Professional Documents

Culture Documents

An Experimental Investigation of Spark Ignition Engine Fueled With Ethanol/Iso-octane and Methanol/Iso-octane Fuel Blends

An Experimental Investigation of Spark Ignition Engine Fueled With Ethanol/Iso-octane and Methanol/Iso-octane Fuel Blends

Uploaded by

Kumar SmitCopyright:

Available Formats

You might also like

- Gate Valve Inspection ChecklistDocument2 pagesGate Valve Inspection ChecklisternmrajaNo ratings yet

- Manual Hatz 1B20-30-40 EDocument37 pagesManual Hatz 1B20-30-40 Eazlan0% (1)

- Declaration of Conformity-Mercury Diesel Sterndrive (VW)Document118 pagesDeclaration of Conformity-Mercury Diesel Sterndrive (VW)Aleksandar VeberovicNo ratings yet

- SSP 442 1.6L TDI Engine With Common Rail Injection SystemDocument48 pagesSSP 442 1.6L TDI Engine With Common Rail Injection SystemNarcisDanielPetrea100% (3)

- Power Plant Review Lecture: By: Engr. Jermhel M. Solis, Ree, RmeDocument14 pagesPower Plant Review Lecture: By: Engr. Jermhel M. Solis, Ree, RmeAt Sa Wakas AyNo ratings yet

- Study of Modified Internal Combustion Engine To Run With Ethanol'Document9 pagesStudy of Modified Internal Combustion Engine To Run With Ethanol'Aasif SheikhNo ratings yet

- The Effects of Ethanol-Gasoline Blends On Performance and Exhaust Emission Characteristics of Spark Ignition EnginesDocument12 pagesThe Effects of Ethanol-Gasoline Blends On Performance and Exhaust Emission Characteristics of Spark Ignition EnginesRodrigo SantosNo ratings yet

- Comparative Assessment of Ethanol and Isobutanol Addition in Gasoline On Engine Performance and Exhaust EmissionsDocument14 pagesComparative Assessment of Ethanol and Isobutanol Addition in Gasoline On Engine Performance and Exhaust Emissionsashraf yusoffNo ratings yet

- Comparing Auto Racing Fuels: Student Guide - SecondaryDocument4 pagesComparing Auto Racing Fuels: Student Guide - SecondaryJanrey DohinogNo ratings yet

- Art 2Document9 pagesArt 2Diego Andres Martinez ForeroNo ratings yet

- A Performance Review of Ethanoldiesel Blended Fuel Samples Incompressionignition Engine 2157 7048 1000256Document6 pagesA Performance Review of Ethanoldiesel Blended Fuel Samples Incompressionignition Engine 2157 7048 1000256helenNo ratings yet

- The Fuel Consumption Study On E85 With Conventional EFI VehicleDocument6 pagesThe Fuel Consumption Study On E85 With Conventional EFI Vehicle莯絕天No ratings yet

- Bio DieselDocument9 pagesBio DieselG.R.AzhaguvelSaranya Professor MechanicalNo ratings yet

- 1 s2.0 S0016236122033312 MainDocument12 pages1 s2.0 S0016236122033312 Maintask51.hevtcpNo ratings yet

- Mohammed 2021Document9 pagesMohammed 2021Tito Adi SuryantoNo ratings yet

- Study and Analysis of Ethanol and Butanol Blends As Fuels For IC EngineDocument8 pagesStudy and Analysis of Ethanol and Butanol Blends As Fuels For IC EngineJohn ShugerNo ratings yet

- Applied Thermal Engineering: Paolo Iodice, Giuseppe Langella, Amedeo AmoresanoDocument9 pagesApplied Thermal Engineering: Paolo Iodice, Giuseppe Langella, Amedeo AmoresanoCJ PerezNo ratings yet

- Effect of Ethanol-Gasoline Blends On Engine Performance PDFDocument7 pagesEffect of Ethanol-Gasoline Blends On Engine Performance PDFclaralisieNo ratings yet

- Systematic Evaluation of 20% Ethanol Gasoline Blend (E20)Document8 pagesSystematic Evaluation of 20% Ethanol Gasoline Blend (E20)Prathamesh AdhavNo ratings yet

- Engine Performance and Exhaust Gas Emissions of Methanol and Ethanol-Diesel Blends - Cenk SayinDocument6 pagesEngine Performance and Exhaust Gas Emissions of Methanol and Ethanol-Diesel Blends - Cenk SayinTan Khai HeanNo ratings yet

- Investigation of The Effects of Gasoline - Ethanol Fuel Blend On Throttle Response and Intake Air Temperature in A Naturally Aspirated S.I. EngineDocument10 pagesInvestigation of The Effects of Gasoline - Ethanol Fuel Blend On Throttle Response and Intake Air Temperature in A Naturally Aspirated S.I. EngineTJPRC PublicationsNo ratings yet

- Balki 2014Document6 pagesBalki 2014Tito Adi SuryantoNo ratings yet

- Quality Improvement of Reformat Gasoline by Using Aniline andDocument9 pagesQuality Improvement of Reformat Gasoline by Using Aniline andRawezh Muhtasim MustafaNo ratings yet

- 21 Ab 11amDocument6 pages21 Ab 11amCJ PerezNo ratings yet

- 28 Ab 10amDocument9 pages28 Ab 10amCJ PerezNo ratings yet

- Performance and Emissions Analysis of N-Butanol Blended With Gasoline in Spark Ignition EngineDocument8 pagesPerformance and Emissions Analysis of N-Butanol Blended With Gasoline in Spark Ignition Engineabd elheq zeguerrouNo ratings yet

- Analysis of Design of Pure Ethanol EnginesDocument13 pagesAnalysis of Design of Pure Ethanol EnginesGuilhermeNo ratings yet

- Study of Combustion Characteristics of An SI Engine Fuelled With Ethanol and Oxygenated Fuel AdditivesDocument7 pagesStudy of Combustion Characteristics of An SI Engine Fuelled With Ethanol and Oxygenated Fuel AdditivesSakthi VelNo ratings yet

- Applied Energy: K. Muralidharan, D. VasudevanDocument10 pagesApplied Energy: K. Muralidharan, D. VasudevanSubhadip DasNo ratings yet

- Ashraf Elfasakhany 2020Document11 pagesAshraf Elfasakhany 2020Tito Adi SuryantoNo ratings yet

- Research ArticleDocument8 pagesResearch ArticleGhanvir SinghNo ratings yet

- An Experimental Investigationto Evaluatethe Effectof EthanolDocument6 pagesAn Experimental Investigationto Evaluatethe Effectof EthanolWagdy KhaterNo ratings yet

- Performance AnalysisDocument10 pagesPerformance AnalysisHimanshu RanjanNo ratings yet

- Alchol As An Alternative To FuelDocument26 pagesAlchol As An Alternative To FuelSandeepKrishnanNo ratings yet

- IIETA JESA Rajnish ReviewDocument10 pagesIIETA JESA Rajnish ReviewRajnishRanjanNo ratings yet

- A Review On Feasibility of Diesel/ Biodiesel/ Ethanol/ Bio-Ethanol Blend As CI Engine FuelDocument4 pagesA Review On Feasibility of Diesel/ Biodiesel/ Ethanol/ Bio-Ethanol Blend As CI Engine FuelInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Ahmad O. Hasan, Hani Al-Rawashdeh, Ala'a H. Al-Muhtaseb, Ahmad Abu-Jrai, Read Ahmad, Joseph ZeaiterDocument7 pagesAhmad O. Hasan, Hani Al-Rawashdeh, Ala'a H. Al-Muhtaseb, Ahmad Abu-Jrai, Read Ahmad, Joseph Zeaitermech mech1No ratings yet

- InvestigacionDocument8 pagesInvestigacionSteve J. CardenasNo ratings yet

- Engineering Science and Technology, An International JournalDocument7 pagesEngineering Science and Technology, An International JournalrohitNo ratings yet

- Elfasakhany 2015Document7 pagesElfasakhany 2015Rifal El-ArbieNo ratings yet

- 10 1016@j Energy 2018 05 120Document32 pages10 1016@j Energy 2018 05 120sanketNo ratings yet

