Professional Documents

Culture Documents

Boiling Water Reactor (BWR)

Boiling Water Reactor (BWR)

Uploaded by

Sudharshan0 ratings0% found this document useful (0 votes)

24 views7 pagesA Boiling Water Reactor (BWR) is described. Key points:

1. BWRs use enriched uranium oxide fuel rods arranged in assemblies with water as both moderator and coolant.

2. Water boils in the core, producing steam that powers the turbine before being condensed and returned to the reactor.

3. Control rods are inserted from the bottom to control the reaction. BWRs have advantages over pressurized water reactors like lower pressure and temperature operation.

Original Description:

it is all about material science

Original Title

ms2019bit

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentA Boiling Water Reactor (BWR) is described. Key points:

1. BWRs use enriched uranium oxide fuel rods arranged in assemblies with water as both moderator and coolant.

2. Water boils in the core, producing steam that powers the turbine before being condensed and returned to the reactor.

3. Control rods are inserted from the bottom to control the reaction. BWRs have advantages over pressurized water reactors like lower pressure and temperature operation.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

24 views7 pagesBoiling Water Reactor (BWR)

Boiling Water Reactor (BWR)

Uploaded by

SudharshanA Boiling Water Reactor (BWR) is described. Key points:

1. BWRs use enriched uranium oxide fuel rods arranged in assemblies with water as both moderator and coolant.

2. Water boils in the core, producing steam that powers the turbine before being condensed and returned to the reactor.

3. Control rods are inserted from the bottom to control the reaction. BWRs have advantages over pressurized water reactors like lower pressure and temperature operation.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 7

UNIT 4

1. Boiling Water Reactor (BWR)

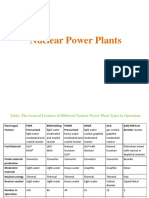

BWR is the abbreviation for the Boiling Water Reactor. Commercial BWR

reactors may be found in Finland, Germany, India, Japan, Mexico, Netherlands,

Spain, Sweden, Switzerland, and Taiwan. Current BWR reactors have electrical

outputs of 570 to 1300

MWe with an efficiency of about 33%

Fuel: Pellets of enriched uranium oxide (UO2) are arranged in zirconium tubes to

form fuel rods. The rods are arranged into fuel assemblies in the reactor core.

BWR fuel assembly comprises 90-100 fuel rods, and there are up to 750 assemblies

in a reactor core, holding up to 140 tonnes of uranium.

Control rods: Control Rods (boron rods) are used to maintain an uniform power

distribution across the reactor during normal operation and shutdown the reactor

during Containment cooling System emergencies. The BWR is unique in that

the control rods are inserted from the bottom by a high pressure hydraulically

operated system.

Moderator. Pure water is used as Moderator in BWR. Moderator is a material

which slows down the fast neutrons released by fission so that they could cause

more fission.

Coolant: In BWR reactor, water is also used as coolant. The BWR allows bulk

boiling of the coolant water in the reactor. Two thirds of the pressure vessel is filled

withwater. In the figure above, water is circulated through the Reactor Core As the

water moves past the fuel assemblies, it picks up heat from them. Part of the water

evaporates.

Steam separators in the upper part of the reactor remove water droplets from the

steam. The Generator produces the electricity. The unused steam is exhausted to

the condenser where it is condensed into water. The resulting water is pumped out

of the condenser with a series of pumps, reheated, and pumped back to the reactor

vessel by the Feed water Pumps. This starts the cycle all over again..

Advantages of BWR (over PWR)

The reactor vessel and associated components operate at a substantially lower

pressure (about 75 atm) when compared to a PWR (about 153 atm)

Pressure vessel is subjected to significantly less neutron irradiation compared to a

PWR, and so does not become as brittle with age.

Operates at a lower nuclear fuel temperature.Less corrosion

BWR does not require steam generators and pressurizer vessel. So it has only

a.fewer components than PWR,

There are fewer pipes and tubes and lesser welded joints inside the BWR

compared to a PWR.

A BWR may be designed to operate using only natural circulation so that

recirculation pumps are eliminated entirely. (The new ESBWR design uses

natural circulation.)

Disadvantages of BWR

Complex calculations are required for managing consumption of nuclear fuel

during operation due to "two phase (water and steam) fluid flow" in the upper part

of the core.

Any fuel leak might make the water radioactive and that radioactivity would

Contaminate the turbine and the rest of the loop by short-lived radioactive

products..

