liquids and Gases Just Got EasierDocument55 pagesModeling Liquids and Gases Just Got Easiergonzalo limachiNo ratings yet

- Estancia PresentaciónDocument5 pagesEstancia Presentaciónislasgonzalezisraelelienai207No ratings yet

- Mwfly Business Magazine EN - CompressedDocument25 pagesMwfly Business Magazine EN - CompressedinfoNo ratings yet

- 2015 Cate Level-1Document27 pages2015 Cate Level-1FlavioRodolfoSevero0% (1)

- Non Pneumatic TyreDocument17 pagesNon Pneumatic Tyrereghurahul88No ratings yet

- Raw Materials of Tyre Industry - Overview (FY 2010-11) : Cord, Polyester Tyre Cord Insufficient To Meet Domestic DemandDocument9 pagesRaw Materials of Tyre Industry - Overview (FY 2010-11) : Cord, Polyester Tyre Cord Insufficient To Meet Domestic DemandGupta GuptaNo ratings yet

- Reddy PDFDocument18 pagesReddy PDF20wj1a0339No ratings yet

- Department of Mechanical Engineering: Seminar Presentation (RME-851) OnDocument22 pagesDepartment of Mechanical Engineering: Seminar Presentation (RME-851) OnshivamNo ratings yet

- 6) Conclusions & Future Scope of Work 308Document1 page6) Conclusions & Future Scope of Work 308Mani SankarNo ratings yet

- Materials in Automotive Application, State of The Art and ProspectsDocument31 pagesMaterials in Automotive Application, State of The Art and ProspectsPaoloMaccaronioNo ratings yet

- 20-20 Vision - Retos de Desarrollo MciDocument5 pages20-20 Vision - Retos de Desarrollo MciDanny RodriguezNo ratings yet

- MICHELIN+CROSSCLIMATEDOSSIER DE PRESSE UK LightDocument12 pagesMICHELIN+CROSSCLIMATEDOSSIER DE PRESSE UK Lightlui lopezNo ratings yet

- Artificial IntelligenceDocument57 pagesArtificial IntelligenceTestNo ratings yet

- Schaeffler de enDocument36 pagesSchaeffler de enzoeNo ratings yet

- Futuro CombustiblesDocument6 pagesFuturo CombustiblesIsamar LópezNo ratings yet

- Tire Technology 032022Document104 pagesTire Technology 032022HYUNSOOK SHINNo ratings yet

- Design of A CFRP Composite Monocoque Simulation ApproachDocument8 pagesDesign of A CFRP Composite Monocoque Simulation ApproachGregory Aguilera LopesNo ratings yet

- Airless TyresDocument20 pagesAirless TyresKingsly Jasper100% (1)

- BCG - The Great Mobility Tech RaceDocument20 pagesBCG - The Great Mobility Tech Raceditokrista100% (1)

- Airless TyreDocument19 pagesAirless TyreSonu KumarNo ratings yet

- BorgWarner - Delphi Technologies Aftermarket - Fuel Brochure - 2020Document12 pagesBorgWarner - Delphi Technologies Aftermarket - Fuel Brochure - 2020Wai MinNo ratings yet

- Michelin Tire Care PDFDocument27 pagesMichelin Tire Care PDFkpil0% (1)

- Airless Tyres: DEPT OF MECHANICAL, AIT, Bangalore - Page 1Document20 pagesAirless Tyres: DEPT OF MECHANICAL, AIT, Bangalore - Page 1Bharath BharmaNo ratings yet

- TSR 051Document3 pagesTSR 051Gokul RajNo ratings yet

- Briefing No.23 Nanotechnology in Automotive TyresDocument4 pagesBriefing No.23 Nanotechnology in Automotive TyresHarilaos VasiliadisNo ratings yet

- Report On Airless TyreDocument22 pagesReport On Airless Tyre7B38 Pratik ShendeNo ratings yet

- The Design and Development of New Hyundai Kappa 1.2L Dual CVVT EngineDocument11 pagesThe Design and Development of New Hyundai Kappa 1.2L Dual CVVT EngineSubbu Kannappan SrinivasanNo ratings yet

- Alfa Sud Four Engine - SAEDocument14 pagesAlfa Sud Four Engine - SAEJulio OrtizNo ratings yet

- Covax D EngineDocument2 pagesCovax D EngineSAJID IBRAHIMNo ratings yet

- Analysis and Simulation of Contact Stress Model For Elastic Wheels On Road SurfaceDocument8 pagesAnalysis and Simulation of Contact Stress Model For Elastic Wheels On Road SurfaceafshinNo ratings yet