- Engine Performance and Pollutant Emission of An SI Engine Using Ethanol-Gasoline Blended FuelsDocument8 pagesEngine Performance and Pollutant Emission of An SI Engine Using Ethanol-Gasoline Blended FuelsISLAM I. FekryNo ratings yet

- Maria Antonietta Costagliola, Maria Vittoria Prati, Salvatore Florio, Pietro Scorletti, Daniele Terna, Paolo Iodice, Dario Buono, Adolfo SenatoreDocument8 pagesMaria Antonietta Costagliola, Maria Vittoria Prati, Salvatore Florio, Pietro Scorletti, Daniele Terna, Paolo Iodice, Dario Buono, Adolfo SenatoreFebriana Ramdhani SNo ratings yet

- IJETR021975Document6 pagesIJETR021975erpublicationNo ratings yet

- Jameel 3 EditedDocument25 pagesJameel 3 EditedKalikapuram RajeshNo ratings yet

- Danaiah 2013Document14 pagesDanaiah 2013Tito Adi SuryantoNo ratings yet

- Renewable and Sustainable Energy ReviewsDocument15 pagesRenewable and Sustainable Energy Reviewsmaa1333No ratings yet

- Akash PosterDocument1 pageAkash PosterPatariya RohanNo ratings yet

- Applied Thermal Engineering: Ambarish Datta, Bijan Kumar MandalDocument13 pagesApplied Thermal Engineering: Ambarish Datta, Bijan Kumar Mandalঅম্বরীশ দত্তNo ratings yet

- Likhanov 2020 IOP Conf. Ser. - Mater. Sci. Eng. 734 012208Document6 pagesLikhanov 2020 IOP Conf. Ser. - Mater. Sci. Eng. 734 012208Ammar AhmadNo ratings yet

- 1 s2.0 S0016236120311091 MainDocument11 pages1 s2.0 S0016236120311091 MainMohamed SalahNo ratings yet

- Kandasamy 2019Document9 pagesKandasamy 2019krs gNo ratings yet

- Corrosion Characteristics of Aluminum Alloy in Bio-Ethanol Blended Gasoline Fuel P1Document7 pagesCorrosion Characteristics of Aluminum Alloy in Bio-Ethanol Blended Gasoline Fuel P1Son NguyenNo ratings yet

- JameelDocument8 pagesJameelKalikapuram RajeshNo ratings yet

- Engine Performance and Octane On Demand Studies of A Dual Fuel Spark Ignition Engine With Ethanol-Gasoline Surrogates As FuelDocument11 pagesEngine Performance and Octane On Demand Studies of A Dual Fuel Spark Ignition Engine With Ethanol-Gasoline Surrogates As FuelcahyaniwindartoNo ratings yet

- Applied Thermal Engineering: Research PaperDocument12 pagesApplied Thermal Engineering: Research PaperDevia GahanaNo ratings yet

- Effect of Ethanol-Gasoline Blends On Engine Performance and Exhaust Emissions in Different Compression RatiosDocument7 pagesEffect of Ethanol-Gasoline Blends On Engine Performance and Exhaust Emissions in Different Compression Ratiosali_isam1100% (1)

- Ethanol As Fuel Pros and Cons PDFDocument2 pagesEthanol As Fuel Pros and Cons PDFRositaNo ratings yet

- Performance Test of Diesel Engines Using Ethanol-Diesel Fuels BlendsDocument7 pagesPerformance Test of Diesel Engines Using Ethanol-Diesel Fuels BlendsRidwan AbdurrahmanNo ratings yet

- Energy: E. Sukjit, J.M. Herreros, K.D. Dearn, R. García-Contreras, A. TsolakisDocument11 pagesEnergy: E. Sukjit, J.M. Herreros, K.D. Dearn, R. García-Contreras, A. TsolakisNiti KlinKaewNo ratings yet

- Ahmet Yakin2021Document14 pagesAhmet Yakin2021Tito Adi SuryantoNo ratings yet

- Ethanol Diesel Fuel Blends A Review PDFDocument9 pagesEthanol Diesel Fuel Blends A Review PDFMantap BroNo ratings yet

- Faraz A Khan Full - PaperDocument8 pagesFaraz A Khan Full - PaperFaraz A KhanNo ratings yet

- Progress in Regulated Emissions of Ethanol-Gasoline Blends From A Spark Ignition EngineDocument26 pagesProgress in Regulated Emissions of Ethanol-Gasoline Blends From A Spark Ignition EngineAnh Vương TùngNo ratings yet

- Ethanol Fuel Learn to Make and Use Ethanol to Power Your VehiclesFrom EverandEthanol Fuel Learn to Make and Use Ethanol to Power Your VehiclesNo ratings yet

- Discovery 4 - LR4 2010-2012 - Sec3 - PowertrainDocument2,747 pagesDiscovery 4 - LR4 2010-2012 - Sec3 - PowertrainCristiano DellazariNo ratings yet

- Sciencedirect: Fuel 279 (2020) 118520Document10 pagesSciencedirect: Fuel 279 (2020) 118520prabhaNo ratings yet

- Installation: Inboard Engines S-Drive ADocument56 pagesInstallation: Inboard Engines S-Drive AEric ZachowNo ratings yet

- M-Class W164 1210Document78 pagesM-Class W164 1210Callum Fearnside100% (2)

- Department of Mechanical Engineering ME-8792 Power Plant Engineering Question Bank Unit-I Coal Based Thermal Power Plants Part-ADocument15 pagesDepartment of Mechanical Engineering ME-8792 Power Plant Engineering Question Bank Unit-I Coal Based Thermal Power Plants Part-ABhagavathi ShankarNo ratings yet

- Audi A6Document12 pagesAudi A6Александр СташкевичNo ratings yet

- Application of The GT35 Industrial Gas Turbine For The Propulsion of Fast FerriesDocument5 pagesApplication of The GT35 Industrial Gas Turbine For The Propulsion of Fast FerriesdislocationNo ratings yet

- 565 DFGBDocument3 pages565 DFGBJefri Heriyanto PanjaitanNo ratings yet

- ME 8792 PPE Unit - 2Document71 pagesME 8792 PPE Unit - 2UdamanNo ratings yet

- Lecture Notes On Advanced I C Engine Part I PDFDocument17 pagesLecture Notes On Advanced I C Engine Part I PDFl8o8r8d8s8i8v8No ratings yet

- Caterpillar C9 Engine SpecsDocument3 pagesCaterpillar C9 Engine SpecsDesta 77No ratings yet

- Recomendaciones CaterpillarDocument8 pagesRecomendaciones CaterpillarJose MinoNo ratings yet

- Handbook of Ship SurveyingDocument776 pagesHandbook of Ship SurveyingAbdul Anis100% (6)

- Egs45 5Document2 pagesEgs45 5anggieNo ratings yet

- Wartsila O E RT Flex PDFDocument24 pagesWartsila O E RT Flex PDFaskewshaun100% (1)

- ECMMMDocument54 pagesECMMMLuigi CasamassimaNo ratings yet

- Technical Specification For APU - EMD LocomotivesDocument16 pagesTechnical Specification For APU - EMD LocomotivesBoora Rajashekher0% (1)

- Tech - Interview QuestionDocument20 pagesTech - Interview Questionrautrajeshv100% (1)

- Manual Motor 721-821e Parte 1Document50 pagesManual Motor 721-821e Parte 1Diego ResendeNo ratings yet

- M.V. Clipper Sterling Ship ParticularsDocument9 pagesM.V. Clipper Sterling Ship ParticularsHendriyana RizkyNo ratings yet

- Thermochemistry & Fuels.8 Dec 19Document60 pagesThermochemistry & Fuels.8 Dec 19Jawad AhmedNo ratings yet

- Mechanisms of Formation of Soot and PM The Lecture ContainsDocument9 pagesMechanisms of Formation of Soot and PM The Lecture ContainsKeval ParmarNo ratings yet

- Ina Lubricants Product CatalogueDocument78 pagesIna Lubricants Product CatalogueDaniel DaiaNo ratings yet