Control rods have to be inserted from below by a dedicated high pressure

hydraulic system for current BWR designs. Most other reactor types use top entry

control rods that are held up in the withdrawn position by electromagnets, causing

them to fall very quickly into the reactor by gravity if power is lost.

FAST BREEDER REACTORS;

In a fast breeder reactor, the core consists of a fissionable fuel surrounded by some

fertile materials such as U238 and Th232. Fast neutrons are used to produce fission

in the fuel material and hence no moderator is used in the reactor. More fast

neutrons than that required for sustaining the controlled chain reaction are produced

but the excess neutrons are allowed to escape from the central core. When U238

captures one of the fast neutrons produced by the fission of Pu239, it gets converted

into Pu239 after the decay of two particles. decay decay

92U238 + 0n1 92U239 93Np239 +-1e0 94 Pu239 + -1e0

Similarly, fertile 90Th232 on capturing a fast neutron becomes 92U233 after the

decay of two particles. decay decay

90Th232 + 0n1 90 Th233 91Pa233 + -1e0 92 U233 + -1e0

(Pa Protactinium)

Construction and working of a fast breeder reactor

There are several designs of fast breeder reactors in use world wide. A POT type

FBTR is described below.

Design of Core : In a stainless steel reactor vessel the small and compact core of

the nuclear rector (1.22m high and 3.36m diameter) is arranged at the center. Oxide

of PU239 or U235 is used as fuel. Fuel pellets (discs) are stacked inside specially

made steel tube cladding which forms the fuel rod. The tubes have hexagonal

cross section. 127 such

fuel rods are arranged together to form a fuel assembly. Each such assembly has

several empty slots to introduce cadmium control rods or for the coolant flow.

Inside the core, about 240 such fuel assemblies are arranged resembling a

honeycomb structure. A Fuel assembly is surrounded by breeder blankets

containing the compounds of fertile

elements.

Breeder reactions for 92U238 and 90Th232

Suppose the breeder blanket has fertile 92U238. Fast fission neutrons are produced

during the fission of fuel element at the centre. some fast neutrons fly out of the

central core towards breeder blanket. The Fertile 238U nuclei in the breeding

blanket capture them. They are converted to fissile Pu239 after two beta-decays.

decay decay 92U238 + 0n1 92U239 93Np239 +-1e0 94 Pu239

+ -1e0 If 90Th232 is used as fertile breeding blanket, on capturing a fast neutron,

fertile Th232 gets converted to fissionable U233 after two beta-decays.

decay decay 90Th232 + 0n1 90 Th233 91Pa233 + -1e0 92

U233 + -1e0

Working

The reactor vessel is made of stainless steel. It houses the (core + breeder

blanket). Fuel at the centre is surrounded by breeder blankets. It is surrounded by a

thick neutron reflector shield made of either Beryllium or graphite. Boron or

Cadmium control rods are inserted from the top. They are adjusted to make the

reactor to work under critical conditions. Usually, no moderator is used to avoid

thermalisation of the fast fission neutrons. Liquid sodium metal is used as the

coolant in two separate closed loops. In the primary loop, liquid sodium is pumped

into the

stainless steel pressure tubes and passes through the core. After removing the heat

generated by fission in the core, it passes through the intermediate heat exchanger

HX1. The secondary liquid Na coolant flows through separate channels (coils)

within HX1. Heat is transferred from the primary coolant to the liquid sodium

coolant The hot, liquid sodium coolant flowing in the closed, secondary coolant

loop then

passes through another heat exchanger HX2. The feed water which is pumped at a

pressure of 25kg /cm2 and at a temperature of about 200C flows through separate

channels (coils) within HX2. It removes heat from hot secondary liquid sodium.

The hot water boils and produces steam at a temperature of 480C. This steam is

used to operate a turbine – power generator combination to convert thermal

energy into

electric power

Advantages:

1. More fuel can be produced than that is consumed

2. The fuel need not be enriched

DISADVANTAGES:

1.Metallic sodium reacts with water violently anf it burns in air. So extreme care

must be taken to avoid leakage of sodium and water coolants.

2. Liquid sodium is highly corrosive and hence corrodes the structural steel.

3. Swelling of steel tubes occur due to high temperature, heavy irradiation from

fast neutrons, gamma rays, etc. Also the tubes loose their mechanical strength and

become brittle

The requirements of moderator

A Moderator should have a high boiling point; It should have a very low absorption

cross section and very high scattering collision cross section for neutrons.