- Ottawa UDocument19 pagesOttawa UafshinNo ratings yet

- Static Analysis On Custom Polyurethane SDocument4 pagesStatic Analysis On Custom Polyurethane SafshinNo ratings yet

- Design and Analysis of Air Less Tires: ISSN: 2454-132X Impact Factor: 4.295Document16 pagesDesign and Analysis of Air Less Tires: ISSN: 2454-132X Impact Factor: 4.295afshinNo ratings yet

- Requirements For Tire Models of The Lightweight Wheeled Mobile RobotsDocument19 pagesRequirements For Tire Models of The Lightweight Wheeled Mobile RobotsafshinNo ratings yet

- Surface & Coatings TechnologyDocument8 pagesSurface & Coatings TechnologyafshinNo ratings yet

- Mack Numeros de Funciones PDFDocument2 pagesMack Numeros de Funciones PDFDarío Ache EmeNo ratings yet

- Electronic Stability ProgramDocument23 pagesElectronic Stability ProgramdwiudNo ratings yet

- Dynapac Vibro CA250Document2 pagesDynapac Vibro CA250Rachmat ArifNo ratings yet

- Catalog FilterDocument89 pagesCatalog FilterAnangtri Wahyudi50% (2)

- Programa TU 19 Junio T3Document1 pagePrograma TU 19 Junio T3cumbiambero lopezNo ratings yet

- Goldwing InstructionsDocument5 pagesGoldwing InstructionsVanadia NohanNo ratings yet

- Mercedes Benz's Motorsport HistoryDocument108 pagesMercedes Benz's Motorsport HistoryCsiki GáborNo ratings yet

- Luhar AerodynamicsDocument39 pagesLuhar AerodynamicsJorge EstradaNo ratings yet

- Hyundai Motor IndiaDocument33 pagesHyundai Motor IndiaarnoteamanNo ratings yet

- 01 AC Compressor2022 Hi-1Document2 pages01 AC Compressor2022 Hi-1فريزون يمن-verlzon YemenNo ratings yet

- Scion XD Fault Codes DTCDocument9 pagesScion XD Fault Codes DTCCesar AguirreNo ratings yet

- 2 Poles LiftDocument5 pages2 Poles LiftQirat KhanNo ratings yet

- Affidavit Claim AuthoDocument4 pagesAffidavit Claim AuthoRanie RgmrgmNo ratings yet

- Elite-I20 Hatchback Brochure PDFDocument14 pagesElite-I20 Hatchback Brochure PDFrajsinhbchauhanNo ratings yet

- Veloster Radio Update TSBDocument9 pagesVeloster Radio Update TSBWassim Ben H'midaNo ratings yet

- 1992 300SE 400SE 500SEL Owner's Manual PDFDocument145 pages1992 300SE 400SE 500SEL Owner's Manual PDFفاديابوزور100% (1)

- Research Project Report: On (A Study of Customer Satisfaction Towards Honda in Two-Wheeler in Lucknow)Document79 pagesResearch Project Report: On (A Study of Customer Satisfaction Towards Honda in Two-Wheeler in Lucknow)Piyush SinghNo ratings yet

- Volvo A35C Fuse and Relay BoxDocument5 pagesVolvo A35C Fuse and Relay BoxIisakki100% (1)

- 2014 JP GrandCherokee SPDocument9 pages2014 JP GrandCherokee SPSteve Ruge100% (1)

- Hey Everyone I Am A New and Used Car Salesperson Here To Help Reddit! AMA - IAmADocument58 pagesHey Everyone I Am A New and Used Car Salesperson Here To Help Reddit! AMA - IAmAUserNo ratings yet

- AuDi Kamera Instalacija - De.enDocument22 pagesAuDi Kamera Instalacija - De.enRivle potNo ratings yet

- JLG 800AJ Rough Terrain Knuckle BoomDocument2 pagesJLG 800AJ Rough Terrain Knuckle Boomseii.chenNo ratings yet

- Citroen Dispatch HandbookDocument324 pagesCitroen Dispatch HandbookControl TechNo ratings yet

- Cashless Garages Pan India List-NewDocument17 pagesCashless Garages Pan India List-NewkkskkssNo ratings yet

- The All-New ToyotaDocument10 pagesThe All-New ToyotaBINNo ratings yet

- Business Proposal New VentureDocument18 pagesBusiness Proposal New VentureBramhananda ReddyNo ratings yet

- Revoflash 3 r19 Vag Ecu List v08 05Document6 pagesRevoflash 3 r19 Vag Ecu List v08 05Gasper Ceballos100% (1)