- UK Purchased Fm-Ul-Cul Approved Ratings KW/BHP: Fire Pump EnginesDocument11 pagesUK Purchased Fm-Ul-Cul Approved Ratings KW/BHP: Fire Pump Enginesluis vilcañaupaNo ratings yet

- 1/ General: 81 KW (1500 RPM) - 97 KW (1800 RPM)Document3 pages1/ General: 81 KW (1500 RPM) - 97 KW (1800 RPM)Jakaria MoinNo ratings yet

An Experimental Investigation of Spark Ignition Engine Fueled With Ethanol/Iso-octane and Methanol/Iso-octane Fuel Blends

An Experimental Investigation of Spark Ignition Engine Fueled With Ethanol/Iso-octane and Methanol/Iso-octane Fuel Blends

Uploaded by

Kumar SmitOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

An Experimental Investigation of Spark Ignition Engine Fueled With Ethanol/Iso-octane and Methanol/Iso-octane Fuel Blends

An Experimental Investigation of Spark Ignition Engine Fueled With Ethanol/Iso-octane and Methanol/Iso-octane Fuel Blends

Uploaded by

Kumar SmitCopyright:

Available Formats

An Experimental Investigation of Spark Ignition

Engine Fueled with Ethanol/Iso-octane and

Methanol/Iso-octane Fuel Blends

S. K. Kamboj1* M.N. Karimi2

Downloaded from ijae.iust.ac.ir at 13:29 IRST on Tuesday March 7th 2017

1,2 Associated Professor, Department of Mechanical Engineering Faculty of Engineering and Technology Jamia Millia

Islamia, New Delhi- 110 025

sandeepkumarkamboj@rediffmail.com

Abstract

Alcohols have been used as a fuel for engines since 19th century. Among the various alcohols, ethanol and

methanol are known as the most suited renewable, bio-based and ecofriendly fuel for spark-ignition (SI)

engines. The most attractive properties of ethanol and methanol as an SI engine fuel are that it can be

produced from renewable energy sources such as sugar, cane, cassava, many types of waste biomass

materials, corn and barley. In addition, ethanol has higher evaporation heat, octane number and

flammability temperature therefore it has positive influence on engine performance and reduces exhaust

emissions. In this study, the effects of unleaded iso-octane, unleaded iso-octane–ethanol blend (E10) and

isooctane-methanol blend (M10) on engine performance were investigated experimentally in a single

cylinder four-stroke spark-ignition engine. The tests were performed by varying the throttle position,

engine speed and loads. Three sets of observations were recorded at (1301 rpm, 16.8 Kg load), (1468 rpm,

15.8 Kg load) and (1544 rpm, 10 Kg load) for all tested fuels. The results of the engine test showed that IP,

IMEP, Volumetric efficiency and thermal efficiency was higher for the E10 fuel and BSFC was lower. In

general, most suited blend for SI engines has been specified as a blend of 10% ethanol. It was also observed

that better performance was recorded during second set of observation for all the tested fuels. It was also

found that ethanol–gasoline blends allow increasing compression ratio (CR) without knock occurrence.

Keywords: Ethanol-Iso-octane blend, Methanol-Iso-octane blend, Iso-octane, Engine speed, IMEP

vehicles has a main role in this pollution. It is not

1. Introduction sufficient to change the design of motor to cope with

the legal regulations, so it is necessary to continue to

Alternative fuels are derived from resources other work on alternative fuel technologies. It is vital that

than petroleum. The benefit of these fuels is that they the alternative fuel used must be produced from

emit less air pollutant compare to gasoline and most renewable resources and it must be usable directly

of them are more economically beneficial compared without requiring any major changes in the structure

to oil and they are renewable. The most common of the engine. Alcohols have been used as a fuel for

fuels that are used as alternative fuels are natural gas, engines since 19th century. Among the various

propane, ethanol, methanol and hydrogen. Lots of alcohols, ethanol is known as the most suited fuel for

works have been done on engine operating with these spark ignition (SI) engines. Usages of alcohols as a

fuels; few numbers of publications have compared fuel for spark ignition engines have some advantages

some of these fuels together. to compare the gasoline. Both methanol and ethanol

Ethanol and methanol are alcohol- based fuels have better anti-knock characteristics than gasoline.

made by fermenting and distilling starch crops, such The engine thermal efficiency can be improved with

as corn. Both ethanol and methanol produce less increasing of compression ratio. Alcohols burns with

emission than gasoline and increasing air pollution is lower flame temperatures and luminosity owing to

one of the most important problems of developed decreasing the peak temperature inside the cylinder.

countries today. Exhaust emissions from motor So that the heat losses and NOx emissions are lower.

International Journal of Automotive Engineering Vol. 3, Number 2, June 2013

369 An Experimental Investigation of Spark Ignition….

Both methanol and ethanol have high latent heat of ethanol addition leads to an increase in brake power,

vaporization. The latent heat cools the intake air, so brake thermal efficiency, volumetric efficiency and

the increased charge density and increases volumetric fuel consumption by about 8.3%, 9%, 7% and 5.7%

efficiency. However the oxygen content of methanol mean average values, respectively. The best result at

and ethanol reduces their heating value compared to the engine performance and exhaust emissions was

gasoline. As a disadvantage for methanol and ethanol obtained by usage of 20% ethanol fuel blend.

which reduce the vehicle range per liter of fuel tank W. Dai [13] did the study of engine cycle

Downloaded from ijae.iust.ac.ir at 13:29 IRST on Tuesday March 7th 2017

capacity [1–6]. simulation of ethanol gasoline blends. In this study,

Hsieh [7] investigated experimentally the engine an ethanol model has been developed using a Ford

performance and emission of a spark ignition engine, propriety engine CAE tool, GESIM (General Engine

using ethanol–gasoline blend fuels in ratios of 5%, Simulation Program) for the simulation of ethanol and

10%, 20% and 30%. The results showed that with ethanol – gasoline blends. GESIM was then validated

increasing the ethanol rate, the heating value of the against experimental data in a 3.0 L V6 2-valve

blended fuel decreased, while the octane number of engine. It was concluded that GESIM has

the blended fuels increased. By using the ethanol– successfully predicted the trends of engine burn rates,

gasoline blended fuels the engine torque and specific fuel consumption, exhaust temperature, and various

fuel consumption slightly increased. exhaust emissions for E22 and E85 fuels.

Abdel-Rahman and Osman [8] conducted C. Wei [14] did the study of air – fuel ratio on

performance tests on a variable compression ratio engine performance and pollutant emission of an SI

engine using different percentages of ethanol in engine using ethanol – gasoline blended fuels. The

gasoline fuel up to 40%. With increasing of ethanol influence of air – fuel ratio (0.6 to 1.4) on torque,

amount in the blend, the octane number also rise up, brake specific fuel consumption, CO emission, CO2

but decrease the heating value. The power increment emission, HC emission, were evaluated for ethanol –

was observed with the addition of the ethanol up to gasoline blended fuels under different rotational

10% at compression ratio of 10:1. The best speeds (3000 & 4000 rpm) and throttle openings. It

compression ratios were found to be 10, 11 and 12 for was concluded that torque output increases slightly at

20%, 30% and 40% ethanol to give maximum small throttle valve opening when ethanol - gasoline

indicated power, respectively. blended fuel was used and CO and HC emission were

Palmar [9] found that the octane number had an reduced with the increase of ethanol content in the

increment of five and the engine output increased 5% blended fuel. It was also found that CO2 emission per

for every 10% ethanol addition to gasoline. Hamdam unit horse power output was similar or less than that

and Jubran [4] concluded that under partial load the for gasoline fuel.

blended fuel containing 5% ethanol had the best H. S. Yucesu [15] did comparative study of

engine performance and the thermal efficiency was mathematical and experimental analysis of spark

increased by 4 to 12%. ignition engine performance used ethanol – gasoline

Badwan [10] studied blended fuels ranging from blend fuel. In this study, ethanol- unleaded gasoline

E10 to E70 and concluded that the highest antiknock blends (E10, E20, E40, and E60) were tested in a

capability was obtained with E50. One major single cylinder, four stroke spark ignition and fuel

objective of using ethanol gasoline blended fuel is its injection engine by varying the ignition timing,

ability to lower the emissions of CO and UHC. Taylor relative air fuel ratio and compression ratio at a

et al[8] compared the performance of four alcohols. constant speed of 2000 rpm and wide open throttle. It

They found little difference in combustion efficiency was concluded that torque with blended fuels was

of the four alcohols from gasoline. However, using higher than that of base gasoline in all the speed range

alcohol can increase charge density because of the and a significant reduction in HC emissions was

evaporative cooling in the intake manifold. observed as a result of the leaning effect and

In Bayraktar [11], the most suitable blend for SI additional fuel oxygen caused by the ethanol addition.

engines, from the engine performance and CO It was suggested that higher compression ratios can

emissions points of view, was determined to be be used with ethanol gasoline blends without knock.