1. In a single collision maximum energy would be transferred if both colliding

particles have equal masses. Hence, this requires that moderators are made of light

elements whose atomic mass is close to that of neutrons.

2. In order to have maximum transfer of energy during collisions, the scattering

cross section of the moderating element for scattering collision with neutron should

be very high.

3. Also, elements of the moderators should not absorb neutrons. Therefore their

neutron absorption cross section should be very small or zero.

Among the lighter elements, Deuterium and oxygen have the lowest absorption

cross section for thermal neutrons. Also they have good collision cross section.

Hence D2O is used as coolant as well as moderator im PHWR (pressurized Heavy

Water Reactor) where the Uranium fuel need not be enriched

5. COOLANT

The heat generated in a nuclear reactor operating under a critical condition is

removed by the coolant. For efficient transfer of heat from the fuel rods to the

coolant, good contact between the cladded fuel and the coolant is necessary. Light

water (H2O) and Heavy water (D2O) are widely used as coolant in thermal

reactors. Liquid sodium and liquid sodium-potassium alloy are used as coolants in

fast breeder reactors. Gaseous air and Helium are used as coolants in gas-cooled

reactors.

The requirements of a coolant

The required properties of a coolant are: 1). High heat capacity, 2) High boiling

point,

3) very small neutron capture cross section, 4) non-corrosive to the fuel cladding,

5) high chemical stability and 6) easy to pump through the volume of the reactor.

FUEL CLADDING

The fuel element is enclosed in a cylindrical jacket called ‘cladding’. Usually,

nuclear fuel in the form of oxides or carbides is pressed into thin circular discs.

After stacking the

fuel pellets into the fuel cladding, the cladding is sealed. The fuel cladding prevents

the fuel elements from being corroded by the coolant. Also it prevents the fission

fragments and other radioactive products from escaping out into the coolant

section. The heat energy generated during fission is conducted by the walls of

cladding to the coolant that is circulating through the core. The required

characteristics of fuel cladding are

1. Ease of fabrication and weldability 2. Low neutron absorption cross 3. Good

tensile strength and good thermal conductivity 4. Resistance to corrosion

5. Resistance to irradiation damage which leads to the ‘swelling’ of the fuel rod

and 6. Low cost.

3. CONTROL RODS:

Control rods are made of materials which absorb neutrons more efficiently. They

maintain the reactor operations under critical conditions by absorbing the excess

neutrons. “Shut down rods” are control rods which are used to instantly shut

down the reactor operations during emergencies by dropping them suddenly into

the core. By this, most of the fission neutrons are absorbed by control rods and the

nuclear reactor goes sub critical (k<<1) and stops the fission reaction completely.

Requirements of a Control Element

The elements used for control rods should have low density, good mechanical

strength, high melting point, easy fabrication, corrosion resistance, reactor

compatibility and most importantly very large absorption cross section for

neutrons. Characteristics of some of the control elements used in nuclear reactors

are given above.: Boron and cadmium are widely used as materials for control

elements. Sometimes, to maintain the reactor control, boric acid is mixed with the

primary coolant.

Enrichment of 92U235:Natural uranium has 99.284% of U238 isotope, with U235

only constituting about 0.711% of its weight. U235 is the only naturally-occurring

nuclear fuel that is fissionable with thermal neutrons. Enriched uranium is a critical

component for both civil nuclear power generation and military nuclear weapons.

Although some nuclear reactors (which use heavy water both as moderator and

coolant) are designed to operate with natural uranium, most of the reactors use

enriched.

Enriched uranium is a type of uranium in which the percent composition

of uranium-235 has been increased through the process of isotope separation. The

different levels of enrichment are given below

Slightly enriched uranium (SEU)

Slightly enriched uranium (SEU) has a 235U concentration of 0.9% to 2%. This

new grade can be used to replace natural uranium (NU) fuel in some heavy water

reactors like the CANDU.

Low-enriched uranium (LEU) : IT has a lower than 20% concentration of 235U.

In commercial light water reactors (LWR), uranium enriched to 3 to 5% 235U are

used as fuel.

Highly enriched uranium (HEU

Highly enriched uranium (HEU) has a 20% or higher concentration of 235U. The

fissile uranium in nuclear weapon primaries usually contains 85% or more of 235U

known as weapon-grade.

METHODS:

1) gaseous diffusion (referred to as first generation) and

2) gas centrifuge (second generation)

Other methods include electromagnetic separation,, laser isotope separation etc.