16.5% theoretically and 7.5% experimentally. CO L. Shenghua [16] did the study of spark ignition

emission was reduced while NO emission was found engine fuelled with methanol gasoline blends. The

to increase due to the rising cylinder temperature. engine was three cylinders with a bore of 68.5 mm.

In the experimental study of Al-Hasan [12], the The methanol was blended with gasoline containing

effects of usage of unleaded gasoline–ethanol blends 10, 15, 20, 25, and 30% in volume. The engine

on spark ignition engine performance and exhaust power, torque and brake thermal efficiency are

emission were investigated. The results showed that measured with the change in speed at WOT condition

International Journal of Automotive Engineering Vol. 3, Number 2, June 2013

S. K. Kamboj and M.N. Karimi 370

with the increased fraction of methanol. Engine efficiency is improved. The maximum pressure is

power and torque decreases while the brake thermal higher than than that of pure gasoline operation under

Downloaded from ijae.iust.ac.ir at 13:29 IRST on Tuesday March 7th 2017

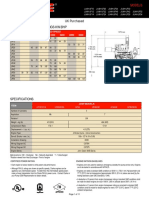

Fig1. Schematic arrangement of the spark ignition engine

F1 Fuel consumption kg/hr

F2 Air consumption kg/hr

F4 Calorimeter water flow kg/hr

T3 Calorimeter water inlet temperature 0K

T4 Calorimeter water outlet temperature 0K

T5 Exhaust gas to calorimeter inlet temperature. 0K

T6 Exhaust gas from calorimeter outlet temperature. 0K

the same engine speed and throttle opening (50% Mustafa KOc [18] evaluated the effects of ethanol

WOT) when engine fuelled with M20. – unleaded gasoline blends on engine performance

M. KOc [17] evaluated the effects of unleaded and exhaust emissions in a spark- ignition engine. In

gasoline and unleaded gasoline ethanol blends (E50 this study, the effects of unleaded gasoline and

and E85) on engine performance and pollutant unleaded gasoline ethanol blends (E50 and E85) on

emissions experimentally in a single cylinder four- engine performance and pollutant emissions were

stroke spark ignition engine at two compression ratios investigated experimentally in a single cylinder four-

(10.1 and 11.1) at varying engine speed 1500 rpm to stroke spark ignition engine at two compression ratios

5000 rpm. The effect of unleaded gasoline- ethanol (10.1 and 11.1) at varying engine speed 1500 rpm to

blends on engine torque, BSFC and HC emission 5000 rpm. The effect of unleaded gasoline- ethanol

were evaluated at different compression ratio. It was blends on engine torque, BSFC and HC emission

concluded that ethanol addition to unleaded gasoline were evaluated at different compression ratio.

increase the engine torque, power and fuel The literature survey shows that using ethanol and

consumption and reduce carbon monoxide (CO), methanol in SI engines by blending with iso-octane is

nitrogen oxides (NOX) and hydrocarbon (HC) more practical than using it alone. If ethanol and

emissions. methanol production can meet the demand and cost of

International Journal of Automotive Engineering Vol. 3, Number 2, June 2013

371 An Experimental Investigation of Spark Ignition…..

blended fuels can compete with that of E10, M10) were tested. These fuels were iso-octane,

conventional iso-octane, widespread use of E10 and iso-octane ethanol blend E10 and iso-octane-

M10 blends can be possible. For this reason, the methanol blend M10, the numbers following E and M

present study is focused on this topic. Here, the indicate percentage of volumetric amount of ethanol,

effects of ethanol and methanol addition to iso-octane methanol. Properties of ethanol, methanol, and

in 10% concentrations on engine performance are gasoline are shown in table 1. Engine indicated

examined by conducting experimental studies. power, brake power, friction power, indicated mean

Downloaded from ijae.iust.ac.ir at 13:29 IRST on Tuesday March 7th 2017

effective pressure, brake mean effective pressure,

2. Experimental Analysis turning moment brake specific fuel consumption,

exhaust gas temperature, volumetric efficiency and

The experiments were conducted at three (1301, thermal efficiency were measured during the

1468 &1544 rpm) engine speeds, with three engine experiments. No data was taken until speed and load

loads (16.82 Kg, 15.8 Kg and 10 Kg) by varying the were maintained at 1% of the fluctuation. For each

throttle openings. Three different fuels ( Iso-octane, experiment, air fuel ratio was changed to maintain the

same speed and load..

Table 1 Comparison of fuel properties

Property Methanol Ethanol Iso-octane

Chemical formula CH3OH C2H5OH C8H18

Molecular weight(Kg/kmol) 32.04 46.07 114.228

Oxyzen present (wt %) 49.9 34.8 -

Density (g cm-1) 792 789 740

Freezing point at 1 atm (0C) -97.778 -80.0 -107.378

Boiling temperature at 1 atm (0C) 64.9 74.4 99.224

Auto-ignition temperature(0C) 463.889 422.778 257.23

Latent heat of vaporization at 200C 1103 840 349

(KJ/Kg)

Stoichiometric air/fuel ratio (AFR) 6.47 9.0 15.2

Lower heating value of the fuel 20000 26900 44300

(KJ/Kg)

Research octane number (RON) 111 108 100

Motor octane number (MON) 92 92 100

Table 2 Specification of the engine

Type 1 cylinder, 4 stroke, water cooled

Cylinder bore and stroke 110 mm, 87.5 mm

Compression ratio 10

Maximum power 4.5 kW at 1800 rpm

Spark variation range 0 – 70 deg btdc

Dynamometer Eddy current, water cooled, with loading unit

Air Box M S fabricated with orifice meter and manometer

Fuel tank Capacity 15 ltr, dual compartment, with fuel

metering pipe of glass

Calorimeter Pipe in pipe

Piezo sensor Combustion 5000 psi

Crank angle sensor 1 deg, speed 5500 rpm with tdc pulse

Temperature sensor Type RTD, PT 100 and Thermocouple, type k

Load indicator Digital, range 0-50 kg, supply 230 V AC

Fuel flow transmitter DP transmitter, Range 0- 500 mm WC

Air Flow Transmitter Pressure transmitter

Rota meter Engine cooling 40- 400 LPH; Calorimeter 25-250

LPH

International Journal of Automotive Engineering Vol. 3, Number 2, June 2013

S. K. Kamboj and M.N. Karimi 372

The setup consists of single cylinder, four stroke, 3. Effect of Ethanol-Iso-octane and Methanol –

Multi-fuel, research engine connected to eddy current Iso-octane Blends on Engine Performance

type dynamometer for loading. The operation mode

of the engine can be changed from diesel to Petrol or This paper is intended to study engine

from Petrol to Diesel with some necessary changes. In performance when it utilizes low fraction of ethanol-

both modes the compression ratio can be varied iso-octane and methanol-iso-octane blends. Three sets

without stopping the engine and without altering the of observations were recorded for the different

Downloaded from ijae.iust.ac.ir at 13:29 IRST on Tuesday March 7th 2017

combustion chamber geometry by specially designed purpose of engine test containing iso-octane, E10 (

tilting cylinder block arrangement. The injection point iso-octane & 10% of ethanol in volume blend) and

and spark point can be changed for research tests. M10( iso-octane & 10% of methanol in volume

Setup is provided with necessary instruments for blend) fuels. Three sets of observations are namely 1.

combustion pressure and crank-angle measurements. (1301 rpm, 16.82 Kg load), 2. (1468 rpm, 15.8 Kg

These signals are interfaced with computer for load) and 3.( 1544 rpm, 10 Kg load).

pressure crank-angle diagrams. Instruments are

provided to interface airflow, fuel flow, temperatures 3.1 INDICATED POWER

and load measurements. The set up has stand-alone

panel box consisting of air box, two fuel tanks for Under the same engine speed and load, see in fig.

duel fuel test, manometer, fuel measuring unit, 2, when the engine is fuelled with different fuels

transmitters for air and fuel flow measurements, (E10, M10, & iso-octane). The indicated power is

process indicator and hardware interface. Rotameters higher than that of iso-octane for E10 and M10 fuels.

are provided for cooling water and calorimeter water It is maximum for E10 and minimum for iso-octane

flow measurement. A battery, starter and battery and maximum increment is 20.2, 15.1 and 8.72%,

charger is provided for engine electric start respectively for 1st, 2nd and 3rd set of observation.

arrangement. The setup enables study of VCR engine The engine power of M10 is about 5.71, 4.8, and 2.9

performance for brake power, indicated power, % higher in comparison to iso-octane. It is because of

frictional power, BMEP, IMEP, brake thermal the reason that oxygenated fuels have better

efficiency, indicated thermal efficiency, Mechanical combustion efficiency and thermal efficiency.

efficiency, volumetric efficiency, specific fuel Thermal efficiency of E10 and M10 are nearly 20 and

consumption, A/F ratio, heat balance and combustion 5% higher than the base fuel. It is also shown in

analysis. Lab view based Engine Performance figure that indicated power increases with the increase

Analysis software package “Engine soft” is provided in engine speed and loads.

for on line performance evaluation.

6

5

Indicated power (kW)

4

3 E10

2 M10

1 Iso-octane

0

1301 (16.82 Kg) 1468 (15.8 Kg) 1544 (10 Kg)

Engine speed (rpm) and load (Kg)

Fig2. The combined effect of engine speed and load on indicated power

International Journal of Automotive Engineering Vol. 3, Number 2, June 2013

373 An Experimental Investigation of Spark Ignition…..

5

4.5

4

Indicated power (kW)

3.5

3

Downloaded from ijae.iust.ac.ir at 13:29 IRST on Tuesday March 7th 2017

2.5 E10

2 M10

1.5 Iso-octane

1

0.5

0

1301 (16.82 Kg) 1468 (15.8 Kg) 1544 (10 Kg)

Engine speed (rpm) and load

Fig3. The combined effect of engine speed and load on the brake power

7

6

5

IMEP (bar)

4

E10

3

M10

2

Iso-octane

1

0

1301 (16.82 Kg) 1468 (15.8 Kg) 1544 (10 Kg)

Engine speed (rpm) and load

Fig4. Combined effect of speed and load on IMEP

Fig.4 shows the variations in indicated mean

3.2 Brake Power

effective pressure with the change in engine speed

and the load. Figure shows that IMEP increases with

Fig.3 shows the variation in brake power with the increase in engine speed for all the tested fuels.

respect to combined effect of engine speed and load

IMEP is maximum for the E10 fuel and this

for all tested fuels. It is shown in the figure that brake

increment is 19.6, 15.1 and 10% greater than the base

power is maximum and equal at medium load and fuel at all set of observations, respectively. IMEP for

medium speed for all tested fuels. The brake power of M10 is nearly 5% greater than the base fuel for all set

M10 is slightly lower than base fuel because of the of observations. It is because of the reason that

reason that friction power of M10 is much lower than thermal efficiency and volumetric efficiency of E10

the iso-octane. and M10 fuels are much higher which results in

3.3 IMEP (indicated mean effective pressure)

International Journal of Automotive Engineering Vol. 3, Number 2, June 2013

S. K. Kamboj and M.N. Karimi 374

5

BMEP (bar)

Downloaded from ijae.iust.ac.ir at 13:29 IRST on Tuesday March 7th 2017

4

E10

3

M10

2 Iso-octane

1

0

1301 (16.82 Kg) 1468 (15.8 Kg) 1544 (10 Kg)

Engine speed (rpm) and load

Fig5. The combined effect of engine speed and load on the BMEP of ethanol and methanol fuel blends

35

30

Turning moment (N-m)

25

20 E10

15 M10

10 Iso-octane

0

1301 (16.82 Kg) 1468 (15.8 Kg) 1544 (10 Kg)

Engine speed (rpm) and load

Fig6. The combied effect of engine speed and load on the engine torque for the ethanol and methanol blend fuel

air), fuel air ratio (effectiveness of air utilization in

higher indicated mean effective pressure in spite combustion and fuel conversion efficiency). In

of lower heating value. supercharged engines BMEP indicates the degree of

success in handling higher gas pressures and thermal

3.4 BMEP loading. It is clearly observed from the figure that

BMEP increases with the increase in engine load.

The result for the ethanol and methanol blends

(Fig.5) show a significant improvement in BMEP 3.5 Turning moment

during first set of observation when compared with

other observations. In naturally aspirated engines, Fig.6 shows the variations in turning moment with

brake mean effective pressure is not stress limited, it the change in speed and load for the E10, M10 and

then reflects the product of efficiency(ability to induct iso-octane fuels. In general, the highest turning

International Journal of Automotive Engineering Vol. 3, Number 2, June 2013

375 An Experimental Investigation of Spark Ignition….

moment is observed with the E10. This is

explained with several reasons. Beneficial effect of

ethanol as an oxygenated fuel is a possible reason for 3.7 Volumetric efficiency

more complete combustion, thereby increasing the

torque. In addition, a larger fuel for the same volume Fig. 8 represents combined effect of engine speed

is injected to the cylinder due to higher density of and load on the volumetric efficiency for all the tested

ethanol. This results in increase in torque and power. fuels. It is shown in the figure that volumetric

Downloaded from ijae.iust.ac.ir at 13:29 IRST on Tuesday March 7th 2017

And finally, the latent heat of evaporation of blended efficiency of E10 and M10 is nearly 10% higher than

fuels is higher than that of base gasoline; this provides the base fuel for two sets of observation and for third

lower temperature intake manifold and increases set of observation, volumetric efficiency is much

volumetric efficiency. The charge into the cylinder lower and it is because of the reasons that as liqid

directly affects on torque and power. The average fuels have high latent heat of vaporization, they

increment in engine torque compared with Iso-octane produce a cooling effect on the intake charge during

was about 0.68% for E10 fuel. vaporization. Therefore, there will be an increase in

intake charge density and consequently in volumetric

3.6 Exhaust temperature efficiency. A/F ratio is another important parameter

that affects volumetric efficiency. When

Fig .7 shows the combined effect of engine speed stoichiometric A/F ratio is high that means there is

and load on the exhaust gas temperature more quantity of air injected in inlet air and results in

corresponding to all tested fuels. It is shown in the increased volumetric efficiency. The methanol and

figure that exhaust temperature is maximum at the ethanol has high latent heat of vaporization than the

medium speed and medium load for all tested fuels. It base fuel and A/F ratio is also high therefore

is also shown from figure that exhaust temperature is volumetric efficiency of methanol is high at medium

maximum for iso-octane for all set of observations speed and loads. The volumetric efficiency of iso-

followed by methanol. Exhaust gas temperature is octane is lower than the E10 and M10 and it is

minimum for the E10 for all set of observations. The because of the reason that latent heat of vaporization

heating value of iso-octane is greater than E10 and of iso-octane is lowest among all the fuels. The latent

M10 and thermal efficiency is low so more heat heat of vaporization of ethanol and methanol is 3.16

would be rejected with the exhaust gases. These and 2.4 times greater than the iso-octane. It is also

variations in exhaust temperature can be attributed to seen from the figure that at low load and high speed,

increase in thermal efficiency or A/F ratio which volumetric efficiency is low for all the tested fuels

affects the combustion temperature. Higher because of rich fuel is supply.

combustion temperature leads to higher exhaust

temperature.