You might also like

- Laser Diffraction Using A RulerDocument7 pagesLaser Diffraction Using A RulerReddyvari Venugopal100% (1)

- ME5129 - Lecture XXIDocument13 pagesME5129 - Lecture XXIAnandNo ratings yet

- M5 - L3 - Different Nuclear ReactorsDocument27 pagesM5 - L3 - Different Nuclear ReactorsGirish DNo ratings yet

- Part - I (General) : Rajasthan Atomic Power StationDocument28 pagesPart - I (General) : Rajasthan Atomic Power StationjbsoniNo ratings yet

- Nuclear PowerplantDocument39 pagesNuclear Powerplantwiljhon sunioNo ratings yet

- Nuclear Power PlantDocument12 pagesNuclear Power PlantAnil BhattaNo ratings yet

- Types of Nuclear ReactorDocument32 pagesTypes of Nuclear Reactorsapna100% (1)

- Types of ReactorsDocument4 pagesTypes of ReactorsPawan PuniaNo ratings yet

- Nuclear ReactorDocument21 pagesNuclear ReactorPrajithNo ratings yet

- Nuclear Power ReactorsDocument10 pagesNuclear Power ReactorsJos TeixeiraNo ratings yet

- Nuclear EnergyDocument2 pagesNuclear Energydhyeypatel2701No ratings yet

- Types of Reactors Used in Nuclear Power Plants: Generation of Electrical ENERGY (13EE63)Document20 pagesTypes of Reactors Used in Nuclear Power Plants: Generation of Electrical ENERGY (13EE63)PreethiNo ratings yet

- Nuclear Power Plant: Swami Keshvanand Institute of Technology Management & Gramothan, JaipurDocument27 pagesNuclear Power Plant: Swami Keshvanand Institute of Technology Management & Gramothan, JaipurNikhil ChopraNo ratings yet

- Nuclear Power PlantDocument27 pagesNuclear Power PlantYash MenonNo ratings yet

- What Is A Nuclear ReactorDocument12 pagesWhat Is A Nuclear ReactorShams ShamsNo ratings yet

- Nuclear Power Reactors: Components of A Nuclear ReactorDocument23 pagesNuclear Power Reactors: Components of A Nuclear ReactorBenjamin LukeNo ratings yet

- Various Types of Reactors With Special Reference To India & Brief Design FeaturesDocument19 pagesVarious Types of Reactors With Special Reference To India & Brief Design Featurespetros jereNo ratings yet

- NuclearPowerReactors AnOverviewDocument11 pagesNuclearPowerReactors AnOverviewcdnaveenNo ratings yet

- Breeder ReactorDocument10 pagesBreeder ReactorwhyreadNo ratings yet

- Nuclear Reactors and Power Plant Types: Chapter ThreeDocument19 pagesNuclear Reactors and Power Plant Types: Chapter ThreeمحمدالفاتحجعفرالخليفةNo ratings yet

- Nuclear Power PlantDocument22 pagesNuclear Power PlantMuhammad Ahkam KhanNo ratings yet

- Research Scope in Nuclear EnergyDocument22 pagesResearch Scope in Nuclear Energymininghod24No ratings yet

- Nuclear Reactors: Presented To: Sir Aiman ShabbirDocument33 pagesNuclear Reactors: Presented To: Sir Aiman Shabbirabubakar chohaanNo ratings yet

- Unit 2Document43 pagesUnit 2A ABHISHEK MARSHALLNo ratings yet

- Isotopes U U MevDocument5 pagesIsotopes U U MevPrasath CkNo ratings yet

- What Is A Nuclear Reactor?: Nuclear Reactors Are Just Exotic Heat Sources. On This PageDocument13 pagesWhat Is A Nuclear Reactor?: Nuclear Reactors Are Just Exotic Heat Sources. On This PageSanskar SoniNo ratings yet

- B Nuclear Power PlantsDocument21 pagesB Nuclear Power PlantsArun PatilNo ratings yet

- Seminar On Nuclear Reactor: Bhabani Sankar Hota ROLL NO - 107EE007Document28 pagesSeminar On Nuclear Reactor: Bhabani Sankar Hota ROLL NO - 107EE007Saptarshi Pal ChaudhuriNo ratings yet