460

Exhaust temperature (0C)

440

420

400 E10

M10

380

Iso-octane

360

340

1301 (16.82 Kg) 1468 (15.8 Kg) 1544 (10 Kg)

Engine speed (rpm) and load

Fig7. The combined effect of speed and load on the exhaust temperature

International Journal of Automotive Engineering Vol. 3, Number 2, June 2013

S. K. Kamboj and M.N. Karimi 376

70

60 E10

M10

Volumetric efficiency (%)

50 Iso-octane

40

Downloaded from ijae.iust.ac.ir at 13:29 IRST on Tuesday March 7th 2017

30

20

10

0

1301 (16.82 Kg) 1468 (15.8 Kg) 1544 (10 Kg)

Engine load (rpm) and speed

Fig8. The combined effect of engine load and speed on the volumetric efficiency

0.5 Fig.9 The combined effect of speed and load on BSFC

0.45

0.4

0.35

0.3

BSFC

0.25 E10

0.2 M10

0.15 Iso-octane

0.1

0.05

0

1301 (16.82 Kg) 1468 (15.8 Kg) 1544 (10 Kg)

Engine speed (rpm) and load

Fig9. The combined effect of speed and load on BSFC

ethanol-iso-octane and methanol iso-octane fuels

3.8 BSFC

causes some increment in BSFC of the engine when it

is used without any modification. The increment

Fig.9 shows the combined effect of engine speed mainly depends upon the percentage of ethanol and

and load at the brake specific fuel consumption for all methanol addition in iso-octane. The heating value of

the fuels. It is well known fact that heating value of

ethanol & methanol are approximately 39.27% &

fuel affects the BSFC. The lower energy content of

International Journal of Automotive Engineering Vol. 3, Number 2, June 2013

377 An Experimental Investigation of Spark Ignition….

35

30

Thermal efficiency (%)

25

Downloaded from ijae.iust.ac.ir at 13:29 IRST on Tuesday March 7th 2017

20

E10

15

M10

10 Iso-octane

0

1301 (16.82 Kg) 1468 (15.8 Kg) 1544 (10 Kg)

Engine speed (rpm) and load

Fig10. The combined effect of engine speed and load on thermal efficiency

Conclusion:

54.85% less than the values of iso-octane.

Therefore, more blends of fuel are required to In this study, engine performance was measured

produce the same power at the same operating on the utilization of the ethanol- iso-octane (E10) and

conditions due to its lower heating value in methanol iso-octane blended fuels (M10) under

comparison to base fuel. As a result, BSFC increases. different engine speed and different loads. General

However, as mentioned earlier, ethanol and methanol results concluded from this study can be summarized

addition to iso-octane makes the engine operation as follows:

leaner and improves combustion and performance. 1. The value of IP, BP, IMEP, Exhaust

Therefore, the thermal efficiency of E10 is 22.4, 20 temperature, volumetric efficiency and thermal

and 36.8% greater than the base fuel and efficiency was higher for the second set of

approximately 5% greater for M10 fuel. For these observation for all the tested fuels.

reason, brake specific fuel consumption of blends are 2. Ethanol and methanol addition to iso-octane

lower than those of iso-octane fueled engine leads to leaner operation because of increased

volumetric efficiency and improves combustion.

3.9 Thermal efficiency Consequently, the cylinder pressure and temperature

increases.

Fig.10 shows the combined effect of engine speed 3. The value of BMEP and turning moment was

and load on thermal efficiency for all the fuels. It is slightly higher for first set of observations because of

shown from the figure that thermal efficiency of E10 higher loads.

and M10 fuels is much higher than the base fuel. It is 4. The value of BSFC was maximum for the third

22.4,20 and 36.8% higher for E10 and approximately set of observation and minimum for second set for all

5% for the M10. It is because of the reason that the tested fuels and its maximum value was for base

volumetric efficiency of E10 and M10 fuels are fuel.

higher than the base fuel. For all sets of observations, 5. IP, IMEP, Volumetric efficiency and thermal

volumetric efficiency of E10 is higher followed by efficiency was higher for the E10 fuel.

M10. 6. In general, most suited blend for SI engines has

been specified as a blend of 10% ethanol. This blend

gives better performance at medium speed and

medium loads.

International Journal of Automotive Engineering Vol. 3, Number 2, June 2013

S. K. Kamboj and M.N. Karimi 378

REFERENCES Atmospheric Environment 2004; 38 : 7093-

7100.

[1]. He BQ, Wang JX, Hao JM, Yan XG, Xiao JH.

A study on emission characteristics of an EFI [15]. Yucesu HS, Sozen A, Topgu T, Arcakliog E.

engine with ethanol blended gasoline fuels. Comparative study of mathematical and

Atmospheric Environment 2003; 37:949–57. experimental analysis of spark ignition engine

[2]. Thring RH. Alternative fuels for spark-ignition performance used ethanol – gasoline blend fuel,

Downloaded from ijae.iust.ac.ir at 13:29 IRST on Tuesday March 7th 2017

engines. SAE paper no: 831685; 1983: 4715– Applied Thermal Engineering 2007; 27: 358–

25. 368.

[3]. Prasad S, Singh A, Joshi HC. Ethanol as an [16]. Shenghua L, Clemente ERC, Tiegang H, Yanjv

alternative fuel from agricultural, industrial and W. Study of spark ignition engine fueled with

urban residues. Resources Conservation and methanol/ gasoline fuel blends. Applied

Recycling 2007;50(1):1–39. Thermal Engineering 2007; 27(11-12): 1904-

[4]. Wagner TO, Gray DS, Zarah BY, Kozinski 1910.

AA. Practicality of alcohols as motor fuel. SAE [17]. Chen R-H , Chiang Li-Bin, Wu M-H, Lin T-H,

paper no: 790429; 1979. Gasoline displacement and NOx reduction in an

[5]. Thring RH. Alternative fuel for spark-ignition SI engine by aqueous alcohol

engines. SAE paper 831685; 1983. injection,Fuel,2010; 89 : 604–610.

[6]. Alasfour FN. Butanol- A single cylinder engine [18]. Koç M, Sekmen Y, Topgu T, Hu- seyin Serdar

study: availability analysis. Applied Thermal Yu-cesu, The effects of ethanol–unleaded

Engineering 1997; 17: 537-549 gasoline blends on engine performance and

[7]. Hsieh WD, Chen RH, Wu TL, Lin TH. Engine exhaust emissions in a spark-ignition engine,

performance and pollutant emission of an SI Renewable Energy,2009; 34 : 2101–2106.

engine using ethanol–gasoline blended fuels.

Atmospheric Environment 2002;36(3):403–10.

[8]. Abdel-Rahman AA, Osman MM. Experimental

investigation on varying the compression ratio

of SI engine working under different ethanol–

gasoline fuel blends. Int J Energy Res 1997;

[9]. Palmer FH. Vehicle performances of gasoline

containing oxygenate. In: International

conference on petroleum based fuels and

automotive applications, London, UK; 1986. p.

33–46.

[10]. Badwan MS. Performance and knock limits of

ethanol–gasoline blends in spark-ignited

engines. SAE paper 850213; 1985.

[11]. Bayraktar H. Experimental and theoretical

investigation of using gasoline– ethanol blends

in spark ignition engines. Renewable Energy

2005; 30:1733–47.

[12]. Al-Hasan M. Effect of ethanol–unleaded

gasoline blends on engine performance and

exhaust emissions. Energy Conversion and

Management 2003; 44:1547–61.

[13]. Dai W, Cheemalamarri S, Eric W, Boussarsar

R, Morton RK. Engine cycle simulation of

ethanol and gasoline blends. SAE paper 2003-

01-3093. Society of Automotive engineers,

2003; 2110 – 2117.

[14]. Wu C-W, Chen R-H, Pu J-Y, Lin T-H. The

influence of air – fuel ratio on engine

performance and pollutant emission of an SI

engine using ethanol – gasoline blended fuels,

International Journal of Automotive Engineering Vol. 3, Number 2, June 2013

You might also like

- Gate Valve Inspection ChecklistDocument2 pagesGate Valve Inspection ChecklisternmrajaNo ratings yet

- Manual Hatz 1B20-30-40 EDocument37 pagesManual Hatz 1B20-30-40 Eazlan0% (1)

- Declaration of Conformity-Mercury Diesel Sterndrive (VW)Document118 pagesDeclaration of Conformity-Mercury Diesel Sterndrive (VW)Aleksandar VeberovicNo ratings yet

- SSP 442 1.6L TDI Engine With Common Rail Injection SystemDocument48 pagesSSP 442 1.6L TDI Engine With Common Rail Injection SystemNarcisDanielPetrea100% (3)

- Power Plant Review Lecture: By: Engr. Jermhel M. Solis, Ree, RmeDocument14 pagesPower Plant Review Lecture: By: Engr. Jermhel M. Solis, Ree, RmeAt Sa Wakas AyNo ratings yet

- Study of Modified Internal Combustion Engine To Run With Ethanol'Document9 pagesStudy of Modified Internal Combustion Engine To Run With Ethanol'Aasif SheikhNo ratings yet

- The Effects of Ethanol-Gasoline Blends On Performance and Exhaust Emission Characteristics of Spark Ignition EnginesDocument12 pagesThe Effects of Ethanol-Gasoline Blends On Performance and Exhaust Emission Characteristics of Spark Ignition EnginesRodrigo SantosNo ratings yet

- Comparative Assessment of Ethanol and Isobutanol Addition in Gasoline On Engine Performance and Exhaust EmissionsDocument14 pagesComparative Assessment of Ethanol and Isobutanol Addition in Gasoline On Engine Performance and Exhaust Emissionsashraf yusoffNo ratings yet

- Comparing Auto Racing Fuels: Student Guide - SecondaryDocument4 pagesComparing Auto Racing Fuels: Student Guide - SecondaryJanrey DohinogNo ratings yet

- Art 2Document9 pagesArt 2Diego Andres Martinez ForeroNo ratings yet

- A Performance Review of Ethanoldiesel Blended Fuel Samples Incompressionignition Engine 2157 7048 1000256Document6 pagesA Performance Review of Ethanoldiesel Blended Fuel Samples Incompressionignition Engine 2157 7048 1000256helenNo ratings yet

- The Fuel Consumption Study On E85 With Conventional EFI VehicleDocument6 pagesThe Fuel Consumption Study On E85 With Conventional EFI Vehicle莯絕天No ratings yet

- Bio DieselDocument9 pagesBio DieselG.R.AzhaguvelSaranya Professor MechanicalNo ratings yet

- 1 s2.0 S0016236122033312 MainDocument12 pages1 s2.0 S0016236122033312 Maintask51.hevtcpNo ratings yet

- Mohammed 2021Document9 pagesMohammed 2021Tito Adi SuryantoNo ratings yet

- Study and Analysis of Ethanol and Butanol Blends As Fuels For IC EngineDocument8 pagesStudy and Analysis of Ethanol and Butanol Blends As Fuels For IC EngineJohn ShugerNo ratings yet

- Applied Thermal Engineering: Paolo Iodice, Giuseppe Langella, Amedeo AmoresanoDocument9 pagesApplied Thermal Engineering: Paolo Iodice, Giuseppe Langella, Amedeo AmoresanoCJ PerezNo ratings yet

- Effect of Ethanol-Gasoline Blends On Engine Performance PDFDocument7 pagesEffect of Ethanol-Gasoline Blends On Engine Performance PDFclaralisieNo ratings yet

- Systematic Evaluation of 20% Ethanol Gasoline Blend (E20)Document8 pagesSystematic Evaluation of 20% Ethanol Gasoline Blend (E20)Prathamesh AdhavNo ratings yet

- Engine Performance and Exhaust Gas Emissions of Methanol and Ethanol-Diesel Blends - Cenk SayinDocument6 pagesEngine Performance and Exhaust Gas Emissions of Methanol and Ethanol-Diesel Blends - Cenk SayinTan Khai HeanNo ratings yet

- Investigation of The Effects of Gasoline - Ethanol Fuel Blend On Throttle Response and Intake Air Temperature in A Naturally Aspirated S.I. EngineDocument10 pagesInvestigation of The Effects of Gasoline - Ethanol Fuel Blend On Throttle Response and Intake Air Temperature in A Naturally Aspirated S.I. EngineTJPRC PublicationsNo ratings yet

- Balki 2014Document6 pagesBalki 2014Tito Adi SuryantoNo ratings yet

- Quality Improvement of Reformat Gasoline by Using Aniline andDocument9 pagesQuality Improvement of Reformat Gasoline by Using Aniline andRawezh Muhtasim MustafaNo ratings yet

- 21 Ab 11amDocument6 pages21 Ab 11amCJ PerezNo ratings yet

- 28 Ab 10amDocument9 pages28 Ab 10amCJ PerezNo ratings yet

- Performance and Emissions Analysis of N-Butanol Blended With Gasoline in Spark Ignition EngineDocument8 pagesPerformance and Emissions Analysis of N-Butanol Blended With Gasoline in Spark Ignition Engineabd elheq zeguerrouNo ratings yet

- Analysis of Design of Pure Ethanol EnginesDocument13 pagesAnalysis of Design of Pure Ethanol EnginesGuilhermeNo ratings yet

- Study of Combustion Characteristics of An SI Engine Fuelled With Ethanol and Oxygenated Fuel AdditivesDocument7 pagesStudy of Combustion Characteristics of An SI Engine Fuelled With Ethanol and Oxygenated Fuel AdditivesSakthi VelNo ratings yet

- Applied Energy: K. Muralidharan, D. VasudevanDocument10 pagesApplied Energy: K. Muralidharan, D. VasudevanSubhadip DasNo ratings yet

- Ashraf Elfasakhany 2020Document11 pagesAshraf Elfasakhany 2020Tito Adi SuryantoNo ratings yet

- Research ArticleDocument8 pagesResearch ArticleGhanvir SinghNo ratings yet

- An Experimental Investigationto Evaluatethe Effectof EthanolDocument6 pagesAn Experimental Investigationto Evaluatethe Effectof EthanolWagdy KhaterNo ratings yet

- Performance AnalysisDocument10 pagesPerformance AnalysisHimanshu RanjanNo ratings yet

- Alchol As An Alternative To FuelDocument26 pagesAlchol As An Alternative To FuelSandeepKrishnanNo ratings yet

- IIETA JESA Rajnish ReviewDocument10 pagesIIETA JESA Rajnish ReviewRajnishRanjanNo ratings yet

- A Review On Feasibility of Diesel/ Biodiesel/ Ethanol/ Bio-Ethanol Blend As CI Engine FuelDocument4 pagesA Review On Feasibility of Diesel/ Biodiesel/ Ethanol/ Bio-Ethanol Blend As CI Engine FuelInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Ahmad O. Hasan, Hani Al-Rawashdeh, Ala'a H. Al-Muhtaseb, Ahmad Abu-Jrai, Read Ahmad, Joseph ZeaiterDocument7 pagesAhmad O. Hasan, Hani Al-Rawashdeh, Ala'a H. Al-Muhtaseb, Ahmad Abu-Jrai, Read Ahmad, Joseph Zeaitermech mech1No ratings yet

- InvestigacionDocument8 pagesInvestigacionSteve J. CardenasNo ratings yet

- Engineering Science and Technology, An International JournalDocument7 pagesEngineering Science and Technology, An International JournalrohitNo ratings yet

- Elfasakhany 2015Document7 pagesElfasakhany 2015Rifal El-ArbieNo ratings yet

- 10 1016@j Energy 2018 05 120Document32 pages10 1016@j Energy 2018 05 120sanketNo ratings yet

- Engine Performance and Pollutant Emission of An SI Engine Using Ethanol-Gasoline Blended FuelsDocument8 pagesEngine Performance and Pollutant Emission of An SI Engine Using Ethanol-Gasoline Blended FuelsISLAM I. FekryNo ratings yet