- ME 5129 - Principles of Thermal Energy Conversion: Introduction To Nuclear Power ReactorsDocument12 pagesME 5129 - Principles of Thermal Energy Conversion: Introduction To Nuclear Power ReactorsAnandNo ratings yet

- Chapter04: Conventional Nuclear Power Reactors Edited Bydr. Mir F. AliDocument8 pagesChapter04: Conventional Nuclear Power Reactors Edited Bydr. Mir F. AliDr. Mir F. AliNo ratings yet

- 2 - Classification of ReactorsDocument28 pages2 - Classification of Reactorspothuraju harithaNo ratings yet

- Nuclear Power Reactor Characteristics: Fuel Coolant Moderator Number in OperationDocument2 pagesNuclear Power Reactor Characteristics: Fuel Coolant Moderator Number in OperationadnanNo ratings yet

- Nuclear ReactorDocument16 pagesNuclear ReactorToma R ShawonNo ratings yet

- AnkndritzDocument24 pagesAnkndritzapi-3740904No ratings yet

- NIHARDocument18 pagesNIHARsubudhihareshNo ratings yet

- Nuclear Power PlantDocument19 pagesNuclear Power PlantMH ApuNo ratings yet

- Nuclear ReactorsDocument45 pagesNuclear ReactorsAtul100% (3)

- Sreekavitha Engineering College: M.Heeralal Asst Prof Mechanical DeptDocument46 pagesSreekavitha Engineering College: M.Heeralal Asst Prof Mechanical DeptMALOTH HEERALALNo ratings yet

- 5th Series by DR - KaleemDocument41 pages5th Series by DR - KaleemBobNo ratings yet

- Nuclear Power PlantDocument12 pagesNuclear Power PlantMohit DalalNo ratings yet

- Nikhil Gaurav MSESP75010Document23 pagesNikhil Gaurav MSESP75010RabinNo ratings yet

- Nuclear Reactor and Power Plant:: Research Reactors Are Operated at Universities and Research CentresDocument19 pagesNuclear Reactor and Power Plant:: Research Reactors Are Operated at Universities and Research CentresNiteshBhuwaniaNo ratings yet

- Lec - 10 PP - Nuclear Power PlantsDocument41 pagesLec - 10 PP - Nuclear Power PlantsLog XNo ratings yet

- Nuclear Power PlantsDocument32 pagesNuclear Power Plantskane likNo ratings yet

- Types of Nuclear ReactorsDocument15 pagesTypes of Nuclear Reactorshafeez khanNo ratings yet

- Submitted By: M David SamuelDocument14 pagesSubmitted By: M David SamueltpatruniNo ratings yet

- CANDU2Document22 pagesCANDU2geanjorgeNo ratings yet

- V.V.N. Harischandra Prasad 4/4 B.E. Metallurgy 690820021Document23 pagesV.V.N. Harischandra Prasad 4/4 B.E. Metallurgy 690820021Harischandra Prasad Vvn100% (1)

- Nuclear Power PlantDocument50 pagesNuclear Power PlantBLACK GAMINGNo ratings yet

- Nuclear Power Plant (II) : Necessary Parts of Plant and PropertiesDocument18 pagesNuclear Power Plant (II) : Necessary Parts of Plant and PropertiesMuhammad Ramiz ZakirNo ratings yet

- of Types of Nuclear ReactorDocument33 pagesof Types of Nuclear Reactormandhir67% (3)

- Nuclear EnergyDocument4 pagesNuclear EnergyAkshara K VijayNo ratings yet

- How Does A Nuclear Power Plant Work?Document4 pagesHow Does A Nuclear Power Plant Work?Cherry ObiasNo ratings yet

- CANDU Nuclear ReactorDocument16 pagesCANDU Nuclear ReactorJeyakrishnan CNo ratings yet

- Nuclear Power Reactors: UraniumDocument13 pagesNuclear Power Reactors: UraniummangyanNo ratings yet

- Candu Reactor ConstructionDocument18 pagesCandu Reactor ConstructionShashank UniyalNo ratings yet

- Nuclear Reactor: How It WorksDocument17 pagesNuclear Reactor: How It WorkscbeprabhugmailNo ratings yet

- Nuclear Power PlantDocument23 pagesNuclear Power Plantvish0909No ratings yet

- Nuclear Plant PDFDocument4 pagesNuclear Plant PDFSamsung TabletNo ratings yet

- Pocket Guide 2009 ReactorsDocument2 pagesPocket Guide 2009 Reactorspantuflo13No ratings yet