- Maria Antonietta Costagliola, Maria Vittoria Prati, Salvatore Florio, Pietro Scorletti, Daniele Terna, Paolo Iodice, Dario Buono, Adolfo SenatoreDocument8 pagesMaria Antonietta Costagliola, Maria Vittoria Prati, Salvatore Florio, Pietro Scorletti, Daniele Terna, Paolo Iodice, Dario Buono, Adolfo SenatoreFebriana Ramdhani SNo ratings yet

- IJETR021975Document6 pagesIJETR021975erpublicationNo ratings yet

- Jameel 3 EditedDocument25 pagesJameel 3 EditedKalikapuram RajeshNo ratings yet

- Danaiah 2013Document14 pagesDanaiah 2013Tito Adi SuryantoNo ratings yet

- Renewable and Sustainable Energy ReviewsDocument15 pagesRenewable and Sustainable Energy Reviewsmaa1333No ratings yet

- Akash PosterDocument1 pageAkash PosterPatariya RohanNo ratings yet

- Applied Thermal Engineering: Ambarish Datta, Bijan Kumar MandalDocument13 pagesApplied Thermal Engineering: Ambarish Datta, Bijan Kumar Mandalঅম্বরীশ দত্তNo ratings yet

- Likhanov 2020 IOP Conf. Ser. - Mater. Sci. Eng. 734 012208Document6 pagesLikhanov 2020 IOP Conf. Ser. - Mater. Sci. Eng. 734 012208Ammar AhmadNo ratings yet

- 1 s2.0 S0016236120311091 MainDocument11 pages1 s2.0 S0016236120311091 MainMohamed SalahNo ratings yet

- Kandasamy 2019Document9 pagesKandasamy 2019krs gNo ratings yet

- Corrosion Characteristics of Aluminum Alloy in Bio-Ethanol Blended Gasoline Fuel P1Document7 pagesCorrosion Characteristics of Aluminum Alloy in Bio-Ethanol Blended Gasoline Fuel P1Son NguyenNo ratings yet

- JameelDocument8 pagesJameelKalikapuram RajeshNo ratings yet

- Engine Performance and Octane On Demand Studies of A Dual Fuel Spark Ignition Engine With Ethanol-Gasoline Surrogates As FuelDocument11 pagesEngine Performance and Octane On Demand Studies of A Dual Fuel Spark Ignition Engine With Ethanol-Gasoline Surrogates As FuelcahyaniwindartoNo ratings yet

- Applied Thermal Engineering: Research PaperDocument12 pagesApplied Thermal Engineering: Research PaperDevia GahanaNo ratings yet

- Effect of Ethanol-Gasoline Blends On Engine Performance and Exhaust Emissions in Different Compression RatiosDocument7 pagesEffect of Ethanol-Gasoline Blends On Engine Performance and Exhaust Emissions in Different Compression Ratiosali_isam1100% (1)

- Ethanol As Fuel Pros and Cons PDFDocument2 pagesEthanol As Fuel Pros and Cons PDFRositaNo ratings yet

- Performance Test of Diesel Engines Using Ethanol-Diesel Fuels BlendsDocument7 pagesPerformance Test of Diesel Engines Using Ethanol-Diesel Fuels BlendsRidwan AbdurrahmanNo ratings yet

- Energy: E. Sukjit, J.M. Herreros, K.D. Dearn, R. García-Contreras, A. TsolakisDocument11 pagesEnergy: E. Sukjit, J.M. Herreros, K.D. Dearn, R. García-Contreras, A. TsolakisNiti KlinKaewNo ratings yet

- Ahmet Yakin2021Document14 pagesAhmet Yakin2021Tito Adi SuryantoNo ratings yet

- Ethanol Diesel Fuel Blends A Review PDFDocument9 pagesEthanol Diesel Fuel Blends A Review PDFMantap BroNo ratings yet

- Faraz A Khan Full - PaperDocument8 pagesFaraz A Khan Full - PaperFaraz A KhanNo ratings yet

- Progress in Regulated Emissions of Ethanol-Gasoline Blends From A Spark Ignition EngineDocument26 pagesProgress in Regulated Emissions of Ethanol-Gasoline Blends From A Spark Ignition EngineAnh Vương TùngNo ratings yet

- Ethanol Fuel Learn to Make and Use Ethanol to Power Your VehiclesFrom EverandEthanol Fuel Learn to Make and Use Ethanol to Power Your VehiclesNo ratings yet

- Discovery 4 - LR4 2010-2012 - Sec3 - PowertrainDocument2,747 pagesDiscovery 4 - LR4 2010-2012 - Sec3 - PowertrainCristiano DellazariNo ratings yet

- Sciencedirect: Fuel 279 (2020) 118520Document10 pagesSciencedirect: Fuel 279 (2020) 118520prabhaNo ratings yet

- Installation: Inboard Engines S-Drive ADocument56 pagesInstallation: Inboard Engines S-Drive AEric ZachowNo ratings yet

- M-Class W164 1210Document78 pagesM-Class W164 1210Callum Fearnside100% (2)

- Department of Mechanical Engineering ME-8792 Power Plant Engineering Question Bank Unit-I Coal Based Thermal Power Plants Part-ADocument15 pagesDepartment of Mechanical Engineering ME-8792 Power Plant Engineering Question Bank Unit-I Coal Based Thermal Power Plants Part-ABhagavathi ShankarNo ratings yet

- Audi A6Document12 pagesAudi A6Александр СташкевичNo ratings yet

- Application of The GT35 Industrial Gas Turbine For The Propulsion of Fast FerriesDocument5 pagesApplication of The GT35 Industrial Gas Turbine For The Propulsion of Fast FerriesdislocationNo ratings yet

- 565 DFGBDocument3 pages565 DFGBJefri Heriyanto PanjaitanNo ratings yet

- ME 8792 PPE Unit - 2Document71 pagesME 8792 PPE Unit - 2UdamanNo ratings yet

- Lecture Notes On Advanced I C Engine Part I PDFDocument17 pagesLecture Notes On Advanced I C Engine Part I PDFl8o8r8d8s8i8v8No ratings yet

- Caterpillar C9 Engine SpecsDocument3 pagesCaterpillar C9 Engine SpecsDesta 77No ratings yet

- Recomendaciones CaterpillarDocument8 pagesRecomendaciones CaterpillarJose MinoNo ratings yet

- Handbook of Ship SurveyingDocument776 pagesHandbook of Ship SurveyingAbdul Anis100% (6)

- Egs45 5Document2 pagesEgs45 5anggieNo ratings yet

- Wartsila O E RT Flex PDFDocument24 pagesWartsila O E RT Flex PDFaskewshaun100% (1)

- ECMMMDocument54 pagesECMMMLuigi CasamassimaNo ratings yet

- Technical Specification For APU - EMD LocomotivesDocument16 pagesTechnical Specification For APU - EMD LocomotivesBoora Rajashekher0% (1)

- Tech - Interview QuestionDocument20 pagesTech - Interview Questionrautrajeshv100% (1)

- Manual Motor 721-821e Parte 1Document50 pagesManual Motor 721-821e Parte 1Diego ResendeNo ratings yet

- M.V. Clipper Sterling Ship ParticularsDocument9 pagesM.V. Clipper Sterling Ship ParticularsHendriyana RizkyNo ratings yet

- Thermochemistry & Fuels.8 Dec 19Document60 pagesThermochemistry & Fuels.8 Dec 19Jawad AhmedNo ratings yet

- Mechanisms of Formation of Soot and PM The Lecture ContainsDocument9 pagesMechanisms of Formation of Soot and PM The Lecture ContainsKeval ParmarNo ratings yet

- Ina Lubricants Product CatalogueDocument78 pagesIna Lubricants Product CatalogueDaniel DaiaNo ratings yet

- UK Purchased Fm-Ul-Cul Approved Ratings KW/BHP: Fire Pump EnginesDocument11 pagesUK Purchased Fm-Ul-Cul Approved Ratings KW/BHP: Fire Pump Enginesluis vilcañaupaNo ratings yet

- 1/ General: 81 KW (1500 RPM) - 97 KW (1800 RPM)Document3 pages1/ General: 81 KW (1500 RPM) - 97 KW (1800 RPM)Jakaria MoinNo ratings yet