- Hydrogen Power: An Introduction to Hydrogen Energy and Its ApplicationsFrom EverandHydrogen Power: An Introduction to Hydrogen Energy and Its ApplicationsRating: 4 out of 5 stars4/5 (3)

- Extraction and Analysis of LipidsDocument22 pagesExtraction and Analysis of LipidsPauline AlfonsoNo ratings yet

- Test On High-Rate Pulverized Blast Furnace Coal Injection Operation at KimitsuDocument8 pagesTest On High-Rate Pulverized Blast Furnace Coal Injection Operation at KimitsuanonimomhotNo ratings yet

- Pma Mixing DesignDocument4 pagesPma Mixing DesignVasile BologaNo ratings yet

- Deep Soil MixingDocument14 pagesDeep Soil MixingBudi ManNo ratings yet

- Vit C HPLC-UV PDFDocument10 pagesVit C HPLC-UV PDFKiki Dian TNo ratings yet

- Reservoir Fluid AnalysisDocument29 pagesReservoir Fluid AnalysisFauzy SaidNo ratings yet

- Temp CoachingDocument7 pagesTemp CoachingSionna KatiyarNo ratings yet

- Fundamentals of RheologyDocument76 pagesFundamentals of Rheologytonysanchez67No ratings yet

- P A S S: You Should Know The - Word For Using Portable Fire ExtinguisherDocument2 pagesP A S S: You Should Know The - Word For Using Portable Fire ExtinguisherYamral WubetuNo ratings yet

- Jual Beli Baru Dan Bekas Theodolite South ET 02 - WA 081290003431Document3 pagesJual Beli Baru Dan Bekas Theodolite South ET 02 - WA 081290003431Global-HutamaNo ratings yet

- 2414 Ficha TecnicaDocument3 pages2414 Ficha TecnicaJoan SifuentesNo ratings yet

- JK White Cement Opc 53 19 2016Document1 pageJK White Cement Opc 53 19 2016Rishav MishraNo ratings yet

- The Chemical Accidents (Emergency Planning, Preparedness and Response) RULES, 1996'Document26 pagesThe Chemical Accidents (Emergency Planning, Preparedness and Response) RULES, 1996'Hemant KuralkarNo ratings yet

- ASTM Hardness Conversion ChartDocument3 pagesASTM Hardness Conversion ChartJose Daniel De la CruzNo ratings yet

- KVG P3 Geomorphic Process Landforms Weathering ErosionDocument296 pagesKVG P3 Geomorphic Process Landforms Weathering Erosionsita kumariNo ratings yet

- An Introduction To Density: by Helen Hanson & John MacalusoDocument23 pagesAn Introduction To Density: by Helen Hanson & John MacalusoMUHAMMAD AKRAMNo ratings yet

- Booklet Conical MountingsDocument41 pagesBooklet Conical MountingsAhmet HamamcıoğluNo ratings yet

- Pipeline GeotechDocument20 pagesPipeline Geotechfalokun100% (1)

- Wispeco Aluminium ProfilesDocument22 pagesWispeco Aluminium ProfilesPatrick153No ratings yet

- Mirrax Esr Heat Treatm - RecDocument4 pagesMirrax Esr Heat Treatm - RechamidharvardNo ratings yet

- Understanding Praziquantel: By:Karl SchoelerDocument2 pagesUnderstanding Praziquantel: By:Karl Schoelerhmalikn7581100% (1)

- Chapter 1 Smith and Van NessDocument41 pagesChapter 1 Smith and Van NessJohn Raymart RaferNo ratings yet

- KTPSDocument22 pagesKTPSjoshimjmitNo ratings yet

- Design Manual For Concrete Pipe Outfall SewersDocument56 pagesDesign Manual For Concrete Pipe Outfall SewersMakita Labiovela100% (3)

- Appendix A: Tables of U-ValuesDocument15 pagesAppendix A: Tables of U-ValuesKg Chit ZawNo ratings yet

- Carnicom Institute Research-2007Document70 pagesCarnicom Institute Research-2007Anonymous i71HvPXNo ratings yet

- Ex TD Starch DCP Placebo2Document4 pagesEx TD Starch DCP Placebo2penguin lucuNo ratings yet

- PU Product IndexDocument20 pagesPU Product IndexSaurabh KadamNo ratings yet

- Lab Model TDS Meter Model: TDS 100Document2 pagesLab Model TDS Meter Model: TDS 100RiyanNo ratings yet